设计简介

摘要

活性炭是一种无毒无味,具有发达细孔结构和巨大比表面积的优良吸附剂。因此,活性炭可以重新恢复吸附活性,重复使用,具有重要的意义。活性炭再生炉的功能是除去吸附的杂质,使活性炭重新恢复吸附活性。

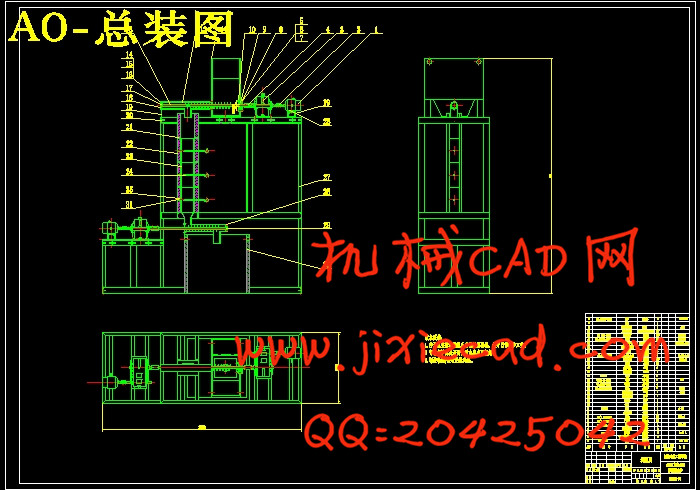

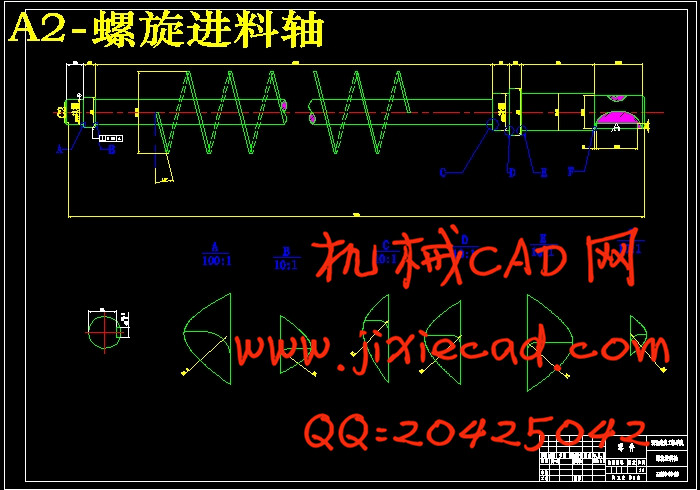

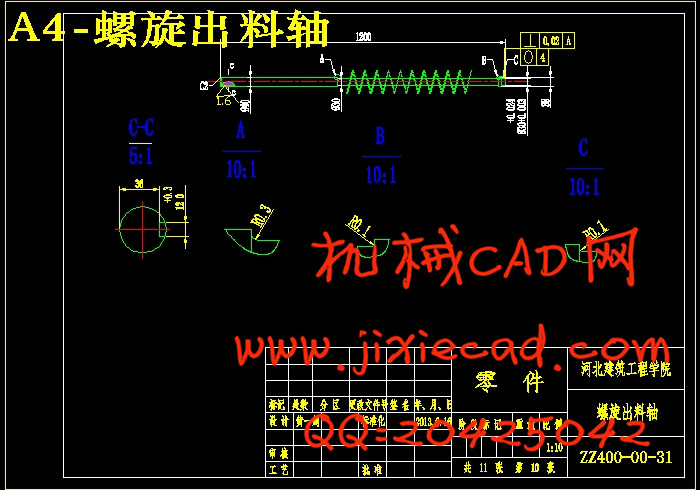

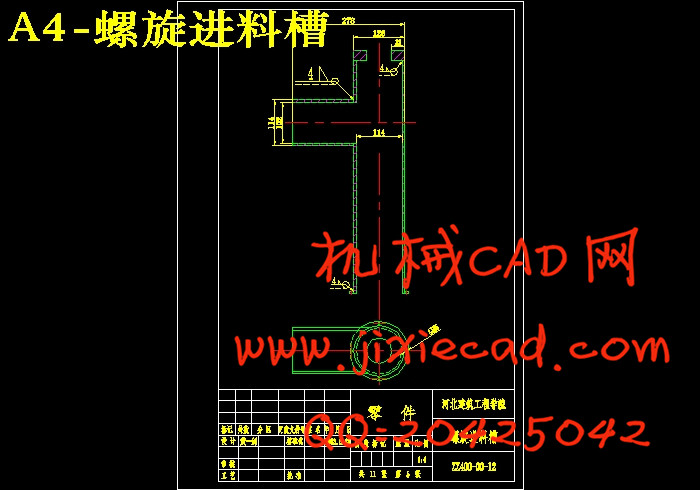

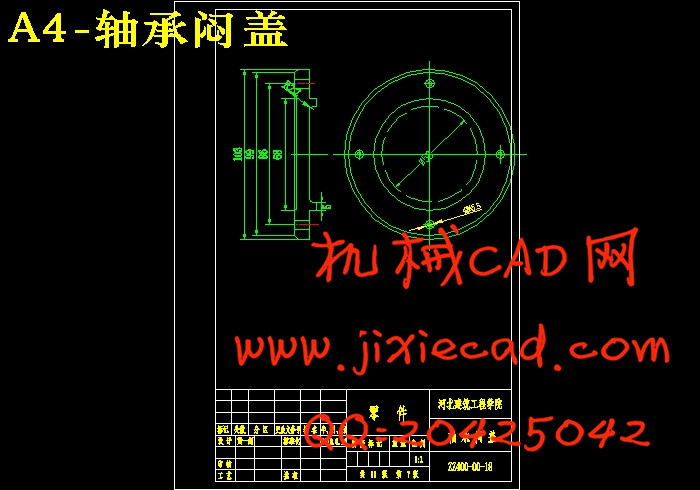

国内活性炭再生设备随着市场的需求向能耗低、效率高、活性炭损失少、再生效果好、性能参数可调、自动化程度高、规格种类较齐全的方向发展。直热式活性炭再生炉的主要组成有再生炉体、进料装置、出料装置、支架和辅助机构等。进料装置和出料装置的核心机构都是螺旋输送机。它控制着进料和出料的速度。由于本设计的难题之一是协调进料的速度和出料的速度两者之间的关系,而由两个同种型号的螺旋输送机控制速度就为解决这个问题提供了很大的方便。活性炭高温热再生方法是通过加热对活性炭进行热处理,使活性炭吸附的有机物在高温下活性炭化分解,最终成为气体逸出,从而使活性炭得到再生。高温加热再生在除去活性炭吸附有机物的同时,还可以除去沉积在活性炭表面的无机盐,而且使活性炭的新微孔生成,使活性炭的活性得到根本的恢复。直热式是利用活性炭的导电性和电阻性直接对活性炭进行加热升温,使杂质进行脱附。

本次设计主要是使活化前的活性炭能通过螺旋输送装置和料槽按既定的速度进入炉体,炉体通过支架能够固定和易于拆装和活化后的活性炭通过叶片均匀的进入冷却装置。

关键词: 活性炭 再生 再生炉 直热式

ABSTRACT

Activated carbon is a kind of non-toxic tasteless which has developed pore structure and huge specific surface area of the adsorbent. Therefore,It has the vital significance that makes the charcoal adsorption activity again. The function of activated carbon regeneration furnace is removal of adsorbed impurities that restores charcoal to adsorption activity.

Domestic activated carbon regeneration equipments along with the market demand to low energy consumption, high efficiency, less loss of activated carbon, regeneration effect is good, the performance parameters are adjustable, high degree of automation, specifications varieties complete.

Direct heat activated carbon regeneration furnace is made of regenerative furnace, feeding device, discharge device, support and auxiliary mechanism, etc. It is the core of the Feeding device and discharging device that is a screw conveyor. It controls the speed of the feeding and discharging. Because this design is one of the problems of coordination of feed speed and discharge rate, the relationship between the two by two of the same type of screw conveyor speed control provides a great convenience to solve the problem. High-temperature heat activated carbon regeneration method is by heating to heat treatment of activated carbon, activated carbon adsorption of organic compounds in high temperature carbonization decomposition, finally become gas escape, so that the regeneration of activated carbon. High temperature heating regeneration in the removal of carbon adsorption of organic compounds at the same time, also can remove deposition on the surface of the carbon, inorganic salt, and makes new microporous carbon generation, on the activity of carbon is fundamental recovery. Direct heat is to use activated carbon conductive and resistive to heat activated carbon directly to heat up, make the impurities for stripping.

This design mainly is to make before activation of activated carbon can through the screw conveyer and the discharge chute according to set speed into the furnace, the furnace can be fixed by stent and easy to tear open outfit and activation of activated carbon by blade evenly into the cooling unit.

KEY WORDS: activated carbon regeneration regeneration furnace directly-heated type

目录

第1章 前言··················································································1

第2章 活性炭···············································································2

2.1 活性炭的概念···········································································2

2.2 活性炭的分类···········································································2

2.3 活性炭的应用···········································································4

第3章 活性炭的再生·····································································6

3.1活性炭再生的意义······································································6

3.2活性炭再生的方法·······································································7

3.3高温加热再生的几种装置·····························································10

3.4 酸洗·····················································································23

第4章 直热式活性炭再生炉设计···················································25

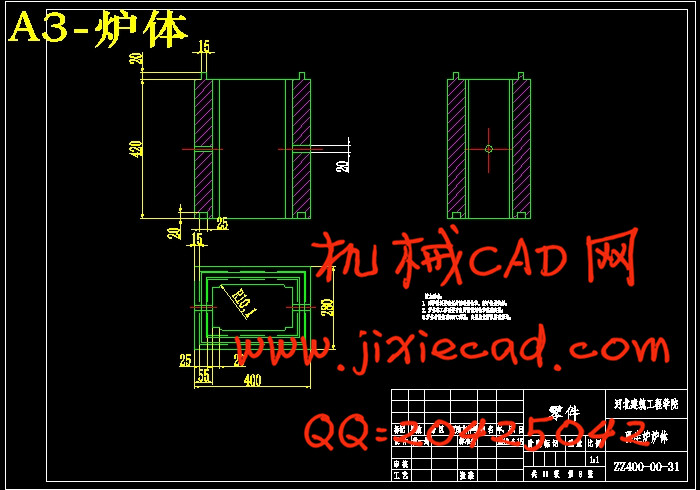

4.1炉体设计················································································25

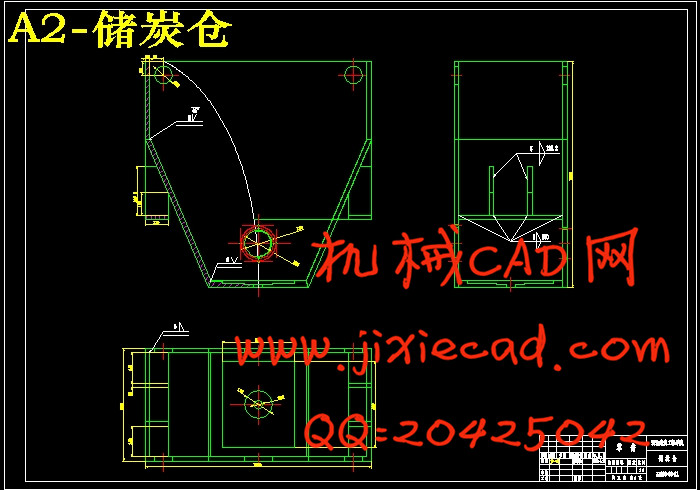

4.2进料部分设计··········································································27

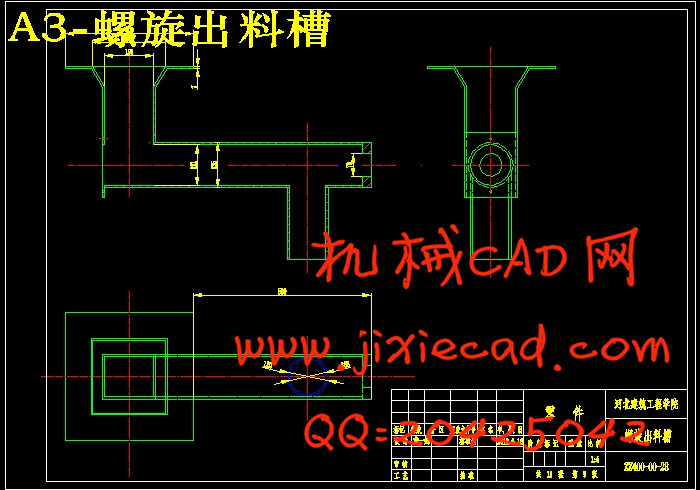

4.3 出料系统设计·········································································34

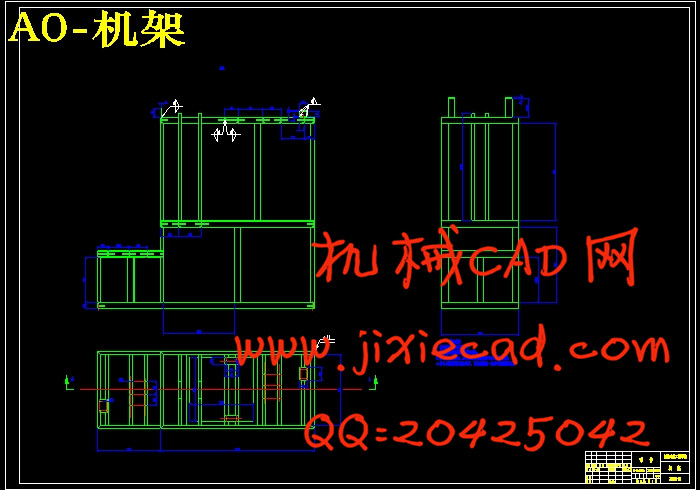

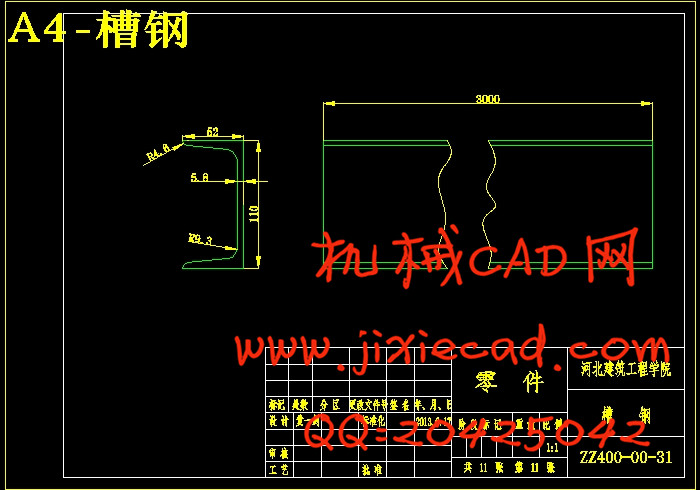

4.4 支架部·················································································35

4.5 辅助系统和操作·······································································36

第5章 活性炭再生评价································································36

5.1 再生效果··············································································36

5.2 再生次数··············································································37

第6章 设计小结··········································································38

参考文献·····················································································42

活性炭是一种无毒无味,具有发达细孔结构和巨大比表面积的优良吸附剂。因此,活性炭可以重新恢复吸附活性,重复使用,具有重要的意义。活性炭再生炉的功能是除去吸附的杂质,使活性炭重新恢复吸附活性。

国内活性炭再生设备随着市场的需求向能耗低、效率高、活性炭损失少、再生效果好、性能参数可调、自动化程度高、规格种类较齐全的方向发展。直热式活性炭再生炉的主要组成有再生炉体、进料装置、出料装置、支架和辅助机构等。进料装置和出料装置的核心机构都是螺旋输送机。它控制着进料和出料的速度。由于本设计的难题之一是协调进料的速度和出料的速度两者之间的关系,而由两个同种型号的螺旋输送机控制速度就为解决这个问题提供了很大的方便。活性炭高温热再生方法是通过加热对活性炭进行热处理,使活性炭吸附的有机物在高温下活性炭化分解,最终成为气体逸出,从而使活性炭得到再生。高温加热再生在除去活性炭吸附有机物的同时,还可以除去沉积在活性炭表面的无机盐,而且使活性炭的新微孔生成,使活性炭的活性得到根本的恢复。直热式是利用活性炭的导电性和电阻性直接对活性炭进行加热升温,使杂质进行脱附。

本次设计主要是使活化前的活性炭能通过螺旋输送装置和料槽按既定的速度进入炉体,炉体通过支架能够固定和易于拆装和活化后的活性炭通过叶片均匀的进入冷却装置。

关键词: 活性炭 再生 再生炉 直热式

ABSTRACT

Activated carbon is a kind of non-toxic tasteless which has developed pore structure and huge specific surface area of the adsorbent. Therefore,It has the vital significance that makes the charcoal adsorption activity again. The function of activated carbon regeneration furnace is removal of adsorbed impurities that restores charcoal to adsorption activity.

Domestic activated carbon regeneration equipments along with the market demand to low energy consumption, high efficiency, less loss of activated carbon, regeneration effect is good, the performance parameters are adjustable, high degree of automation, specifications varieties complete.

Direct heat activated carbon regeneration furnace is made of regenerative furnace, feeding device, discharge device, support and auxiliary mechanism, etc. It is the core of the Feeding device and discharging device that is a screw conveyor. It controls the speed of the feeding and discharging. Because this design is one of the problems of coordination of feed speed and discharge rate, the relationship between the two by two of the same type of screw conveyor speed control provides a great convenience to solve the problem. High-temperature heat activated carbon regeneration method is by heating to heat treatment of activated carbon, activated carbon adsorption of organic compounds in high temperature carbonization decomposition, finally become gas escape, so that the regeneration of activated carbon. High temperature heating regeneration in the removal of carbon adsorption of organic compounds at the same time, also can remove deposition on the surface of the carbon, inorganic salt, and makes new microporous carbon generation, on the activity of carbon is fundamental recovery. Direct heat is to use activated carbon conductive and resistive to heat activated carbon directly to heat up, make the impurities for stripping.

This design mainly is to make before activation of activated carbon can through the screw conveyer and the discharge chute according to set speed into the furnace, the furnace can be fixed by stent and easy to tear open outfit and activation of activated carbon by blade evenly into the cooling unit.

KEY WORDS: activated carbon regeneration regeneration furnace directly-heated type

目录

第1章 前言··················································································1

第2章 活性炭···············································································2

2.1 活性炭的概念···········································································2

2.2 活性炭的分类···········································································2

2.3 活性炭的应用···········································································4

第3章 活性炭的再生·····································································6

3.1活性炭再生的意义······································································6

3.2活性炭再生的方法·······································································7

3.3高温加热再生的几种装置·····························································10

3.4 酸洗·····················································································23

第4章 直热式活性炭再生炉设计···················································25

4.1炉体设计················································································25

4.2进料部分设计··········································································27

4.3 出料系统设计·········································································34

4.4 支架部·················································································35

4.5 辅助系统和操作·······································································36

第5章 活性炭再生评价································································36

5.1 再生效果··············································································36

5.2 再生次数··············································································37

第6章 设计小结··········································································38

参考文献·····················································································42