设计简介

摘 要

链式输送机是用绕过若干链轮的无端链条作牵引构件,由驱动链轮通过轮齿与链节的啮合将圆周牵引力传递给链条,在链条上或固接着一定的工作构件上输送货物。链式输送机的类型很多,用于港口、货栈的主要有链板输送机、刮板输送机和埋刮板输送机。链条有滑动和滚动之分,运送物料的方式可以是滑移6或载运。输送机由于所选用链条种类及运送物料的方式不同而有不同的型式,如下表所示。滑动链条类输送机的构造简单,运行的零部件较少, 造价比较低廉,而冲击。滚动链条的输送机与滑动链条的输送机比较,前者在输送物料时更为平滑,摩擦阻力较小,所需的驱动也较低,为了保证滚轮的寿命,这类链条不宜用于粗糙、污浊、含有细砂粒物料的输送。

用特殊形状的链片制成的链条,可以用来安装各种附件,如托板等。45。如果链条辊子的支承力方向垂直于链条的回转平面,则可以制成水平回转的链板输送机。如果托板铰接条上,可以侧向倾翻,则可以制成自动分选机。在需要把货物卸出的地点使托板倾翻,即可使货物滑到相应的输送分选溜槽内。

链板输送机的结构和工作原理与带式输送机相似,它们的区别在于带式输送机用输送带牵引和承载货物,靠摩擦驱动传递牵引力,而链板输送机则用链条牵引、用固定在链条上的板片承载货物,靠啮合驱动传递牵引力。链板输送机主要用于部分仓库或内河港口中输送件货。它与带式输送机相比,优点是板片上能承放较重的件货,链条挠性好、强度高,可采用较小直径的链轮和传递较大的牵引力。

关键词:链条;辊子;回转平面;啮合

Abstract

Chain conveyor is no reason to bypass a number of sprocket chain for traction components, the drive wheel through gear meshing with the segment will be passed to the traction circle chain, the chain or solid components and then work on certain goods transport .Many types of chain conveyor, for the port, warehouses in the main chain conveyor, scraper conveyor and scraper conveyor. Chain with sliding and rolling of the points, the transportation of materials approach can be a slip or carriage. Conveyor chain as the selected species and transportation of materials in different ways and have different types, as shown below. Sliding chain conveyor type structure is simple, small parts, relatively low cost, and impact. Rolling and sliding chain conveyor chain conveyor comparison, when the former is more smooth in the transportation of materials, low friction, and lower the required drive, in order to ensure the wheel of life, such chains should not be used for rough, muddy , the delivery of materials containing fine sand.

A special type of chain with a piece made of chain, can be used to install various accessories, such as pallets, etc.. Chain and the pallet with the composition of the chain conveyor is another widely used as a continuous conveyor machinery. If the chain rollers of the support force of the rotary direction perpendicular to the chain plane, made of the level, you can turn the chain conveyor. Articulated in the chain if the pallets can be side tipping, you can be made automatic sorting machine. Unloading the goods needed to make pallet tipping sites, you can slide the corresponding transport of goods sorting chute inside.

Chain conveyor structure and working principle and the belt is similar to the difference between them is pulling the conveyor belt and carrying goods passing through the friction drive traction, while the chain conveyor chain traction is used, with fixed plate on the chain carrying goods delivered by meshing drive traction. Chain conveyor is mainly used for part of the warehouse or inland port in the pieces of cargo transportation. It is compared with the belt, the advantage of bearing plate can be put on the heavier pieces of cargo, chain flexibility, and high strength, can use smaller diameter sprocket and transmission of large traction.

Key words: chain; roll; rotation plane; gear drive

目 录

摘要III

ABSTRACTIV

1.绪论 1

1.1链式输送机的概述 1

1.2链式输送机的零部件设计 2

1.3 国内外的研究概述 3

1.4本课题的研究内容和所需解决的问题 3

2 .总体方案设计 5

2.1链式输送滚床和带式输送滚床 5

2.2带式输送机的特点及分类 6

2.2链式滚床输送机的选择 6

2.2.1 电动机在外 6

2.2.2 电动机在内 6

2.3 带式滚床和链式滚床输送机的对比 7

2.4比较并确定最终方案 7

3.链式滚床的参数计算 8

3.1传送链的设计 8

3.2驱动电机的选型 9

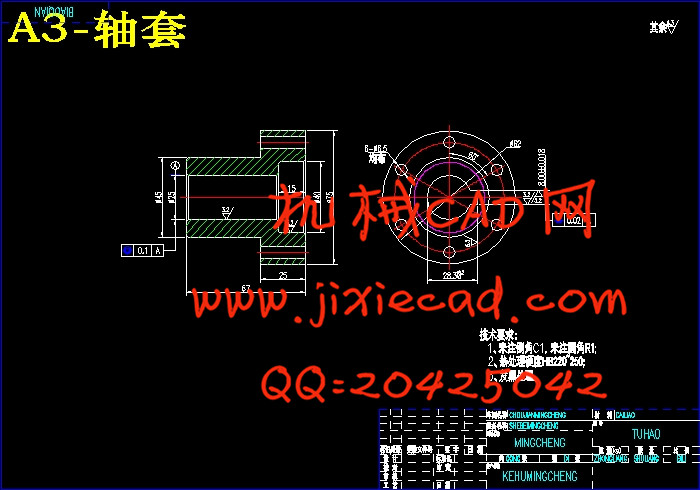

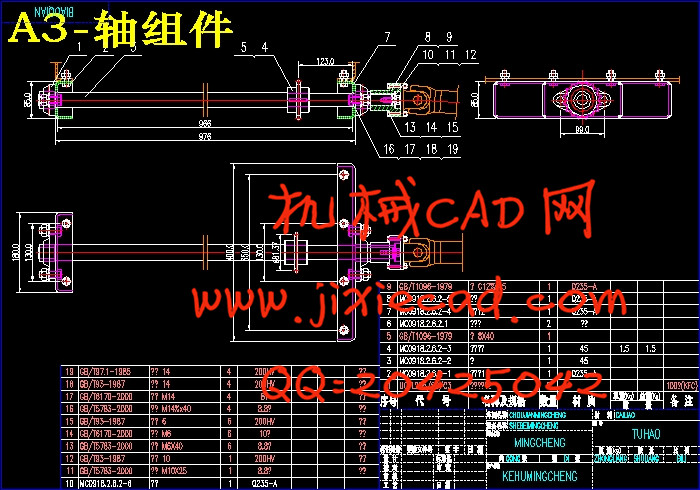

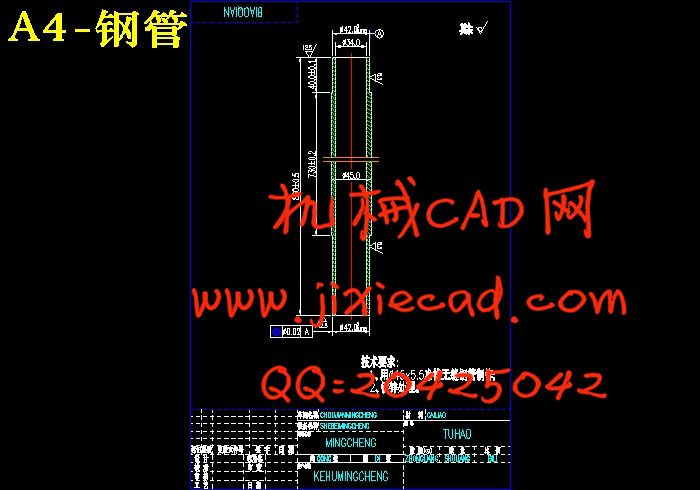

3.3链式滚床轴的设计 10

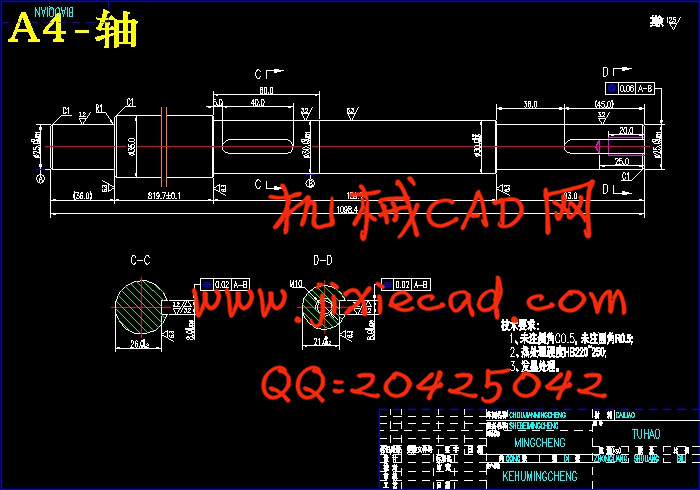

3.3.1 驱动轴的设计 10

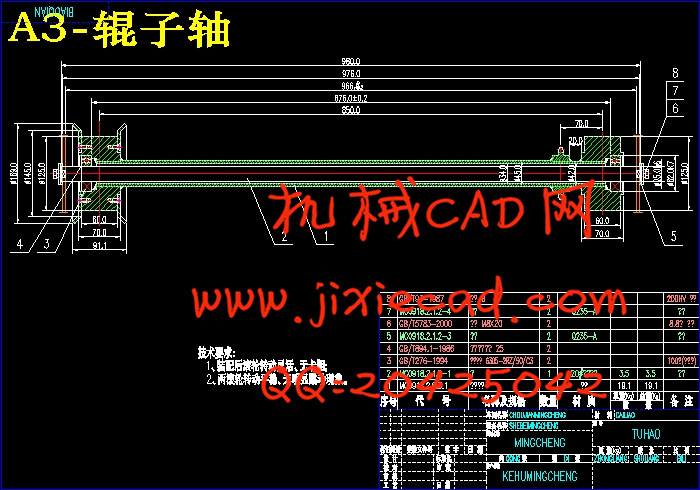

3.3.2 滚轮轴的设计 12

3.4轴承的选型及校核 15

3.5链式输送机强度计算 17

3.5.1 链传动的运动特性 17

3.5.2 链传动的动载荷 19

3.5.3 链传动的受力分析 19

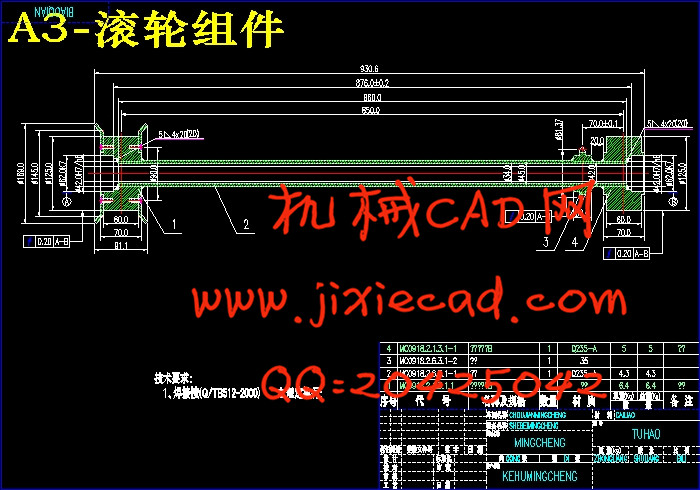

3.5.4 滚床滚轮接触强度的计算 20

4.链式滚床的其他部件设计 22

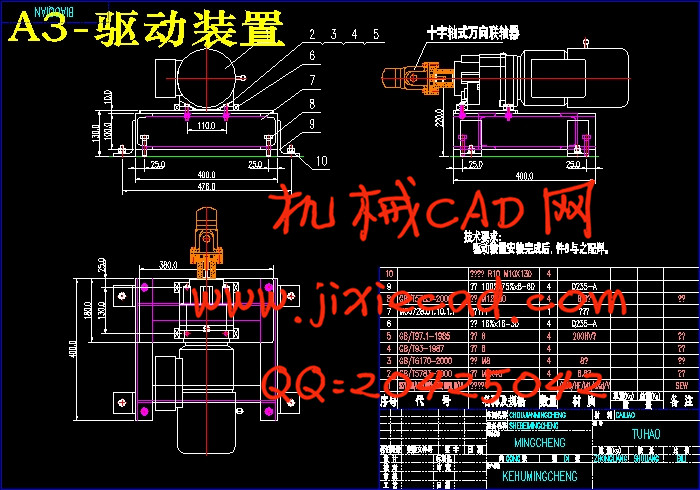

4.1链式滚床的驱动装置 22

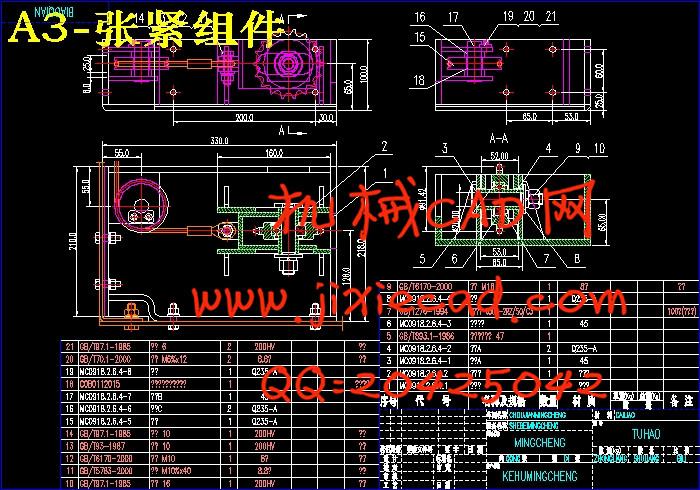

4.2 链式输送机的张紧装置 22

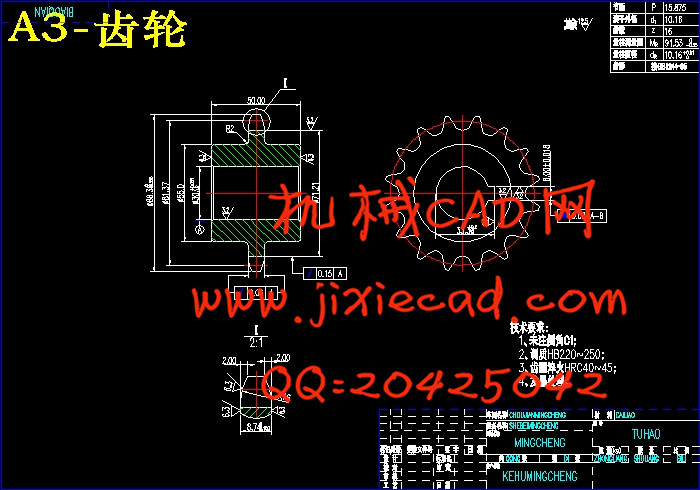

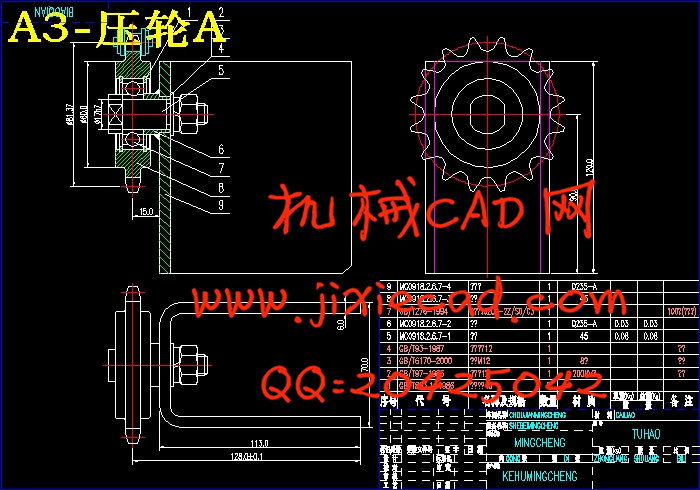

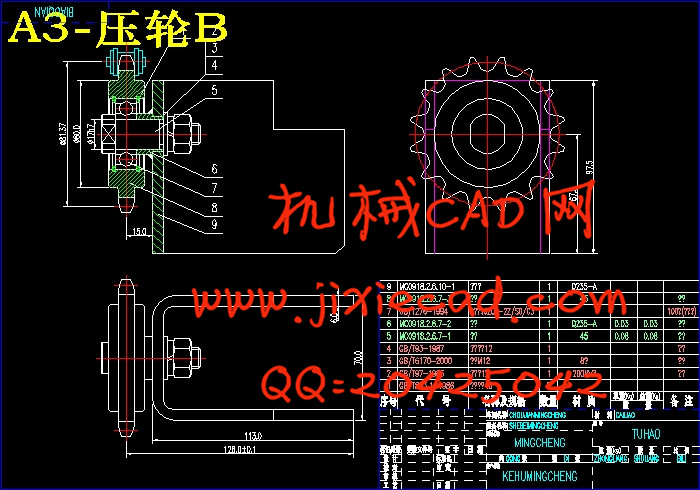

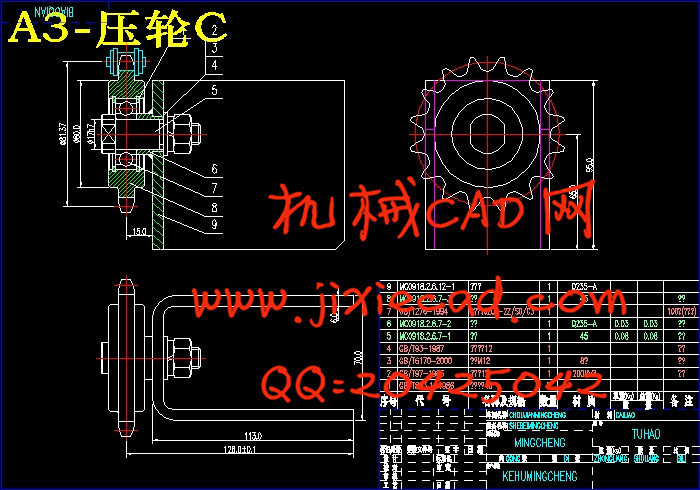

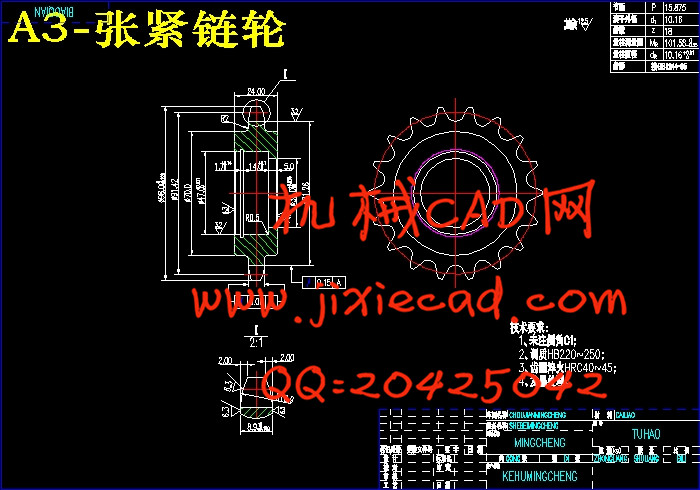

4.3链式输送机的链轮 24

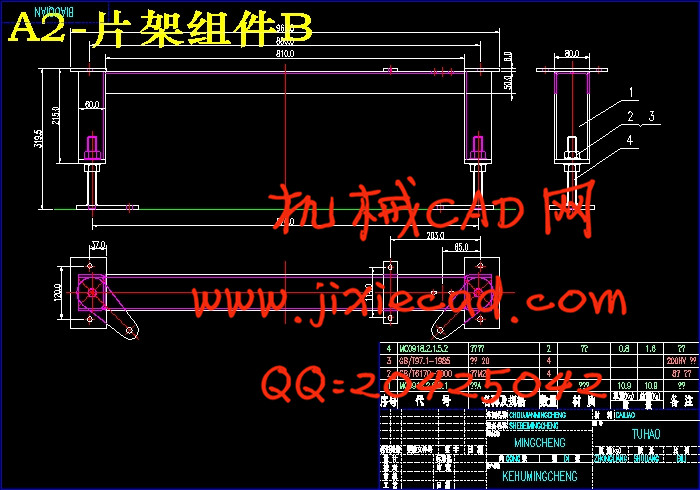

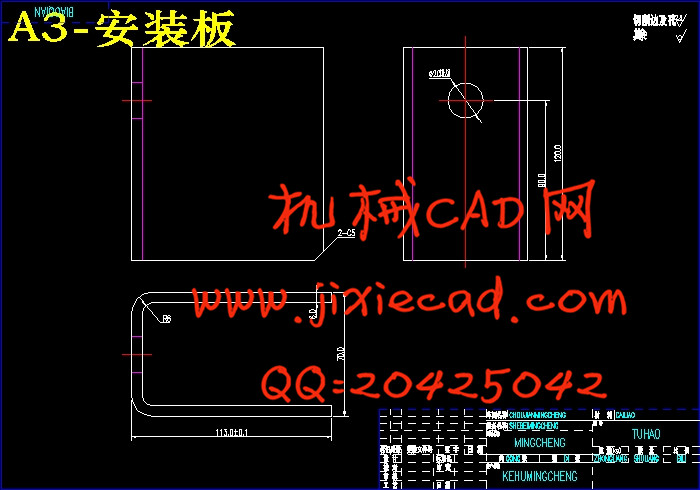

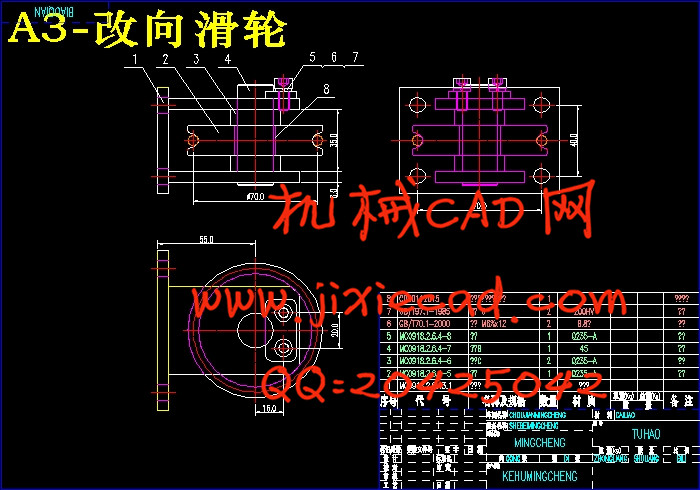

4.4 改向滑轮 24

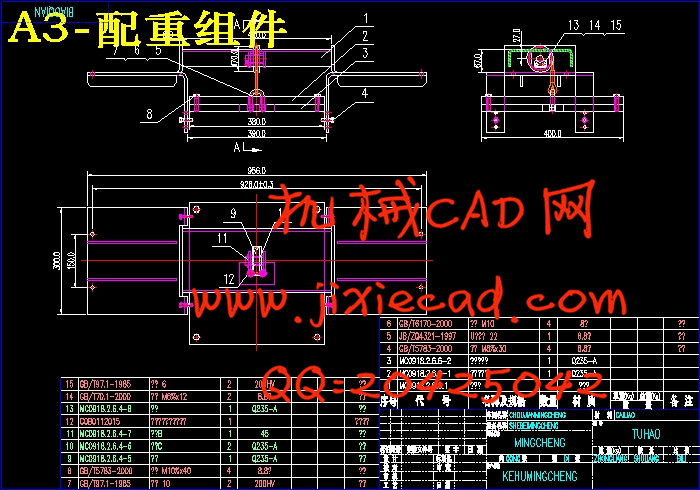

4.5配重组件 25

4.6 带档边的滚轮 25

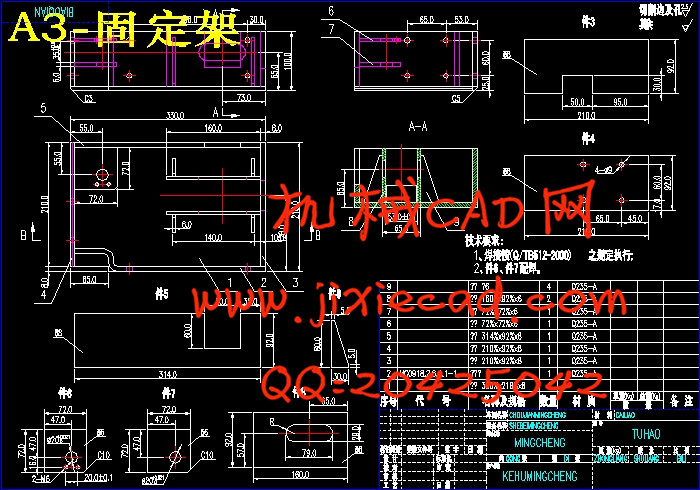

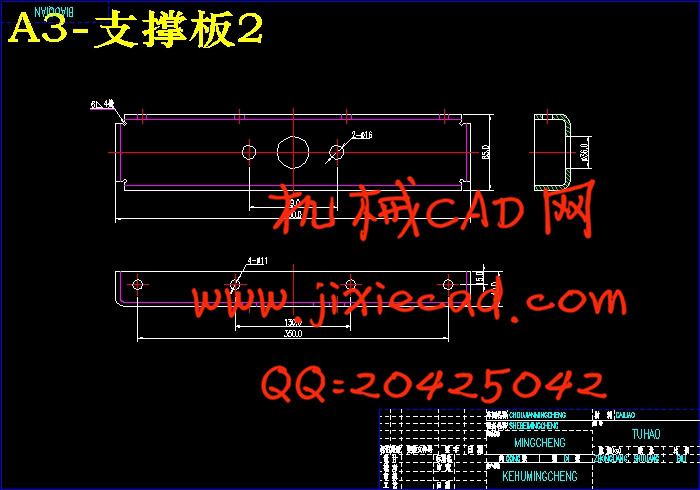

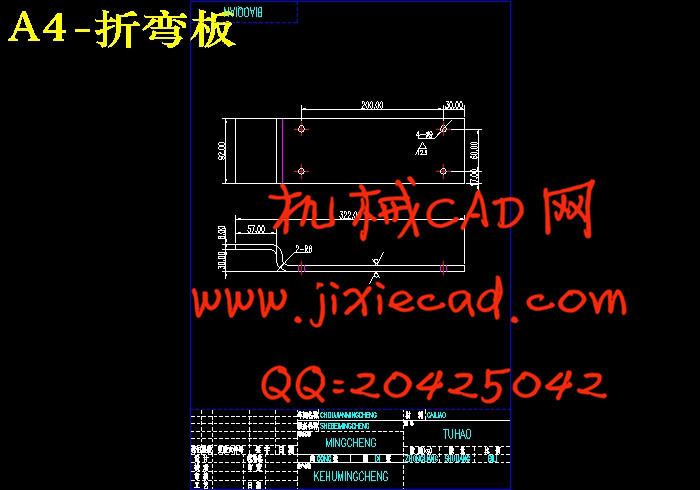

4.7 调整片架 26

致 谢 28

参考文献 29