设计简介

摘 要

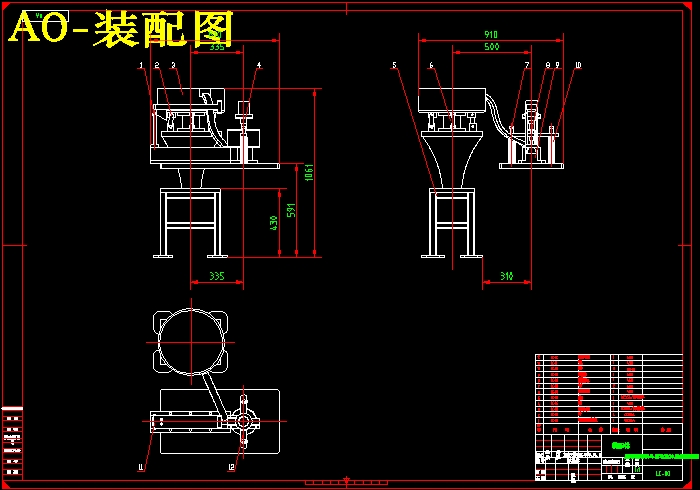

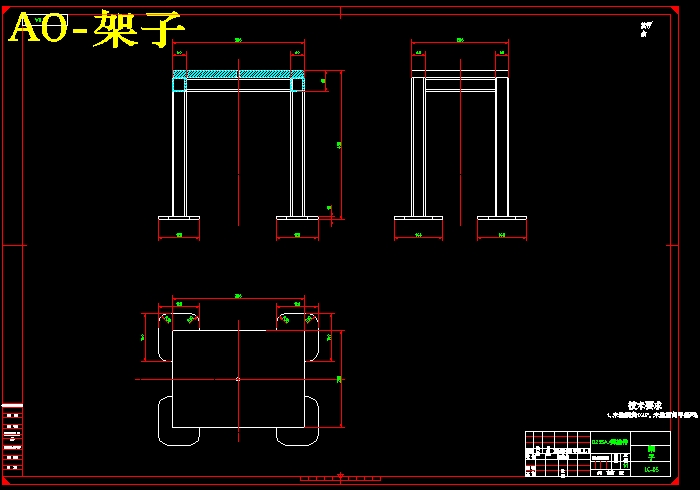

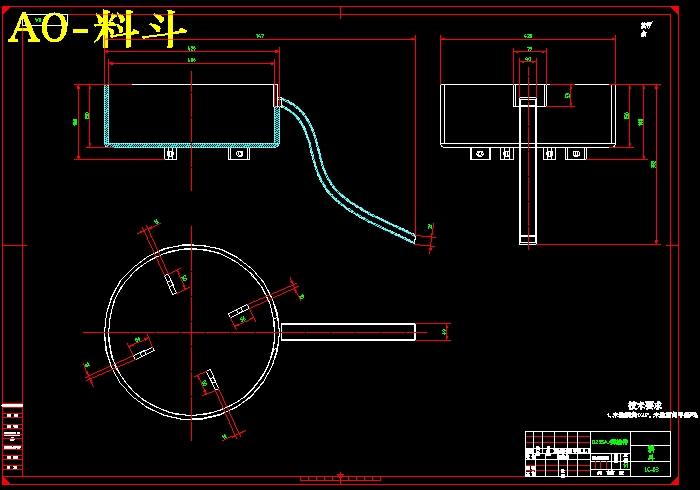

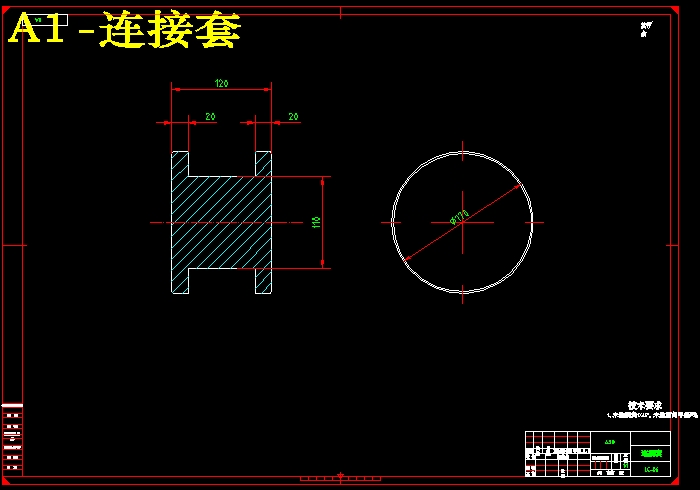

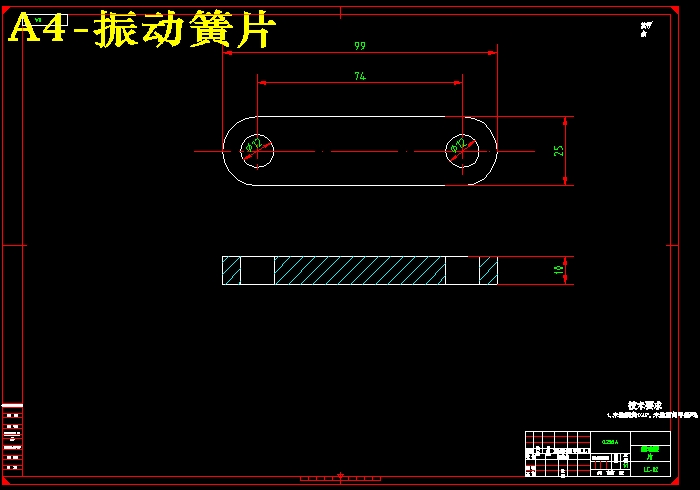

模具工业是一个国家的重要产业,模具工业的发展无时不刻都在影响着国家经济的发展,人类的进步离不开模具工业的发展。在全球经济发展的大环境下,中国各个行业被其他国家的先进技术影响的同时,越来越多的外国企业和品牌传播到中国已经成为现实。在新的市场需求的推动下,对自动冷挤压模进行改良和优化是当务之急。有大型自动冷挤压模生产制造企业对设备的安全指标的有着一定生产的严格要求。在生产设备的企业,充分考虑到在设备运行中可能出现的问题,从而减少噪声污染引起的振动或不当操作设备的现象等。国内自动冷挤压模的研发及制造要与全球号召的高效经济、安全稳定主题保持一致。自动冷挤压模的发展与人类社会的进步和科学技术的水平密切相关。本次设计是具有振动料斗的自动冷挤压模的设计,制件为小圆筒形件。本文借鉴了冷挤压模具设计的全部过程。文章主要过程是从产品的工艺分析到最后设计挤压模具,首先,通过对制件的特点的了解,进一步对制件进行工艺分析,确定该制件符合冷挤压加工的要求,确定挤压工艺方案和结构,并对冷挤压模具进行设计。具有振动料斗的自动冷挤压模由电振动料斗和滑轨实现的,采用圆柱形冷挤毛坯生产小圆筒形件,本文运用大学所学相关知识对冷挤压模具进行设计,最终通过AutoCAD进行绘图,得到相关零件的零件图及冷挤压模具的装配图。

关键词:自动冷挤压模;振动料斗;设计

Abstract

This design is the air refreshing agent box as a design model, the injection mold related knowledge as the basis, elaborated the whole design process of plastic injection mould.The content of graduation design is the injection mold of air refreshing agent box, the material is according to the structure characteristics and the correct analysis of the air refreshing agent box molding process.determine the overall layout of the cavity, the choice of parting surface, gating system design to determine the stripping method, etc.; at the same time this paper gives a brief introduction about the injection mould, the main parts of injection mold design and calculation, in the design process focuses on the actual production in the economy and rationality.

With the development of science and technology, interdisciplinary mutual infiltration, mutual exchanges between the various industry, extensive use of new structure, new materials, new technology, the sleeve pressing machine is large, efficient, reliable, energy saving,

Recently, the use of machinery industry, bearing and shaft sleeve shaft were investigated, found that the shaft, bearings and bushings in the machinery industry is one of the key parts. Come very naturally in the assembly of the installation is also very simple. In the installation if the use of artificial pressure with not only the labor intensity is too large and the size of each other is not easy to ensure the shaft, bearing and shaft sleeve, so the design of a special press be imperative. Graduation project this time is a tube axial compressive loading machine. This paper introduces the theoretical calculation to design sleeve pressing machine structure, working principle and main parts of the strength check and the advantages of the sleeve, pressing machine is efficient, economical, and high safety, stable operation. The overall plan is: the relative position of two axle sleeve on the plane, the motor reducer to provide power through belt drives the screw rod to rotate, and drives the head movement, a nut, a rotary motion of the linear motion of press. Block type safety clutch overload protection with teeth, pressure distribution in the corresponding position of the pipe after drilling through the drilling template.

Keywords:The plastic mold;the parametrization;;divides the profile;

目 录

摘要 II

Abstract III

第一章 绪论 1

1.1 模具介绍 3

1.2 模具在加工工业中的地位 4

1.3 模具的发展趋势 6

1.4 冷挤压模具的分类 7

1.5我国模具行业的发展方向和前景 8

1.6 冲压加工的特点 10

第二章 零件的工艺分析 13

第三章 零件工艺方案的选定 13

第四章 工序设计 14

4.1 毛坯的制备 15

4.2 毛坯的软化处理 15

4.3 毛坯表面处理与润滑 16

4.4 毛坯尺寸的确定 16

第五章 工艺计算 17

5.1 许用变形程度计算 17

5.2 挤压力的计算 17

5.3 压力机的选择 17

第六章 冷挤压模具的机构设计 18

6.1 凹模的设计 18

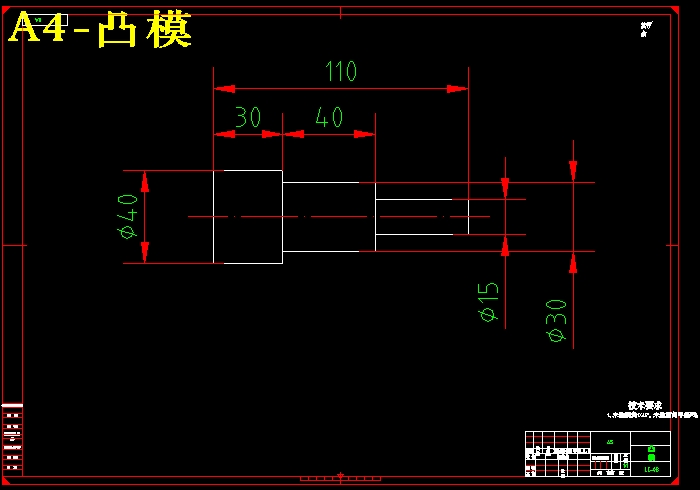

6.2 凸模的设计 19

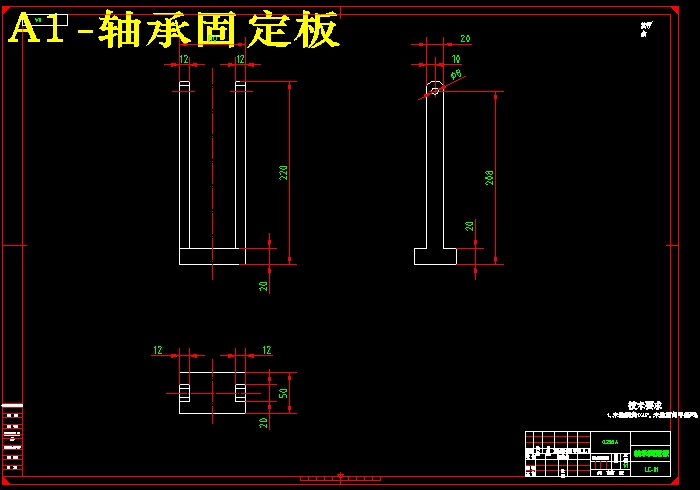

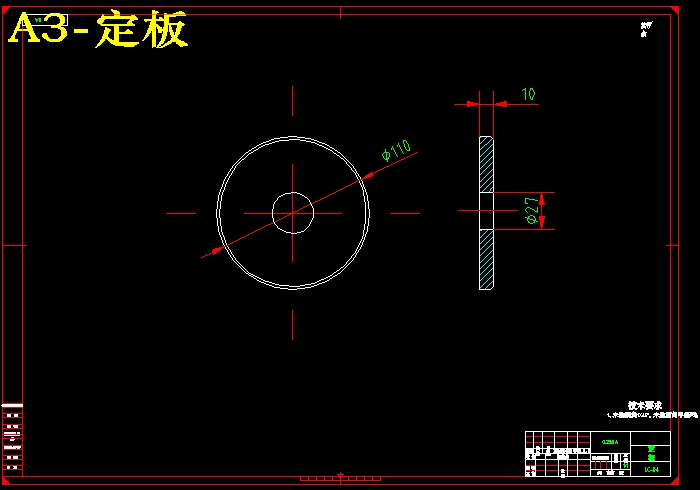

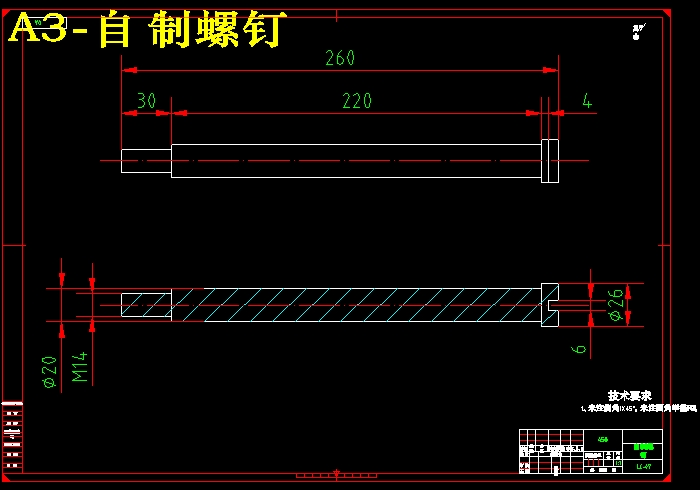

6.3 模具其他部分的设计 19

6.4 模具的固定 19

第七章 工作零件材料的要求与使用注意事项 20

结论 21

参考文献 22

致 谢 23