设计简介

现代轧机发展的趋向是连续化、自动化、专业、,产品质量高、消耗低。60年代以来轧机在设计,研究和制造方面取得了很大的进展,使带材冷热轧机、厚板轧机、高速线材轧机、H型材轧机和连轧管机组等性能更加完善,并出现了轧制速度高达每秒钟 115米的线材轧机、全连续式带材冷轧机、5500毫米宽厚板轧机和连续式 H型钢轧机等一系列先进设备。轧机用的原料单重增大,液压 AGC、板形控制、电子计算机程序控制及测试手段越来越完善,轧制品种不断扩大。一些适用于连续铸轧、控制轧制等新轧制方法,以及适应新的产品质量要求和提高经济效益的各种特殊结构的轧机都在发展中

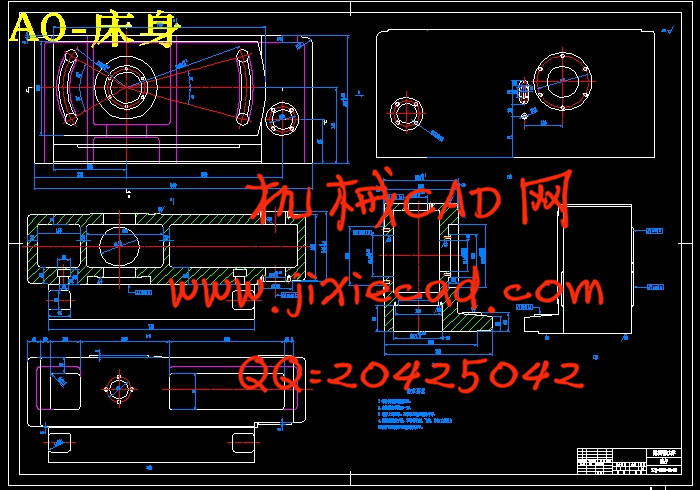

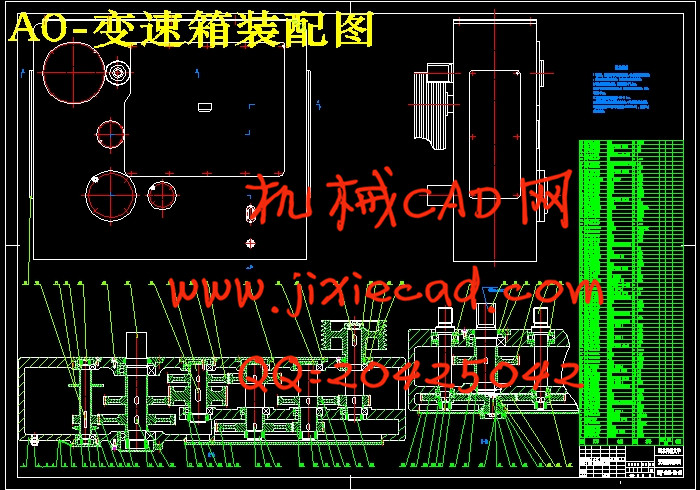

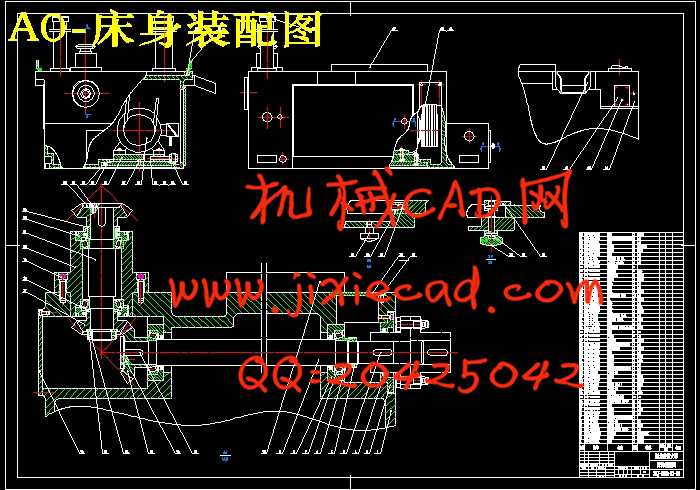

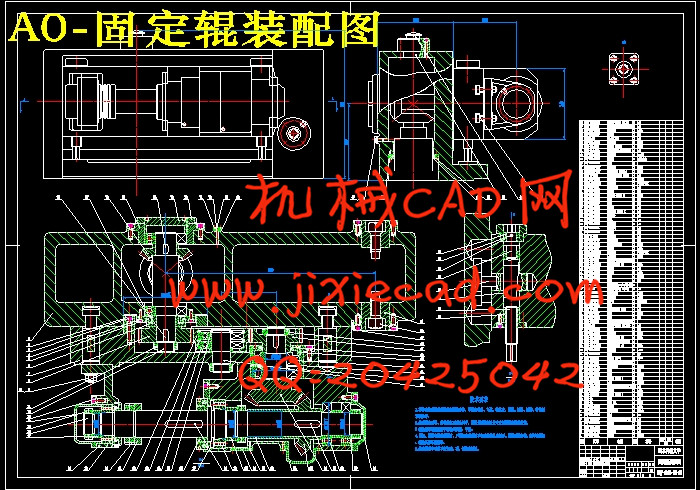

本论文主要介绍了轧机的历史、发展、组成和部件选择及其设计。电机带动带轮、齿轮、输入轴之后带动固定辊和移动辊,进行轧制。所选用的部件都是有所依据,非标准件都符合设计标准,做出了比较完善的措施。

关键词:轧机发展、齿轮、轧制

The development of the modern trend is a continuous rolling mill, automation, professional, high product quality, low energy consumption. 60 years since the mill in the design, research and manufacturing has made great progress, so that hot and cold strip mill, plate mill, high speed wire rod mill, H profiles Pipe Mill and other mills and the performance more perfect, and the emergence of rolling system speeds up to 115 meters per second, the wire rod mill, all continuous strip rolling mill, 5500 mm wide plate mill and the continuous series of advanced H steel mill equipment. Mill with raw material unit weight increases, the hydraulic AGC, flatness control, computer process control and testing methods become more perfect, rolling growing varieties. That apply to continuous casting, controlled rolling and other new rolling method, and adapt to new product quality requirements and improve the economic efficiency of the various special structures in the development of mill。

This paper describes the mill's history, development, composition and component selection and design. Motor driven pulley, gears, input shaft driven after the fixed roll and mobile roller for rolling The selected components are a basis, non-standard items are in line with design standards, made a more perfect measures.

Key Words :mill delelopment,gears,rolling

目 录

1引言……………………………………………………………………………………… 1

1.1轧机的发展………………………………………………………………… 1

1.2轧机的主要装备……………………………………………………………………… 1

1.3 多辊轧机的用途…………………………………………………………………… 1

1.4多辊轧机的发展和优点…………………………………………………………… 2

2总体方案的设计……………………………………………………………………… 3

2.1 技术参数要求……………………………………………………………………… 3

2.2 方案设计………………………………………………………………………… 3

2.2.1固定辊的设计………………………………………………………………… 3

2.2.2传动方案的设定…………………………………………………………………… 4

2.2.3机架的选择………………………………………………………… 5

2.2.4电机的选择 ………………………………………………………………… 6

3机械装置设计 ………………………………………………………… 6

3.1V带设计 ………………………………………………………6

3.1.1V带设计的注意事项……………………………………………………………… 7

3.1.2V带设计过程……………………………………………………………………… 7

3.2输入轴及其齿轮的设计…………………………………………………………… 9

3.2.1齿轮设计………………………………………………………………… 9

3.2.2齿轮弯曲强度设计…………………………………………………………… 11

3.2.3输入轴的设计………………………………………………………………… 13

3.2.4输入轴的校核………………………………………………………………… 13

3.2.5作用在齿轮上的力…………………………………………………………… 14

3.2.6计算支撑力…………………………………………………………………… 14

3.2.7校核轴的强度……………………………………………………………… 14

3.2.8键的校核……………………………………………………………………………15

3.2.9轴承介绍……………………………………………………………………………15

3.3 Ⅱ轴上的齿轮设计 ……………………………………………………………… 17

3.3.1选择齿轮类型、材料、精度等级、及齿数 ………………………………… 17

3.3.2按齿轮弯曲强度设计………………………………………………………………19

3.3.3几何尺寸计算………………………………………………………………………20

3.4Ⅲ轴上的齿轮设计……………………………………………………………………21

3.4.1选择齿轮类型、材料、精度等级、及齿数………………………………………21

3.4.2按齿轮弯曲强度设计………………………………………………………………23

3.4.3几何尺寸计算………………………………………………………………………24

3.5固定辊的设计…………………………………………………………………………24

3.5.1介绍…………………………………………………………………………………24

3.5.2固定辊的具体设计…………………………………………………………………25

3.5.3轧辊的强度校核……………………………………………………………………26

3.5.4轧辊轴承的工作特点………………………………………………………………27

结术语………………………………………………………………………………… 28

致谢……………………………………………………………………………………… 29

参考文献………………………………………………………………………………… 30

本论文主要介绍了轧机的历史、发展、组成和部件选择及其设计。电机带动带轮、齿轮、输入轴之后带动固定辊和移动辊,进行轧制。所选用的部件都是有所依据,非标准件都符合设计标准,做出了比较完善的措施。

关键词:轧机发展、齿轮、轧制

The development of the modern trend is a continuous rolling mill, automation, professional, high product quality, low energy consumption. 60 years since the mill in the design, research and manufacturing has made great progress, so that hot and cold strip mill, plate mill, high speed wire rod mill, H profiles Pipe Mill and other mills and the performance more perfect, and the emergence of rolling system speeds up to 115 meters per second, the wire rod mill, all continuous strip rolling mill, 5500 mm wide plate mill and the continuous series of advanced H steel mill equipment. Mill with raw material unit weight increases, the hydraulic AGC, flatness control, computer process control and testing methods become more perfect, rolling growing varieties. That apply to continuous casting, controlled rolling and other new rolling method, and adapt to new product quality requirements and improve the economic efficiency of the various special structures in the development of mill。

This paper describes the mill's history, development, composition and component selection and design. Motor driven pulley, gears, input shaft driven after the fixed roll and mobile roller for rolling The selected components are a basis, non-standard items are in line with design standards, made a more perfect measures.

Key Words :mill delelopment,gears,rolling

目 录

1引言……………………………………………………………………………………… 1

1.1轧机的发展………………………………………………………………… 1

1.2轧机的主要装备……………………………………………………………………… 1

1.3 多辊轧机的用途…………………………………………………………………… 1

1.4多辊轧机的发展和优点…………………………………………………………… 2

2总体方案的设计……………………………………………………………………… 3

2.1 技术参数要求……………………………………………………………………… 3

2.2 方案设计………………………………………………………………………… 3

2.2.1固定辊的设计………………………………………………………………… 3

2.2.2传动方案的设定…………………………………………………………………… 4

2.2.3机架的选择………………………………………………………… 5

2.2.4电机的选择 ………………………………………………………………… 6

3机械装置设计 ………………………………………………………… 6

3.1V带设计 ………………………………………………………6

3.1.1V带设计的注意事项……………………………………………………………… 7

3.1.2V带设计过程……………………………………………………………………… 7

3.2输入轴及其齿轮的设计…………………………………………………………… 9

3.2.1齿轮设计………………………………………………………………… 9

3.2.2齿轮弯曲强度设计…………………………………………………………… 11

3.2.3输入轴的设计………………………………………………………………… 13

3.2.4输入轴的校核………………………………………………………………… 13

3.2.5作用在齿轮上的力…………………………………………………………… 14

3.2.6计算支撑力…………………………………………………………………… 14

3.2.7校核轴的强度……………………………………………………………… 14

3.2.8键的校核……………………………………………………………………………15

3.2.9轴承介绍……………………………………………………………………………15

3.3 Ⅱ轴上的齿轮设计 ……………………………………………………………… 17

3.3.1选择齿轮类型、材料、精度等级、及齿数 ………………………………… 17

3.3.2按齿轮弯曲强度设计………………………………………………………………19

3.3.3几何尺寸计算………………………………………………………………………20

3.4Ⅲ轴上的齿轮设计……………………………………………………………………21

3.4.1选择齿轮类型、材料、精度等级、及齿数………………………………………21

3.4.2按齿轮弯曲强度设计………………………………………………………………23

3.4.3几何尺寸计算………………………………………………………………………24

3.5固定辊的设计…………………………………………………………………………24

3.5.1介绍…………………………………………………………………………………24

3.5.2固定辊的具体设计…………………………………………………………………25

3.5.3轧辊的强度校核……………………………………………………………………26

3.5.4轧辊轴承的工作特点………………………………………………………………27

结术语………………………………………………………………………………… 28

致谢……………………………………………………………………………………… 29

参考文献………………………………………………………………………………… 30