设计简介

摘 要

汽车的轻量化,就是在保证汽车的强度和安全性能的前提下,尽可能地降低汽车的整备质量,从而提高汽车的动力性,减少燃料消耗,降低排气污染。实验证明,若汽车整车重量降低10%,燃油效率可提高6%―8%;汽车整备质量每减少100公斤,百公里油耗可降低0.3―0.6升;汽车重量降低1%,油耗可降低0.7%。当前,由于环保和节能的需要,汽车的轻量化已经成为世界汽车发展的潮流。汽车的动力总成在汽车庞大的系统中扮演着至关重要的角色。现代汽车上广泛采用内燃机作为动力源,其转矩和转速变化范围较小,而复杂的使用条件则要求汽车的动力性和燃油经济性能在相当大的范围内变化。动力总成主要包括发动机、变速器、离合器以及主减速器。

本文以本田WH125-6型发动机的一些参数为依据,进行变速器的轻量化改制设计。设计的主要内容包括变速器传动机构布置方案的确定,变速器主要参数如挡数、传动比范围、中心距、各挡传动比、外形尺寸、齿轮参数、各挡齿轮齿数的选择,齿轮、轴、轴承的设计校核操纵机构及箱体的设计。在设计的过程中,本文根据摩托车变速器的设计要求和车辆动力传动系统自身的特点,参考多篇文献资料,以及国内外设计图册,从经济性和实用性方面着手进行分析,将动力总成轻量化。

关键词:摩托车;变速器;箱体;齿轮;轴;设计

ABSTRACT

The lightweight car, the car is to ensure strength and security of the premise, as far as possible to reduce the car's curb weight, therby enhancing the car's power, reducing fuel consumption and reduce exhaust pollution. Experiments show that if 10% of automobile weight reduction, fuel effictiency can be increased of by 6% -8%; vehicle curb weight is reduced by 100 kg hunded kilometer can be reduced 0.3-0.6 liters; 1% of vehicle weight reduction, fuel consumption can be reduced 0.7 %. At present, due to the environmental protection and energy saving, lightweight car has become the world trend of automobile development.Vehicle powertrain system in the car huge play a vital role. Widly used in modern car engine as a power source, the less torqu and speed range, and complex condition require

the use of the car's dynamic performance and fuel economy to a large range. Powertrain including the engine, transmission, clutch and final drive.

In this paper, Honda WH125-6 engine of some parameters as the basis for restructing

the transmission of lightweight design. Design of the main transmission gear box layout

the program include the determination of key parameters such as the transmission block number, the transission ratio range, the center distance, the gear transmission ratio, size, gear parameters, choice of the block of gear teeth, gear, shaft, bearings The design check box control mechanism and design. In the design process, this motorcycle transmission according to the design requirements and characteristics of the vehicle powertrain itself, many articles refers literature, as well as domestic and international design books, from

an economic and practical aspects for analysis, the total power into a lightweight.

Key words: Motorcycle;Transmission;Shell;Gear;Shaft; Design

目 录

摘要………………………………………………………………………………………...……..ⅠAbstract……………………………………………………………………………….……….. Ⅱ

第1章 绪论 …………………………………………………………………………………1

1.1课题研究现状…………………………………………………………………………. 2

1.2轻量化的意义…………………………………………………………………………. 2

1.3研究的目的…………………………………………………………………………….. 3

1.4研究内容及研究方法………………………………………………………………… 4

第2章 变速器的设计与计算…………………………………………………….……5

2.1变速器主要参数计算………………………………………………………………… 5

2.1.1档数……………………………………………………………………………… 5

2.1.2传动比范围…………………………………………………………………….. 5

2.1.3各档传动比确定………………………………………………………………. 6

2.1.4中心距的选择…………………………………………………………………..7

2.1.5变速器的外形尺寸…………………………………………………………….7

2.1.6齿轮参数的选择 7

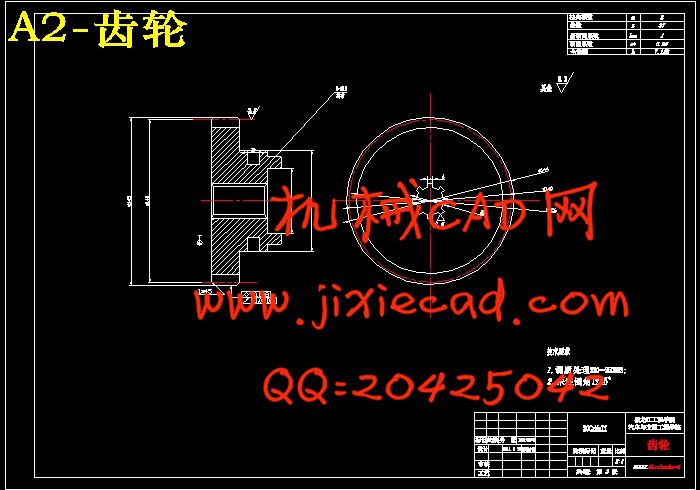

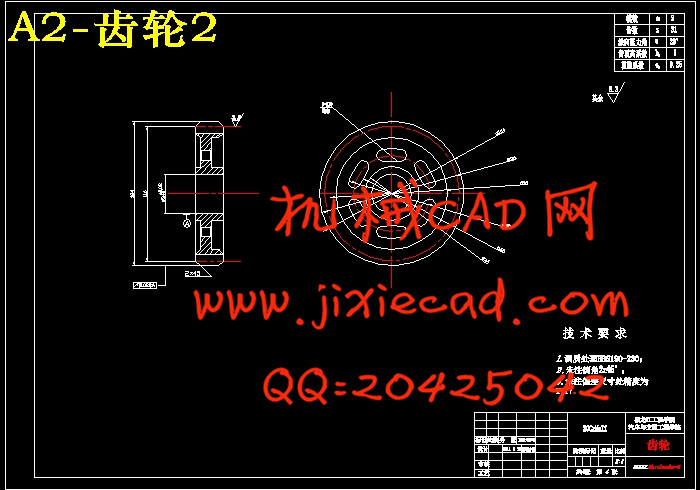

2.1.7各档齿轮齿数的分配及传动比的计算…………………………………… 9

2.2 变速器齿轮强度校核……………………………………………………………….12

2.2.1齿轮材料的选择原则………………………………………………………...12

2.2.2齿轮损坏的原因及形式…………………………………………………….. 12

2.3变速器齿轮弯曲强度计算.........................................................................................13

2.3.1变速器齿轮强度弯曲计算..............................................................................15

2.3.2轮齿接触应力校核............................................................................................18

2.4材料的选择及热处理……………………………………………………………….18

2.4.1齿轮材料的选择原则…………………………………………………………….19

2.4.2变速器齿轮轮齿表面渗碳度…………………………………………………….19

2.5本章小结……………………………………………………………………………....19

第3章 轴的结构设计与校核………………………………………………………20

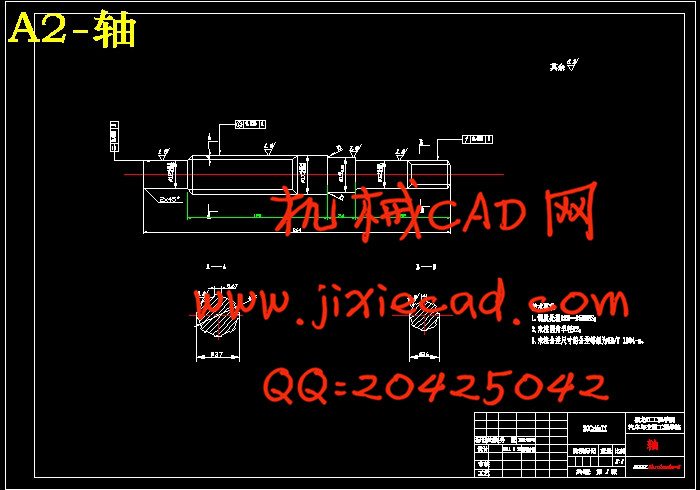

3.1轴的结构和尺寸设计………………………………………………………………... 19

3.1.1轴径的选择…………………….………………………………………..……..20

3.2 轴的强度验算………………………………………………………………………... 21

3.2.1轴的刚度计算与校核………………………………………………………..22

3.2.2轴的强度计算与校核………………………………………………………..26

3.3输出轴的实体建模及有限元分析………………………………………….27

3.4轴承选择与寿命计算………………………..……………………………….……..33

3.4.1输入轴轴承的选择与寿命计算……………………………………………33

3.5本章小结……………………………………………………………………………... 33

第4章 箱体的设计及离合器的选择…………………………………………...…34

4.1 离合器的功能及选择……………………………………………………………… 34

4.1.1离合器的功能及分类……………………………………………………… 34

4.1.2离合器的选择………………………………………………………………. 35

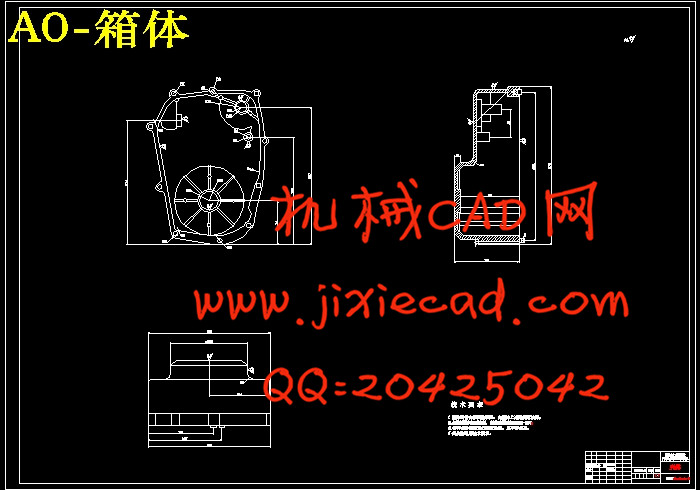

4.2变速器壳体的设计…………………………………………………………………..35

4.3本章小结……………………………………………………………………………….35

第5章 总体优化及结果………………………………………………………………..36

5.1变速器的优化及结果…………………………………………………………….…36

5.2启动离合器飞轮的优化及结果…………………………………………...………37

5.3本章小结……………………………………………………………………………....39

结论.…………..…………………………………..…………………………………..........40

参考文献…………………………………………………………………….……….………...41

致谢……………………………………………………………………….……….………..……42