设计简介

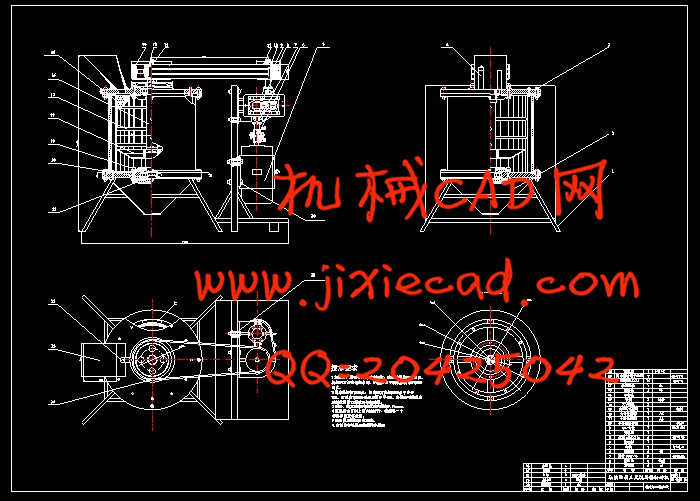

【摘 要】:本产品主要针对非金属矿物的粉碎而设计。根据产品的主要粉碎对象与其内部结构命名为块状物质立式搅拌棒粉碎机。文章首先介绍了非金属矿物的现状及一些相关内容,然后说明粉碎机的发展史以及目前国内现状和未来的发展方向,并根据产品的性能等要求,说明产品的设计方案由来。在粉碎机的设计过程中,对主要的部件进行了详细的设计,并根据粉碎机的性能确定了V带、齿轮、电机、轴的具体参数。再根据这些参数绘制出了粉碎机的装配图,同时论文对其他的部件也进行了说明,如:进料口、搅拌棒等。此产品的主要优点在于物料粉碎均匀,能耗低等。详细信息请参考本文。

【关键词】:块状物质 粉碎机 搅拌棒 结构设计

【Abstract】:This product is designed mainly for crushing of non-metallic minerals. According to the product main crushing object and its internal structure named clumps of vertical mixing rod mill. This article first introduces the status of non-metallic minerals and some related content, then explain the history of the development of mill and the present situation and the future development direction, and according to the product performance requirements, design scheme of product origin. In the design process of mill, has carried on the detailed design to the main component, and the specific parameters of V belt, gear, shaft, motor was determined according to the performance of crusher. According to these parameters to draw the assembly drawing mill, at the same time, the other parts are also described, such as: inlet, a stirring bar. The main advantage of this product is to crush materials uniform, low energy consumption. Detailed information please refer to this article.

【Key words】: bulk material mill stirring rod structure design

目 录

绪论 1

1 设计概述 3

1.1 非金属矿产资源概述 3

1.2 我国非金属的发展现状 3

1.3超细粉碎技术现状及发展趋势 5

1.4超细粉碎设备现状 6

1.5粉碎机的发展方向 6

1.6本次设计思路 7

2粉碎机的理论与要求 8

2.1非金属性能 8

2.2粉碎机的结构设计 8

2.3粉碎机的工作原理 10

3粉碎机的设计 11

3.1电机 11

3.2传动装置设计 12

3.2.1动力学和运动学计算 12

3.2.2带传动设计计算 13

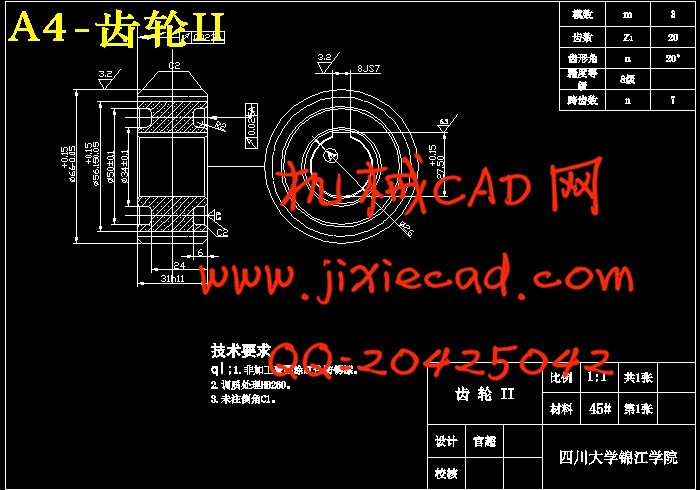

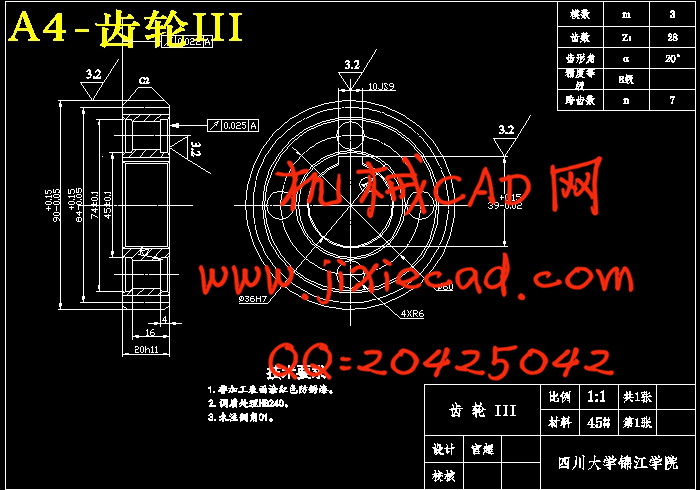

3.2.3齿轮结构与传动的设计计算 15

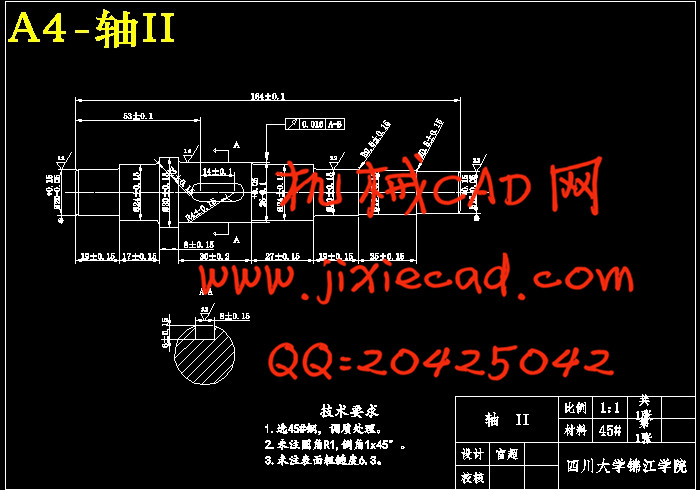

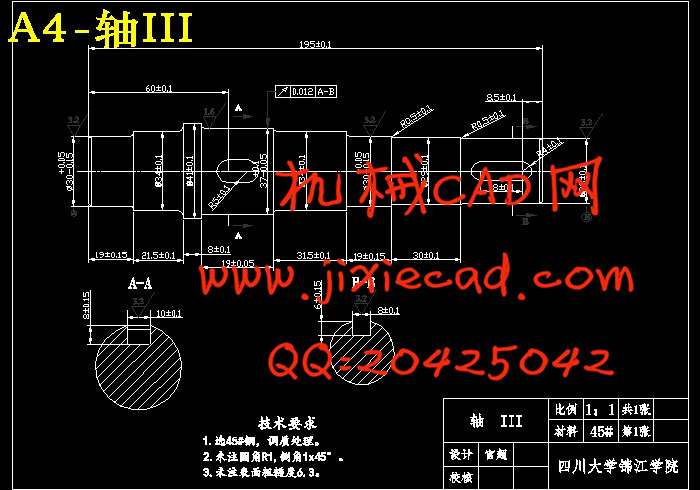

3.2.4轴的初步计算 19

3.2.5初选联轴器和轴承 24

3.3粉碎机的主体设计 24

3.3.1中心轴及搅拌棒 25

3.3.2筒体 25

3.3.3进料口和出料口 26

3.3.4搅拌棒 26

3.3.5旋转挡板 27

3.3.6机体支撑装置 27

总结 28

参考文献 29

致 谢 30

【关键词】:块状物质 粉碎机 搅拌棒 结构设计

【Abstract】:This product is designed mainly for crushing of non-metallic minerals. According to the product main crushing object and its internal structure named clumps of vertical mixing rod mill. This article first introduces the status of non-metallic minerals and some related content, then explain the history of the development of mill and the present situation and the future development direction, and according to the product performance requirements, design scheme of product origin. In the design process of mill, has carried on the detailed design to the main component, and the specific parameters of V belt, gear, shaft, motor was determined according to the performance of crusher. According to these parameters to draw the assembly drawing mill, at the same time, the other parts are also described, such as: inlet, a stirring bar. The main advantage of this product is to crush materials uniform, low energy consumption. Detailed information please refer to this article.

【Key words】: bulk material mill stirring rod structure design

目 录

绪论 1

1 设计概述 3

1.1 非金属矿产资源概述 3

1.2 我国非金属的发展现状 3

1.3超细粉碎技术现状及发展趋势 5

1.4超细粉碎设备现状 6

1.5粉碎机的发展方向 6

1.6本次设计思路 7

2粉碎机的理论与要求 8

2.1非金属性能 8

2.2粉碎机的结构设计 8

2.3粉碎机的工作原理 10

3粉碎机的设计 11

3.1电机 11

3.2传动装置设计 12

3.2.1动力学和运动学计算 12

3.2.2带传动设计计算 13

3.2.3齿轮结构与传动的设计计算 15

3.2.4轴的初步计算 19

3.2.5初选联轴器和轴承 24

3.3粉碎机的主体设计 24

3.3.1中心轴及搅拌棒 25

3.3.2筒体 25

3.3.3进料口和出料口 26

3.3.4搅拌棒 26

3.3.5旋转挡板 27

3.3.6机体支撑装置 27

总结 28

参考文献 29

致 谢 30