设计简介

摘 要

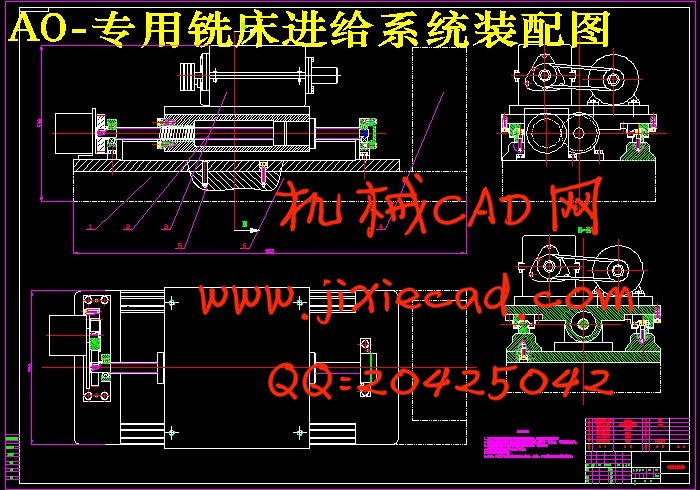

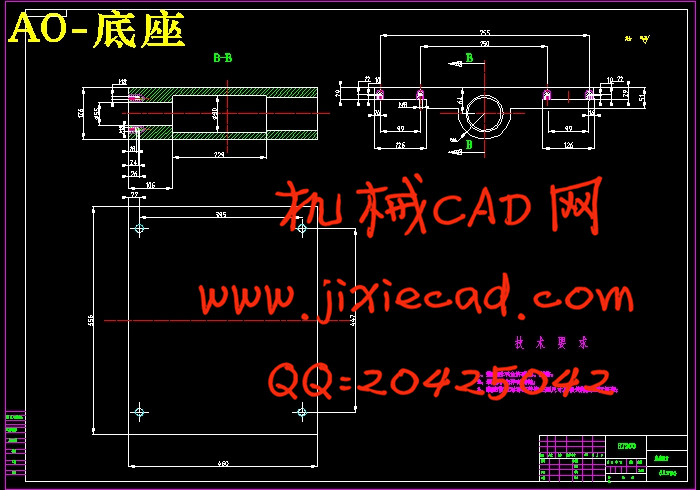

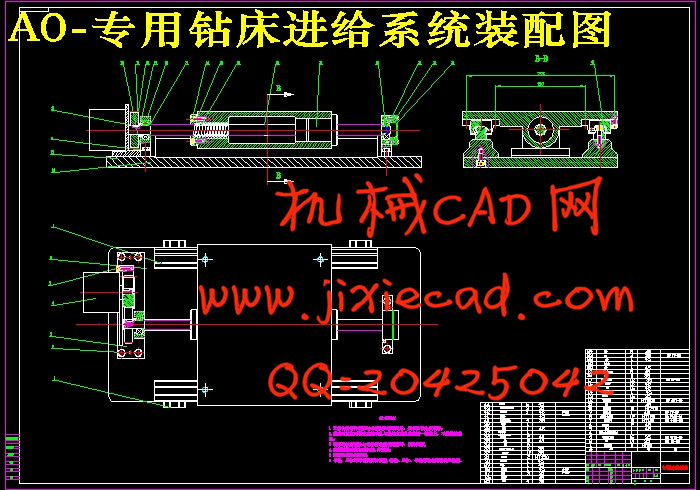

本论文主要说明专用铣床设计的基本过程及要求。专用铣床是由大量的通用部件和少量专用部件组成的工序集中的高效率专用机床。它能够对一种(或几种)零件进行多刀、多轴、多面、多工位加工。专用铣床的设计,目前基本上有两种情况:其一,是根据具体加工对象的具体情况进行专门设计,这是当前最普遍的做法。其二,随着专用铣床在我国机械行业的广泛使用,广大工人总结自己生产和使用专用铣床的经验,发现专用铣床不仅在其组成部件方面有共性,可设计成通用部件。而且一些行业的在完成一定工艺范围的专用铣床是极其相似的,有可能设计为通用机床,这种机床称为“专能专用铣床”。这种专用铣床就不需要每次按具体加工对象进行专门设计和生产,而是可以设计成通用品种,组织成批生产,然后按被加工的零件的具体需要,配以简单的夹具及刀具,即可组成加工一定对象的高效率设备。

关键词:专用铣床;设计;过程;功能

Abstract

This thesis mainly explain the basic process and the requirements of special milling machine design. Special milling machine is high efficient special machine is composed of the large number of common parts and a small amount of special parts of the process of. It is capable of a (or several) multi knife, multi axis, multi, multi station processing parts.

Design of special milling machine, there are two cases basically at present: first, is specially designed according to the specific situation of the processing object, this is the most common practice. Secondly, with the special milling machine is used widely in China machinery industry, workers summaries of their production and use of special milling machine experience, found special milling machine not only common in its components, can be designed into general parts. But some in the industry special milling machine complete process range is very similar, it is possible to design for the general machine, this machine called "special special milling machine". The special milling machine does not need each special design and production according to the specific processing objects, but can be designed into general varieties, organization of production, then according to the need of the machined parts, fixture and cutting tool with simple, high efficiency equipment can form processing a certain object.

Keywords: special milling machine; design; process; function

目 录

摘 要 II

Abstract III

目 录 IV

第1章 绪论 1

1.1 课题研究意义 1

1.2专用铣床设备应用 1

1.3国外进给系统现状与发展 2

1.4国内进给系统现状与发展 2

1.5 专用铣床设备发展趋势 4

第2章 铣床总体设计要求 5

2.1切削参数要求 5

2.2 进给系统设计要求 7

第3章 专用铣床进给系统设计 7

3.1常见丝杠支承方式 7

3.2 脉冲当量选择 8

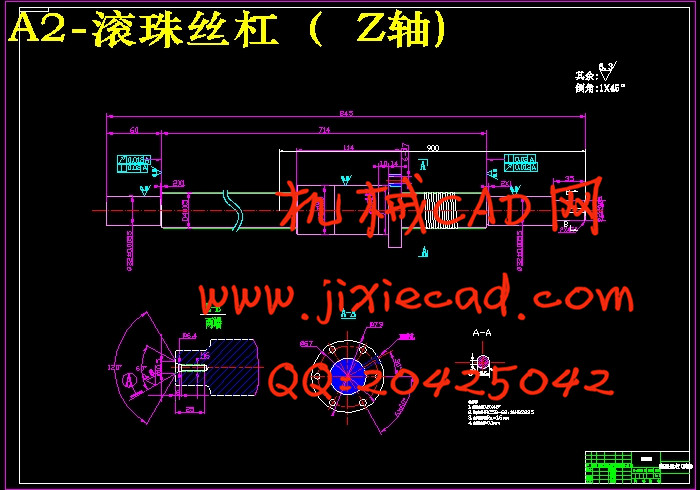

3.3滚珠丝杠设计计算 8

3.4滚珠丝杠副的载荷计算 9

3.5传动效率计算 12

3.6稳定性验算 12

3.6 刚度验算 12

3.7 滚珠丝杠精度等级确定 12

3.8 滚动导轨副的防护 15

3.9 直线滚动导轨副的计算、选择 15

3.10电机至丝杠之间齿轮减速传动设计 17

3.11等效转动惯量计算(不计传动效率) 20

3.12 电机的计算选型 20

3.13 联轴器选择 21

第4章 进给变速箱设计 21

4.1 专用进给变速箱设计 21

4.2传动系统的设计 21

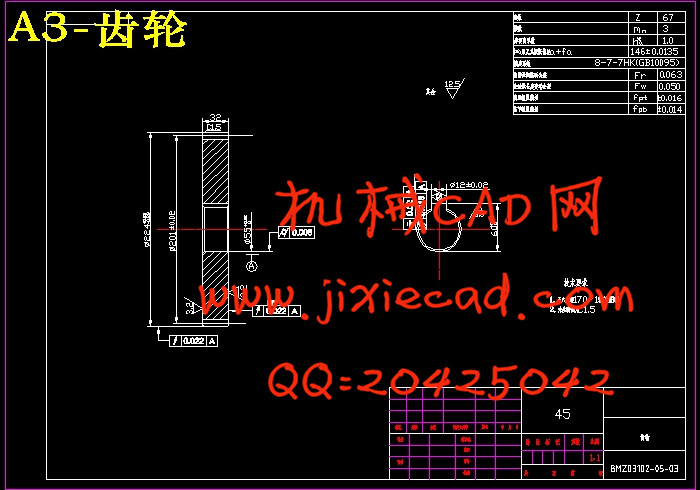

4.3 齿轮的设计及参数的确定 23

4.3.1齿轮的设计 23

4.3.2齿轮参数的确定 25

4.4 轴承的选择 28

结 论 30

致 谢 31

参考文献 32