设计简介

摘要

现代数控机床是未来工厂自动化的基础。数控系统设计车床的研究具有重要意义。本文在叙述了数控技术的历史、现状和发展的基础上,通过对旧机床的分析,结合机床设计的总体思想,提出了数控化设计的技术方案和新数控系统的选型配置方案;针对旧机床的要求,进行了传动系统的重新设计,提高了传动的精度,重新设计机床的控制逻辑,通过对伺服系统的分析,完成了机床各主要参数的优化和匹配。

本机床设计后将会展示出强大的功能、稳定的性能,将完全符合机床的技术规格和精度标准,加工出合格的零件,大大提高了车床的性能,是一次有益的尝试。

关键词:Φ630;机床;设计;数控系统。

Abstract

The modern Computer Numerical Control (CNC)machine is the foundation of the modern manufactory. The remaking of old machine for CNC is an efficient means to promote the progress of the manufactory, which is adapted to the circumstance for our country. Its range is wide, its cost is low and its period is short. Therefore, it is very important to study a remarking the lathe machine by using CNC system.This paper introduces the history and the development of CNC system. Based on its theory, through the analysis about the components of the old machine, presents the remaking transmission system to raise the precision of the lathe。Presents the remaking schemes of the CNC system. According to the old machine, the detail design and adjustment of the electric system have been completed, including the design of hardware and control software:Have introduced the one-chip computer system briefly, and has designed the electric control circuit of the numerical control lathe with the one-chip computer;And also redesign the control logic of the machine, through analyzing of the servo system, the main parameters of the machine have been confirmed and optimized also.

Have discussed two kinds interpolation numerical control lathes with thematic part, and design the interpolation forms for the numerical control lathe.

The remarked machine will show its powerful ability and high reliability, it conforms to the technical regulation and the accuracy standard of the machine.,and will process the qualified part, it has improved the performance of the lathe greatly, it’s a beneficial try.

Keywords:Φ630;lathe ; Remake ; CNC system ; One-chip computer.

目录

摘要 II

Abstract III

目录 IV

第1章 数控机床发展概述 1

1.1数控机床 1

1.1.1数控机床的特点 1

1.1.2数控机床的发展简史 1

1.1.3数控机床的分类 2

1.1.4数控机床的组成 5

1.1.5数控机床的数字控制 5

1.1.6数控机床的伺服机构 6

1.1.7数控机床的关键零部件 6

1.1.8数控机床的发展方向 7

1.2数控机床的工艺范围及加工精度 11

1.2.1工艺范围 11

1.2.2加工精度 11

1.3数控机床的经济分析 11

1.4数控机床的发展趋向 14

第2章 数控机床总体方案的制订及比较 15

2.1 总体方案比较 15

2.2 数控车床方案确定 15

2.3机床设计的总体任务 16

2.4运动系统方案确定 16

2.4.1伺服系统的选择 16

2.4.2传动方式的选择 17

2.5数控系统软硬件总体设计 17

2.6数控系统硬件结构 18

2.7数控系统软件结构 18

第3章 确定切削用量及选择刀具 19

3.1刀具选择 19

3.2切削用量确定 19

3.3切削三要素 20

3.4加工精度和表面粗糙度 20

3.5刀具材料 23

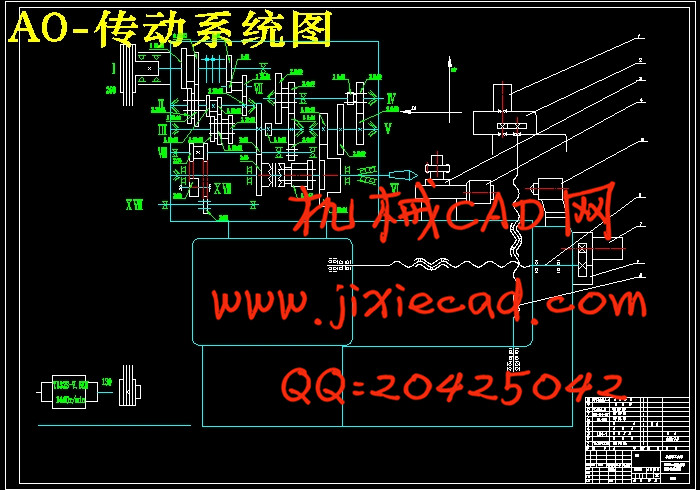

第4章 传动系统图的设计计算 24

4.1 参数的确定 24

4. 2 传动设计 26

4.3转速图的拟定 28

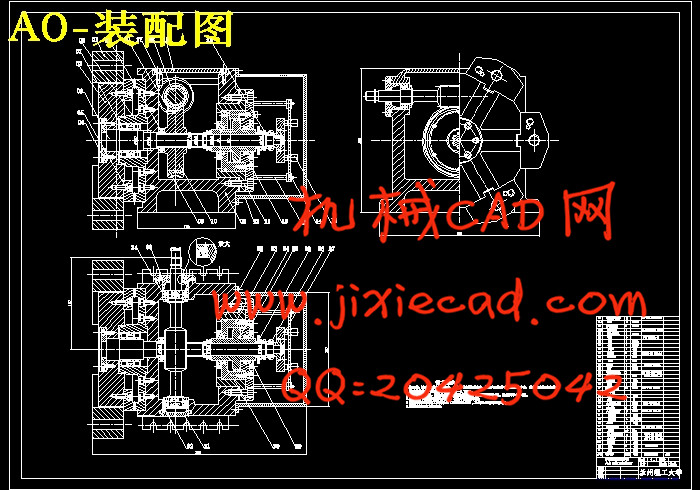

第5章 Φ630数控车床六角回转刀架的结构设计 32

5.1设计内容和研究方法 32

5.2车床刀架的功能,类型和应满足的要求 33

5.2.1车床刀架的功能 33

5.2.2机床刀架的类型 34

5.2.3机床刀架应满足的要求 34

5.3数控车床刀架总体方案设计与选择 35

5.3.1刀架的整体方案设计 35

5.3.2车床刀架的转位机构方案设计 35

5.3.3刀架定位机构方案设计 36

5.4 车床刀架的工作原理 37

5.5刀架的设计计算 37

5.5.1 驱动刀架的伺服电机的选择计算 37

5.5.2 蜗轮蜗杆的设计计算 41

5.5.3 刀架主轴的结构设计计算 45

结论 47

致谢 48

参考文献 49