设计简介

摘要

随着科学技术的发展,五轴联动表面感应加热淬火机床设计的应用也显得越来越频繁,先进切割技术的发展总是不断地从新科技的成果中获得新的起点。目前,五轴联动表面感应加热淬火机床设计技术在电子科技、计算机技术及机器人的制造中都起着重要的作用。无论在什么情况下,五轴联动表面感应加热淬火机床设计才能提高淬火的水平和质量。我们只有将数控机技术淬火淬火技术有效的结合才能更好的推动新科技的发展,因此数控淬火机床的设计对于解决这一难题至关重要。本课题针对龙门式火焰淬火的横梁及火焰切割头的机械部分X、Y方向的结构及传动设计进行了设计。横梁的机构设计主要对其结构的确定,之后对传动装置进行了选择及计算检验,最后对主要传动的零部件进行选择校核。其中主要对滚动丝杠的强度及传动效率等进行了计算校核。并对横梁设计中存在的结构部件的联接问题进行了改进。火焰切割头是在传动装置的基础上运用丝杠的转速控制运动,经过验证取得了很好的效果,实现预期目的。

关键词:五轴联动,机构设计,五轴联动表面感应加热淬火机床设计

Abstract

With the development of science and technology, application and design of heating quenching machine five axis surface induction is becoming more and more frequent, the development of advanced cutting technology is constantly from the new achievements of science and technology in the new starting point. At present, five axis surface induction hardening machine design technology has played an important role in the manufacture of electronic technology, computer technology and robot. In any case, five axis surface induction hardening machine design to improve the level and quality of welding. We will only quenching technology combined effectively in order to better promote the development of new technology for CNC machine welding technology, the NC quenching machine tool design is very important for solving this problem.The structure and design of transmission of the Longmen type flame cutting beam and the flame cutting machine head of mechanical part X, Y direction is designed. Mechanism design of beam is mainly determined the structure of the transmission device, the selection and calculation of main drive test, finally the parts selection check. The major was calculated on the rolling of screw strength and transmission efficiency etc.. Was improved and the structure of existing beam in the design of the connection problem. Flame cutting head is the speed control based on motion by using screw transmission device, good results were achieved after verification, to achieve the desired objective.

Keywords: five axis linkage, mechanism design, the design of five axis surface induction hardening machine

目 录

摘要 IIAbstract III

目 录 IV

第1章 绪论 1

1.1五轴联动表面感应加热淬火机床设计的研究目的及意义 1

1.1.1五轴联动表面感应加热淬火机床设计背景 1

1.1.2五轴联动表面感应加热淬火机床设计简介 1

1.1.3意义 1

1.2研究现状及发展趋势 1

1.3淬火机床国内外的现状 2

1.4 淬火机床发展前景 5

1.5本课题研究的内容及方法 6

1.5.2 课题研究内容 6

1.5.2设计要求 6

1.5.3关键的技术问题 6

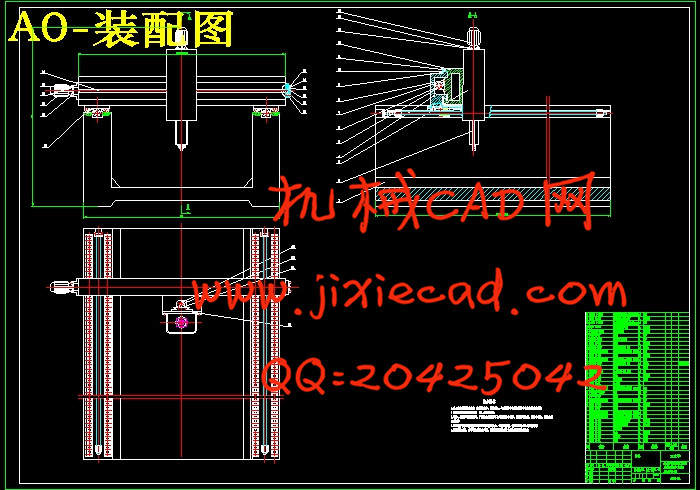

第2章 总体方案机构设计 7

2.1设计概念 7

2.2设计原理 7

2.3方案讨论 7

第3章 X向机械结构及传动设计 8

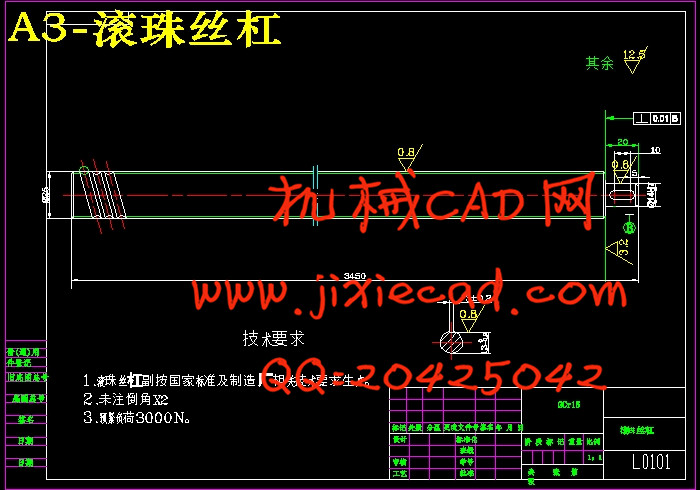

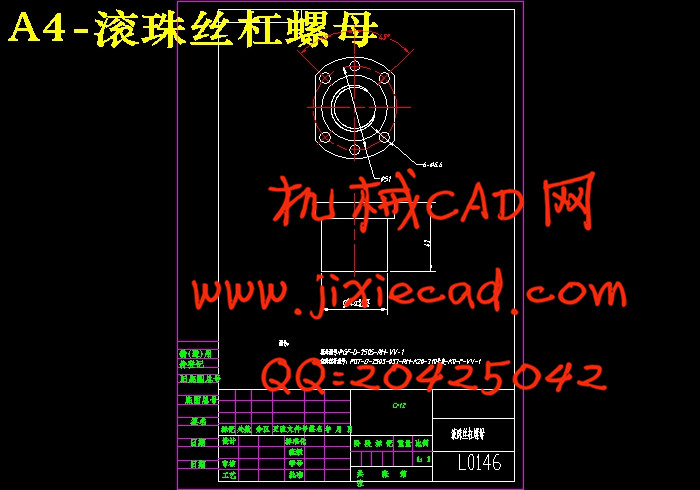

3.1 X向滚珠丝杆副的选择 9

3.1.1导程确定 9

3.1.2确定丝杆的等效转速 9

3.1.3估计工作台质量及负重 9

3.1.4确定丝杆的等效负载 9

3.1.5确定丝杆所受的最大动载荷 10

3.1.6精度的选择 11

3.1.7选择滚珠丝杆型号 11

3.2校核 11

3.2.1 临界压缩负荷验证 12

3.2.2临界转速验证 13

3.2.3丝杆拉压振动与扭转振动的固有频率 13

3.3电机的选择 14

3.3.1电机轴的转动惯量 14

3.3.2电机扭矩计算 15

3.4 导轨的选型及计算 16

第4章 Y向机械机构及传动设计 19

4.1 龙门式横梁结构设计 19

4.1.1 确定龙门式火焰切割机横梁结构 19

4.1.2 传动装置类型的选用 19

4.1.3 传动方案的选取 20

4.2 机床零部件的设计 20

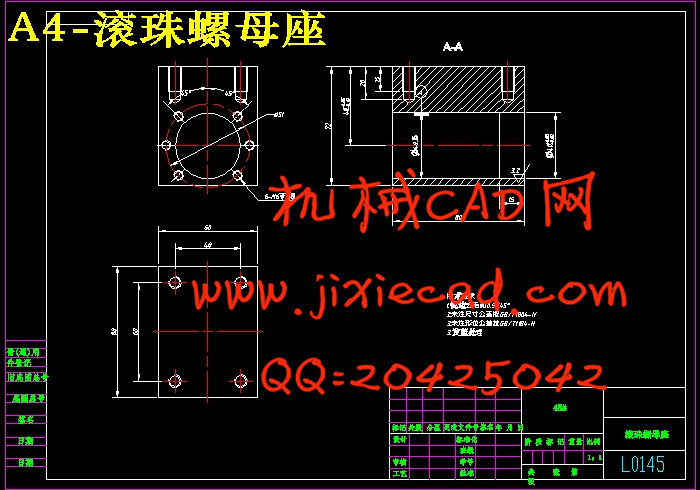

4.2.1 丝杠副的选取 21

3.2.2联轴器的选取 25

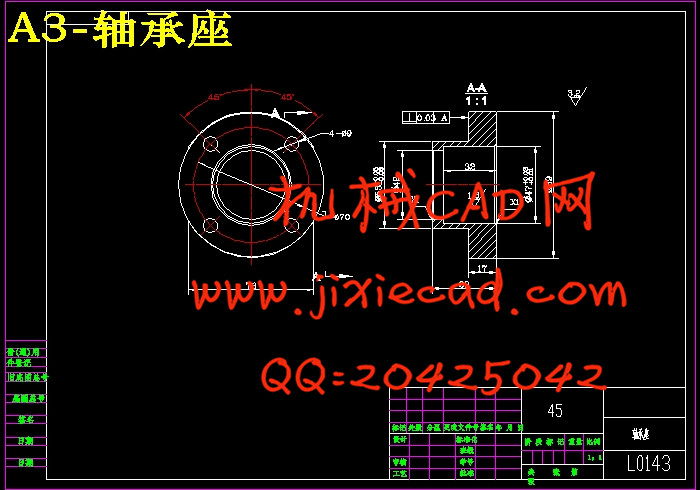

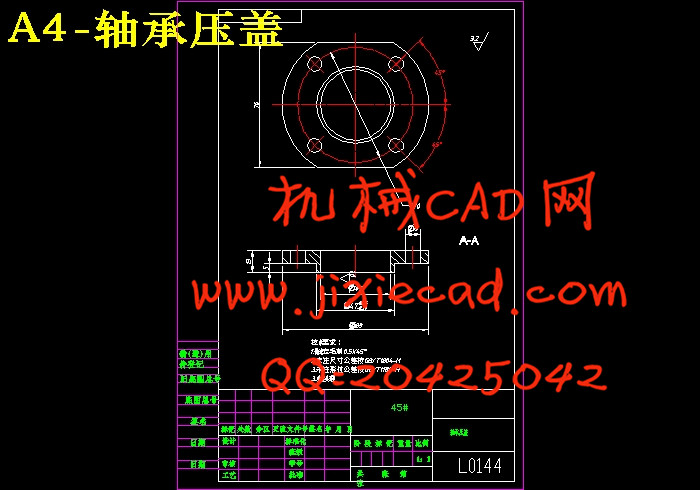

4.2.4 轴承的选取 27

4.2.5滚动丝杠的计算 27

4.2.6 步进电机的选取 30

第5章 机架的设计 34

5.1 床身结构 34

5.1.1 对床身结构的基本要求 34

5.1.2 床身的结构 35

总结与展望 39

致 谢 42