设计简介

精密凸轮轴非接触测量仪设计

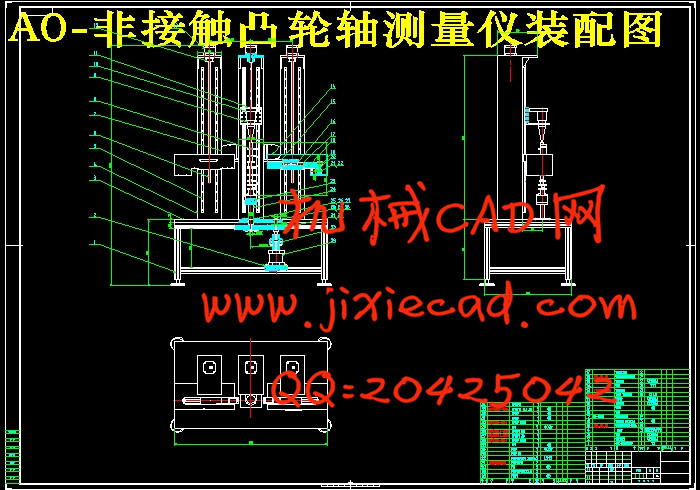

摘要:凸轮轴测量仪采用精密机械、光栅、微型计算机等技术,为满足汽车、摩托车发动机凸轮轴、汽车前后桥刹车凸轮轴等检测要求而特殊设计制造的新型测量仪器,可测量凸轮轴的桃形型而误差、桃形对定位键槽的相位角误差、桃形间相位角误差、轴径的径向跳动及凸轮的速度、加速度等测量项目。仪器采用通用微机系统进行测量循环控制、测量数据采集处理以及测量误差评值和测量结果输出。最大凸轮轴测量长度可达1.5米。

非接触式测量是指不接触被测物体的前提下进行精准测量。其测量精度可以达到μm非接触式测量仪利用CCD采集变焦镜下样品的影像,再配合XYZ轴移动平台及自动变焦镜,运用影像分析原理,通过计算机处理影像信号,对科研生产零件进行精密的几何数据的测量,并可进行CPK数值的分析。

关键词:凸轮轴;测量仪;非接触;光电传感器

Precision Camshaft Design of non-contact measuring instrument

Abstract:Camshaft measuring instrument with precision machinery, grating, micro-computer technology, to meet the automotive, motorcycle engine camshaft, cam brakes front and rear axles and other automotive testing requirements and special design and manufacture of new measuring instruments, to measure camshaft Peach Type of error, Peach keyway positioning error of the phase angle, phase angle error between Peach, and the cam shaft of the radial velocity, acceleration and other measurements. Equipment using a common computer system for measuring loop control, measurement data acquisition and processing, and measurement error evaluation and measurement results output. Camshaft measurements maximum length of up to 1.5 meters.

Non-contact non-contact measurement is the premise of the measured object for accurate measurements. The measurement accuracy can be achieved μm non-contact measuring microscope samples using CCD image acquisition zoom, coupled with the XYZ axes mobile platform and automatic zoom lens, the use of image analysis principle, through computer processing the image signal, on the research and production of precision parts Measurement geometry, and numerical analysis of the CPK

Keywords: Camshaft; measuring instrument; non-contact; photoelectric sensor

目 录

摘要………………………………………………………………………3

Abstract………………………………………………………………4

第1章 绪论……………………………………………………………….5

1.1引言…………………………………………………………………….5

1.2技术特点……………………………………………………………….5

1.3 非接触式测量及光电传感器的应用………………………………….5

1.4 非接触式凸轮轴测量仪的设计思路………………………………….7

第2章 传动机构和测量平台的设计…………………………………….7

2.1导轨的选择…………………………………………………………….7

2.2导轨的确定…………………………………………………………….9

2.3丝杆的确定选择与计算………………………………………………10

2.4 齿轮选择计算与校核………………………………………………..20

2.5 同步带轮选择………………………………………………………..22

2.6 步进电机选取与计算………………………………………………..25

第3章 光电传感器的选择…………………………………………..27

3.1光电传感器的选型……………………………………………………27

3.2 LS-7000系列测量头的选取………………………………………….29

3.3.测量凸轮轴的应用……………………………………………………32

结论…………………………………………………………………………34

致谢…………………………………………………………………………35

参考文献……………………………………………………………………36

摘要:凸轮轴测量仪采用精密机械、光栅、微型计算机等技术,为满足汽车、摩托车发动机凸轮轴、汽车前后桥刹车凸轮轴等检测要求而特殊设计制造的新型测量仪器,可测量凸轮轴的桃形型而误差、桃形对定位键槽的相位角误差、桃形间相位角误差、轴径的径向跳动及凸轮的速度、加速度等测量项目。仪器采用通用微机系统进行测量循环控制、测量数据采集处理以及测量误差评值和测量结果输出。最大凸轮轴测量长度可达1.5米。

非接触式测量是指不接触被测物体的前提下进行精准测量。其测量精度可以达到μm非接触式测量仪利用CCD采集变焦镜下样品的影像,再配合XYZ轴移动平台及自动变焦镜,运用影像分析原理,通过计算机处理影像信号,对科研生产零件进行精密的几何数据的测量,并可进行CPK数值的分析。

关键词:凸轮轴;测量仪;非接触;光电传感器

Precision Camshaft Design of non-contact measuring instrument

Abstract:Camshaft measuring instrument with precision machinery, grating, micro-computer technology, to meet the automotive, motorcycle engine camshaft, cam brakes front and rear axles and other automotive testing requirements and special design and manufacture of new measuring instruments, to measure camshaft Peach Type of error, Peach keyway positioning error of the phase angle, phase angle error between Peach, and the cam shaft of the radial velocity, acceleration and other measurements. Equipment using a common computer system for measuring loop control, measurement data acquisition and processing, and measurement error evaluation and measurement results output. Camshaft measurements maximum length of up to 1.5 meters.

Non-contact non-contact measurement is the premise of the measured object for accurate measurements. The measurement accuracy can be achieved μm non-contact measuring microscope samples using CCD image acquisition zoom, coupled with the XYZ axes mobile platform and automatic zoom lens, the use of image analysis principle, through computer processing the image signal, on the research and production of precision parts Measurement geometry, and numerical analysis of the CPK

Keywords: Camshaft; measuring instrument; non-contact; photoelectric sensor

目 录

摘要………………………………………………………………………3

Abstract………………………………………………………………4

第1章 绪论……………………………………………………………….5

1.1引言…………………………………………………………………….5

1.2技术特点……………………………………………………………….5

1.3 非接触式测量及光电传感器的应用………………………………….5

1.4 非接触式凸轮轴测量仪的设计思路………………………………….7

第2章 传动机构和测量平台的设计…………………………………….7

2.1导轨的选择…………………………………………………………….7

2.2导轨的确定…………………………………………………………….9

2.3丝杆的确定选择与计算………………………………………………10

2.4 齿轮选择计算与校核………………………………………………..20

2.5 同步带轮选择………………………………………………………..22

2.6 步进电机选取与计算………………………………………………..25

第3章 光电传感器的选择…………………………………………..27

3.1光电传感器的选型……………………………………………………27

3.2 LS-7000系列测量头的选取………………………………………….29

3.3.测量凸轮轴的应用……………………………………………………32

结论…………………………………………………………………………34

致谢…………………………………………………………………………35

参考文献……………………………………………………………………36