设计简介

摘要

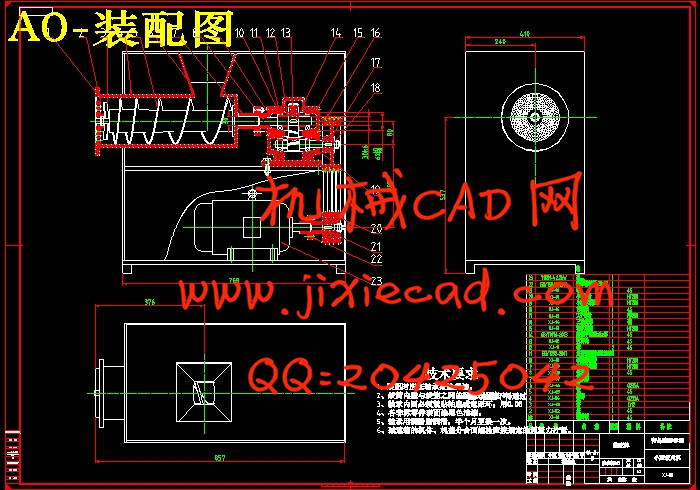

本文论述了肉类加工机械—小型绞肉机的工作原理,结构组成以及一些传动机构的设计计算和生产能力分析。

课题设计的小型绞碎机为普通家用,不仅可以用来绞碎肉类,还可以用来碎花生、碎冰、香料等食物,要求功率小,动力采用电机驱动,结构设计合理,能满足家庭厨房一般肉类食品为主的绞碎所需。

本次小型绞肉机的设计,大大地提高了传统绞肉机的工作效率和质量,并且对后续的小型绞肉机的开发和研制都有着一定的影响,在某种程度上大大提升了该设备在国内外的竞争力,体现了机械工业重要性这一核心价值。

关键词:绞肉机,结构设计,绞刀,价值

Abstract

本文论述了肉类加工机械—小型绞肉机的工作原理,结构组成以及一些传动机构的设计计算和生产能力分析。

课题设计的小型绞碎机为普通家用,不仅可以用来绞碎肉类,还可以用来碎花生、碎冰、香料等食物,要求功率小,动力采用电机驱动,结构设计合理,能满足家庭厨房一般肉类食品为主的绞碎所需。

本次小型绞肉机的设计,大大地提高了传统绞肉机的工作效率和质量,并且对后续的小型绞肉机的开发和研制都有着一定的影响,在某种程度上大大提升了该设备在国内外的竞争力,体现了机械工业重要性这一核心价值。

关键词:绞肉机,结构设计,绞刀,价值

Abstract

The principle, technical pare-maters, transmiting system and main parts structure of mincing ma-chine were introduced. The productingcapacity was analysed.Keywords Mincing machine Holds plate Cutting blade Transfer auger

This paper discusses the meat processing machinery - crusher working principle, main technical parameters, transmission system, the typical parts of the structure design and production capacity analysis.

Small twisted paper broken machine for ordinary home, not only can be used for minced meat, can also be used with crushed peanuts, crushed ice, spices and other food, small power requirements, powered by the motor drive, reasonable structure design, can meet the family kitchen generally meat food consisting mainly of minced required.

Key words: meat chopper;reame;processing;required.

目 录

摘要...............................................................I

Abstrac...........................................................II

1 绪论............................................................ 1

2 结构及工作原理.................................................. 2

2.1绞肉机的结构................................................ 3

2.1.1送料机构................................................ 5

2.1.2切割机构................................................ 6

2.1.3驱动机构................................................ 7

2.2绞肉机的工作原理............................................ 9

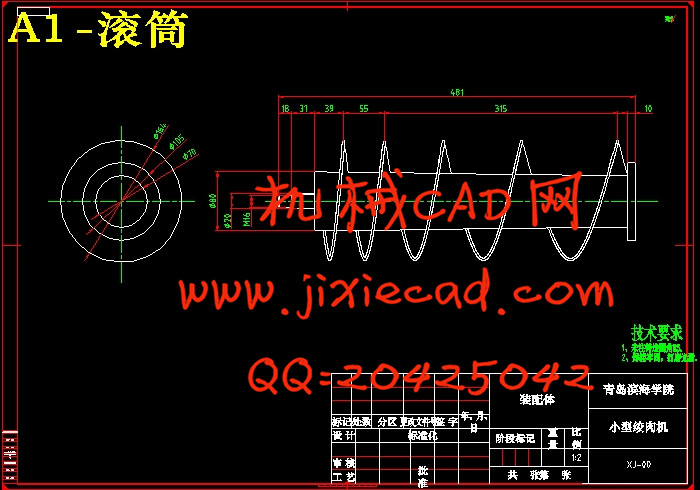

3 螺旋供料器的设计................................................ 10

3.1绞笼的设计.................................................. 11

3.1.1绞笼的材料.............................................. 11

3.1.2螺旋直径................................................ 11

3.1.3螺旋供料器的转速........................................ 11

3.1.4螺旋节距................................................ 11

3.2绞筒的设计................................................. 12

4 传动系统的设计.................................................. 13

4.1电机的选择.................................................. 13

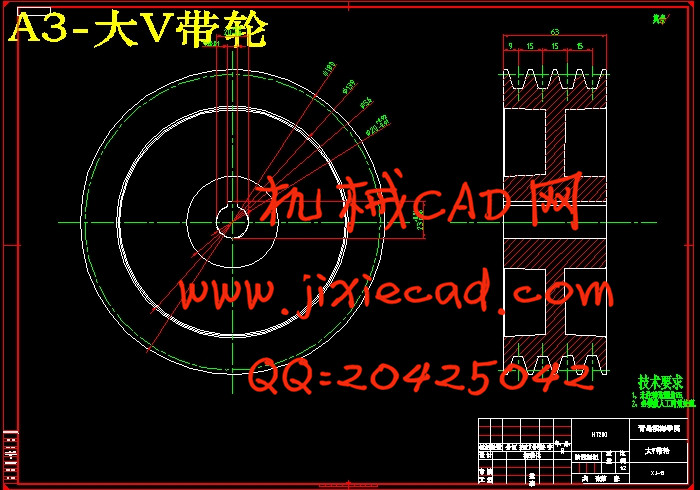

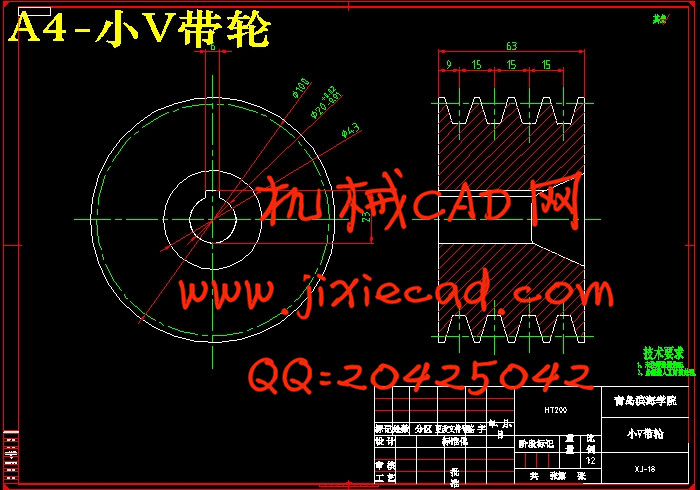

4.2带传动的设计................................................ 14

4.2.1设计功率................................................ 14

4.2.2 选定带型................................................ 14

4.2.3 传动比.................................................. 14

4.2.4 小带轮基准直径.......................................... 15

4.2.5 大带轮基准直径.......................................... 15

4.2.6 带速验算................................................ 15

Abstrac...........................................................II

1 绪论............................................................ 1

2 结构及工作原理.................................................. 2

2.1绞肉机的结构................................................ 3

2.1.1送料机构................................................ 5

2.1.2切割机构................................................ 6

2.1.3驱动机构................................................ 7

2.2绞肉机的工作原理............................................ 9

3 螺旋供料器的设计................................................ 10

3.1绞笼的设计.................................................. 11

3.1.1绞笼的材料.............................................. 11

3.1.2螺旋直径................................................ 11

3.1.3螺旋供料器的转速........................................ 11

3.1.4螺旋节距................................................ 11

3.2绞筒的设计................................................. 12

4 传动系统的设计.................................................. 13

4.1电机的选择.................................................. 13

4.2带传动的设计................................................ 14

4.2.1设计功率................................................ 14

4.2.2 选定带型................................................ 14

4.2.3 传动比.................................................. 14

4.2.4 小带轮基准直径.......................................... 15

4.2.5 大带轮基准直径.......................................... 15

4.2.6 带速验算................................................ 15

4.2.7 初定轴间距.............................................. 15

4.2.8 所需带的基准长度........................................ 16

4.2.9 实际轴间距.............................................. 17

4.2.10 小带轮包角..............................................18

4.2.11单根V带的基本额定功率................................. 19

4.2.12 时单根V带型额定功率增量........................... 20

时单根V带型额定功率增量........................... 20

4.2.13 V带的根数............................................. 20

4.2.14 单根V带的预紧力....................................... 20

4.2.15作用在轴上的力......................................... 20

4.2.16带轮的结构和尺寸....................................... 22

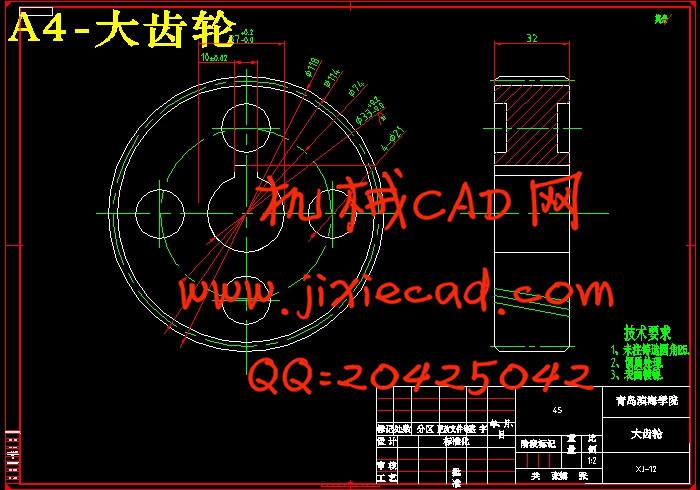

4.3齿轮传动设计................................................ 22

4.3.1选择材料,确定 和

和 及精度等级...................... 22

及精度等级...................... 22

4.3.2按接触强度进行初步设计................................... 22

4.3.2.1确定中心距........................................... 23

4.3.2.2 确定模数............................................. 23

4.3.2.3确定齿数............................................. 23

4.3.2.4计算主要的几何尺寸................................... 23

4.3.3校核齿面接触强度......................................... 24

4.3.4校核齿根的强度........................................... 24

4.3.5齿轮及齿轮副精度的检验项目计算........................... 25

4.3.5.1确定齿厚偏差代号..................................... 25

4.3.5.2确定齿轮的三个公差组的检验项目及公差值............... 26

4.3.5.3确定齿轮副的检验项目与公差值......................... 26

4.3.5.4 确定齿坯的精度....................................... 26

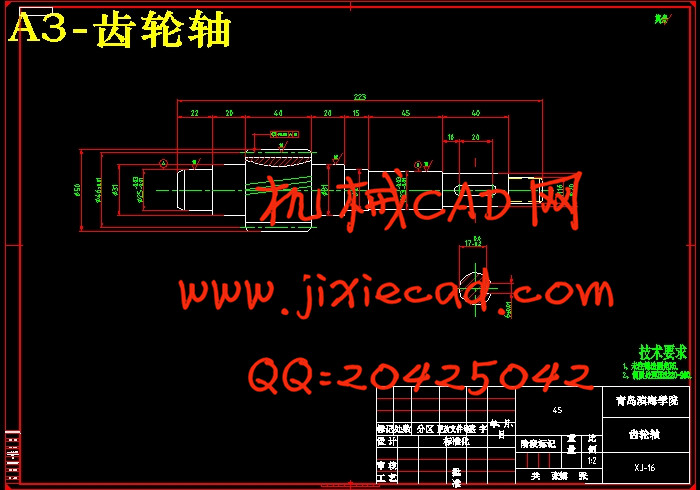

4.4轴的设计..................................................... 26

4.4.1按扭转强度计算........................................... 26

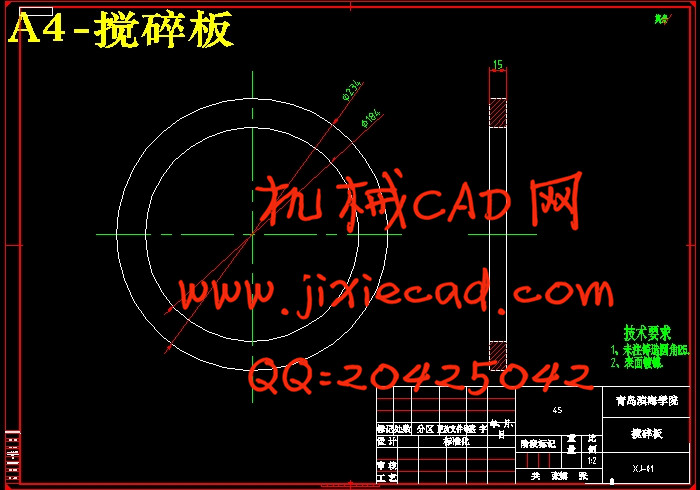

5 绞刀的设计...................................................... 27

5.1绞刀的设计.................................................... 27

4.2.8 所需带的基准长度........................................ 16

4.2.9 实际轴间距.............................................. 17

4.2.10 小带轮包角..............................................18

4.2.11单根V带的基本额定功率................................. 19

4.2.12

4.2.13 V带的根数............................................. 20

4.2.14 单根V带的预紧力....................................... 20

4.2.15作用在轴上的力......................................... 20

4.2.16带轮的结构和尺寸....................................... 22

4.3齿轮传动设计................................................ 22

4.3.1选择材料,确定

4.3.2按接触强度进行初步设计................................... 22

4.3.2.1确定中心距........................................... 23

4.3.2.2 确定模数............................................. 23

4.3.2.3确定齿数............................................. 23

4.3.2.4计算主要的几何尺寸................................... 23

4.3.3校核齿面接触强度......................................... 24

4.3.4校核齿根的强度........................................... 24

4.3.5齿轮及齿轮副精度的检验项目计算........................... 25

4.3.5.1确定齿厚偏差代号..................................... 25

4.3.5.2确定齿轮的三个公差组的检验项目及公差值............... 26

4.3.5.3确定齿轮副的检验项目与公差值......................... 26

4.3.5.4 确定齿坯的精度....................................... 26

4.4轴的设计..................................................... 26

4.4.1按扭转强度计算........................................... 26

5 绞刀的设计...................................................... 27

5.1绞刀的设计.................................................... 27

5.1.1刀刃的起讫位置.......................................... 29

5.1.2刀刃的前角.............................................. 30

5.1.3刀刃的后角.............................................. 30

5.1.4刀刃的刃倾角............................................ 31

5.1.5刀刃上任一点位量上绞肉速度.............................. 31

5.1.6绞刀片的结构............................................ 31

6 生产能力分析................................................... 31

6.1绞刀的切割能力.............................................. 31

6.2 绞肉机的生产能力............................................ 32

6.3功率消耗.................................................... 33

总结.............................................................. 34

致谢.............................................................. 35

参考文献.......................................................... 36