设计简介

摘 要

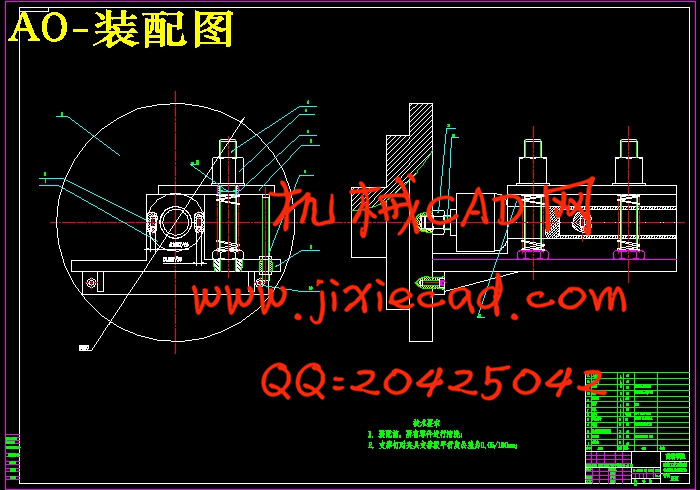

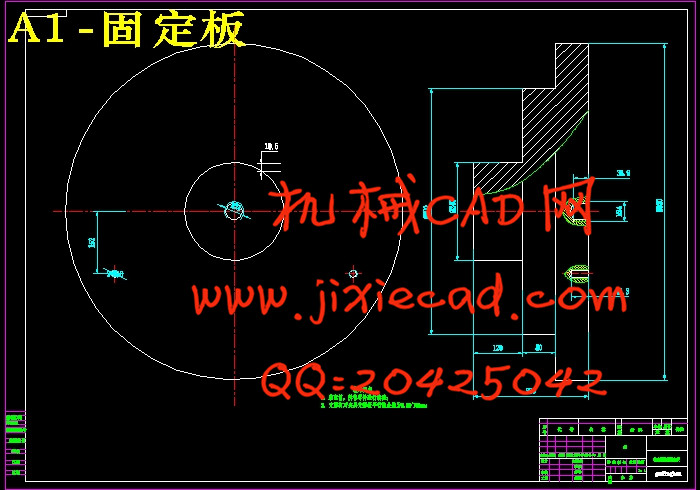

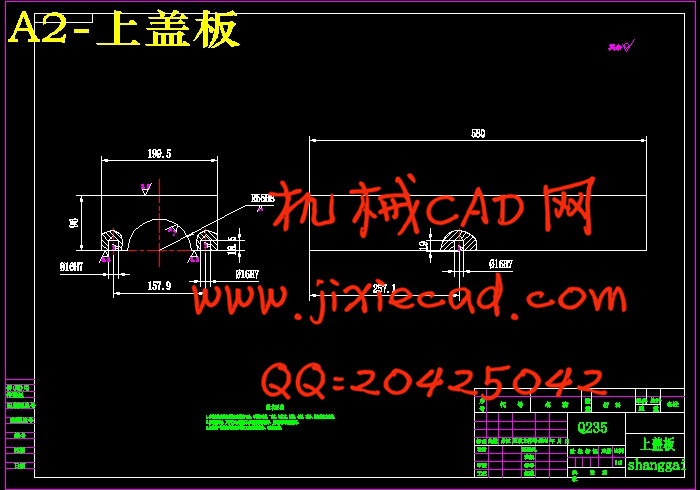

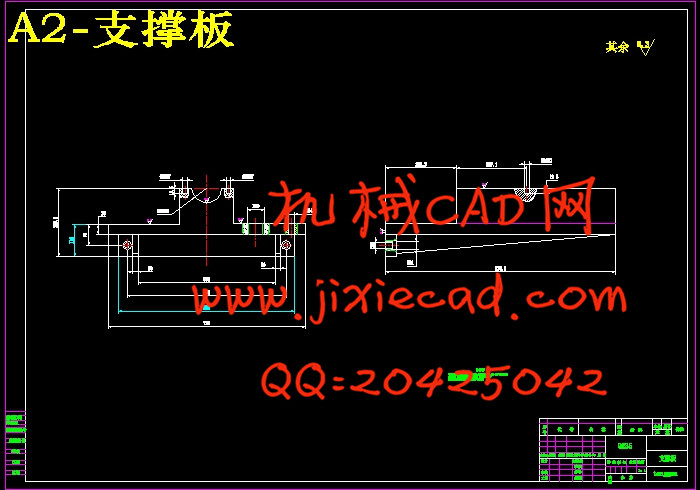

本文是结合目前实际生产中,常常发现仅用通用夹具不能满足生产要求,用通用夹具装夹工件生产效率低劳动强大,加工质量不高,而且往往需要增加划线工序,而专门设计夹具:车床夹具,主要包括夹具的定位方案,夹紧方案、对刀方案,夹具体与定位键的设计及加工精度等方面的分析。本设计车床夹具有良好的加工精度,针对性强,主要用于零件孔工序的加工。其具有夹紧力装置,具备现代机床夹具所要求的高效化和精密化的特点,可以有效的减少工件加工的基本时间和辅助时间,大大提高了劳动生产力,从而可以有效地减轻工人的劳动强度和增加劳动效率。因此,对夹具知识的认识和学习以及设计新式的适合实际生产的夹具在今天显得尤为重要起来。

在工艺设计中要首先对零件进行分析,了解零件的工艺,并选择好零件的加工基准,设计出零件的工艺路线;接着对零件各个工步的工序进行尺寸计算,关键是决定出各个工序的工艺装备及切削用量;然后进行专用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件;计算出夹具定位是产生的定位误差,分析夹具结构的合理性与不足之处,并在以后设计中注意改进。

关键词:工艺、工序、切削用量、夹紧、定位、误差

Abstract

This thesis is combined with the actual production, often found only universal fixture can not meet production requirements, workpiece clamping fixture with low production efficiency of labor power, the processing quality is not high, and often need to increase the marking process, specially designed fixture: lathe fixture, including fixture locating scheme, clamping programme, setting scheme, key clip and location specific design and machining precision analysis and etc..The design of lathe clamp has good machining precision, strong pertinence, the main components used in hole process. It has a clamping force device, equipped with modern machine tool required for high efficiency and precision of the characteristics, the workpiece can be effectively reduced processing time and supporting basic time, greatly increased the labor productivity, which can effectively reduce the labor intensity of workers and increased labor efficiency. Therefore, understanding and knowledge of the clamp study and design the new fit to actual production fixture in today is particularly important.

In the design process should first of all parts for analysis, to understand the parts of the process, and select good parts processing base, design parts of the process route; and then the various parts of process dimension calculation, is the key to determine the various processes and process equipment and cutting parameters; then the special fixture design, selection of design of fixture for the various components, such as positioning devices, clamping elements, the guide element, clamp and the machine tool connecting parts and other components; calculate fixture is to produce a positioning error, analysis of fixture structure rationality and deficiency, and later in the design of improved.

Key Words: process, process, cutting dosage, clamping, positioning, error

目 录

摘 要 IIAbstract III

目 录 IV

第1章 绪论 6

1.1 夹具概述 6

1.2 机床夹具的功能 6

1.3机床夹具的发展趋势 7

1.3.1机床夹具的现状 7

1.3.2现代机床夹具的发展方向 7

第2章 课题研究内容及要求 9

2.1设计内容 9

2.2设计要求 9

第3章 夹具设计概述 10

3.1 夹具的组成 10

3.2 常用定位元件及选用 10

3.2.1工件以平面定位 11

3.2.2工件以外圆柱定位 11

3.2.3工件以内孔定位 11

3.2.4 对定位元件的基本要求 12

3.2.5常用定位元件所能限制的自由度 12

3.3 工件的夹紧 12

3.3.1夹紧装置的组成 12

3.3.2夹紧装置的设计原则 13

3.3.3定位夹紧力的基本原则 13

3.3.4减小夹紧变形的措施 15

3.4 机床夹具设计原理 15

2支承点与定位元件 16

第4章 薄壁零件车削加工注意事项 18

4.1 概述 18

4.2 加工薄壁零件在夹具上所采取的措施 19

4.2.1 将局部夹紧力机构改成均匀夹紧力机构 19

4.2.2 增加辅助支承面 20

4.2.3 改变夹紧力的作用点(部位) 20

4.2.4 采用心轴夹紧 21

4.3 加工薄壁零件在车削时所采取的措施 22

4.3.1 合理选择车刀材料及其几何参数 22

4.3.2 减少切削用量,减小吃刀深度、进给量和切削速度 22

4.3.2 合理选择切削液 22

第5章 具体夹具设计 22

5.1 车床夹具的主要类型 22

5.2车床夹具的设计要点 23

5.3 定位机构 24

5.4夹紧机构 25

5.5零件的车床夹具的加工误差分析 26

5.6 零件的车床专用夹具的总体设计 27

总结 28

参考文献 29

致 谢 30