设计简介

摘 要

机械工业是一个国家的重要产业,机械工业的发展无时不刻都在影响着国家经济的发展,人类的进步离不开机械工业的发展。在全球经济发展的大环境下,中国各个行业被其他国家的先进技术影响的同时,越来越多的外国企业和品牌传播到中国已经成为现实。在新的市场需求的推动下,对带头罩躺椅进行改良和优化是当务之急。有大型躺椅生产设备企业对带头罩躺椅的安全指标的有着一定生产的严格要求。在生产设备的企业,充分考虑到在使用过程中可能出现的问题,从而减少噪声污染引起的振动或不当操作设备的现象等。国内带头罩躺椅的研发及制造要与全球号召的高效经济、安全稳定主题保持一致。带头罩躺椅的发展与人类社会的进步和科学技术的水平密切相关。

本设计所要研究的带头罩躺椅以链传动机构,以及通过扭簧实现头罩的折叠机构等等所组成,从设计要求出发以及各类参考文献中得出了最适合此类戴头罩躺椅的最优化结构并且进行了应用材料的确定、杆件的力学分析和整体的结构设计,最后完成了实体3D模型的制作。所以本设计的带头罩躺椅是由单一自由度收折零件,不需使用任何拆卸工具即可以达到收折后体积小、重量轻、操作简便,像行李箱拖行等特性,适用于下肢瘫痪、年老体弱多病和行动不方便者,是一种非常理想的代步和娱乐健身工具,此次带头罩躺椅的设计,在某种程度上大大提升了该种类型的躺椅在国内外的竞争力,体现了机械工业重要性这一核心价值。

关键词:机械工业;带头罩躺椅;模型;价值

Abstract

The environment of global economic development, China industries affected by other countries advanced technology at the same time, foreign enterprises and brand spread to more and more Chinese has become an opportunity. Cap pressing machine in industry through a variety of ways have been working with the relevant technology, and constantly improve their own strength and core competitiveness, and narrow the gap with developed countries. In the new market demand, update the sleeve pressing machine is a pressing matter of the moment. The production of pipe pressing machine equipment manufacturing enterprises to fully tap the potential of the market, vigorously develop the sleeves of large low cost pressing special machinery and equipment, plays a positive role in the evolution of automatic assembly, the assembly of mechanical equipment. There is a large pipe equipment on equipment safety index has strict requirements of production.

With the development of science and technology, interdisciplinary mutual infiltration, mutual exchanges between the various industry, extensive use of new structure, new materials, new technology, the sleeve pressing machine is large, efficient,reliable,energysaving, Recently, the use of machinery industry, bearing and shaft sleeve shaft were investigated, found that the shaft, bearings and bushings in the machinery industry is one of the key parts. Come very naturally in the assembly of the installation is also very simple. In the installation if the use of artificial pressure with not only the labor intensity is too large and the size of each other is not easy to ensure the shaft, bearing and shaft sleeve, so the design of a special press be imperative. Graduation project this time is a tube axial compressive loading machine. This paper introduces the theoretical calculation to design sleeve pressing machine structure, working principle and main parts of the strength check and the advantages of the sleeve.

Key word: pneumatic manipulator; cylinder; pneumatic loop;value

目 录

摘要 I

Abstract II

第一章 绪论 1

1.1 课题的来源与研究的目的和意义 1

1.2 本课题研究的内容 2

1.3 Solidworks设计基础 4

1.3.1 草图绘制 5

1.3.2 基准特征,参考几何体的创建 6

1.3.3 拉伸、旋转、扫描和放样特征建 7

1.3.4 工程图的设计 8

1.3.5 装配设计 9

第二章 带头罩躺椅总体结构的设计 10

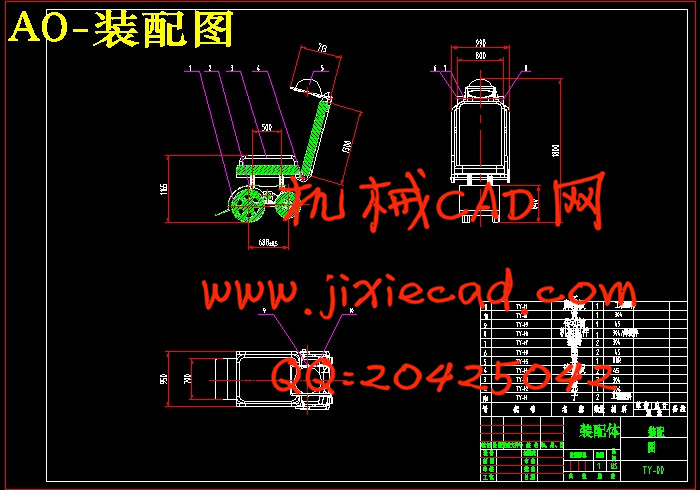

2.1 带头罩躺椅的总体方案图 12

2.2 机械传动部分的设计计算 13

2.2.1 主传动电机的选型计算 14

2.2.2 链传动的设计计算 16

第三章 各主要零部件强度的校核 17

3.1传动轴强度的校核与计算 18

3.2螺栓强度的校核计算 19

第四章 带头罩躺椅中主要零件的三维建模 20

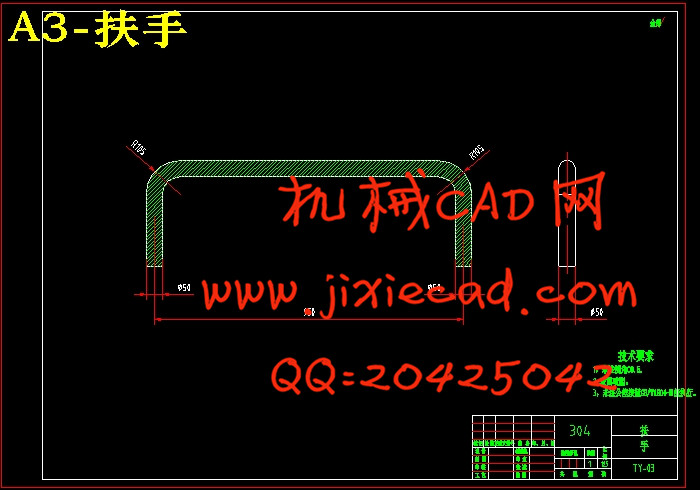

4.1扶手的三维建模 22

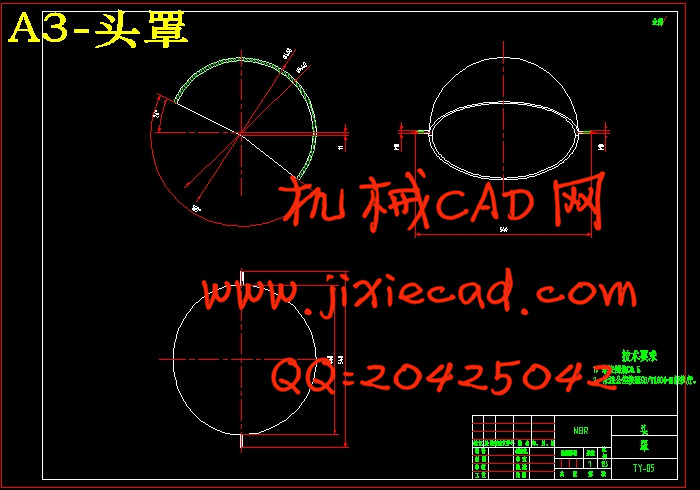

4.2头罩的三维建模 25

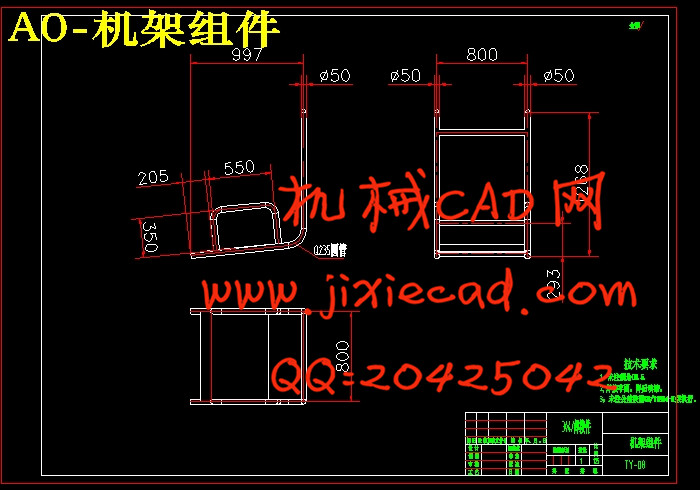

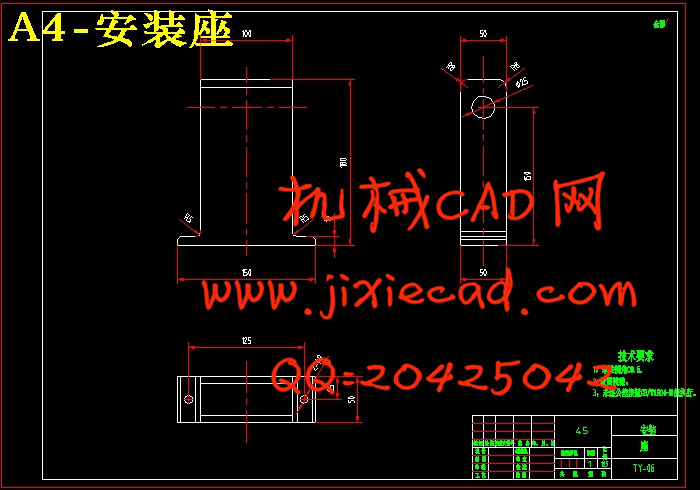

4.3安装座的三维建模 27

4.4带头罩躺椅的三维建模 31

第五章 三维软件设计总结 32

结论 33

致谢 34

参考文献 35

机械工业是一个国家的重要产业,机械工业的发展无时不刻都在影响着国家经济的发展,人类的进步离不开机械工业的发展。在全球经济发展的大环境下,中国各个行业被其他国家的先进技术影响的同时,越来越多的外国企业和品牌传播到中国已经成为现实。在新的市场需求的推动下,对带头罩躺椅进行改良和优化是当务之急。有大型躺椅生产设备企业对带头罩躺椅的安全指标的有着一定生产的严格要求。在生产设备的企业,充分考虑到在使用过程中可能出现的问题,从而减少噪声污染引起的振动或不当操作设备的现象等。国内带头罩躺椅的研发及制造要与全球号召的高效经济、安全稳定主题保持一致。带头罩躺椅的发展与人类社会的进步和科学技术的水平密切相关。

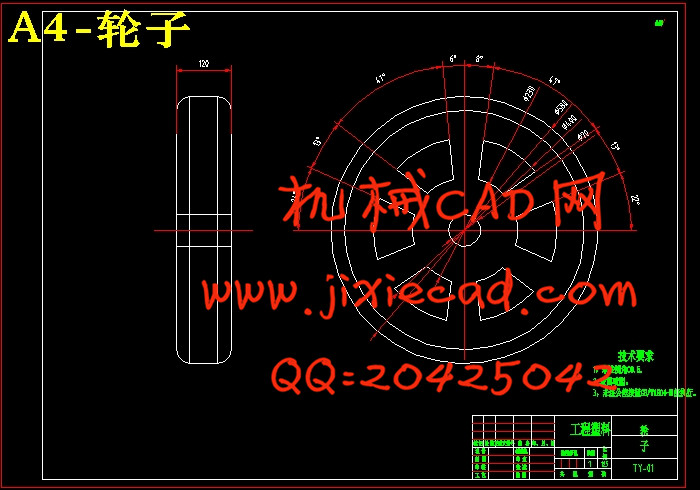

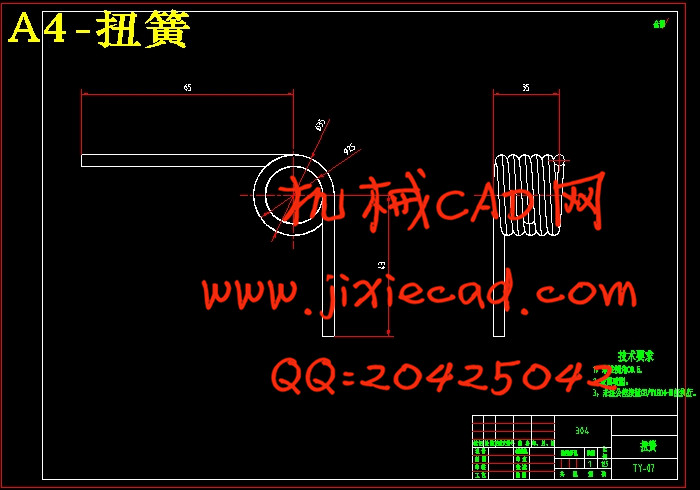

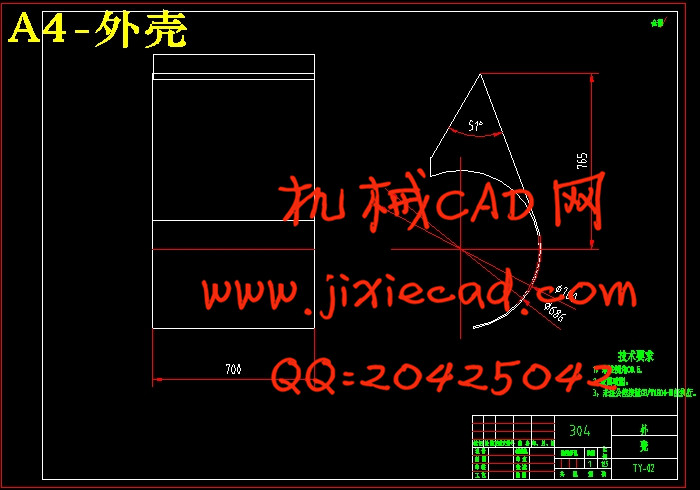

本设计所要研究的带头罩躺椅以链传动机构,以及通过扭簧实现头罩的折叠机构等等所组成,从设计要求出发以及各类参考文献中得出了最适合此类戴头罩躺椅的最优化结构并且进行了应用材料的确定、杆件的力学分析和整体的结构设计,最后完成了实体3D模型的制作。所以本设计的带头罩躺椅是由单一自由度收折零件,不需使用任何拆卸工具即可以达到收折后体积小、重量轻、操作简便,像行李箱拖行等特性,适用于下肢瘫痪、年老体弱多病和行动不方便者,是一种非常理想的代步和娱乐健身工具,此次带头罩躺椅的设计,在某种程度上大大提升了该种类型的躺椅在国内外的竞争力,体现了机械工业重要性这一核心价值。

关键词:机械工业;带头罩躺椅;模型;价值

Abstract

The environment of global economic development, China industries affected by other countries advanced technology at the same time, foreign enterprises and brand spread to more and more Chinese has become an opportunity. Cap pressing machine in industry through a variety of ways have been working with the relevant technology, and constantly improve their own strength and core competitiveness, and narrow the gap with developed countries. In the new market demand, update the sleeve pressing machine is a pressing matter of the moment. The production of pipe pressing machine equipment manufacturing enterprises to fully tap the potential of the market, vigorously develop the sleeves of large low cost pressing special machinery and equipment, plays a positive role in the evolution of automatic assembly, the assembly of mechanical equipment. There is a large pipe equipment on equipment safety index has strict requirements of production.

With the development of science and technology, interdisciplinary mutual infiltration, mutual exchanges between the various industry, extensive use of new structure, new materials, new technology, the sleeve pressing machine is large, efficient,reliable,energysaving, Recently, the use of machinery industry, bearing and shaft sleeve shaft were investigated, found that the shaft, bearings and bushings in the machinery industry is one of the key parts. Come very naturally in the assembly of the installation is also very simple. In the installation if the use of artificial pressure with not only the labor intensity is too large and the size of each other is not easy to ensure the shaft, bearing and shaft sleeve, so the design of a special press be imperative. Graduation project this time is a tube axial compressive loading machine. This paper introduces the theoretical calculation to design sleeve pressing machine structure, working principle and main parts of the strength check and the advantages of the sleeve.

Key word: pneumatic manipulator; cylinder; pneumatic loop;value

目 录

摘要 I

Abstract II

第一章 绪论 1

1.1 课题的来源与研究的目的和意义 1

1.2 本课题研究的内容 2

1.3 Solidworks设计基础 4

1.3.1 草图绘制 5

1.3.2 基准特征,参考几何体的创建 6

1.3.3 拉伸、旋转、扫描和放样特征建 7

1.3.4 工程图的设计 8

1.3.5 装配设计 9

第二章 带头罩躺椅总体结构的设计 10

2.1 带头罩躺椅的总体方案图 12

2.2 机械传动部分的设计计算 13

2.2.1 主传动电机的选型计算 14

2.2.2 链传动的设计计算 16

第三章 各主要零部件强度的校核 17

3.1传动轴强度的校核与计算 18

3.2螺栓强度的校核计算 19

第四章 带头罩躺椅中主要零件的三维建模 20

4.1扶手的三维建模 22

4.2头罩的三维建模 25

4.3安装座的三维建模 27

4.4带头罩躺椅的三维建模 31

第五章 三维软件设计总结 32

结论 33

致谢 34

参考文献 35