设计简介

摘 要

在国民经济建设中,石材是不可或缺的基础原材料。作为重要的基础产业,石材行业的发展程度成为一个国家社会发展水平和综合实力的重要衡量指标。我国经济正处于高速发展期,基础设施建设成为国内投资最主要的方式。因此,石材作为最主要的原材料之一,必然也处于扩张阶段水泥生产过程中,大部分原料要进行石材切割,石材是生产水泥砖,柱子用量最大的原料,开采后的面积较大,硬度较高,因此石材的切割在石材加工厂家中占有比较重要的地位。在新的市场需求的驱动下,石材开采设备的更新和优化升级更加迫切。国内石材切割设备生产企业充分挖掘市场潜力,大力发展大型环保节能的石材切割机械设备,在绿色环保化石材开采的转变中挥积极作用。一般生产大型石材气割机设备的企业对设备环保指数上都有严格的要求。各企业在生产设备时,都充分考虑到设备在运行中可能会出现的种题。

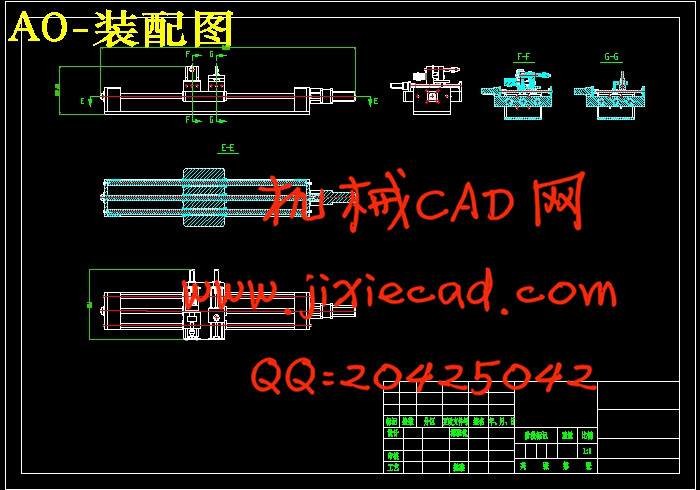

液压系统自世纪问世以来发展很快,在工作中的广泛适应性,使其在国民经济各部门获得了广泛的应用。由于液压缸在结构方面,功能方面,已经比较成熟,目前国内外液压缸的发展不仅体现在控制系统方面,也主要表现在高速化、高效化、低能耗;机电液一体化,以充分合理利用机械和电子的先进技术促进整个液压系统的完善;自动化、智能化,实现对系统的自动诊断和调整,具有故障预处理功能;液压元件集成化、标准化,以有效防止泄露和污染等四个方面。作为液压缸两大组成部分的控制元件和执行元件,由于技术发展趋于成熟,国无较大差距,主要差别在于加工工艺和安装方面。良好的工艺使液压缸在过滤、冷却及防止冲击和振动方面,有较明显改善。在油路结构设计方面,国内外液压缸都趋向于集成化、封闭式设计,插装阀、叠加阀和复合化元件及其本身在液压系统中得到较广泛的应用作为现代机械设备实现传动与控制的重要技术手段,液压技术在国民经济各领域得到了广泛的应用。与其他传动控制技术相比,液压技术具有能量密度高﹑配置灵活方便﹑调速范围大﹑工作平稳且快速性好﹑易于控制并过载保护﹑易于实现自动化和机电体化整合﹑系统设计制造和使用维护方便等多种显著的技术优势,因而使其成为现代机械工程的基本技术构成和现代控制工程的基本技术要素。智能石材切割机是加工各种石材的主要设备,适用于各类石材厂的石材的加工,如下料、开孔、开槽、拉伸等。本文根据智能石材切割机的用途﹑特点和要求,利用液压传动的基本原理,拟定出合理的液压系统图,再经过必要的计算来确定液压系统的参数,然后按照这些参数来选用液压元件的规格和进行系统的结构设计。智能石材切割机的液压系统呈长方形布置,外形新颖美观,动力系统采用液压系统,结构简单、紧凑、动作灵敏可靠。该机并设有脚踏开关,可实现半自动工艺动作的循环。液压传动和气压传动称为流体传动,是根据17世纪帕斯卡提出的液体静压力传动原理而发展起体传动技术水平的高低已成为一个国家工业发展水平的重要标志。由此可见,随着科学技术的迅速发展,液压技术将获得进一步发展,在各种机械设备上的应用将更加广泛。随着经济的发展和人们生活水平的提要求也进一步提高,因此作为高档次的居家装修材料——石材的需求量也逐年增加,由于天然石材的不规则性和石材资源的有限性使用使得石材的合理使用方法——石材切割技术得到迅速的发展,并通过PLC控制系统来控制整个石材机械的动作,使石材的加工得到自动化的水平。因此石材切割机的需求量也大量增加,国内外各种高性能的石材切割机种类很多,但是价格也极为昂贵.

absraote在国民经济建设中,石材是不可或缺的基础原材料。作为重要的基础产业,石材行业的发展程度成为一个国家社会发展水平和综合实力的重要衡量指标。我国经济正处于高速发展期,基础设施建设成为国内投资最主要的方式。因此,石材作为最主要的原材料之一,必然也处于扩张阶段水泥生产过程中,大部分原料要进行石材切割,石材是生产水泥砖,柱子用量最大的原料,开采后的面积较大,硬度较高,因此石材的切割在石材加工厂家中占有比较重要的地位。在新的市场需求的驱动下,石材开采设备的更新和优化升级更加迫切。国内石材切割设备生产企业充分挖掘市场潜力,大力发展大型环保节能的石材切割机械设备,在绿色环保化石材开采的转变中挥积极作用。一般生产大型石材气割机设备的企业对设备环保指数上都有严格的要求。各企业在生产设备时,都充分考虑到设备在运行中可能会出现的种题。

液压系统自世纪问世以来发展很快,在工作中的广泛适应性,使其在国民经济各部门获得了广泛的应用。由于液压缸在结构方面,功能方面,已经比较成熟,目前国内外液压缸的发展不仅体现在控制系统方面,也主要表现在高速化、高效化、低能耗;机电液一体化,以充分合理利用机械和电子的先进技术促进整个液压系统的完善;自动化、智能化,实现对系统的自动诊断和调整,具有故障预处理功能;液压元件集成化、标准化,以有效防止泄露和污染等四个方面。作为液压缸两大组成部分的控制元件和执行元件,由于技术发展趋于成熟,国无较大差距,主要差别在于加工工艺和安装方面。良好的工艺使液压缸在过滤、冷却及防止冲击和振动方面,有较明显改善。在油路结构设计方面,国内外液压缸都趋向于集成化、封闭式设计,插装阀、叠加阀和复合化元件及其本身在液压系统中得到较广泛的应用作为现代机械设备实现传动与控制的重要技术手段,液压技术在国民经济各领域得到了广泛的应用。与其他传动控制技术相比,液压技术具有能量密度高﹑配置灵活方便﹑调速范围大﹑工作平稳且快速性好﹑易于控制并过载保护﹑易于实现自动化和机电体化整合﹑系统设计制造和使用维护方便等多种显著的技术优势,因而使其成为现代机械工程的基本技术构成和现代控制工程的基本技术要素。智能石材切割机是加工各种石材的主要设备,适用于各类石材厂的石材的加工,如下料、开孔、开槽、拉伸等。本文根据智能石材切割机的用途﹑特点和要求,利用液压传动的基本原理,拟定出合理的液压系统图,再经过必要的计算来确定液压系统的参数,然后按照这些参数来选用液压元件的规格和进行系统的结构设计。智能石材切割机的液压系统呈长方形布置,外形新颖美观,动力系统采用液压系统,结构简单、紧凑、动作灵敏可靠。该机并设有脚踏开关,可实现半自动工艺动作的循环。液压传动和气压传动称为流体传动,是根据17世纪帕斯卡提出的液体静压力传动原理而发展起体传动技术水平的高低已成为一个国家工业发展水平的重要标志。由此可见,随着科学技术的迅速发展,液压技术将获得进一步发展,在各种机械设备上的应用将更加广泛。随着经济的发展和人们生活水平的提要求也进一步提高,因此作为高档次的居家装修材料——石材的需求量也逐年增加,由于天然石材的不规则性和石材资源的有限性使用使得石材的合理使用方法——石材切割技术得到迅速的发展,并通过PLC控制系统来控制整个石材机械的动作,使石材的加工得到自动化的水平。因此石材切割机的需求量也大量增加,国内外各种高性能的石材切割机种类很多,但是价格也极为昂贵.

关键词: 石材 石材加工设备 PLC控制 自动化

Pneumatic manipulator is a automated devices that can mimic the human hand and arm movements to do something,aslo can according to a fixed procedure to moving objects or control tools. It can replace the heavy labor in order to achieve the production mechanization and automation, and can work in dangerous working environments to protect the personal safety, Therefore widely used in machine building, metallurgy, electronics, light industry and atomic energy sectors.

This article is mainly of the pneumatic manipulator the overall design, and pneumatic design. This mechanism of manipulator includes cylinders and claws and connectors parts, it can move according to the due track on the movement of grabbing, carrying and unloading. The pneumatic part of the design is primarily to choose the right valves and design a reasonable pneumatic control loop, by controlling and regulating pressure, flow and direction of the compressed air to make it get the necessary strength, speed and changed the direction of movement in the prescribed procedure work.It can replace the heavy labor in order to achieve the production mechanization and automation, and can work in dangerous working environments to protect the personal safety, Therefore widely used in machine building, metallurgy, electronics, light industry and atomic .The principle, technical pare-maters, transmiting system and main parts structure of mincing ma-chine were introduced.The productingcapacity was analysed.Keywords Mincing machine Holds plate Cutting blade Transfer augerFixture design process of drilling pump cover and reaming holes is designed with 18H7 include part machining process design, process design and fixture three. In process design should first of all parts for analysis, to understand part of the process to design blank structure, and choose the good parts machining datum, design the process routes of the parts; then the parts of each step in the process to the size calculation, the key is to determine the craft equipment and the cutting dosage of each working procedure design; then the special fixture, the fixture for the various components of the design, such as the connecting part positioning devices, clamping element, a guide element, fixture and machine tools and other components; positioning error calculated by the analysis of fixture, jig structure the rationality and the deficiency, pay attention to improving and will design in.

Concurrent Engineering is the first to shorten product development cycles as a means to develop. Products will be characterized by the development, production engineering involved in the acts broken down into a series of tasks, such as market analysis, design, process design, production plans and equipment purchases, processing, quality assurance, testing and after sales service. These sub-tasks as far as possible and consider synchronous parallel to achieve improved design to shorten the cycle and improve quality, reduce costs, optimize the design purpose. It stressed that integrated, coordinated and parallel, namely:

(1) management, design, production, and service of all project-related personnel and product information integration as a whole, and stressed that all relevant departments and the interests of the overall goal line.

(2) to the establishment of a competent and reasonable charge of the project personnel structure of the working group coordinated management model, by the Working Group in the ministries responsible for project elements, and the promotion of the coordination of tasks.

(3) parallel processing stages of the work. According to the project in the different tasks of the linkages between the different ministries mandate of the elements of the work process can be completely overlap or duplication. In accordance with these principles, formulate a reasonable, and optimize the work plan, and the location in which the necessary settings assessment, the Working Group by the project implementation so that all sub-tasks in parallel, to move forward in an orderly manner, so as to ensure the smooth implementation of the whole project .

According to the traditional methods of work, the work of the various stages in a row serial. In such a product development approach, divorced from each other at various stages, are not related, resulting in increased design error, and difficult to discover such a design rework, to lengthen the development cycle, adding to the costs.

This paper discusses the meat processing machinery - crusher working principle, main technical parameters, transmission system, the typical parts of the structure design and production capacity analysis.

Small twisted paper broken machine for ordinary home, not only can be used for minced meat, can also be used with crushed peanuts, crushed ice, spices and other food, small power requirements, powered by the motor drive, reasonable structure design, can meet the family kitchen generally meat food consisting mainly of minced required.

Key word: pneumatic manipulator cylinder pneumatic loop Four degrees of freedom

目 录

1绪论 9

1.1课题的来源与研究的目的与意义..........................................................................10

1.2异型石材加工中心的应用........................................................................................10

1.3异型石材加工中心的组成........................................................................................10

1.4 石材加工机械的发展现状.......................................................................................10

1.4.1石材加工机械的分类.....................................................................................10

2智能石材切割机液压控制系统的总体结构分析.........................................................10

2.1 异型石材加工中心工作头部件的方案的确定...............................................10

2.2 异型石材加工中心工作头部件的工作原理....................................................10

3机械传动部分的设计计算......................................................................................................10

3.1横向伺服电机的选择与计算....................................................................................10

3.2滚珠丝杆的选择与计算.............................................................................................10

3.3齿轮选择计算与校核..................................................................................................10

3.4直线导杆的选型计算..................................................................................................10

3.5垂直升降伺服电机的选型计算...............................................................................10

4 各主要零部件强度的校核....................................................................................................10

4.1滚珠丝杆强度的校核...................................................................................................10

4.2轴承强度的校核.............................................................................................................10

4.3机架强度的校核............................................................................................................10

结论 45

参考文献 46

致谢........................................................................................................................................................10