设计简介

摘 要

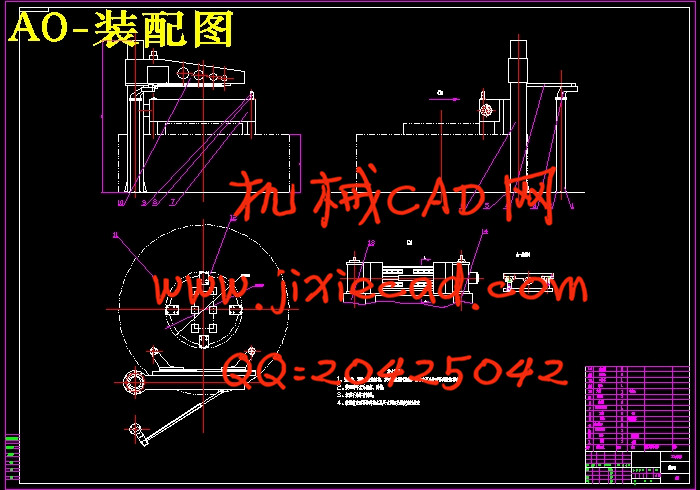

抛光机是一种重要的精密和超精密加工方法。它是指利用磨具通过磨料作用于工件表面,,进行微量加工的过程。抛光机加工的特征是加工精度和质量高。因此,抛光机机是保证抛光机加工的重要条件,为此人们专门研究了各种不同的抛光机机。目前国内生产高速抛光机机的厂家不少,但由于抛光机加工的针对性较强,对不同的工件,抛光机加工的方法也有很大的差别。环抛光机是精加工零件的专用机床,该机床可加工零件。为了提高加工整体质量,在对原机进行深入分析的基础上,研制了一种新型高加工精度的环零件精加工机。该机器通过两部分动力源分别控制研具的运动。对整个传动系统进行了分析,传动采用传动设计。在设计完各个部分的基础上,进行了总体结构布置。新机器克服了原有机器的一些缺点,成功提高了传动效率和加工精度。本次设计在原有的基础有利于提高生产效率。该机床的特点:加工精度高,工艺性能稳定,生产率高。

关键词:抛光机;机械传动;上下料

Abstract

Polishing machine is a kind of precision and ultraprecision machining method. It refers to the use of tools by abrasive on the surface of a workpiece, process, micro machining. Characteristics of polishing machining is machining accuracy and high quality. Therefore, the polishing machine is the important condition to guarantee the polishing machine, so people devoted to the study of the different polishing machine. The current domestic production of high speed polishing machine manufacturers a lot, but due to the polishing machine targeted, for different workpiece, method of polishing machine to also have very big difference.Ring polishing machine is a special machine tool precision machining parts, the machine can process parts. In order to improve the overall quality of processing, based on in-depth analysis of the original machine, developed the ring parts finishing machine is a new type of high precision. The machine control lapping tool movement through the two parts of the power source. On the whole transmission system is analyzed, the design of the transmission gear. In the design of the base of each part of the general structure of the arrangement. The new machine overcomes some shortcomings of the original machine, successfully improve transmission efficiency and precision. This design is helpful to improve the production efficiency in the original foundation. The characteristic of the machine: high precision processing technology, stable performance, high productivity.

Keywords: polishing machine; mechanical drive; loading and unloading

目 录

摘 要 IAbstract II

目 录 III

1 绪论 1

1.1抛光机概念、研究现状及发展 1

1.2 国内外研究情况 3

1.3 研究目的和意义 4

1.4 课题要求 8

2 4.4米环抛光机总体方案设计 9

2.1设计要求 9

2.2 环抛光机整体方案的确定 9

2.2.1 环抛光机类型分析 9

2.2.2 环抛光机方案比较 9

2.2.3 综合考虑选出最佳设计方案 10

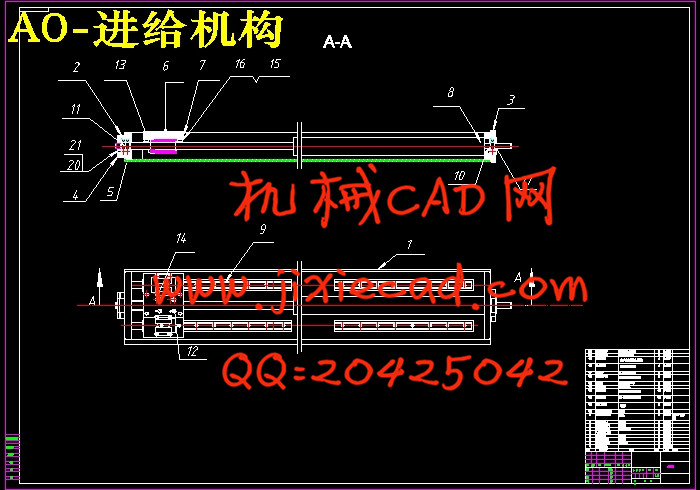

3 4.4米环抛光机工件环上下料机构设计 11

3.1 步进推杆使整个工件环转动 11

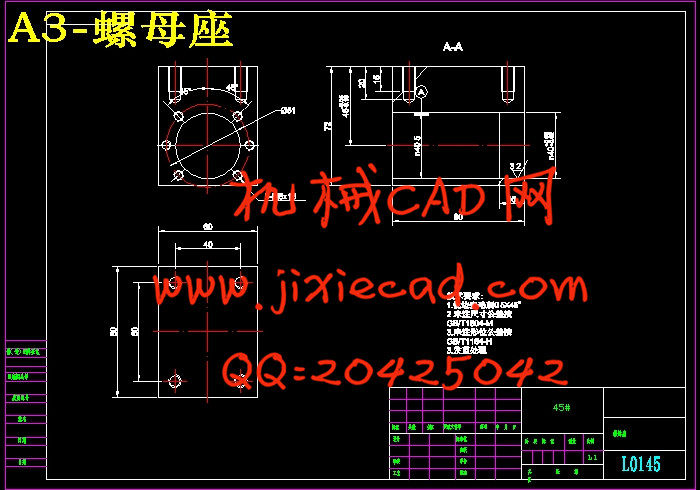

3.2 丝杠传动设计计算 12

3.2.1常见丝杠支承方式 12

3.2.2 脉冲当量选择 13

3.2.3滚珠丝杠设计计算 13

3.2.4滚珠丝杠副的载荷计算 14

3.2.5传动效率计算 16

3.2.6 刚度验算 16

3.2.7 滚珠丝杠精度等级确定 16

3.3 滚动导轨副的防护 19

3.4 直线滚动导轨副的计算、选择 19

3.5齿轮减速传动设计 21

3.6等效转动惯量计算(不计传动效率) 23

3.7 电机的计算选型 24

3.8 联轴器选择 25

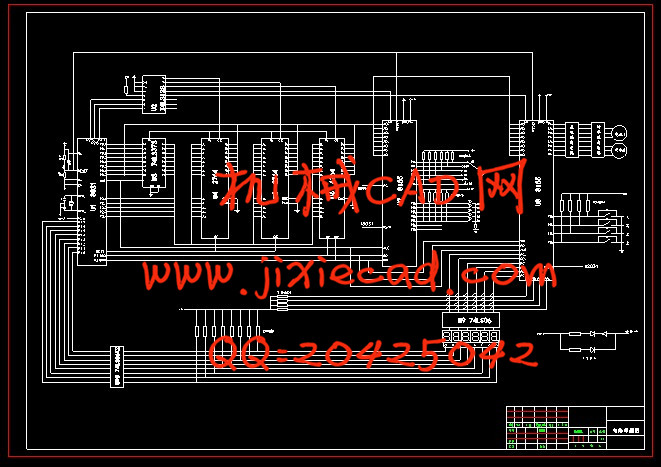

4 数控硬件电路设计 26

4.1硬件电路设计 26

4.1.1 数控系统的硬件结构 26

4.1.2 数控系统硬件电路的功能 26

4.2关于各线路元件之间线路连接 27

4.3关于电路原理图的一些说明 28

总结与展望 31

参考文献 32

致 谢 33