设计简介

摘 要

汽油机可变气门技术作为一种性价比相当高的技术方案,得到了广泛的应用。特别是近几年由于油价的攀升和日趋严格的环保法规,可变配气机构对节省燃油、降低废气污染、提高发动机功率都有显著作用。

本论文针对广泛用于现代轿车用汽油机最新技术完全可变气门驱动机构本田发动机的结构、原理方面的技术分析,以及对本人的新设计思路进行浅析。主要研究内容包括:

1.对以本田为代表的日系轿车完全可变气门技术的结构和工作原理进行分析,从而进一步的了解可变气门技术;

2.对以本田VTEC为代表的日系轿车可变气门技术的结构和工作原理进行分析;

3.对本人设计的凸轮轴设计图、工作原理进行浅析,比较和现有技术的优缺点。

本文通过对本田VTEC可变气门技术进行分析,以及新式凸轮轴的思维方向,进而对未来发动机技术的发展趋势进行一定的探索。

关键词:发动机,可变气门技术,凸轮轴,新技术

absraote

The gasoline engine variable valve technology as a cost-effective quite high technical scheme, been widely used. Especially in recent years because of rising oil prices and increasingly strict environmental protection laws and regulations, variable of valve-train saving fuel and reduce exhaust pollution and increase engine power are significantly. Widely used in this paper with the latest technology of modern car engine - totally variable valve driving mechanism VVA BMW new series engine, Toyota VTEC - I engine of the structure, principle and technical analysis, the new design idea of my bai. The main research contents include:

1. To BMW completely variable valve technical structure and workingprinciple of carry on the analysis, thus further understanding of variable valve technology;

2. The Honda VTEC variable valve structure and working principle of technology analysis;

3. To my design camshafts, comparison and the guide-subject advantages and disadvantages of existing technology.

This article through to Honda new engine completely variable valve technology, Honda VTEC variable valve technologies were analyzed, and the new camshaft thinking direction, and then to the development trend of future engine technology for certain exploration.

Small twisted paper broken machine for ordinary home, not only can be used for minced meat, can also be used with crushed peanuts, crushed ice, spices and other food, small power requirements, powered by the motor drive, reasonable structure design, can meet the family kitchen generally meat food consisting mainly of minced required.

Keyword:Eengine,Variable valve technology , The Camshaft, New Technology

目录

摘要..........................................................................................................2

Abstract................................................................................................2

第一章 引言...........................................................................................3

1.1 课题的研究背景和意义.......................................................................4

1.2可变气门配气机构的国内外研究概况.....................................................4

1.3可变气门配气机构简介.........................................................................4

1.3.1可变气门配气机构的分类...............................................................5

1.3.2可变气门配气机构的特点...............................................................5

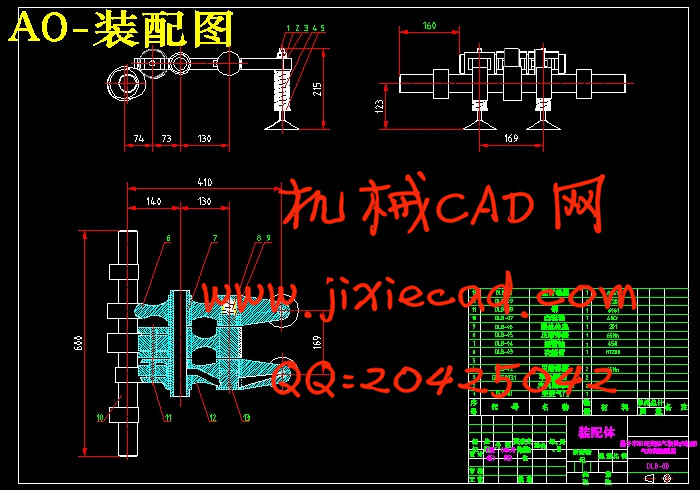

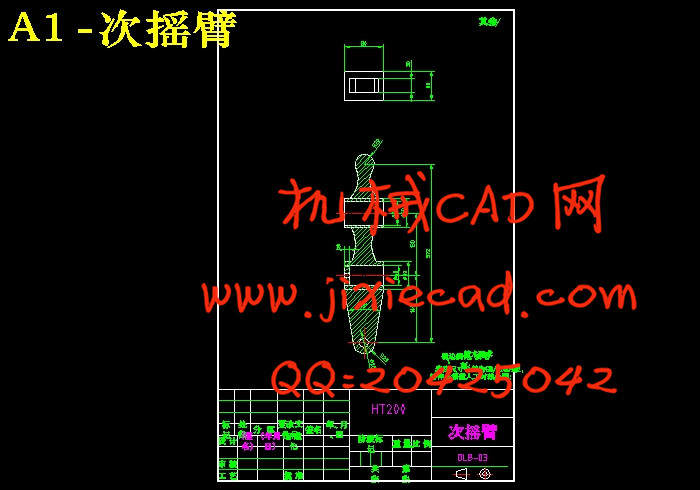

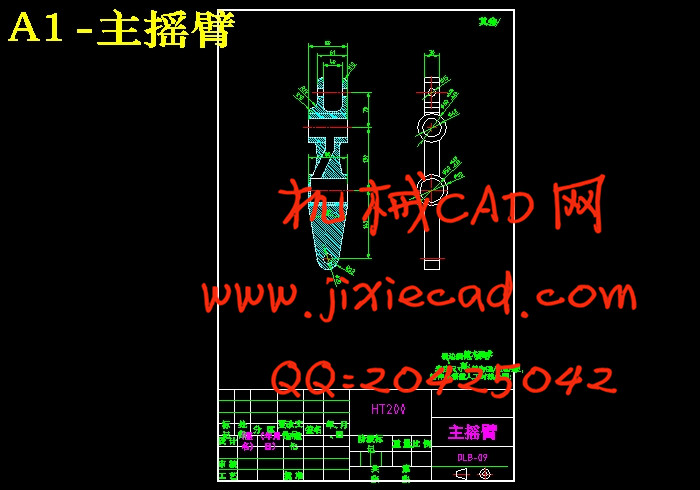

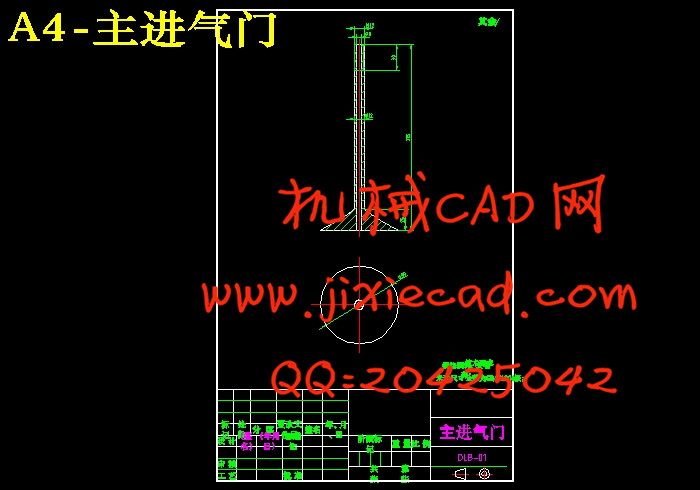

1.3.3可变气门配气机构总体结构图.........................................................6

1.4可变气门配气系统的工作原理.............................................................6

第二章可变配气系统结构的总体设计..............................................7

2.1 系统实现结构图.................................................................................9

2.2 可变配气凸轮轴的设计......................................................................10

2.2.1 可变配气凸轮轴的作用...............................................................11

2.2.2 可变配气凸轮轴的工作原理.......................................................12

2.2.3传统凸轮轴与新式凸轮轴的比较.................................................13

第三章排气凸轮轴的设计................................................................18

3.1 排气凸轮轴简介...............................................................................20

3.2 凸轮轴在汽车发动机中的作用和用途..................................................25

3.3 凸轮轴的分类..................................................................................25

3.4 凸轮轴的传动原理............................................................................25

3.5 凸轮轴常见的故障............................................................................26

3.6 凸轮轴的生产技术............................................................................26

结论........................................................................................................27

致谢........................................................................................................28

参考文献................................................................................................29

汽油机可变气门技术作为一种性价比相当高的技术方案,得到了广泛的应用。特别是近几年由于油价的攀升和日趋严格的环保法规,可变配气机构对节省燃油、降低废气污染、提高发动机功率都有显著作用。

本论文针对广泛用于现代轿车用汽油机最新技术完全可变气门驱动机构本田发动机的结构、原理方面的技术分析,以及对本人的新设计思路进行浅析。主要研究内容包括:

1.对以本田为代表的日系轿车完全可变气门技术的结构和工作原理进行分析,从而进一步的了解可变气门技术;

2.对以本田VTEC为代表的日系轿车可变气门技术的结构和工作原理进行分析;

3.对本人设计的凸轮轴设计图、工作原理进行浅析,比较和现有技术的优缺点。

本文通过对本田VTEC可变气门技术进行分析,以及新式凸轮轴的思维方向,进而对未来发动机技术的发展趋势进行一定的探索。

关键词:发动机,可变气门技术,凸轮轴,新技术

absraote

The gasoline engine variable valve technology as a cost-effective quite high technical scheme, been widely used. Especially in recent years because of rising oil prices and increasingly strict environmental protection laws and regulations, variable of valve-train saving fuel and reduce exhaust pollution and increase engine power are significantly. Widely used in this paper with the latest technology of modern car engine - totally variable valve driving mechanism VVA BMW new series engine, Toyota VTEC - I engine of the structure, principle and technical analysis, the new design idea of my bai. The main research contents include:

1. To BMW completely variable valve technical structure and workingprinciple of carry on the analysis, thus further understanding of variable valve technology;

2. The Honda VTEC variable valve structure and working principle of technology analysis;

3. To my design camshafts, comparison and the guide-subject advantages and disadvantages of existing technology.

This article through to Honda new engine completely variable valve technology, Honda VTEC variable valve technologies were analyzed, and the new camshaft thinking direction, and then to the development trend of future engine technology for certain exploration.

Small twisted paper broken machine for ordinary home, not only can be used for minced meat, can also be used with crushed peanuts, crushed ice, spices and other food, small power requirements, powered by the motor drive, reasonable structure design, can meet the family kitchen generally meat food consisting mainly of minced required.

Keyword:Eengine,Variable valve technology , The Camshaft, New Technology

目录

摘要..........................................................................................................2

Abstract................................................................................................2

第一章 引言...........................................................................................3

1.1 课题的研究背景和意义.......................................................................4

1.2可变气门配气机构的国内外研究概况.....................................................4

1.3可变气门配气机构简介.........................................................................4

1.3.1可变气门配气机构的分类...............................................................5

1.3.2可变气门配气机构的特点...............................................................5

1.3.3可变气门配气机构总体结构图.........................................................6

1.4可变气门配气系统的工作原理.............................................................6

第二章可变配气系统结构的总体设计..............................................7

2.1 系统实现结构图.................................................................................9

2.2 可变配气凸轮轴的设计......................................................................10

2.2.1 可变配气凸轮轴的作用...............................................................11

2.2.2 可变配气凸轮轴的工作原理.......................................................12

2.2.3传统凸轮轴与新式凸轮轴的比较.................................................13

第三章排气凸轮轴的设计................................................................18

3.1 排气凸轮轴简介...............................................................................20

3.2 凸轮轴在汽车发动机中的作用和用途..................................................25

3.3 凸轮轴的分类..................................................................................25

3.4 凸轮轴的传动原理............................................................................25

3.5 凸轮轴常见的故障............................................................................26

3.6 凸轮轴的生产技术............................................................................26

结论........................................................................................................27

致谢........................................................................................................28

参考文献................................................................................................29