设计简介

摘要:

机械加工是一种用加工机械对工件的外形尺寸或性能进行改变的过程。按被加工的工件处于的温度状态﹐分为冷加工和热加工。一般在常温下加工,并且不引起工件的化学或物相变化﹐称冷加工。一般在高于或低于常温状态的加工﹐会引起工件的化学或物相变化﹐称热加工。冷加工按加工方式的差别可分为切削加工和压力加工。热加工常见有热处理﹐煅造﹐铸造和焊接。

Machining is a kind of used machinery for the appearance of workpiece dimension or performance change process. According to the processed workpiece in the temperature of the condition, divided into cold and hot working. General processing at room temperature, and does not cause the chemical and phase change of workpiece, says cold work. General processing in higher or lower than the normal temperature condition, can cause artifacts of chemical or physical phase change, say hot working. Cold work according to the difference of processing methods can be divided into cutting machining and pressure. Hot working common heat treatment, forging, casting and welding.

目录

1 引言··········································1

2 机床用途及设计数据····························3

2.1机床用途··································3

2.2设计数据··································3

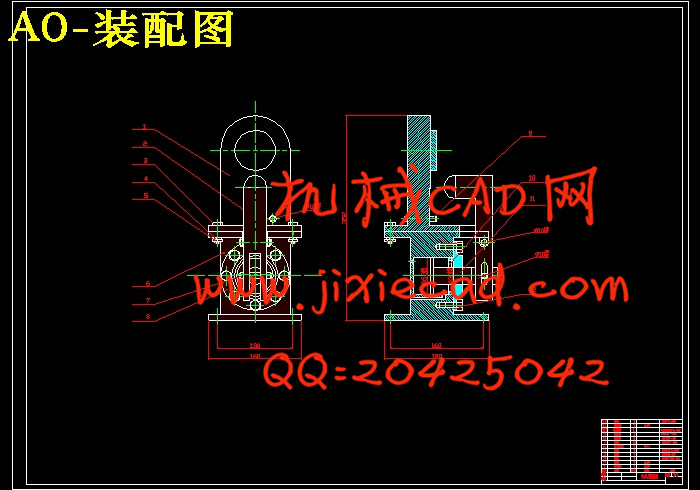

3 总体设计······································5

3.1工件研究及查询资料························5

3.2设计方案··································7

3.3设计计算··································7

3.4组合机床各部分选取························9

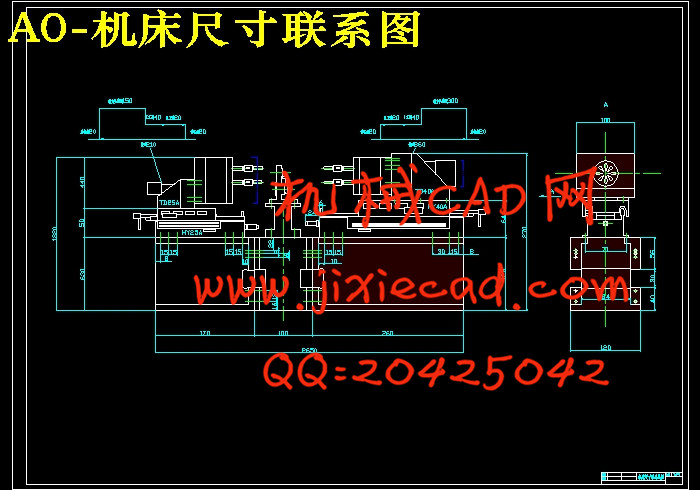

3.5 机床的总体布局···························10

3.6 “三图一卡”的制定·······················11

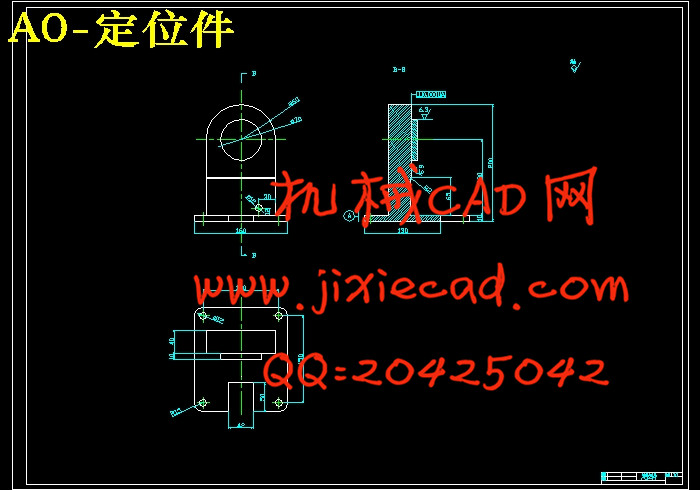

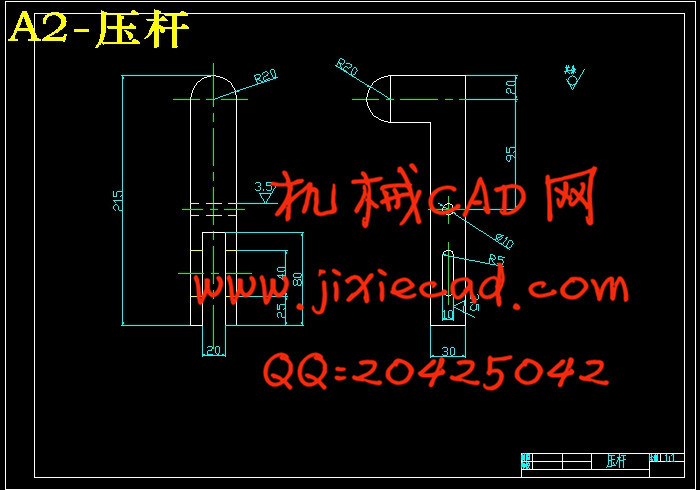

4 夹具设计·····································16

4.1 机床夹具·································16

4.2 方案拟定·································17

4.3 夹具的受力计算···························20

4.4 夹具的主要零件设计及选用·················21

5 结束语·······································25

6 致谢·········································26

7参考文献······································27

机械加工是一种用加工机械对工件的外形尺寸或性能进行改变的过程。按被加工的工件处于的温度状态﹐分为冷加工和热加工。一般在常温下加工,并且不引起工件的化学或物相变化﹐称冷加工。一般在高于或低于常温状态的加工﹐会引起工件的化学或物相变化﹐称热加工。冷加工按加工方式的差别可分为切削加工和压力加工。热加工常见有热处理﹐煅造﹐铸造和焊接。

Machining is a kind of used machinery for the appearance of workpiece dimension or performance change process. According to the processed workpiece in the temperature of the condition, divided into cold and hot working. General processing at room temperature, and does not cause the chemical and phase change of workpiece, says cold work. General processing in higher or lower than the normal temperature condition, can cause artifacts of chemical or physical phase change, say hot working. Cold work according to the difference of processing methods can be divided into cutting machining and pressure. Hot working common heat treatment, forging, casting and welding.

目录

1 引言··········································1

2 机床用途及设计数据····························3

2.1机床用途··································3

2.2设计数据··································3

3 总体设计······································5

3.1工件研究及查询资料························5

3.2设计方案··································7

3.3设计计算··································7

3.4组合机床各部分选取························9

3.5 机床的总体布局···························10

3.6 “三图一卡”的制定·······················11

4 夹具设计·····································16

4.1 机床夹具·································16

4.2 方案拟定·································17

4.3 夹具的受力计算···························20

4.4 夹具的主要零件设计及选用·················21

5 结束语·······································25

6 致谢·········································26

7参考文献······································27