设计简介

摘要

本文是关于木板自动包装设备的设计,首先对木板自动包装设备作了简单的概述;接着分析了木板自动包装设备的选型原则及计算方法;然后根据这些设计准则与计算选型方法按照给定参数要求进行选型设计;接着对所选择的木板自动包装设备各主要零部件进行了校核。最后简单的说明了木板自动包装设备的安装与维护。目前,木板自动包装设备正朝着长距离,高速度,低摩擦的方向发展。在木板自动包装设备的设计、制造以及应用方面,目前我国与国外先进水平相比仍有较大差距,国内在设计制造木板自动包装设备过程中存在着很多不足。

对于木板自动包装设备的设计,通过对比对照,对传统的木板自动包装设备的结构进行了改进和优化,使得此种类型的木板自动包装设备的使用范围更广泛,更加灵活,并且对今后的选型设计工作有一定的参考价值。

关键词:木板自动包装设备;设计;传统;参考

Abstract

This graduation design is about the optimum design of the roller conveyor drive first driven roller conveyor has been made a brief overview; then drive roller conveyor has been analyzed the selection principle and the calculation method; and has been calculated based on these design criteria and selection method in accordance with the given parameters requirements for selection design; then the conveyor main parts has been checked. The conveyor has been a simple description of the installation and maintenance. At present, the driving roller conveyor has been towards long distance, high speed, low friction direction. The driving drum of belt conveyor is designed and manufacture and application, at present our country and the overseas advanced level compared to still have a large gap, domestically driven roller conveyor has been in the design and manufacturing process exists many problems.

Driven roller conveyor has been the design, optimization design, has been adopted compared with the control, the drive traditional roller conveyor structure has been improved and optimized, this type of drive roller conveyor has been made more widely, more flexible, and has been for future design and selection have been to have certain reference value.

Key words:Driving roller type conveyer optimal; Design; Transport; selection

目 录

本文是关于木板自动包装设备的设计,首先对木板自动包装设备作了简单的概述;接着分析了木板自动包装设备的选型原则及计算方法;然后根据这些设计准则与计算选型方法按照给定参数要求进行选型设计;接着对所选择的木板自动包装设备各主要零部件进行了校核。最后简单的说明了木板自动包装设备的安装与维护。目前,木板自动包装设备正朝着长距离,高速度,低摩擦的方向发展。在木板自动包装设备的设计、制造以及应用方面,目前我国与国外先进水平相比仍有较大差距,国内在设计制造木板自动包装设备过程中存在着很多不足。

对于木板自动包装设备的设计,通过对比对照,对传统的木板自动包装设备的结构进行了改进和优化,使得此种类型的木板自动包装设备的使用范围更广泛,更加灵活,并且对今后的选型设计工作有一定的参考价值。

关键词:木板自动包装设备;设计;传统;参考

Abstract

This graduation design is about the optimum design of the roller conveyor drive first driven roller conveyor has been made a brief overview; then drive roller conveyor has been analyzed the selection principle and the calculation method; and has been calculated based on these design criteria and selection method in accordance with the given parameters requirements for selection design; then the conveyor main parts has been checked. The conveyor has been a simple description of the installation and maintenance. At present, the driving roller conveyor has been towards long distance, high speed, low friction direction. The driving drum of belt conveyor is designed and manufacture and application, at present our country and the overseas advanced level compared to still have a large gap, domestically driven roller conveyor has been in the design and manufacturing process exists many problems.

Driven roller conveyor has been the design, optimization design, has been adopted compared with the control, the drive traditional roller conveyor structure has been improved and optimized, this type of drive roller conveyor has been made more widely, more flexible, and has been for future design and selection have been to have certain reference value.

Key words:Driving roller type conveyer optimal; Design; Transport; selection

目 录

第1章 绪论 1

1.1 课题的来源与研究的目的和意义 1

1.2 本课题研究的内容 2

1.3 研究的意义 4

第2章 木板自动包装设备的设计 6

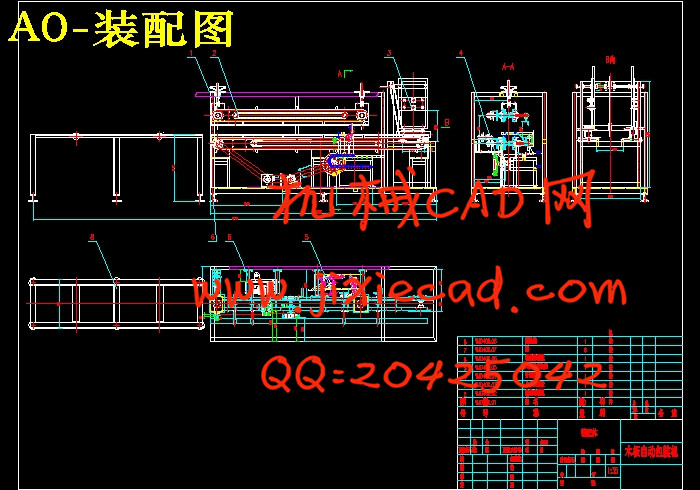

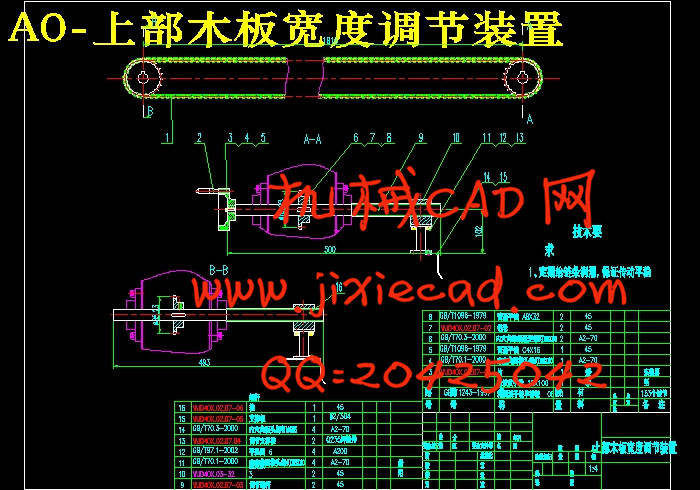

2.1木板自动包装设备的方案布局图的确定 7

2.2木板自动包装设备的工作原理 8

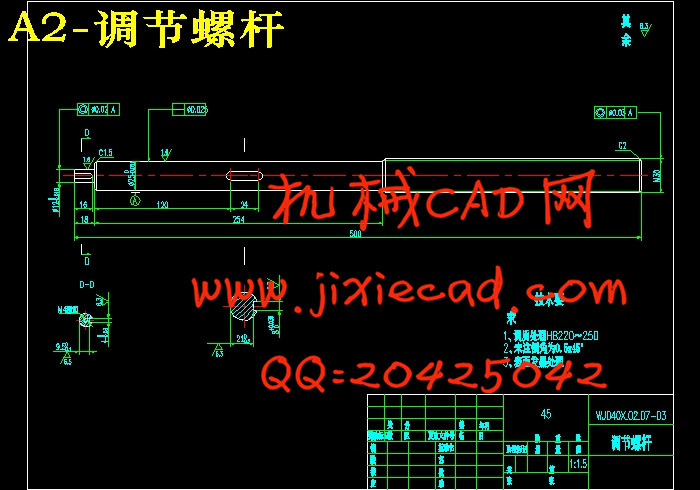

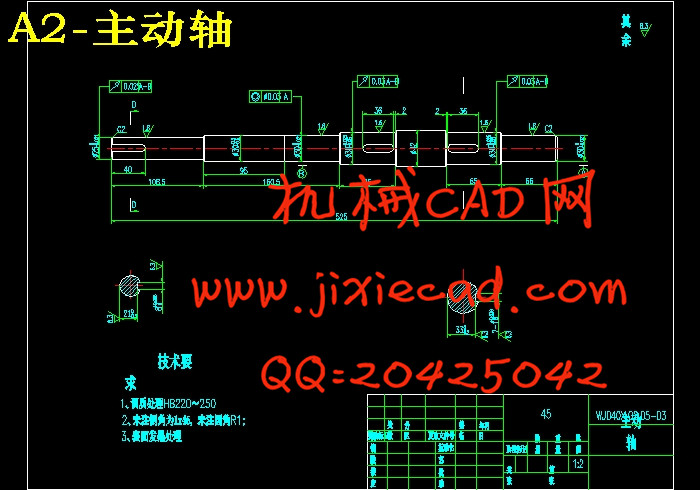

第3章 机械传动部分的选型计算 10

3.1电机的选型计算 12

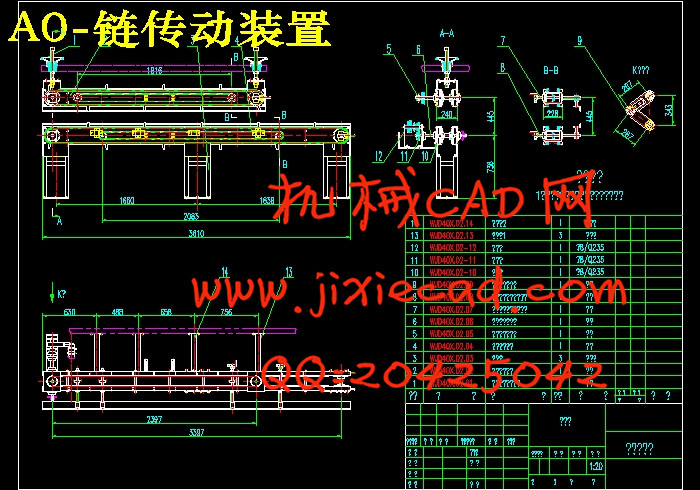

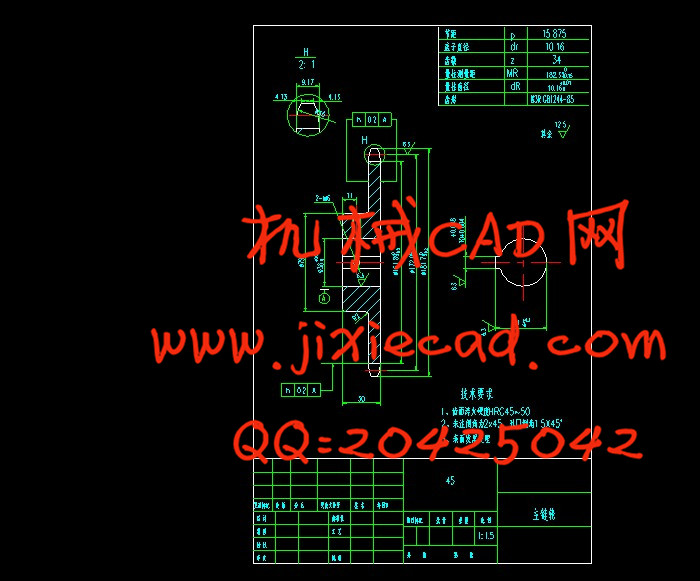

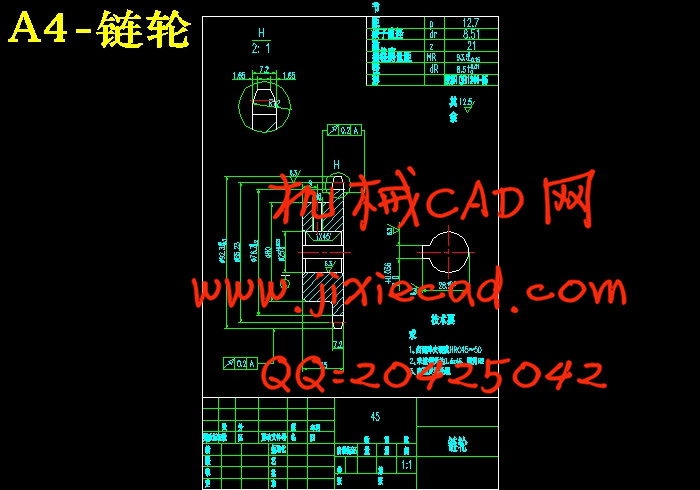

3.2链轮传动的设计计算 13

3.3带传动的设计计算 15

3.4生产能力的设计计算 18

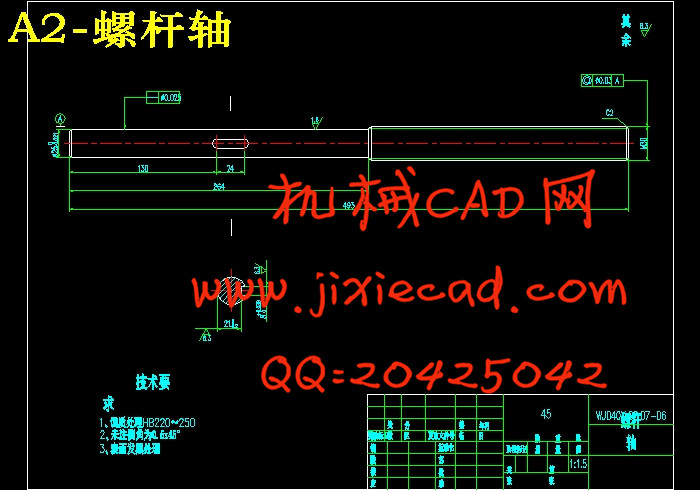

3.5平键的选型计算 18

第4章 各重要组成部分的强度校核 19

4.1机架强度的校核与计算 22

4.2螺栓强度的校核计算 23

4.3轴承强度的校核 25

第5章 设计总结 27

第6章 木板自动包装机的三维建模 29

结论 31

参考文献 32

致谢 33

1.1 课题的来源与研究的目的和意义 1

1.2 本课题研究的内容 2

1.3 研究的意义 4

第2章 木板自动包装设备的设计 6

2.1木板自动包装设备的方案布局图的确定 7

2.2木板自动包装设备的工作原理 8

第3章 机械传动部分的选型计算 10

3.1电机的选型计算 12

3.2链轮传动的设计计算 13

3.3带传动的设计计算 15

3.4生产能力的设计计算 18

3.5平键的选型计算 18

第4章 各重要组成部分的强度校核 19

4.1机架强度的校核与计算 22

4.2螺栓强度的校核计算 23

4.3轴承强度的校核 25

第5章 设计总结 27

第6章 木板自动包装机的三维建模 29

结论 31

参考文献 32

致谢 33