设计简介

摘 要

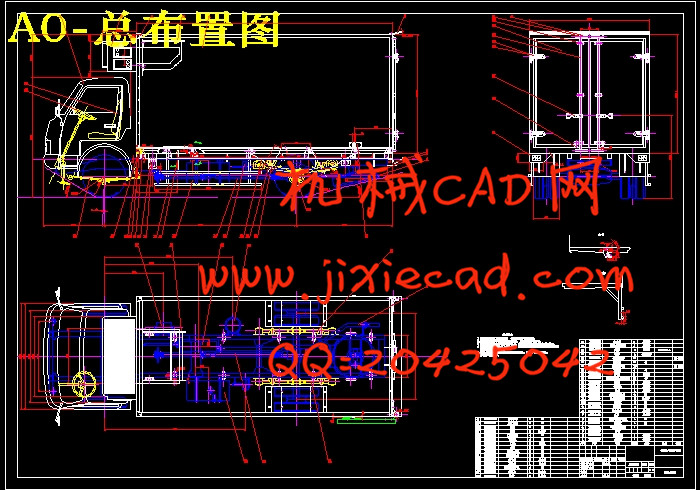

通过对隔热车厢结构及尺寸的分析比较,完成冷藏车车厢总成设计,其中包括车厢设计、车厢对开门设计及性能计算与校核。

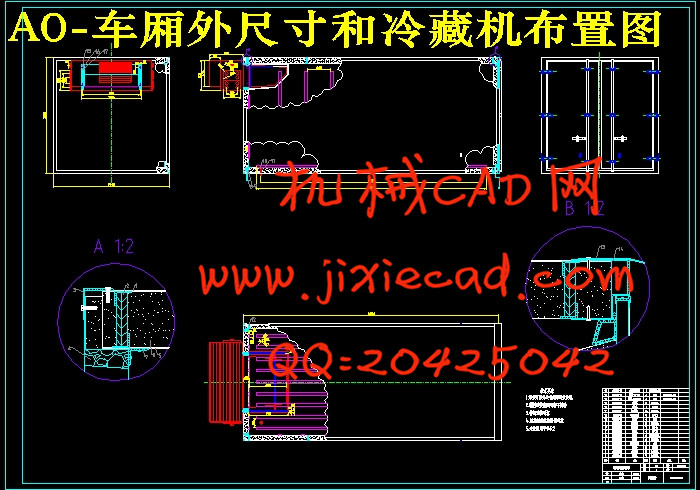

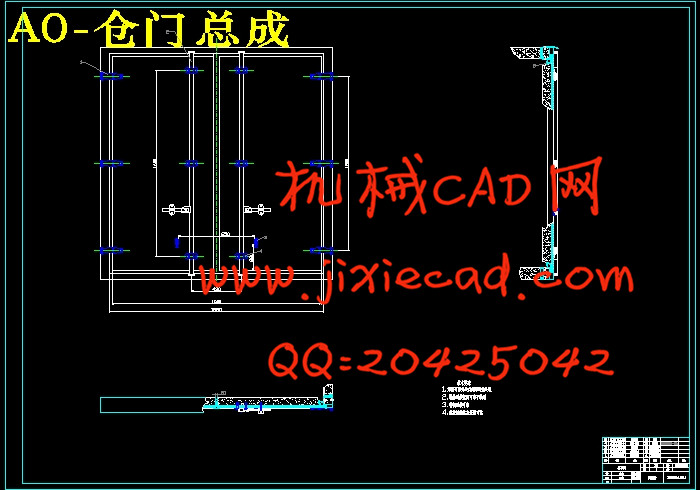

本设计的隔热车厢各部分之间的连接多采用粘接剂而非螺栓和铆钉等金属件,不仅减少了热桥,而且增加了平整度和美观度。隔热材料选用应用最广泛的聚氨酯泡沫,其导热系数较小且具有一定的抗拉抗弯强度,与钢板和胶合板的粘接力较强且密度低,减少了隔热壁厚度,在车厢外尺寸确定的情况下增大了车厢装载容积。车厢门及其附件尽量采用简单可靠的零部件和装配固定方法,确保密封性。根据计算确定的热工参数选用合适的制冷机组并合理完成各部分的安装与固定。

本设计的车厢总成结构简单,性能良好,成本不高,高性能材料和先进技术的应用有效降低了车厢的自重,各参数均符合设计要求。

关键词:冷藏保温汽车,隔热材料,制冷机组,传热系数

ABSTRACT

This paper completed the assemble design of the compartment of the refrigerated truck including the carriage design, the open door design, the performance calculation and verification through analysis and comparison the structure and the size of the insulated compartment.

In this design, the connection between the parts mostly use adhesive rather than rivets, bolts and other metal pieces, which not only reduced the thermal bridge, but also increases the level and degree of beauty. The most extensive application of polyurethane foam is selected for insulation material which not only has small coefficient of thermal conductivity, but also has certain tensile strength and bend strength. The polyurethane foam has excellent adhesive force with the armor plate and the plywood. And the density is low which reduces the thickness of the insulated wall. So when the compartment has fixed external size the stowage volume of the compartment is increased. The door and its accessories as much as possibly use a simple and reliable parts and assembly method to ensure the seal. We should choose a appropriate refrigeration unit according to calculating the parameter of the heat engineering and complete the installation and fixed of various parts reasonably.

This design of the compartment assemble has simple structure, good performance, low cost and the usage of high-performance materials and advanced technology which reduce the compartment’s weight. All parameters in this design are in line with the design requirements.

KEY WORDS: refrigerated and insulated car, insulation material, refrigeration unit, heat transfer coefficient

目录

第一章 绪论··························································3

1.1 冷藏保温汽车的特点···············································3

1.2 冷藏保温汽车的经济意义···········································4

1.3 国内外冷藏保温汽车的发展过程和现状·······························4

1.3.1 冷藏保温汽车的发展过程·······································4

1.3.2 国外冷藏保温汽车的发展现状···································5

1.3.3 我国冷藏保温汽车的发展现状···································6

1.4 我国冷藏保温汽车的发展趋势·······································7

第二章 隔热车厢结构···············································10

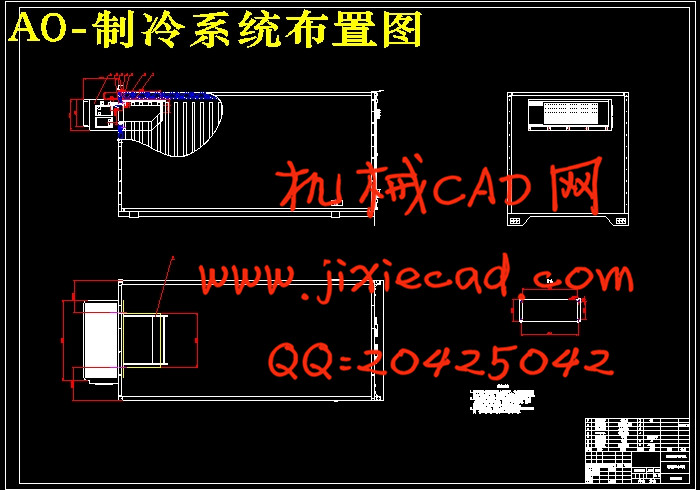

2.1 制冷装置························································10

2.2 隔热车厢分类····················································12

2.3 隔热车厢结构····················································13

2.3.1 隔热车厢的结构型式··········································13

2.3.2 隔热层材料及其厚度··········································14

2.3.3 断热桥结构··················································15

2.3.4 车厢蒙皮····················································15

2.3.5 密封条······················································16

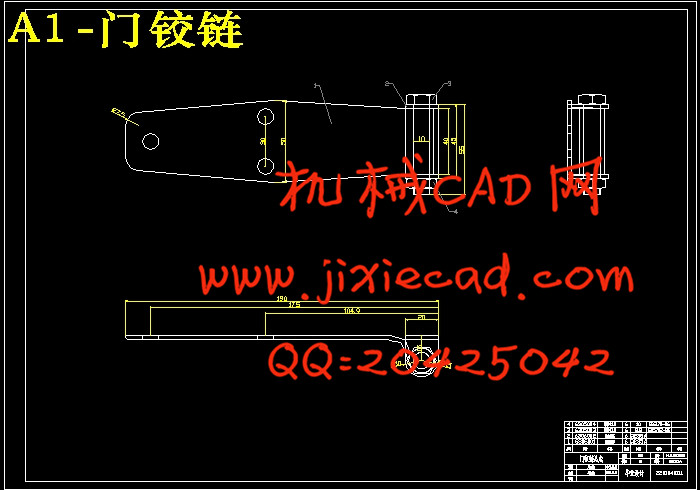

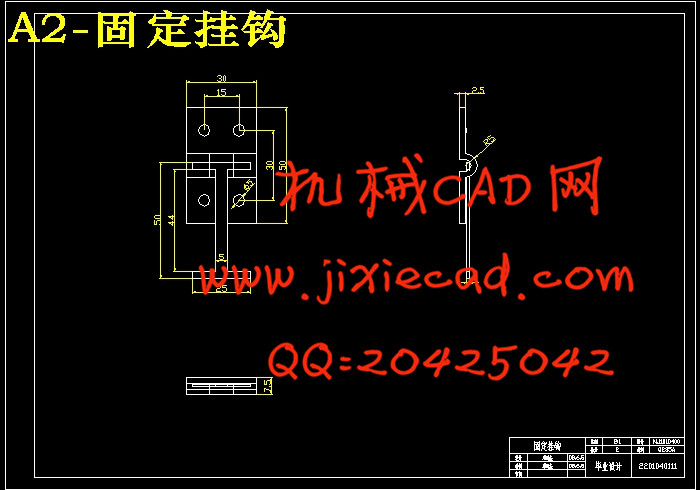

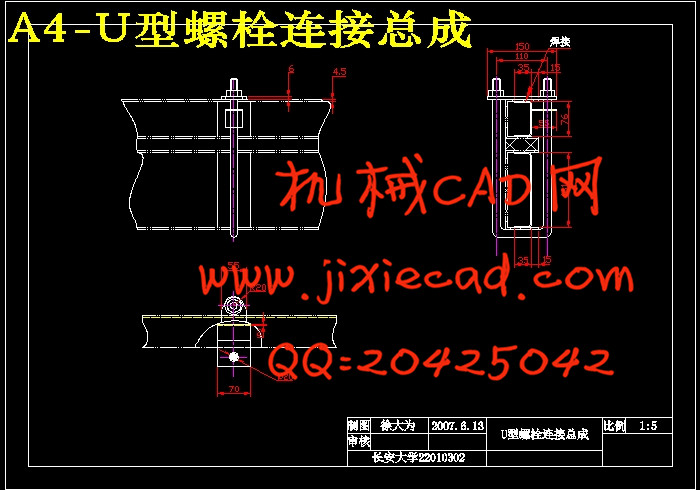

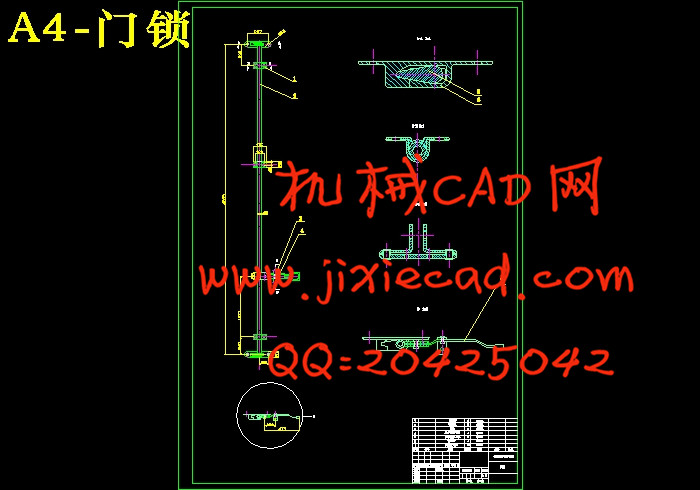

2.3.6 车厢门及其附件··············································16

2.3.7 车厢内外附件················································18

2.4 车厢制作技术现状················································20

第三章 隔热车厢设计···············································21

3.1 车厢主要结构型式和技术参数的确定································21

3.2 车厢设计主要技术参数分析和计算··································22

3.2.1 车厢隔热壁传热系数的计算····································22

3.2.2 隔热车厢平均传热系数的计算··································25

3.2.3 制冷设备热负荷的计算········································25

3.3 制冷机组的选择··················································28

3.4 车厢换气倍数的确定··············································28

3.5 车厢重量的计算··················································29

总结··································································30

通过对隔热车厢结构及尺寸的分析比较,完成冷藏车车厢总成设计,其中包括车厢设计、车厢对开门设计及性能计算与校核。

本设计的隔热车厢各部分之间的连接多采用粘接剂而非螺栓和铆钉等金属件,不仅减少了热桥,而且增加了平整度和美观度。隔热材料选用应用最广泛的聚氨酯泡沫,其导热系数较小且具有一定的抗拉抗弯强度,与钢板和胶合板的粘接力较强且密度低,减少了隔热壁厚度,在车厢外尺寸确定的情况下增大了车厢装载容积。车厢门及其附件尽量采用简单可靠的零部件和装配固定方法,确保密封性。根据计算确定的热工参数选用合适的制冷机组并合理完成各部分的安装与固定。

本设计的车厢总成结构简单,性能良好,成本不高,高性能材料和先进技术的应用有效降低了车厢的自重,各参数均符合设计要求。

关键词:冷藏保温汽车,隔热材料,制冷机组,传热系数

ABSTRACT

This paper completed the assemble design of the compartment of the refrigerated truck including the carriage design, the open door design, the performance calculation and verification through analysis and comparison the structure and the size of the insulated compartment.

In this design, the connection between the parts mostly use adhesive rather than rivets, bolts and other metal pieces, which not only reduced the thermal bridge, but also increases the level and degree of beauty. The most extensive application of polyurethane foam is selected for insulation material which not only has small coefficient of thermal conductivity, but also has certain tensile strength and bend strength. The polyurethane foam has excellent adhesive force with the armor plate and the plywood. And the density is low which reduces the thickness of the insulated wall. So when the compartment has fixed external size the stowage volume of the compartment is increased. The door and its accessories as much as possibly use a simple and reliable parts and assembly method to ensure the seal. We should choose a appropriate refrigeration unit according to calculating the parameter of the heat engineering and complete the installation and fixed of various parts reasonably.

This design of the compartment assemble has simple structure, good performance, low cost and the usage of high-performance materials and advanced technology which reduce the compartment’s weight. All parameters in this design are in line with the design requirements.

KEY WORDS: refrigerated and insulated car, insulation material, refrigeration unit, heat transfer coefficient

目录

第一章 绪论··························································3

1.1 冷藏保温汽车的特点···············································3

1.2 冷藏保温汽车的经济意义···········································4

1.3 国内外冷藏保温汽车的发展过程和现状·······························4

1.3.1 冷藏保温汽车的发展过程·······································4

1.3.2 国外冷藏保温汽车的发展现状···································5

1.3.3 我国冷藏保温汽车的发展现状···································6

1.4 我国冷藏保温汽车的发展趋势·······································7

第二章 隔热车厢结构···············································10

2.1 制冷装置························································10

2.2 隔热车厢分类····················································12

2.3 隔热车厢结构····················································13

2.3.1 隔热车厢的结构型式··········································13

2.3.2 隔热层材料及其厚度··········································14

2.3.3 断热桥结构··················································15

2.3.4 车厢蒙皮····················································15

2.3.5 密封条······················································16

2.3.6 车厢门及其附件··············································16

2.3.7 车厢内外附件················································18

2.4 车厢制作技术现状················································20

第三章 隔热车厢设计···············································21

3.1 车厢主要结构型式和技术参数的确定································21

3.2 车厢设计主要技术参数分析和计算··································22

3.2.1 车厢隔热壁传热系数的计算····································22

3.2.2 隔热车厢平均传热系数的计算··································25

3.2.3 制冷设备热负荷的计算········································25

3.3 制冷机组的选择··················································28

3.4 车厢换气倍数的确定··············································28

3.5 车厢重量的计算··················································29

总结··································································30