设计简介

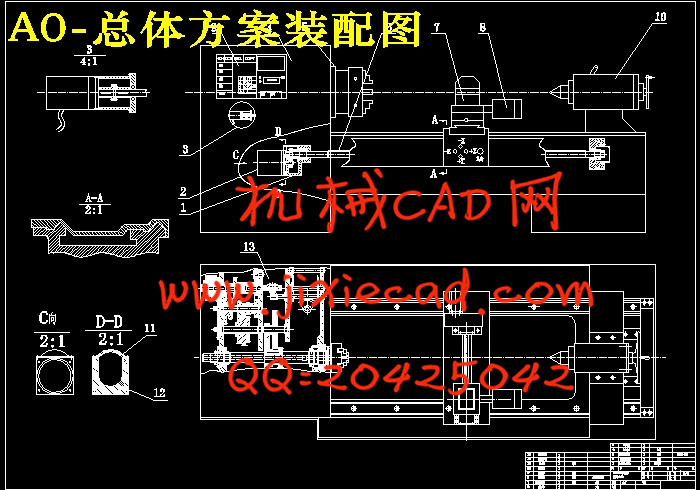

[摘要] 针对现有常规C6143普遍车床的缺点提出数控改装方案和单片机系统设计,提高加工精度和扩大机床使用范围,并提高生产率。本论文说明了普通车床的数控化改造的设计过程,较详尽地介绍了C6143机械改造部分的设计及数控系统部分的设计。采用以8031为CPU的控制系统对信号进行处理,由I/O接口输出步进脉冲,经一级齿轮传动减速后,带动滚动丝杠转动,从而实现纵向、横向的进给运动。

结合我国实际国情,经济型数控车床是我国从普通车床向数控车床发展的及其重要的台阶。利用现有的普通车床,对其进行数控化改造是一条低成本,高效益的途径。数控车床作为机电一体化的典型产品,在机械制造业中发挥着巨大的作用,很好地解决了现代机械制造中结构复杂、精密、批量小、多变零件的加工问题,且能稳定产品的加工质量,大幅度地提高生产效率。我国作为机床大国,数控机床的占有率还不足百分之三,但是在欧美等发达国家数控机床的占有率达到了百分之三十六以上,单从数字上来看我过和欧美等发达国家还有相当大的距离。其主要原因为数控车床价格较贵,一次性投资较大使企业心有余而力不足。对普通机床数控化改造不失为一种较好的良策。在金属加工行业中车床在所有加工设备中占有最大比重,例如最常见的轴类零件,就是由车床加工而成本论文针对目前国内企业现状,以C6143普通车床为例提出简易型经济数控改造思路和设计方法。

关键词:数控机床, 单片机数控系统,改装设计, 伺服电机 传动系统 控制系统 数控改造,

Abstract

To remedy the defects of ordinary lathe C6143, a design of data processing system and its single chip microcomputer system program is put forward to raise the processing precision and extend the machine’s usage, and to improve production rate。This paper presents the process of designing numerical control reform,and explicitly introduces the design of mechanical and numerical control system reforms。We adopt control system which has 8031 as cpu to cope with the signal,and output the step pulse through the I/O interface。After transmitting and slowing down by force 1 gear, the step pulses drive the leading screw to roll。Thus achieve the vertical movement and the crosswise movement。

China's actual conditions and economic CNC lathe is from the ordinary to the lathe and NC lathe important development stage.Use of existing ordinary lathe, NC transformation is its low cost and highly efficient way.CNC lathe as a typical electromechanical integration products, machinery manufacturing plays an enormous role,good solution to the structural complexity of modern machinery, precision, small batches, changeable parts processing,able to stabilize the quality of the processing products, a significant increase in production efficiency.As the big machine, CNC machine tools was less than 3.0% share.However, in Europe and the United States and other developed countries to achieve the 36% share of the CNC machine moreI can see from the figures over Europe and the United States and other developed countries there is still a considerable distance.The main reason for the higher prices of CNC lathe, a one-time investment to fill larger enterprises.CNC transformation of the ordinary would be a better process.Lathe in the metal processing industry accounts for the largest proportion of all processing equipment, for example, the most common shaft.Papers from the machining cost is the present status of domestic enterprises.Simple C6143 made to the general economic NC lathe ideas and design methods.

KEY WORDS: numerical control machine tool, single chip microcomputer system,reform design,The C6143 servo electrical machinery transmission system control system electricity control line economical numerical control changes

目录

摘要………………………………………………………………………………………2

Abstract………………………………………………………………………………3

第1章 绪论……………………………………………………………………………5

1.1 数控技术的产生和发展………………………………………………………5

1.2 数控机床的发展趋势…………………………………………………………6

1.3 车床数控改造的必要性与可行性……………………………………………8

第2章 设计任务………………………………………………………………………9

第3章 总体方案的确定………………………………………………………………9

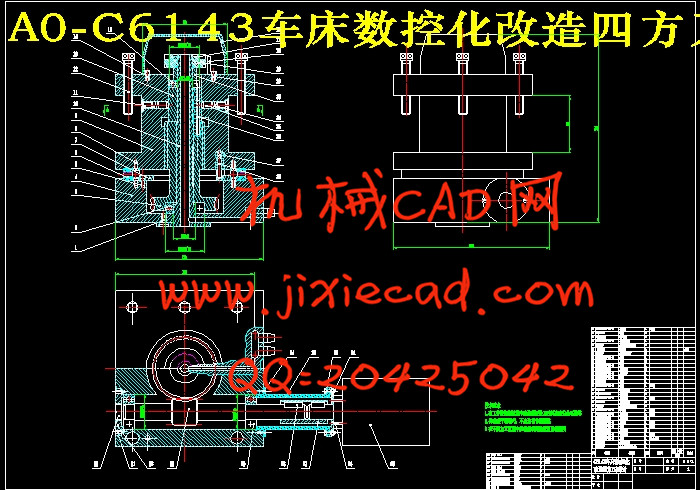

第4章.四方回转刀架部分设计与计算………………………………………10

第5章. 步进电动机的计算与选型………………………………………… 20

4.1步进电动机选用的基本原则………………………… ………………… 20

4.2步进电动机的选折……………………………… ……………………… 21

第6章.主轴交流伺服电机…………………………… …………………………22

5.1主轴的变速变速范围…………………………………………………… 22

5.2初选主轴电机的型号…………………………………………………… 22

5.3主轴电机的校核………………………………………………………… 22

结论…………………………………………………………………………… 29

参考文献………………………………………………………………………… 30

结合我国实际国情,经济型数控车床是我国从普通车床向数控车床发展的及其重要的台阶。利用现有的普通车床,对其进行数控化改造是一条低成本,高效益的途径。数控车床作为机电一体化的典型产品,在机械制造业中发挥着巨大的作用,很好地解决了现代机械制造中结构复杂、精密、批量小、多变零件的加工问题,且能稳定产品的加工质量,大幅度地提高生产效率。我国作为机床大国,数控机床的占有率还不足百分之三,但是在欧美等发达国家数控机床的占有率达到了百分之三十六以上,单从数字上来看我过和欧美等发达国家还有相当大的距离。其主要原因为数控车床价格较贵,一次性投资较大使企业心有余而力不足。对普通机床数控化改造不失为一种较好的良策。在金属加工行业中车床在所有加工设备中占有最大比重,例如最常见的轴类零件,就是由车床加工而成本论文针对目前国内企业现状,以C6143普通车床为例提出简易型经济数控改造思路和设计方法。

关键词:数控机床, 单片机数控系统,改装设计, 伺服电机 传动系统 控制系统 数控改造,

Abstract

To remedy the defects of ordinary lathe C6143, a design of data processing system and its single chip microcomputer system program is put forward to raise the processing precision and extend the machine’s usage, and to improve production rate。This paper presents the process of designing numerical control reform,and explicitly introduces the design of mechanical and numerical control system reforms。We adopt control system which has 8031 as cpu to cope with the signal,and output the step pulse through the I/O interface。After transmitting and slowing down by force 1 gear, the step pulses drive the leading screw to roll。Thus achieve the vertical movement and the crosswise movement。

China's actual conditions and economic CNC lathe is from the ordinary to the lathe and NC lathe important development stage.Use of existing ordinary lathe, NC transformation is its low cost and highly efficient way.CNC lathe as a typical electromechanical integration products, machinery manufacturing plays an enormous role,good solution to the structural complexity of modern machinery, precision, small batches, changeable parts processing,able to stabilize the quality of the processing products, a significant increase in production efficiency.As the big machine, CNC machine tools was less than 3.0% share.However, in Europe and the United States and other developed countries to achieve the 36% share of the CNC machine moreI can see from the figures over Europe and the United States and other developed countries there is still a considerable distance.The main reason for the higher prices of CNC lathe, a one-time investment to fill larger enterprises.CNC transformation of the ordinary would be a better process.Lathe in the metal processing industry accounts for the largest proportion of all processing equipment, for example, the most common shaft.Papers from the machining cost is the present status of domestic enterprises.Simple C6143 made to the general economic NC lathe ideas and design methods.

KEY WORDS: numerical control machine tool, single chip microcomputer system,reform design,The C6143 servo electrical machinery transmission system control system electricity control line economical numerical control changes

目录

摘要………………………………………………………………………………………2

Abstract………………………………………………………………………………3

第1章 绪论……………………………………………………………………………5

1.1 数控技术的产生和发展………………………………………………………5

1.2 数控机床的发展趋势…………………………………………………………6

1.3 车床数控改造的必要性与可行性……………………………………………8

第2章 设计任务………………………………………………………………………9

第3章 总体方案的确定………………………………………………………………9

第4章.四方回转刀架部分设计与计算………………………………………10

第5章. 步进电动机的计算与选型………………………………………… 20

4.1步进电动机选用的基本原则………………………… ………………… 20

4.2步进电动机的选折……………………………… ……………………… 21

第6章.主轴交流伺服电机…………………………… …………………………22

5.1主轴的变速变速范围…………………………………………………… 22

5.2初选主轴电机的型号…………………………………………………… 22

5.3主轴电机的校核………………………………………………………… 22

结论…………………………………………………………………………… 29

参考文献………………………………………………………………………… 30