设计简介

摘 要

数控技术及数控机床在当今机械制造业中的重要地位和巨大效益,显示了其在国家基础工业现代化中的战略性作用,并已成为传统机械制造工业提升改造和实现自动化、柔性化、集成化生产的重要手段和标志。数控技术及数控机床的广泛应用,给机械制造业的产业结构、产品种类和档次以及生产方式带来了革命性的变化。数控机床是现代加工车间最重要的装备。它的发展是信息技术(1T)与制造技术(MT)结合发展的结果。现代的CAD/CAM、FMS、CIMS、敏捷制造和智能制造技术,都是建立在数控技术之上的。掌握现代数控技术知识是现代机电类专业学生必不可少的。

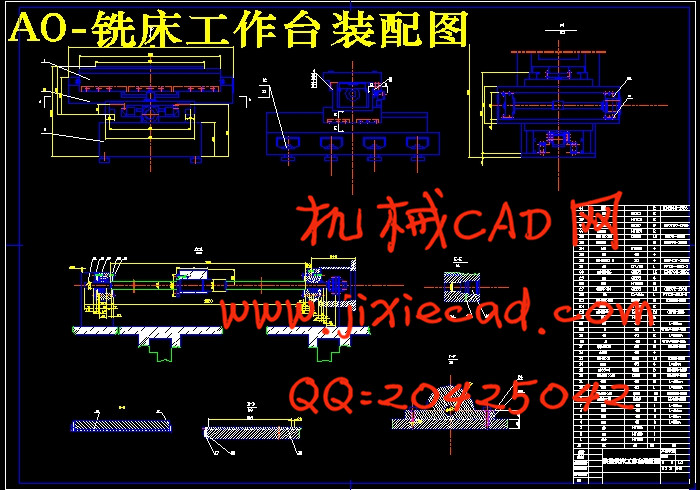

本次设计内容介绍了数控铣床的特点、电机选型以及计算误差的一般分析。并通过一定的实例详细的介绍了数控车床改造的分析方法。

关键词: 数控技术 数控改造 步进电动机 电气控制

Abstract

numerical control technology and the numerically-controlled machine tool in now in the machine-building industry the important position and the huge benefit, had demonstrated it in the key industry modernization's strategic function, and has become the traditional machine manufacture industry promotion to transform and to realize the automation, the flexibility, the integrated production important means and the sign. The numerical control technology and numerically-controlled machine tool's widespread application, for machine-building industry's industrial structure, the product type and the scale as well as the production method has brought the revolutionary change. The numerically-controlled machine tool is the modern Processing workshop most important equipment. Its development is the information technology (1T) and the technique of manufacture (MT) union development result. Modern CAD/CAM, FMS, CIMS, the agile manufacture and the intelligence technique of manufacture, is the establishment above the numerical control technology. Masters the modern numerical control technical knowledge is the modern mechanical and electrical kind of college major is essential.

This design content introduced the numerical control lathe's characteristic, the electrical machinery shaping as well as counting error's general analysis. And through certain example detailed introduction the analysis method which numerical control lathe transformed.

Key words: the numerical control technology numerical control transformation step-by-steps the electric motor electric control.

摘要…………………………………………………………………………………Ⅰ

Abstract…………………………………………………………………………Ⅱ

引言…………………………………………………………………………………6

1 概述………………………………………………………………………………7

2 设计计算………………………………………………………………………8

2.1 计算切削分力…………………………………………………………………8

2.2 导轨摩擦力的计算……………………………………………………………8

2.3 计算滚珠丝杠螺母副的轴向负载力…………………………………………9

2.4 滚珠丝杠的动载荷计算与直径估算…………………………………………9

2.4.1 确定滚珠丝杠的导程…………………………………………………9

2.4.2 计算滚珠丝杠螺母副的平均转速和平均载荷………………………9

2.4.3 确定滚珠丝杠预期的额定功率………………………………………11

2.4.4 按精度要求确定允许的滚珠丝杠的最小螺纹底径…………………11

2.4.5 初步确定滚珠丝杠螺母副的规格型号………………………………12

2.4.6 确定滚珠丝杠螺母副的预紧力………………………………………12

2.4.7 计算滚珠丝杠螺母副的目标行程补偿值与预紧伸力………………13

2.4.8 确定滚珠丝杠螺母副支撑用的规格型号……………………………15

3 滚珠丝杠螺母副的承载能力校验………………………………………15

3.1 滚珠丝杠螺母副临界压缩载荷的校验……………………………………15

3.2 滚珠丝杠螺母副临界转速的校验…………………………………………15

3.3 滚珠丝杠螺母副寿命的校验……………………………………………… 15

4计算机械传动系统的刚度…………………………………………………17

4.1 机械传动系统的刚度计算………………………………………………17

4.2 滚珠丝杠螺母副的扭转刚度计算…………………………………………17

4.3 计算滚珠与滚道的接触刚度…………………………………………17

4.4 计算进给传动系统的综合拉压刚度………………………………………18

4.5 齿轮传动比的计算………………………………………………………18

5驱动电动机的选用与计算……………………………………………………20

5.1 计算折算到电动机轴上的负载惯量………………………………………20

5.2 计算折算到电动机轴上的负载力矩………………………………………21

5.3 计算坐标折算到电动机轴上的各种所需的力矩…………………………22

5.4选择驱动电动机的型号…………………………………………………23

6机械传动系统的动态分析…………………………………………………24

6.1 计算丝杠-工作台纵向振动系统的最低固有频率…………………………24

6.2 计算扭转振动系统的最低固有频率………………………………………24

7机械传动系统的误差计算与分析……………………………………………25

7.1 计算机械传动系统的反向死区Δ…………………………………………25

7.2 计算机械传动系统由综合拉压刚度变化引起的定位误差………………25

7.3 计算滚珠丝杠因扭转变形产生的误差……………………………………25

8确定滚珠丝杠螺母副的精度等级和规格型号………………………………26

8.1 确定滚珠丝杠螺母副的精度等级…………………………………………26

8.2 确定滚珠丝杠螺母副的规格型号…………………………………………26

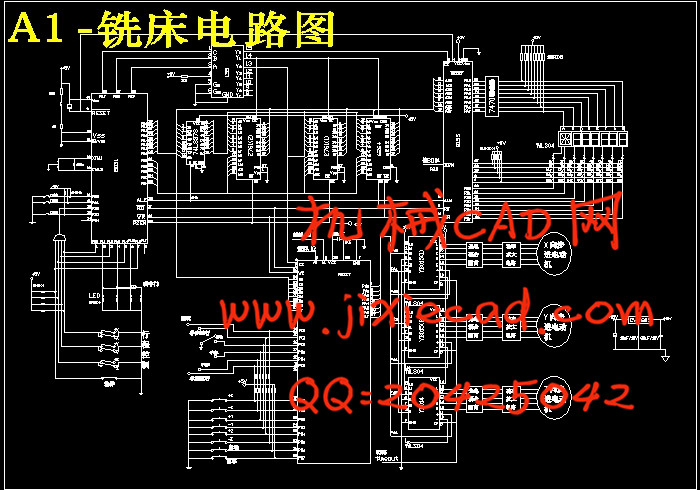

9微机控制系统的设计…………………………………………………………27

结论…………………………………………………………………………………33

参考文献……………………………………………………………………………35

致谢…………………………………………………………………………………36

数控技术及数控机床在当今机械制造业中的重要地位和巨大效益,显示了其在国家基础工业现代化中的战略性作用,并已成为传统机械制造工业提升改造和实现自动化、柔性化、集成化生产的重要手段和标志。数控技术及数控机床的广泛应用,给机械制造业的产业结构、产品种类和档次以及生产方式带来了革命性的变化。数控机床是现代加工车间最重要的装备。它的发展是信息技术(1T)与制造技术(MT)结合发展的结果。现代的CAD/CAM、FMS、CIMS、敏捷制造和智能制造技术,都是建立在数控技术之上的。掌握现代数控技术知识是现代机电类专业学生必不可少的。

本次设计内容介绍了数控铣床的特点、电机选型以及计算误差的一般分析。并通过一定的实例详细的介绍了数控车床改造的分析方法。

关键词: 数控技术 数控改造 步进电动机 电气控制

Abstract

numerical control technology and the numerically-controlled machine tool in now in the machine-building industry the important position and the huge benefit, had demonstrated it in the key industry modernization's strategic function, and has become the traditional machine manufacture industry promotion to transform and to realize the automation, the flexibility, the integrated production important means and the sign. The numerical control technology and numerically-controlled machine tool's widespread application, for machine-building industry's industrial structure, the product type and the scale as well as the production method has brought the revolutionary change. The numerically-controlled machine tool is the modern Processing workshop most important equipment. Its development is the information technology (1T) and the technique of manufacture (MT) union development result. Modern CAD/CAM, FMS, CIMS, the agile manufacture and the intelligence technique of manufacture, is the establishment above the numerical control technology. Masters the modern numerical control technical knowledge is the modern mechanical and electrical kind of college major is essential.

This design content introduced the numerical control lathe's characteristic, the electrical machinery shaping as well as counting error's general analysis. And through certain example detailed introduction the analysis method which numerical control lathe transformed.

Key words: the numerical control technology numerical control transformation step-by-steps the electric motor electric control.

摘要…………………………………………………………………………………Ⅰ

Abstract…………………………………………………………………………Ⅱ

引言…………………………………………………………………………………6

1 概述………………………………………………………………………………7

2 设计计算………………………………………………………………………8

2.1 计算切削分力…………………………………………………………………8

2.2 导轨摩擦力的计算……………………………………………………………8

2.3 计算滚珠丝杠螺母副的轴向负载力…………………………………………9

2.4 滚珠丝杠的动载荷计算与直径估算…………………………………………9

2.4.1 确定滚珠丝杠的导程…………………………………………………9

2.4.2 计算滚珠丝杠螺母副的平均转速和平均载荷………………………9

2.4.3 确定滚珠丝杠预期的额定功率………………………………………11

2.4.4 按精度要求确定允许的滚珠丝杠的最小螺纹底径…………………11

2.4.5 初步确定滚珠丝杠螺母副的规格型号………………………………12

2.4.6 确定滚珠丝杠螺母副的预紧力………………………………………12

2.4.7 计算滚珠丝杠螺母副的目标行程补偿值与预紧伸力………………13

2.4.8 确定滚珠丝杠螺母副支撑用的规格型号……………………………15

3 滚珠丝杠螺母副的承载能力校验………………………………………15

3.1 滚珠丝杠螺母副临界压缩载荷的校验……………………………………15

3.2 滚珠丝杠螺母副临界转速的校验…………………………………………15

3.3 滚珠丝杠螺母副寿命的校验……………………………………………… 15

4计算机械传动系统的刚度…………………………………………………17

4.1 机械传动系统的刚度计算………………………………………………17

4.2 滚珠丝杠螺母副的扭转刚度计算…………………………………………17

4.3 计算滚珠与滚道的接触刚度…………………………………………17

4.4 计算进给传动系统的综合拉压刚度………………………………………18

4.5 齿轮传动比的计算………………………………………………………18

5驱动电动机的选用与计算……………………………………………………20

5.1 计算折算到电动机轴上的负载惯量………………………………………20

5.2 计算折算到电动机轴上的负载力矩………………………………………21

5.3 计算坐标折算到电动机轴上的各种所需的力矩…………………………22

5.4选择驱动电动机的型号…………………………………………………23

6机械传动系统的动态分析…………………………………………………24

6.1 计算丝杠-工作台纵向振动系统的最低固有频率…………………………24

6.2 计算扭转振动系统的最低固有频率………………………………………24

7机械传动系统的误差计算与分析……………………………………………25

7.1 计算机械传动系统的反向死区Δ…………………………………………25

7.2 计算机械传动系统由综合拉压刚度变化引起的定位误差………………25

7.3 计算滚珠丝杠因扭转变形产生的误差……………………………………25

8确定滚珠丝杠螺母副的精度等级和规格型号………………………………26

8.1 确定滚珠丝杠螺母副的精度等级…………………………………………26

8.2 确定滚珠丝杠螺母副的规格型号…………………………………………26

9微机控制系统的设计…………………………………………………………27

结论…………………………………………………………………………………33

参考文献……………………………………………………………………………35

致谢…………………………………………………………………………………36