设计简介

刨丝机设计

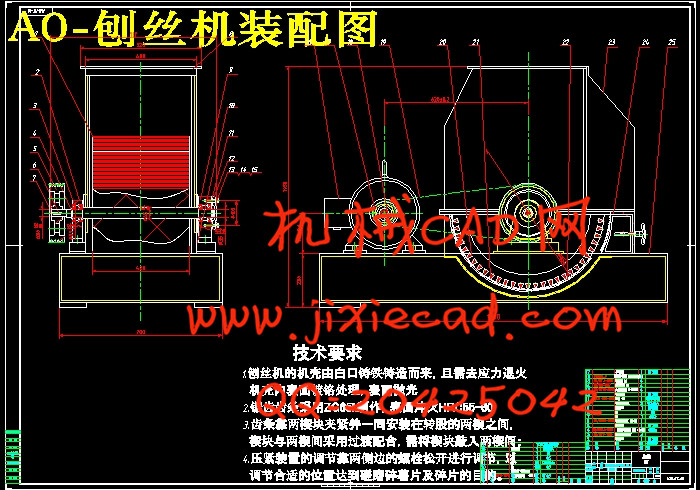

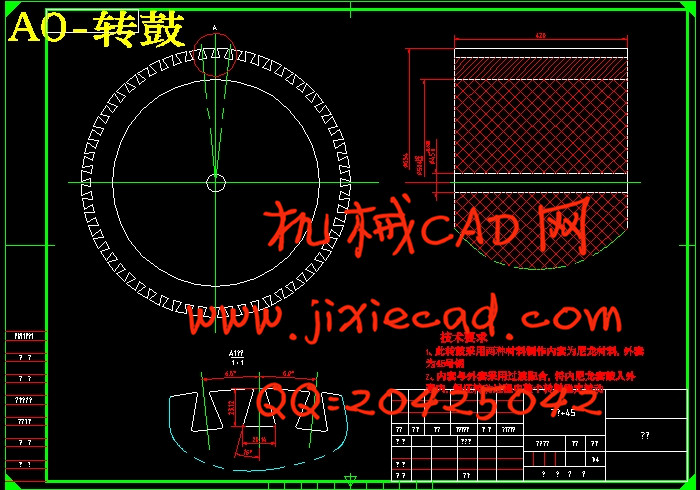

摘要:本文论述了马铃薯精制淀粉生产线的关键核心设备之一刨丝机的用途,工作原理,主要技术参数,传动系统,典型零件的结构设计等。随着国民经济的提高和人民生活水平的提高,人们对食品的要求也随之提高,不仅仅是要求吃饱,而且要求吃得有营养。根据大家的要求,现在的食品已经朝着营养、绿色、方便等功能食品主流发展,而刨丝机即是这些食品加工的设备之一。刨丝机主要用于淀粉生产中的鲜薯破碎,其工作原理是利用高速旋转的齿刃对鲜薯进行刨削而达到破碎的目的,对淀粉质量和生产线经济效益有着重大影响。刨丝机的出现不仅减少了劳动力提高了食品加工的效率,更重要的是也保证了食品的卫生和营养。该课题来源于生活,对我们综合大学所学的课程,理论联系实际,进行独立的设计实践,培养设计能力、实践能力和创新能力具有重要的意义。

关键词:刨丝机;筛片;齿条;压紧装置

Abstract:This paper discusses the refined starch production line of potato one of key equipment in the wood wool making machine USES, working principle, main technical parameters, transmission system, the structure design of typical parts etc. With the development of economic increase and the improvement of people's living standard, people on food demands increases, not only is the requirement, but also requires satiate eat nutritious. According to everyone's request, the current food has toward nutrition, green, is convenient wait for a functional food development, and wood wool making machine that is one of these food processing equipment. Wood wool making machine is mainly used for the potato starch production fresh its working principle is broken, using high-speed rotating tooth blades for cutting fresh potato chips and achieve the purpose of starch, crushing the quality and production line has a significant effect on economic benefit. The emergence of wood wool making machine planer not only reduced the labor force increased food processing efficiency, the more important is also guaranteed the food hygiene and nutrition. This subject to our originates from life, comprehensive university studies, link theory with practice and independent design practice, training design ability, practice ability and innovation ability has the vital significance.

Keywords: Wood Wool Making Machine ;Sieving slice; Rack; Pressure device

目 录

1 绪论…………………………………………………………………………………

1.1刨丝机工作原理…………………………………………………………………

1.2 刨丝机研究主要内容…………………………………………………………

1.3 国内外现状及发展趋势…………………………………………………………

2 传动系统的设计……………………………………………………………………

2.1 电动机的选择……………………………………………………………………

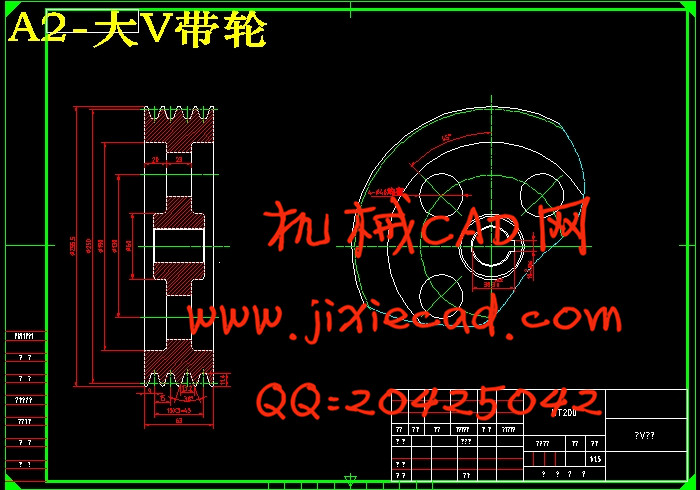

2.2 带传动设计………………………………………………………………………

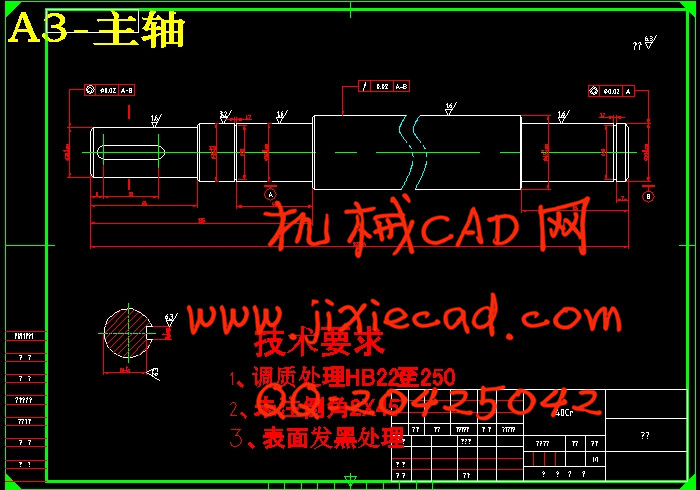

3 传动轴的设计校核…………………………………………………………………

4零部件的选择与设计………………………………………………………………

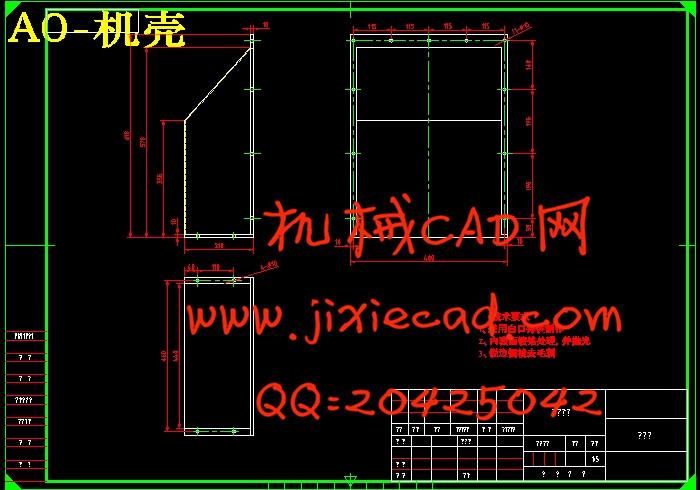

4.1 机壳的选择与设计…………………………………………………………

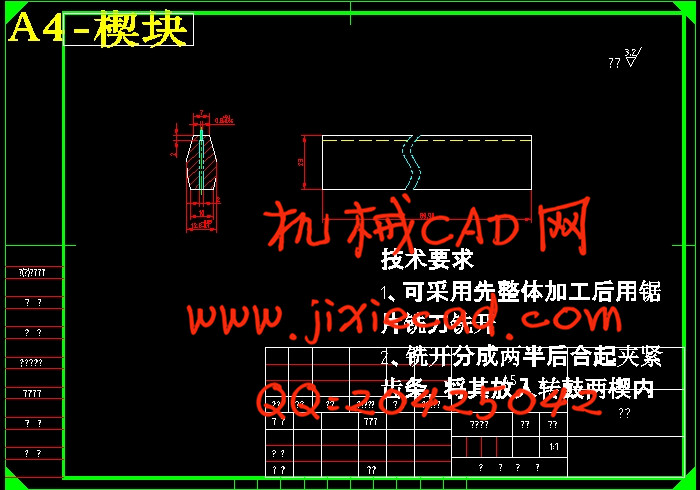

4.2 压紧装置的设计与安装…………………………………………………………

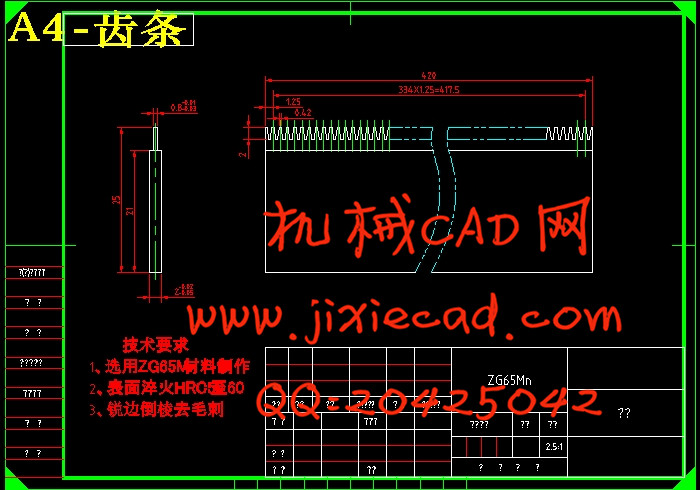

4.3 齿条的设计……………………………………………………………….

4.4筛片的选择与设计………………………………………………………

4.5轴承的设计与分析……………….………………………………………

4.6键的选择与校核……………………………………………………………………

结论 …………………………………………………………………………………

致谢 …………………………………………………………………………………

摘要:本文论述了马铃薯精制淀粉生产线的关键核心设备之一刨丝机的用途,工作原理,主要技术参数,传动系统,典型零件的结构设计等。随着国民经济的提高和人民生活水平的提高,人们对食品的要求也随之提高,不仅仅是要求吃饱,而且要求吃得有营养。根据大家的要求,现在的食品已经朝着营养、绿色、方便等功能食品主流发展,而刨丝机即是这些食品加工的设备之一。刨丝机主要用于淀粉生产中的鲜薯破碎,其工作原理是利用高速旋转的齿刃对鲜薯进行刨削而达到破碎的目的,对淀粉质量和生产线经济效益有着重大影响。刨丝机的出现不仅减少了劳动力提高了食品加工的效率,更重要的是也保证了食品的卫生和营养。该课题来源于生活,对我们综合大学所学的课程,理论联系实际,进行独立的设计实践,培养设计能力、实践能力和创新能力具有重要的意义。

关键词:刨丝机;筛片;齿条;压紧装置

Abstract:This paper discusses the refined starch production line of potato one of key equipment in the wood wool making machine USES, working principle, main technical parameters, transmission system, the structure design of typical parts etc. With the development of economic increase and the improvement of people's living standard, people on food demands increases, not only is the requirement, but also requires satiate eat nutritious. According to everyone's request, the current food has toward nutrition, green, is convenient wait for a functional food development, and wood wool making machine that is one of these food processing equipment. Wood wool making machine is mainly used for the potato starch production fresh its working principle is broken, using high-speed rotating tooth blades for cutting fresh potato chips and achieve the purpose of starch, crushing the quality and production line has a significant effect on economic benefit. The emergence of wood wool making machine planer not only reduced the labor force increased food processing efficiency, the more important is also guaranteed the food hygiene and nutrition. This subject to our originates from life, comprehensive university studies, link theory with practice and independent design practice, training design ability, practice ability and innovation ability has the vital significance.

Keywords: Wood Wool Making Machine ;Sieving slice; Rack; Pressure device

目 录

1 绪论…………………………………………………………………………………

1.1刨丝机工作原理…………………………………………………………………

1.2 刨丝机研究主要内容…………………………………………………………

1.3 国内外现状及发展趋势…………………………………………………………

2 传动系统的设计……………………………………………………………………

2.1 电动机的选择……………………………………………………………………

2.2 带传动设计………………………………………………………………………

3 传动轴的设计校核…………………………………………………………………

4零部件的选择与设计………………………………………………………………

4.1 机壳的选择与设计…………………………………………………………

4.2 压紧装置的设计与安装…………………………………………………………

4.3 齿条的设计……………………………………………………………….

4.4筛片的选择与设计………………………………………………………

4.5轴承的设计与分析……………….………………………………………

4.6键的选择与校核……………………………………………………………………

结论 …………………………………………………………………………………

致谢 …………………………………………………………………………………