设计简介

GQ50型钢筋切断机的结构设计与运动仿真

摘要

本产品的设计是根据黄河科技学院工学院机械系2012届毕业设计的要求,在参观调研的基础上,对大学四年已学知识的总结、实践与提高。按照指导老师的要求,我首先查阅了大量关于此产品设计的资料,做好初期准备。然后到河南省长葛市黄河旋风股份有限公司参观,深入了解钢筋切断机的工作原理及使用要求,在此基础上,形成自己初步的设计思路。

本产品设计给定的原始参数是:切断能力为(φ6-φ50)mm的圆钢;电机功率为4kw;冲切次数为28次/min;切断行程为40mm。此次设计的主要研究内容和技术关键是:根据钢筋切断机的使用要求,确定其工作原理,在此基础上进行钢筋切断机的结构设计,确定主要结构尺寸。主要包括以下几点:1、电动机的选择;2、传动装置的设计和计算;3、轴承的选择;4、曲轴连杆机构的设计;5、机体的设计;6、刀片的设计选择。然后根据这些设计数据进行产品的建模及运动仿真。

本次产品建模使用的是美国Autodesk公司的三维设计软件Inventor 2011。首先是根据设计数据建立各个零件的草图,在草图的基础上运用零件特征生成三维实体;然后在Inventor 2011软件的虚拟环境中进行虚拟装配,建立数字样机;最后进行应力分析、运动干涉分析及运动仿真。

本设计可以大幅降低钢筋切断机的研发周期及成本,从而提高产品的市场竞争力和企业的经济效益。

关键词:钢筋切断机,结构设计,Inventor 2011,虚拟装配,运动仿真

Disc Centrifuge Spindle Box Design

Abstract

This product is designed according to the college of engineering science and technology of 2012 member of graduation design requirements, during a visit to a research, on the basis of the university for four years have already learn knowledge summary, practice and improve. According to the requirements of the guiding teacher, I first looked a lot about this product design information, do well to the early. And then to the Yellow River in henan province ChangGe city whirlwind visit to a joint stock limited company, understand reinforced cutting machine and working principle of the use requirement, and based on this, the preliminary design to form their own ideas.

This product design parameters are given of the original: cutting ability for (phi 6-phi 50) mm round steel; The motor power for 4 kw; For punching number 28 times/min; Cut off the trip to 40 mm. The design of the main research contents, technology and the key is: according to the use requirement reinforced cutting machine, determine its working principle, and based on the structure of the steel cutting machine design, confirming the main structure size. Mainly include the following: 1, the choice of the motor; 2, the design and calculation of transmission device; 3, bearing choice; 4, crankshaft connecting rod design of organization; 5, the body's design; 6, the blade design choices. Then according to the design data modeling of products and movement simulation.

This product modeling is using the company's 3 d design Autodesk Inventor 2011 software. First of all is according to the design data to set up the various parts of the sketch, in the sketch of the use part features based on 3 d entity; And then in the Inventor 2011 software virtual environment in virtual assembly, to build digital prototype; Finally in stress analysis, motion interference analysis and simulation movement.

This design can dramatically reduce the reinforced cutting machine development cycle and cost, so as to improve the market competitiveness of products and the economic efficiency of enterprises.

Keywords: steel cutting machine, the structure design, Inventor 2011, virtual assembling, movement simulation

目 录

1 绪论 1

2 设计前的准备 3

2.1计划任务书 3

2.1.1 产品设计的依据 3

2.1.2 计划任务书 3

2.2 设计前的准备 3

3钢筋切断机的总体设计 4

3.1钢筋切断机的工作原理 4

3.2钢筋切断机的基本结构 4

4传动方案的设计 5

4.1 基本传动数据计算 5

4.1.1分配传动比 5

4.1.2计算各州的运动及动力参数 5

4.2 带传动的设计 6

4.2.1带型的选择 6

4.2.2带轮基准直径的确定 6

4.2.2带速的确定 6

4.2.3中心距、带长及包角的确定。 6

4.2.4 确定带的根数 7

4.2.5 带轮结构与尺寸 7

4.3 齿轮传动的设计 7

4.3.1选材料、确定初步参数 7

4.3.2齿面疲劳强度计算 8

4.3.3齿根抗弯疲劳强度验算 10

5 Autodesk Inventor 2011 12

5.1 Inventor 2011的组成 12

5.2三维绘图软件Inventor 2011的优点 12

5.2.1 二维工程图处理能力比较好 12

5.2.2 具有良好的设计项目管理功能 13

5.2.3 参数化技术和变量化技术 13

5.2.4 简便的操作风格 13

5.2.5 精彩的显示功能 13

6 主要零件的设计及建模 14

6.1机体的设计流程 14

6.2其他主要零件的建模效果展示 23

7钢筋切断机的装配 29

7.1装配流程 29

7.2大侧盖的装配步骤 29

7.2.1新建文件 30

7.2.2装入所有零件 30

7.2.3向机体安装大侧盖 30

7.3装配效果图展示 33

8应用Inventor软件进行干涉检查 34

8.1检查零部件之间的干涉 34

8.2 连杆及连杆铜瓦的干涉检查 34

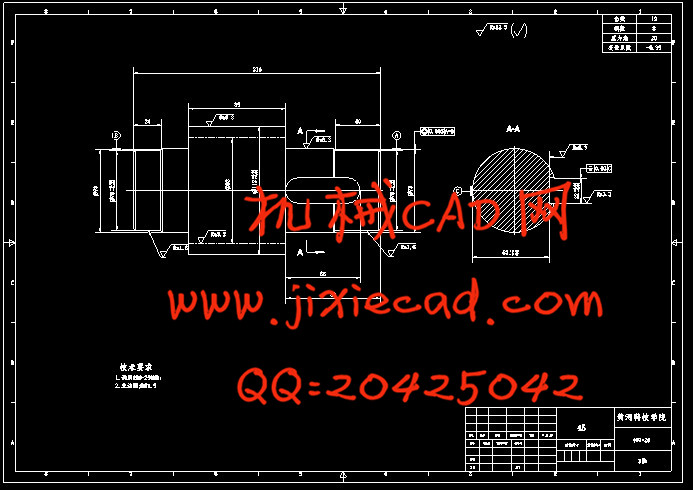

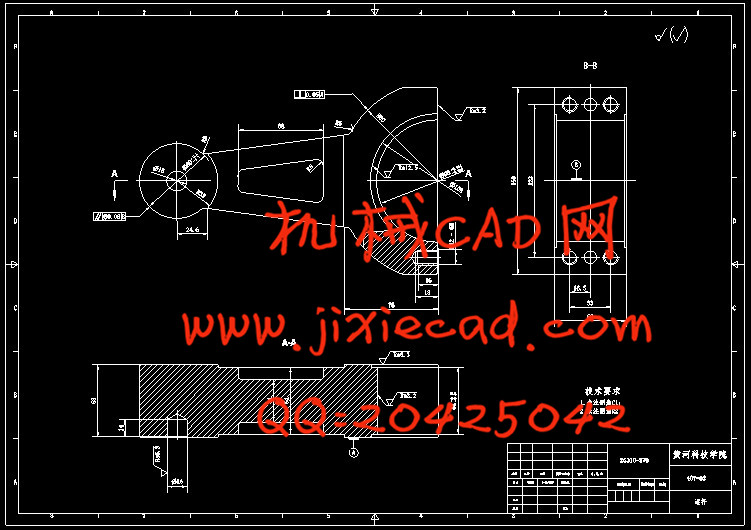

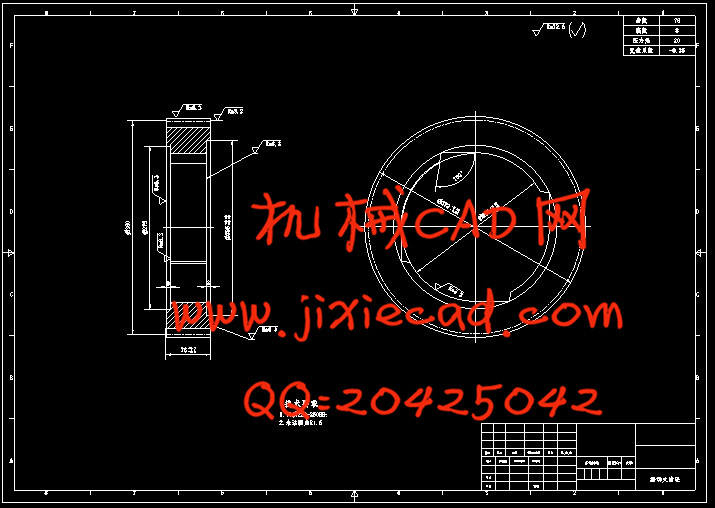

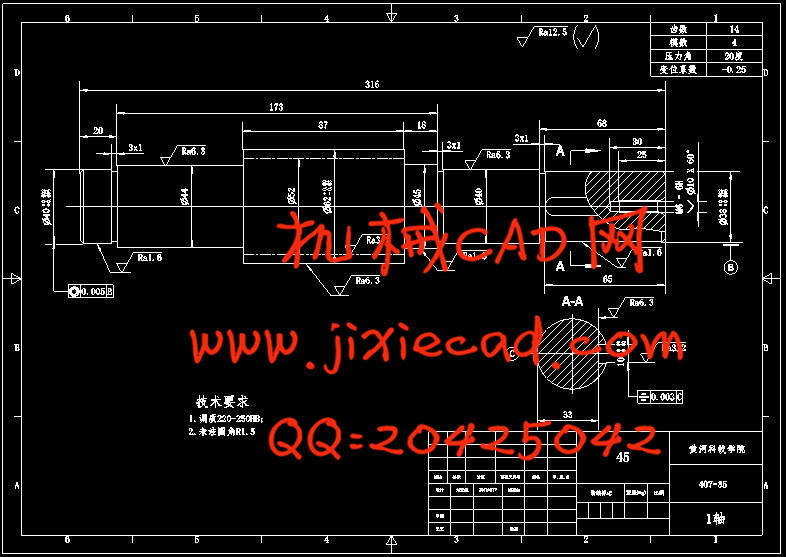

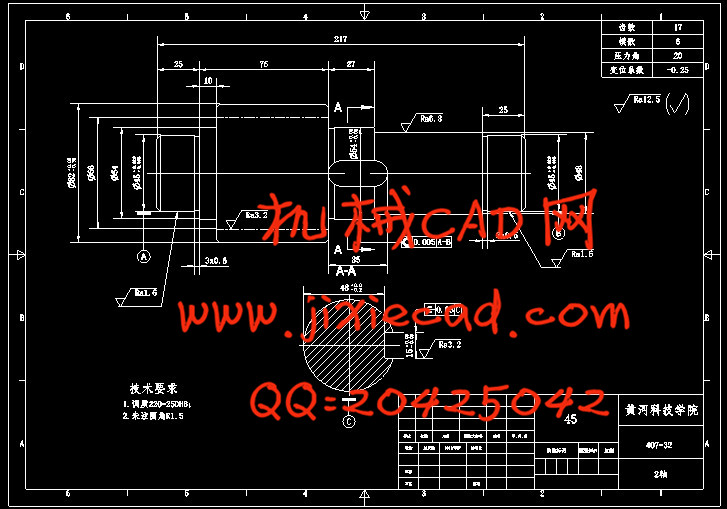

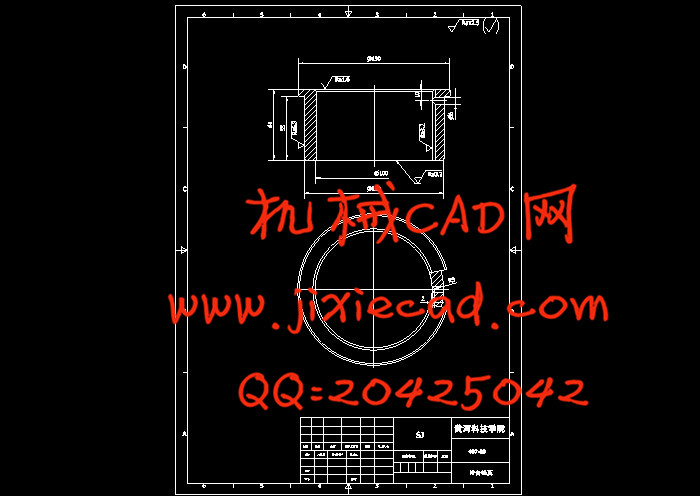

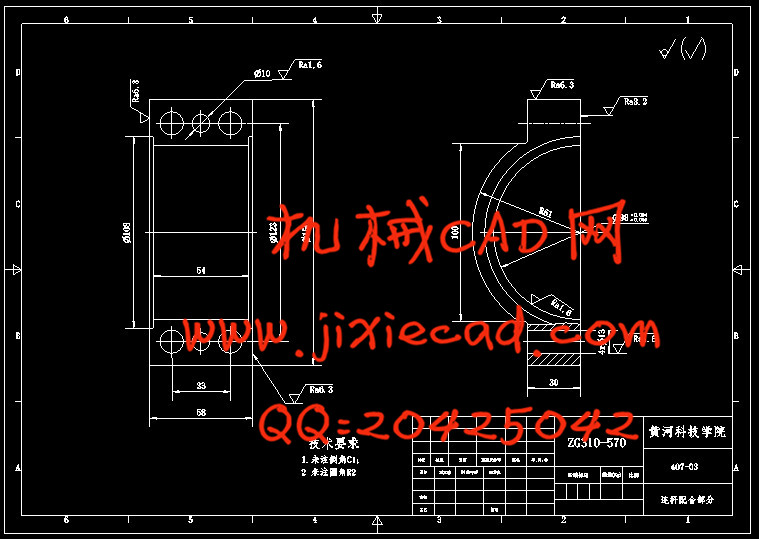

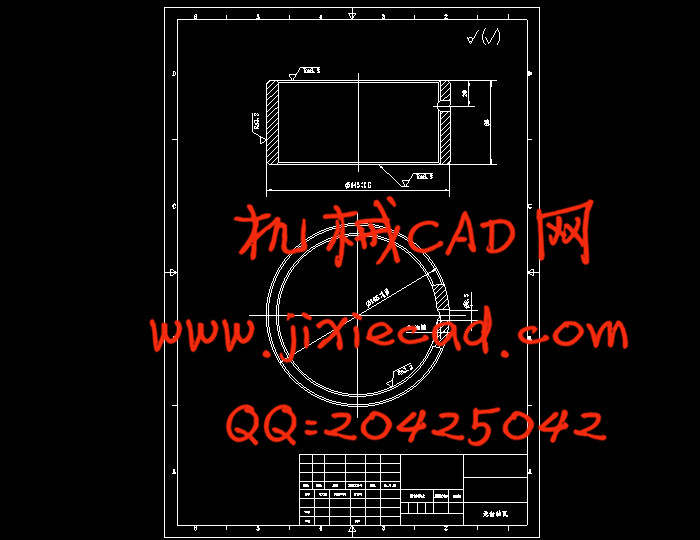

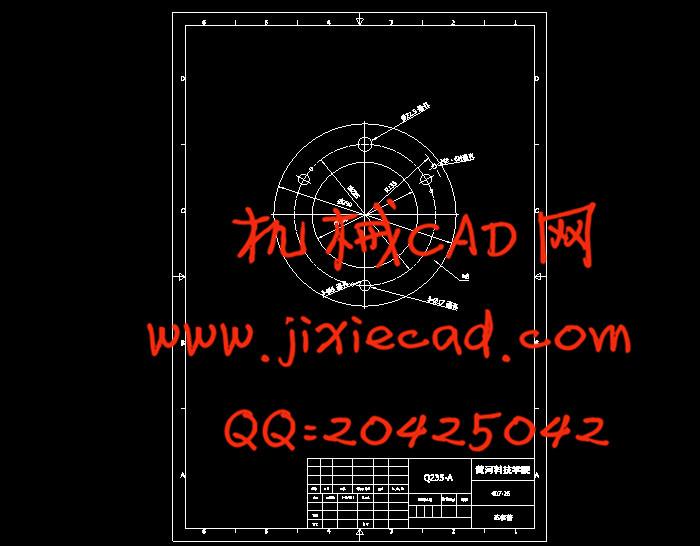

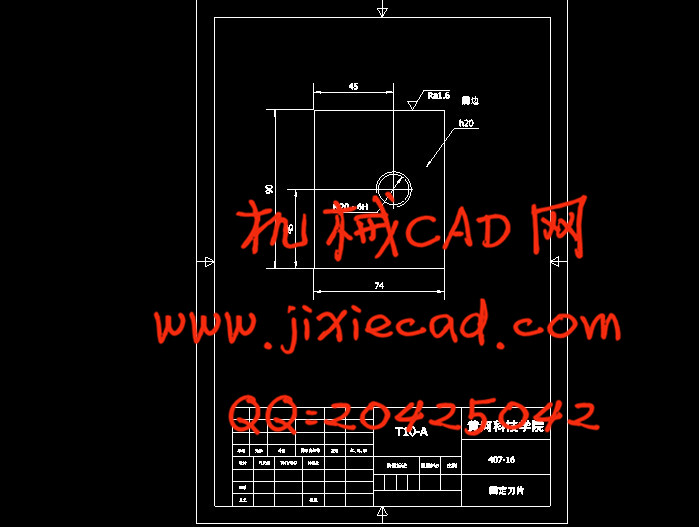

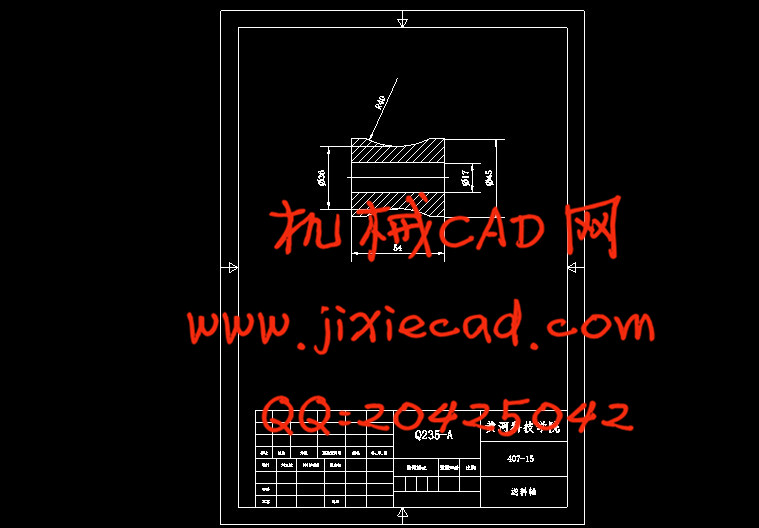

9绘制各主要零件的工程图 37

10 传动结构的运动仿真 41

10.1建立一个简单的装配 41

10.2运动仿真步骤 41

致谢 45

参考文献 46

摘要

本产品的设计是根据黄河科技学院工学院机械系2012届毕业设计的要求,在参观调研的基础上,对大学四年已学知识的总结、实践与提高。按照指导老师的要求,我首先查阅了大量关于此产品设计的资料,做好初期准备。然后到河南省长葛市黄河旋风股份有限公司参观,深入了解钢筋切断机的工作原理及使用要求,在此基础上,形成自己初步的设计思路。

本产品设计给定的原始参数是:切断能力为(φ6-φ50)mm的圆钢;电机功率为4kw;冲切次数为28次/min;切断行程为40mm。此次设计的主要研究内容和技术关键是:根据钢筋切断机的使用要求,确定其工作原理,在此基础上进行钢筋切断机的结构设计,确定主要结构尺寸。主要包括以下几点:1、电动机的选择;2、传动装置的设计和计算;3、轴承的选择;4、曲轴连杆机构的设计;5、机体的设计;6、刀片的设计选择。然后根据这些设计数据进行产品的建模及运动仿真。

本次产品建模使用的是美国Autodesk公司的三维设计软件Inventor 2011。首先是根据设计数据建立各个零件的草图,在草图的基础上运用零件特征生成三维实体;然后在Inventor 2011软件的虚拟环境中进行虚拟装配,建立数字样机;最后进行应力分析、运动干涉分析及运动仿真。

本设计可以大幅降低钢筋切断机的研发周期及成本,从而提高产品的市场竞争力和企业的经济效益。

关键词:钢筋切断机,结构设计,Inventor 2011,虚拟装配,运动仿真

Disc Centrifuge Spindle Box Design

Abstract

This product is designed according to the college of engineering science and technology of 2012 member of graduation design requirements, during a visit to a research, on the basis of the university for four years have already learn knowledge summary, practice and improve. According to the requirements of the guiding teacher, I first looked a lot about this product design information, do well to the early. And then to the Yellow River in henan province ChangGe city whirlwind visit to a joint stock limited company, understand reinforced cutting machine and working principle of the use requirement, and based on this, the preliminary design to form their own ideas.

This product design parameters are given of the original: cutting ability for (phi 6-phi 50) mm round steel; The motor power for 4 kw; For punching number 28 times/min; Cut off the trip to 40 mm. The design of the main research contents, technology and the key is: according to the use requirement reinforced cutting machine, determine its working principle, and based on the structure of the steel cutting machine design, confirming the main structure size. Mainly include the following: 1, the choice of the motor; 2, the design and calculation of transmission device; 3, bearing choice; 4, crankshaft connecting rod design of organization; 5, the body's design; 6, the blade design choices. Then according to the design data modeling of products and movement simulation.

This product modeling is using the company's 3 d design Autodesk Inventor 2011 software. First of all is according to the design data to set up the various parts of the sketch, in the sketch of the use part features based on 3 d entity; And then in the Inventor 2011 software virtual environment in virtual assembly, to build digital prototype; Finally in stress analysis, motion interference analysis and simulation movement.

This design can dramatically reduce the reinforced cutting machine development cycle and cost, so as to improve the market competitiveness of products and the economic efficiency of enterprises.

Keywords: steel cutting machine, the structure design, Inventor 2011, virtual assembling, movement simulation

目 录

1 绪论 1

2 设计前的准备 3

2.1计划任务书 3

2.1.1 产品设计的依据 3

2.1.2 计划任务书 3

2.2 设计前的准备 3

3钢筋切断机的总体设计 4

3.1钢筋切断机的工作原理 4

3.2钢筋切断机的基本结构 4

4传动方案的设计 5

4.1 基本传动数据计算 5

4.1.1分配传动比 5

4.1.2计算各州的运动及动力参数 5

4.2 带传动的设计 6

4.2.1带型的选择 6

4.2.2带轮基准直径的确定 6

4.2.2带速的确定 6

4.2.3中心距、带长及包角的确定。 6

4.2.4 确定带的根数 7

4.2.5 带轮结构与尺寸 7

4.3 齿轮传动的设计 7

4.3.1选材料、确定初步参数 7

4.3.2齿面疲劳强度计算 8

4.3.3齿根抗弯疲劳强度验算 10

5 Autodesk Inventor 2011 12

5.1 Inventor 2011的组成 12

5.2三维绘图软件Inventor 2011的优点 12

5.2.1 二维工程图处理能力比较好 12

5.2.2 具有良好的设计项目管理功能 13

5.2.3 参数化技术和变量化技术 13

5.2.4 简便的操作风格 13

5.2.5 精彩的显示功能 13

6 主要零件的设计及建模 14

6.1机体的设计流程 14

6.2其他主要零件的建模效果展示 23

7钢筋切断机的装配 29

7.1装配流程 29

7.2大侧盖的装配步骤 29

7.2.1新建文件 30

7.2.2装入所有零件 30

7.2.3向机体安装大侧盖 30

7.3装配效果图展示 33

8应用Inventor软件进行干涉检查 34

8.1检查零部件之间的干涉 34

8.2 连杆及连杆铜瓦的干涉检查 34

9绘制各主要零件的工程图 37

10 传动结构的运动仿真 41

10.1建立一个简单的装配 41

10.2运动仿真步骤 41

致谢 45

参考文献 46