设计简介

摘 要

随着变型运输拖拉机和农用运输车的发展,原来依靠农村运输业发展起来的小四轮拖拉机逐步转向田间地头。然而,目前小四轮拖拉机田间作业能力差,又没有很多配套的农业机械,农忙季节短,致使大量小四轮拖拉机一年中作业时间短,被迫长期闲置着。这影响了农村专业户的作业效益,也造成了不应该有的资源浪费。针对这些情况,我们在原有小四轮拖拉机的基础上稍微作些改动,使它的功能延伸。譬如可在原来小四轮拖拉机的基础上,改变座位、方向盘、离合、油门、刹车的方位,把拖拉机变成倒开式,在变速箱后安装挖掘装置、铲运装置或装载装置而成。

本次设计是对机械专业学生在毕业前的一次全面训练,目的在于巩固和扩大学生在校期间所学的基础知识和专业知识,训练学生综合运用所学知识分析和解决问题的能力。是培养、锻炼学生独立工作能力和创新精神之最佳手段。毕业设计要求每个学生在工作过程中,要独立思考,刻苦钻研,有所创造的分析、解决技术问题。通过毕业设计,使学生掌握改造方案的拟定、比较、分析及进行必要的计算。

关键字:齿轮 操纵机构 轴 轴承 锁定机构

DESING of a CERTAIN TYPE of TRACTOR GEARBOX

With variant transport tractors and agricultural the development of carriage car, depends on rural transportation industry to develop the small four-wheel tractor to field edge of a field. However, at present, small four-wheel the tractor field work ability is poor, and not many ancillary agricultural machinery, busy season is short, resulting in a large number of small four-wheel tractor year short operation time, forced long-term idle. The influence of rural specialist work benefit, also cause should not be some waste of resources. In light of these circumstances, we in the original small four-wheel tractor based on slightly to make some changes, make it functional extension. For example, in the original small four-wheel tractor based on, change seats, steering wheel, clutch, throttle, brake position, the tractor into inverted open, in a gearbox installed after digging device, lifting device or a loading device.

The graduation design is about mechanical speciality students before graduation and a comprehensive training, purpose is to consolidate and expand the students learn the basic knowledge and professional knowledge, training students' comprehensive use of the knowledge the ability to analyze and solve problems. Is training, training students the ability to work independently and the spirit of innovation is the best means. Graduation design requirements of each student in the course of the work, we need to think independently, study assiduously, create somewhat analysis, solving technical problems. Through the graduation project, so that students master the transformation plan formulation, comparison, analysis and necessary calculation.

Key words: Gear Manipulation of body Axis Bearing Locking mechanism

目 录

1 绪论 ............................................................................................................ ..1

1.1 变速箱概述..............................................................................................1

1.1.1 变速箱的功用.......................................................................................1

1.1.2 变速箱的类型....................................................................................1

1.1.3 变速箱的工作原理............................................................................2

2 变速箱设计要求及初始数据........................................................................3

2.1 变速箱设计要求...................................................................................3

2.2 变速箱设计初始数据...........................................................................3

3 变速箱设计过程........................................................................................... 4

3.1 变速箱的设计步骤...............................................................................4

3.2 变速箱结构的选择............................................................................... 4

3.3 根据总体计算确定挡位数与各档传动比...........................................4

3.4 根据总体布置要求确定变速箱外形尺寸允许范围...........................5

3.5 草拟变速箱的传动方案.......................................................................5

3.6 变速箱主要参数的确定.......................................................................6

3.6.1 齿轮模数的确定......................................................................6

3.6.2 齿轮压力角的确定..................................................................6

3.6.3 齿宽的确定..............................................................................6

3.6.4 相齿合齿轮的齿数和 .........................................................8

.........................................................8

3.7 选配齿轮.....................................................................................8

3.8 变速箱主要零件的计算.............................................................................9

3.7.1 齿轮的计算....................................................................................9

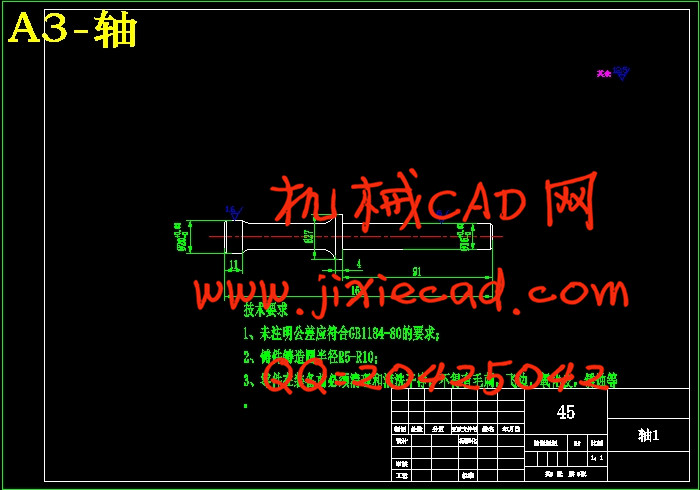

3.7.2 轴的计算......................................................................................12

3.7.3 轴承的计算...................................................................................16

4 主要零件的布置要点及倒档和减速器的布置方案............................... .. 18

4.1 变速箱主要零件的布置要点.................................................................18

4.2 倒档和减速器的布置方案.....................................................................18

4.2.1 倒档布置方案.............................................................................18

4.2.2 减速器布置方案.........................................................................19

5 变速箱壳和操纵机构的设计.......................................................................19

5.1 变速箱壳的设计....................................................................................19

5.2 变速箱操纵机构的设计........................................................................19

5.2.1换挡机构................................................................................. ..20

5.2.2锁定机构......................................................................................20

参考文献.............................................................................................................21

致 谢........................................................................................................... .. 22

随着变型运输拖拉机和农用运输车的发展,原来依靠农村运输业发展起来的小四轮拖拉机逐步转向田间地头。然而,目前小四轮拖拉机田间作业能力差,又没有很多配套的农业机械,农忙季节短,致使大量小四轮拖拉机一年中作业时间短,被迫长期闲置着。这影响了农村专业户的作业效益,也造成了不应该有的资源浪费。针对这些情况,我们在原有小四轮拖拉机的基础上稍微作些改动,使它的功能延伸。譬如可在原来小四轮拖拉机的基础上,改变座位、方向盘、离合、油门、刹车的方位,把拖拉机变成倒开式,在变速箱后安装挖掘装置、铲运装置或装载装置而成。

本次设计是对机械专业学生在毕业前的一次全面训练,目的在于巩固和扩大学生在校期间所学的基础知识和专业知识,训练学生综合运用所学知识分析和解决问题的能力。是培养、锻炼学生独立工作能力和创新精神之最佳手段。毕业设计要求每个学生在工作过程中,要独立思考,刻苦钻研,有所创造的分析、解决技术问题。通过毕业设计,使学生掌握改造方案的拟定、比较、分析及进行必要的计算。

关键字:齿轮 操纵机构 轴 轴承 锁定机构

DESING of a CERTAIN TYPE of TRACTOR GEARBOX

With variant transport tractors and agricultural the development of carriage car, depends on rural transportation industry to develop the small four-wheel tractor to field edge of a field. However, at present, small four-wheel the tractor field work ability is poor, and not many ancillary agricultural machinery, busy season is short, resulting in a large number of small four-wheel tractor year short operation time, forced long-term idle. The influence of rural specialist work benefit, also cause should not be some waste of resources. In light of these circumstances, we in the original small four-wheel tractor based on slightly to make some changes, make it functional extension. For example, in the original small four-wheel tractor based on, change seats, steering wheel, clutch, throttle, brake position, the tractor into inverted open, in a gearbox installed after digging device, lifting device or a loading device.

The graduation design is about mechanical speciality students before graduation and a comprehensive training, purpose is to consolidate and expand the students learn the basic knowledge and professional knowledge, training students' comprehensive use of the knowledge the ability to analyze and solve problems. Is training, training students the ability to work independently and the spirit of innovation is the best means. Graduation design requirements of each student in the course of the work, we need to think independently, study assiduously, create somewhat analysis, solving technical problems. Through the graduation project, so that students master the transformation plan formulation, comparison, analysis and necessary calculation.

Key words: Gear Manipulation of body Axis Bearing Locking mechanism

目 录

1 绪论 ............................................................................................................ ..1

1.1 变速箱概述..............................................................................................1

1.1.1 变速箱的功用.......................................................................................1

1.1.2 变速箱的类型....................................................................................1

1.1.3 变速箱的工作原理............................................................................2

2 变速箱设计要求及初始数据........................................................................3

2.1 变速箱设计要求...................................................................................3

2.2 变速箱设计初始数据...........................................................................3

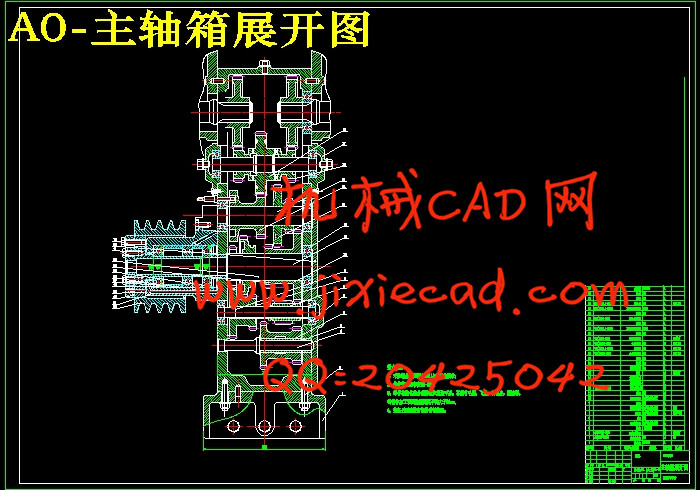

3 变速箱设计过程........................................................................................... 4

3.1 变速箱的设计步骤...............................................................................4

3.2 变速箱结构的选择............................................................................... 4

3.3 根据总体计算确定挡位数与各档传动比...........................................4

3.4 根据总体布置要求确定变速箱外形尺寸允许范围...........................5

3.5 草拟变速箱的传动方案.......................................................................5

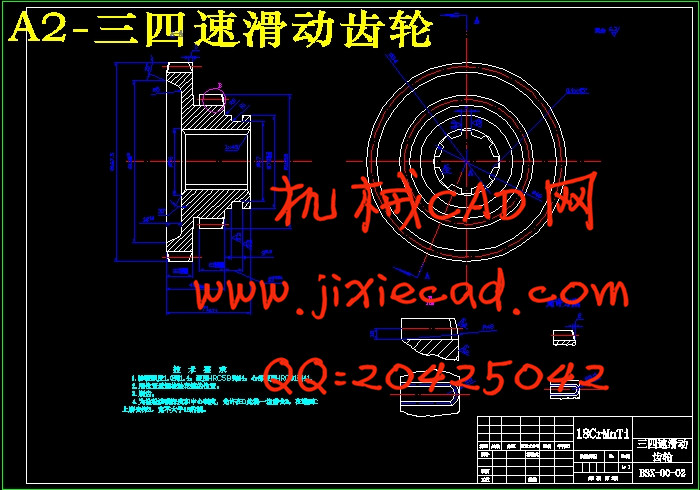

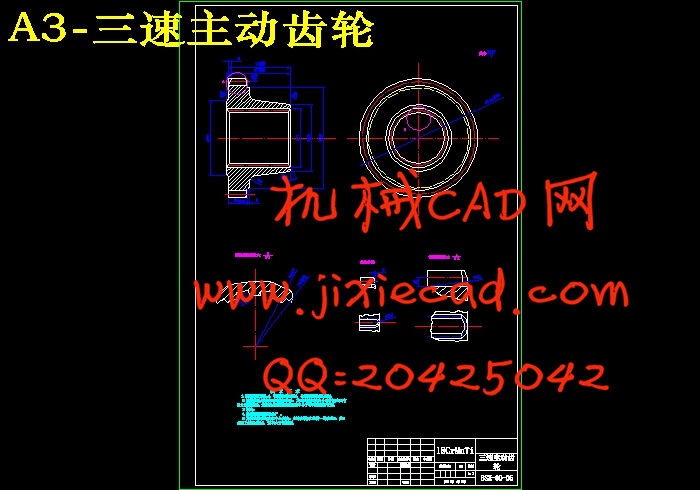

3.6 变速箱主要参数的确定.......................................................................6

3.6.1 齿轮模数的确定......................................................................6

3.6.2 齿轮压力角的确定..................................................................6

3.6.3 齿宽的确定..............................................................................6

3.6.4 相齿合齿轮的齿数和

3.7 选配齿轮.....................................................................................8

3.8 变速箱主要零件的计算.............................................................................9

3.7.1 齿轮的计算....................................................................................9

3.7.2 轴的计算......................................................................................12

3.7.3 轴承的计算...................................................................................16

4 主要零件的布置要点及倒档和减速器的布置方案............................... .. 18

4.1 变速箱主要零件的布置要点.................................................................18

4.2 倒档和减速器的布置方案.....................................................................18

4.2.1 倒档布置方案.............................................................................18

4.2.2 减速器布置方案.........................................................................19

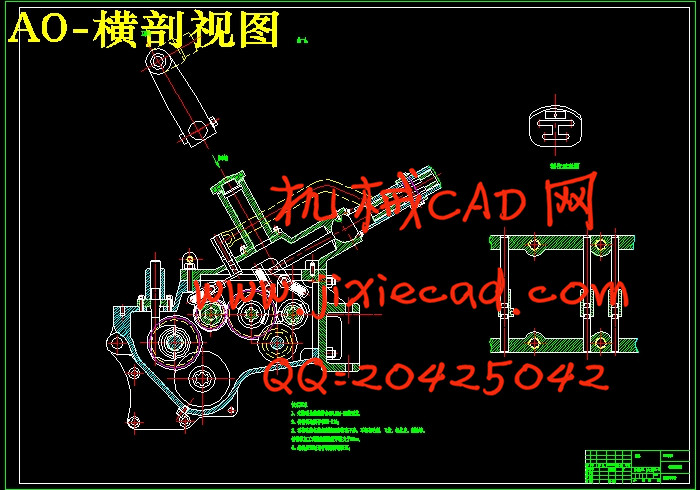

5 变速箱壳和操纵机构的设计.......................................................................19

5.1 变速箱壳的设计....................................................................................19

5.2 变速箱操纵机构的设计........................................................................19

5.2.1换挡机构................................................................................. ..20

5.2.2锁定机构......................................................................................20

参考文献.............................................................................................................21

致 谢........................................................................................................... .. 22