设计简介

摘 要

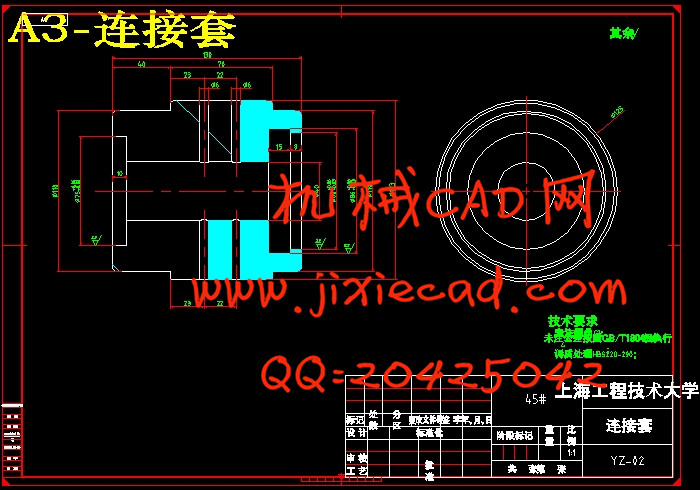

本论文根据对齿轮齿条式转向器的研究以及资料的查阅,着重阐述了齿轮齿条式转向器类型选择,不同类型齿轮齿条式转向器的优缺点和各种类型齿轮齿条式转向器应用状况。 根据原有数据计算转向系的传动比,并确定齿轮齿条的几何参数。 齿轮齿条式转向器总体设计,受力分析,及对齿轮齿条的疲劳强度校核、齿根弯曲疲劳强度校核。修正齿轮 齿条式转向器中不合理的数据。通过对齿轮齿条式转向器的设计,选取出相关的零件如螺钉、轴承等,并在说明书中画出相关零件的零件图。通过说明书并画出齿轮齿条式转向器的零件图。

本题目为设计类实际课题,来源于华晨宝马齿轮齿条式转向器的设计过程。我国生产的宝马车齿轮齿条式转向器从仿制开始起步,近期产品的质量较早期有所提高。但受国产配套件质量及设计水平等的影响,我国目前生产的宝马车的总体水平,与进口产品及港口用户的要求仍有较大差距,齿轮齿条式转向器的生产也是如此,为满足市场需求,特开发华晨宝马齿轮齿条式转向器。通过对华晨宝马齿轮齿条式转向器的设计,能培养学生综合运用所学的基本理论、基本知识解决问题的能力,培养学生英语阅读和翻译能力,学习专用汽车设计经验,掌握汽车设计基本方法。

关键词:齿轮齿条;转向器;基本理论;汽车设计

Abstract

With development of all kind of science technology and global economy, Pneumatic manipulator is a automated devices that can mimic the human hand and arm movements to do something,aslo can according to a fixed procedure to moving objects or control tools. It can replace the heavy labor in order to achieve the production mechanization and automation, and can work in dangerous working environments to protect the personal safety.

Therefore widely used in machine building, metallurgy, electronics, light industry and atomic energy sectors.The pneumatic part of the design is primarily to choose the right valves and design a reasonable pneumatic control loop, by controlling and regulating pressure,atcompressedneceengththdirectionprocedurework.The inverted pendulum is a typical high order system, with multi variable, non-linear, strong-coupling, fleet and absolutely instable. It is representative as an ideal model to prove new control theory and techniques. During the control process, pendulum can effectively reflect many key problems such as equanimity, robust, follow-up and track, therefore.This paper studies a control method of double inverted pendulum . First of all, the mathematical model of the double inverted pendulum is established, then make a control design to double inverted pendulum on the mathematical model, and determine the system performance index weightmatrix , by using genetic algorithm in order to attain the system state feedback control matrix. Finally, the simulation of the system is made by . After several test matrix value the results are not satisfactory response, then we optimize matrix by using Genetic Algorithm. Simulation results show: The system response can meet the design requirements effectively after Genetic Algorithm optimization. Small twisted paper broken machine for ordinary home, not only can be used for minced meat, can also be used with crushed peanuts, crushed ice, spices and otherfood, small power requirements, powered by the motor drive, reasonable structuredesign.

Key word: Rack and pinion;steering ; basic throey ; car design

目 录

摘要 2

Abstract 3

第一章 绪论 4

1.1 课题的来源与研究的目的和意义 5

1.2 汽车转向装置的发展趋势 6

1.3 本课题研究的主要内容 6

第二章 华晨宝马齿轮齿条转向器总体结构的设计 7

2.1 齿轮齿条转向器的总体方案图 8

2.2 齿轮齿条转向器的转向原理 9

2.3 传动比的计算 10

2.3.1汽车方向盘(转向盘) 11

2.3.2转向阻力矩 11

2.3.3角传动比与力传动比 12

2.4 齿轮设计 12

2.4.1 齿轮参数的选择 12

2.4.2齿轮几何尺寸确定 12

2.4.3齿根弯曲疲劳强度计算 12

2.4.4齿轮精度等级、材料及参数的选择 12

2.4.5齿轮的齿根弯曲强度设计 12

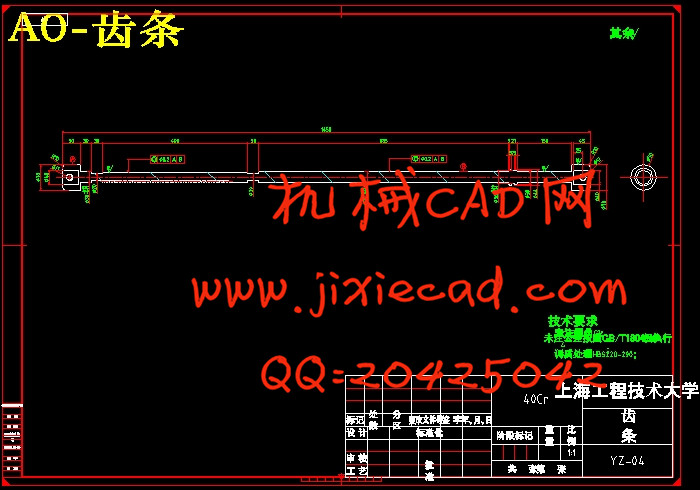

2.5齿条的设计 12

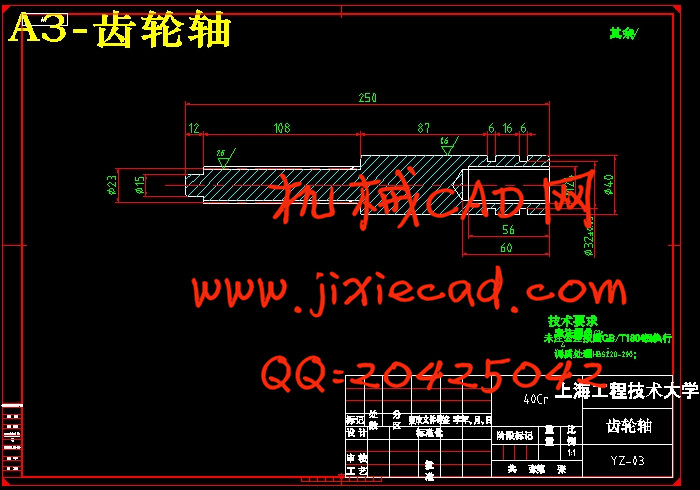

2.6齿轮轴的设计 22

第三章 各主要零部件强度的校核 25

3.1轴承强度的校核与计算 26

3.2传动轴强度的校核计算 27

第四章 齿轮齿条转向器中主要零件的三维建模 29

4.1方向盘的三维建模 32

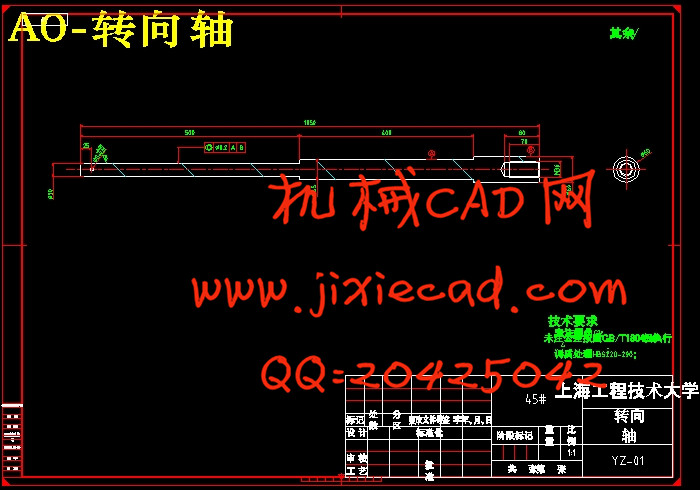

4.2转向轴的三维建模 32

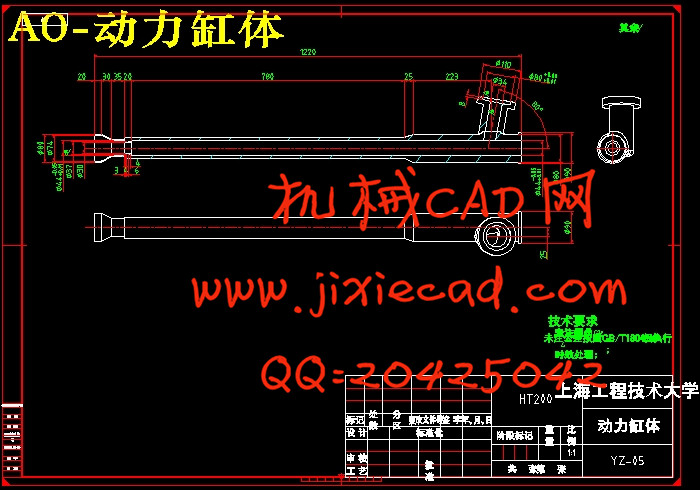

4.3动力缸体的三维建模 33

4.4齿轮齿条转向器的三维建模 34

第五章 三维软件设计总结 37

结论 38

致谢 39

参考文献 40

本论文根据对齿轮齿条式转向器的研究以及资料的查阅,着重阐述了齿轮齿条式转向器类型选择,不同类型齿轮齿条式转向器的优缺点和各种类型齿轮齿条式转向器应用状况。 根据原有数据计算转向系的传动比,并确定齿轮齿条的几何参数。 齿轮齿条式转向器总体设计,受力分析,及对齿轮齿条的疲劳强度校核、齿根弯曲疲劳强度校核。修正齿轮 齿条式转向器中不合理的数据。通过对齿轮齿条式转向器的设计,选取出相关的零件如螺钉、轴承等,并在说明书中画出相关零件的零件图。通过说明书并画出齿轮齿条式转向器的零件图。

本题目为设计类实际课题,来源于华晨宝马齿轮齿条式转向器的设计过程。我国生产的宝马车齿轮齿条式转向器从仿制开始起步,近期产品的质量较早期有所提高。但受国产配套件质量及设计水平等的影响,我国目前生产的宝马车的总体水平,与进口产品及港口用户的要求仍有较大差距,齿轮齿条式转向器的生产也是如此,为满足市场需求,特开发华晨宝马齿轮齿条式转向器。通过对华晨宝马齿轮齿条式转向器的设计,能培养学生综合运用所学的基本理论、基本知识解决问题的能力,培养学生英语阅读和翻译能力,学习专用汽车设计经验,掌握汽车设计基本方法。

关键词:齿轮齿条;转向器;基本理论;汽车设计

Abstract

With development of all kind of science technology and global economy, Pneumatic manipulator is a automated devices that can mimic the human hand and arm movements to do something,aslo can according to a fixed procedure to moving objects or control tools. It can replace the heavy labor in order to achieve the production mechanization and automation, and can work in dangerous working environments to protect the personal safety.

Therefore widely used in machine building, metallurgy, electronics, light industry and atomic energy sectors.The pneumatic part of the design is primarily to choose the right valves and design a reasonable pneumatic control loop, by controlling and regulating pressure,atcompressedneceengththdirectionprocedurework.The inverted pendulum is a typical high order system, with multi variable, non-linear, strong-coupling, fleet and absolutely instable. It is representative as an ideal model to prove new control theory and techniques. During the control process, pendulum can effectively reflect many key problems such as equanimity, robust, follow-up and track, therefore.This paper studies a control method of double inverted pendulum . First of all, the mathematical model of the double inverted pendulum is established, then make a control design to double inverted pendulum on the mathematical model, and determine the system performance index weightmatrix , by using genetic algorithm in order to attain the system state feedback control matrix. Finally, the simulation of the system is made by . After several test matrix value the results are not satisfactory response, then we optimize matrix by using Genetic Algorithm. Simulation results show: The system response can meet the design requirements effectively after Genetic Algorithm optimization. Small twisted paper broken machine for ordinary home, not only can be used for minced meat, can also be used with crushed peanuts, crushed ice, spices and otherfood, small power requirements, powered by the motor drive, reasonable structuredesign.

Key word: Rack and pinion;steering ; basic throey ; car design

目 录

摘要 2

Abstract 3

第一章 绪论 4

1.1 课题的来源与研究的目的和意义 5

1.2 汽车转向装置的发展趋势 6

1.3 本课题研究的主要内容 6

第二章 华晨宝马齿轮齿条转向器总体结构的设计 7

2.1 齿轮齿条转向器的总体方案图 8

2.2 齿轮齿条转向器的转向原理 9

2.3 传动比的计算 10

2.3.1汽车方向盘(转向盘) 11

2.3.2转向阻力矩 11

2.3.3角传动比与力传动比 12

2.4 齿轮设计 12

2.4.1 齿轮参数的选择 12

2.4.2齿轮几何尺寸确定 12

2.4.3齿根弯曲疲劳强度计算 12

2.4.4齿轮精度等级、材料及参数的选择 12

2.4.5齿轮的齿根弯曲强度设计 12

2.5齿条的设计 12

2.6齿轮轴的设计 22

第三章 各主要零部件强度的校核 25

3.1轴承强度的校核与计算 26

3.2传动轴强度的校核计算 27

第四章 齿轮齿条转向器中主要零件的三维建模 29

4.1方向盘的三维建模 32

4.2转向轴的三维建模 32

4.3动力缸体的三维建模 33

4.4齿轮齿条转向器的三维建模 34

第五章 三维软件设计总结 37

结论 38

致谢 39

参考文献 40