设计简介

摘要

本课题中所研究的物流分拣系统是一种十分先进而高效的设备,它不但提高了物流分拣的效率、速度而且还提高了分拣工作的正确率。设计本课题的目的在于实现物流分拣的自动化,提高工作效率和准确率,节省人工的成本并降低作业成本。

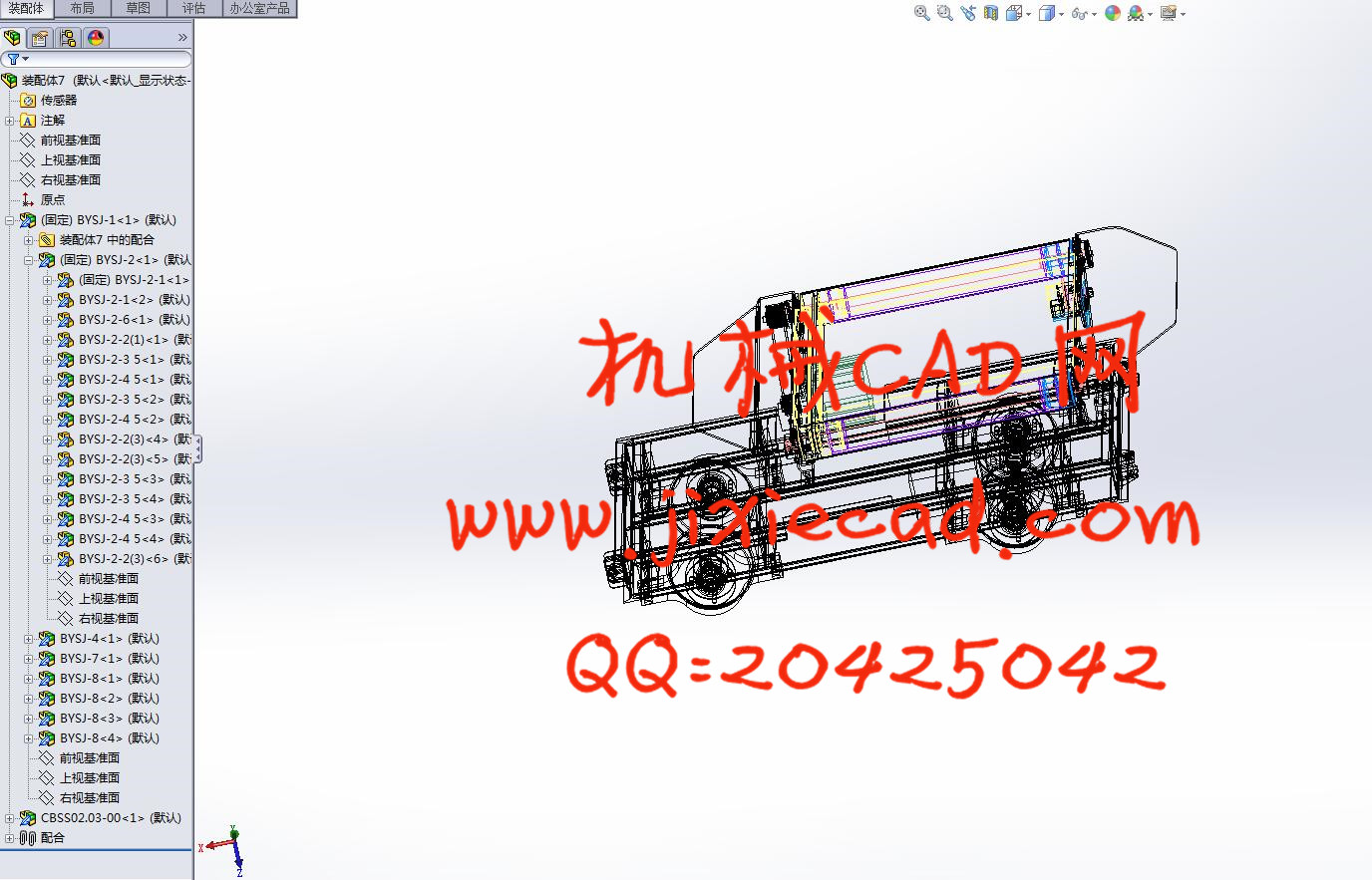

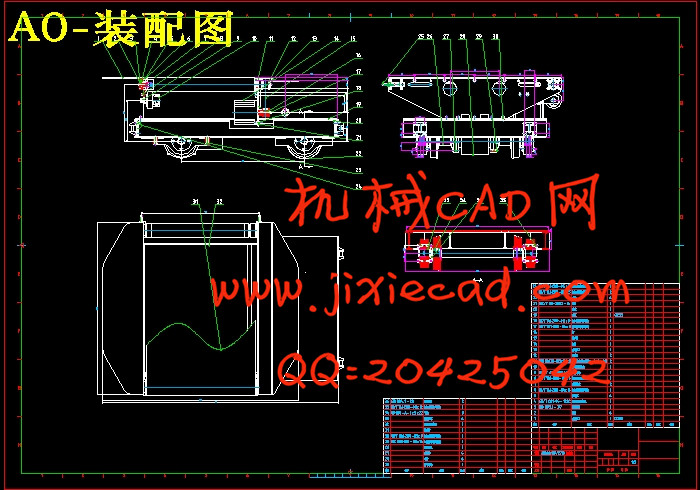

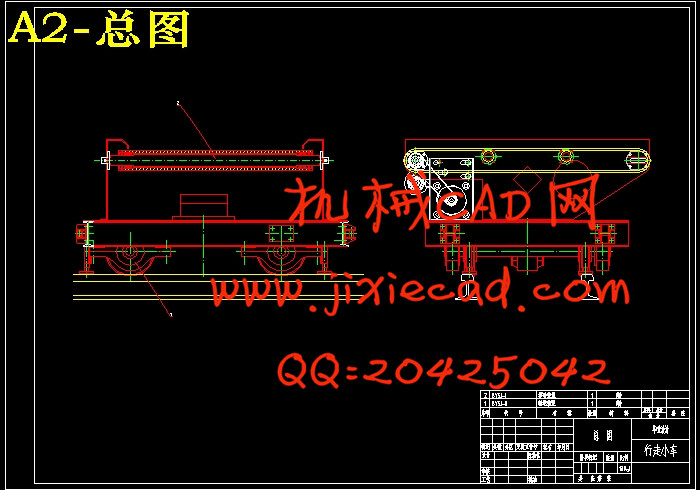

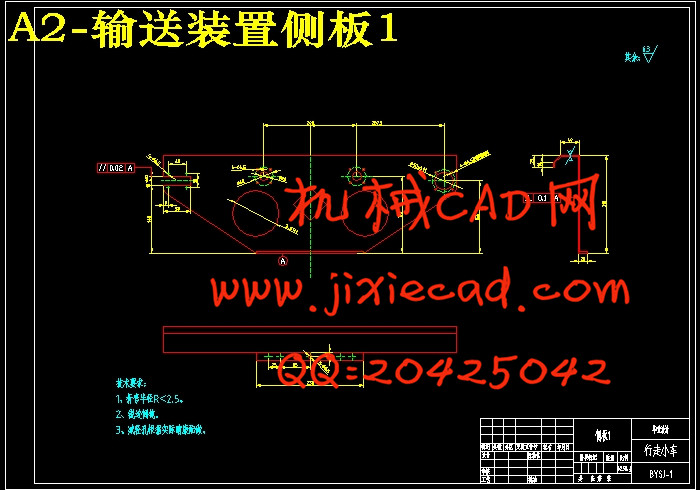

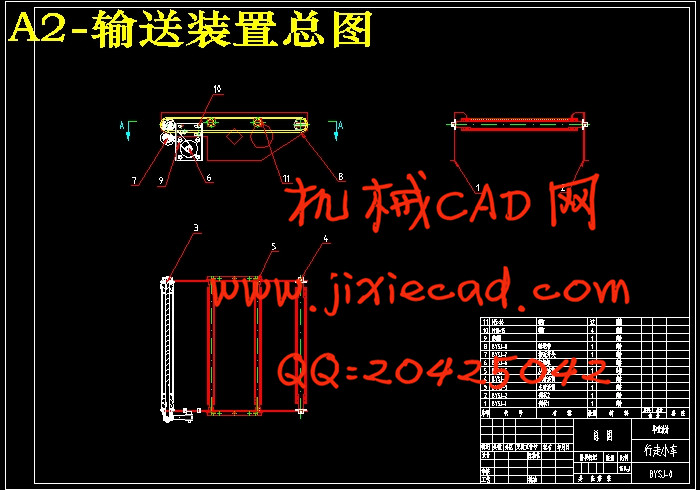

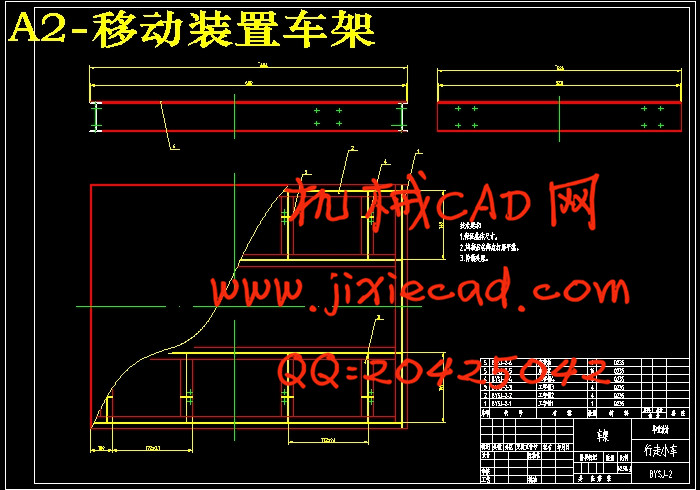

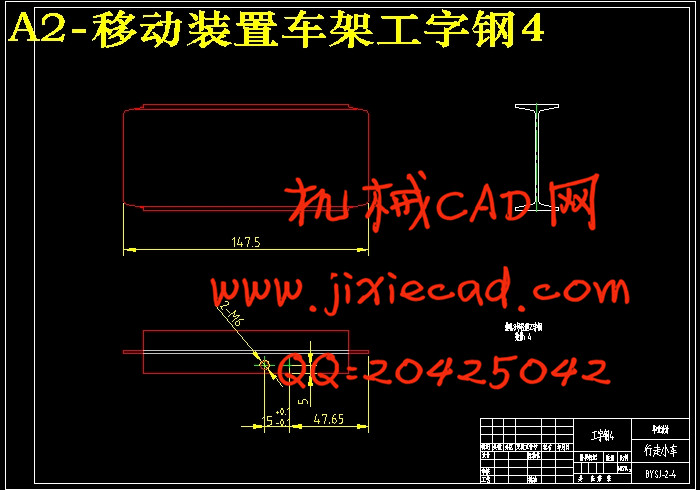

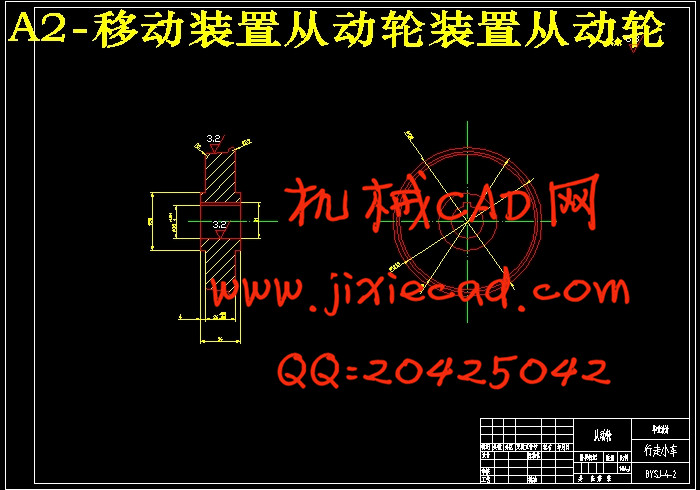

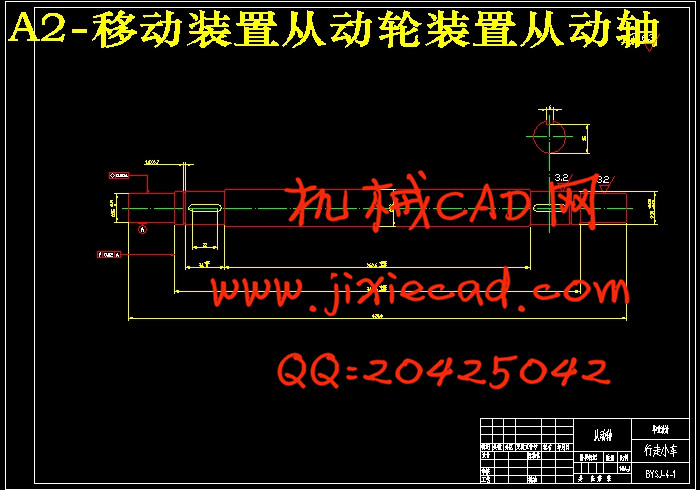

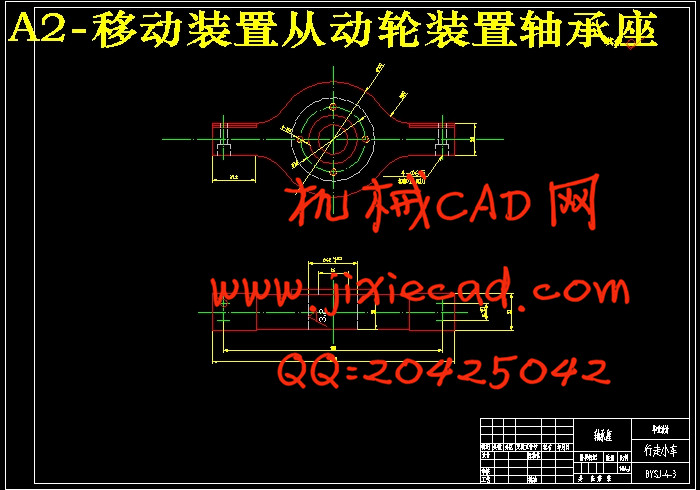

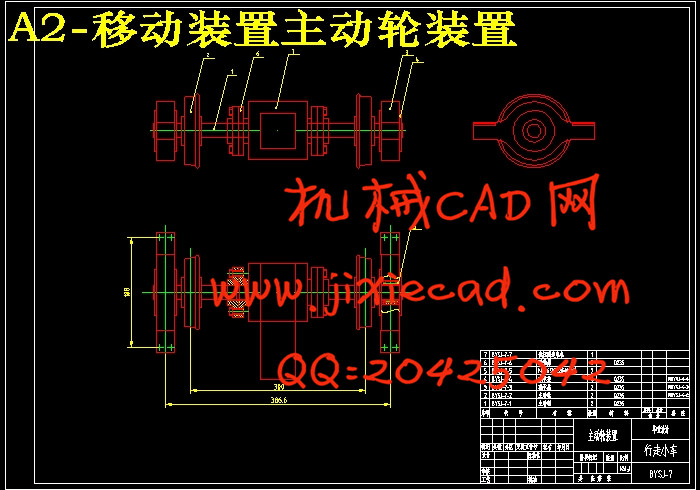

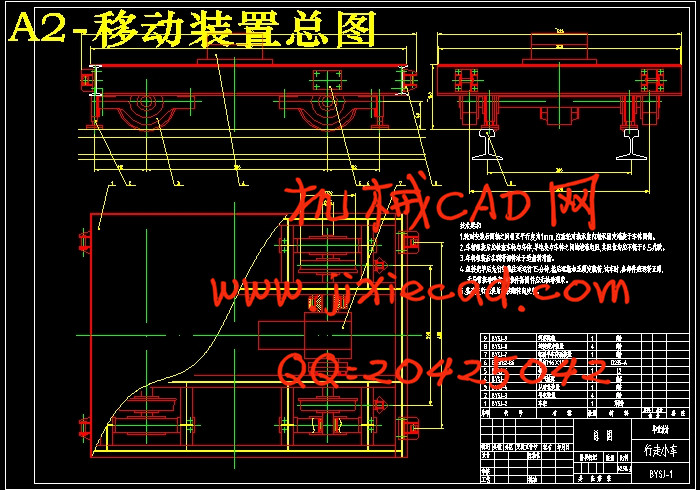

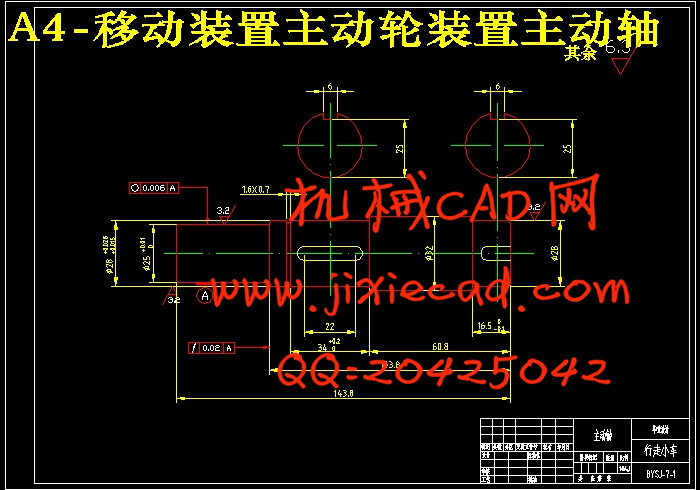

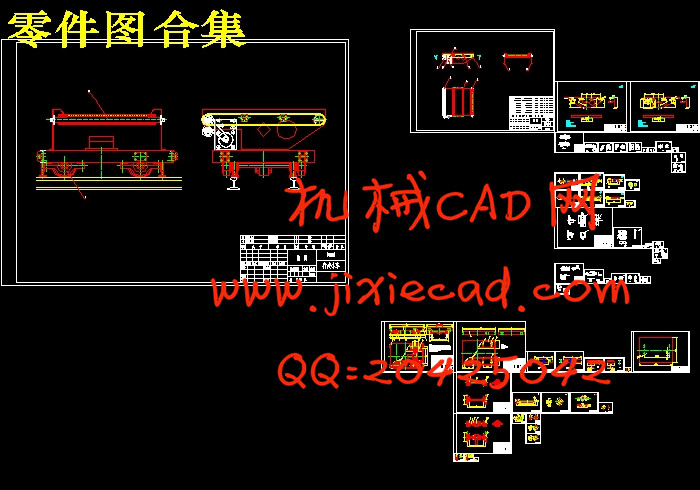

设计中的行走小车,是物流分拣系统中快件传送的一个环节,用于完成快件从上包机至分拣通道之间的传输工作。整个输送过程是由程序控制的,从而达成了节省人工以及作业成本的目标。

关键词:程序 高效 正确率 自动化 节省

目 录

第一章 绪论··············································1

第二章 物流分拣系统·······································1

2.1物流分拣系统综述······································1

2.2国内外分拣系统应用现状及趋势··························4

2.3物流分拣系统的组成····································7

2.4物流分拣系统的特点····································9

2.5物流分拣系统的适用条件································10

2.6物流分拣系统的分类····································11

第三章 方案的确定·······································14

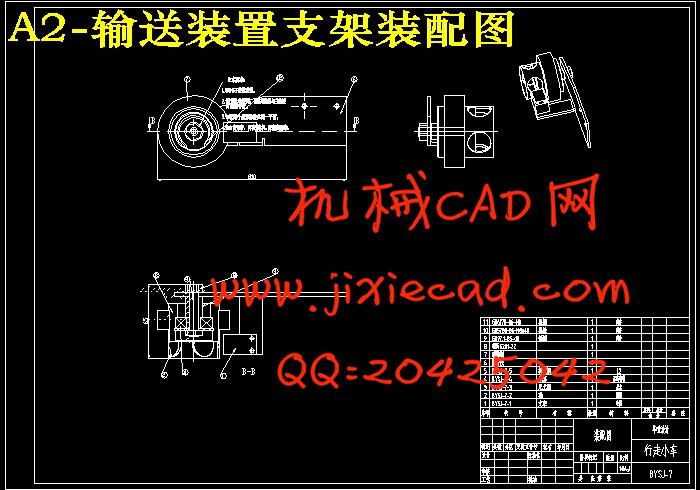

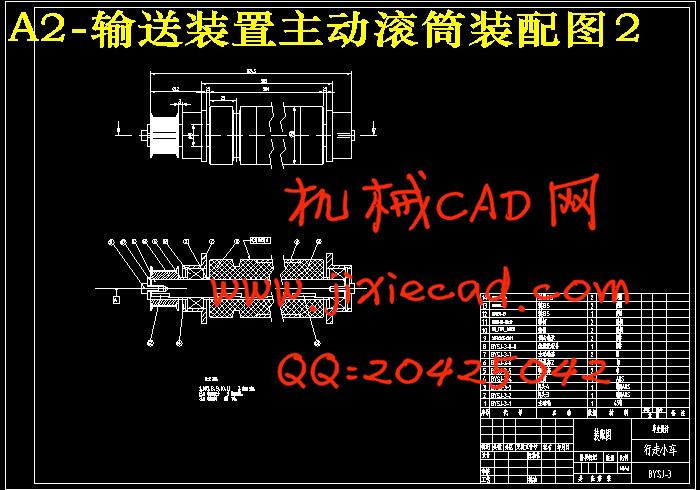

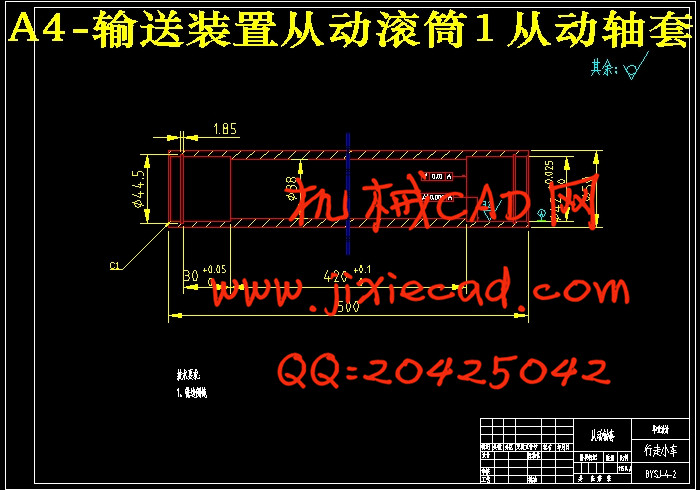

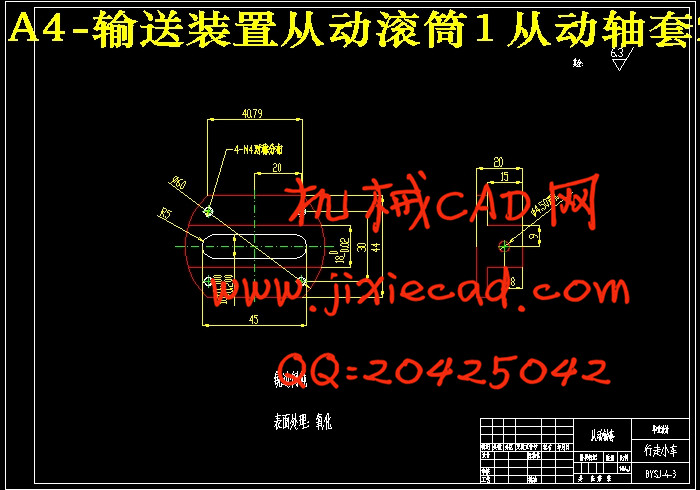

3.1小车上的输送装置(带式输送机)························14

3.1.1带式输送机的分类·································14

3.2.2带式输送机的结构及布置方式·······················15

3.1.3输送带的分类·····································15

3.1.4输送带的选择·····································18

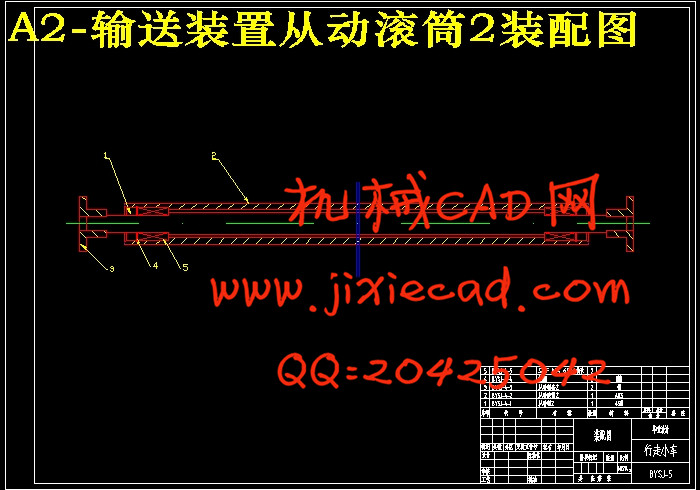

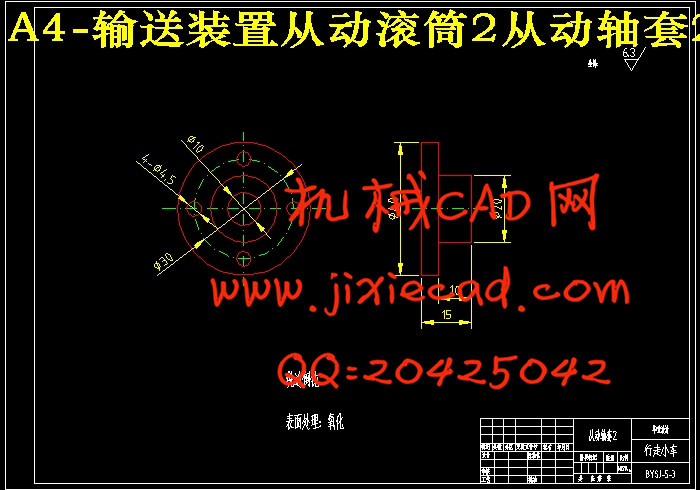

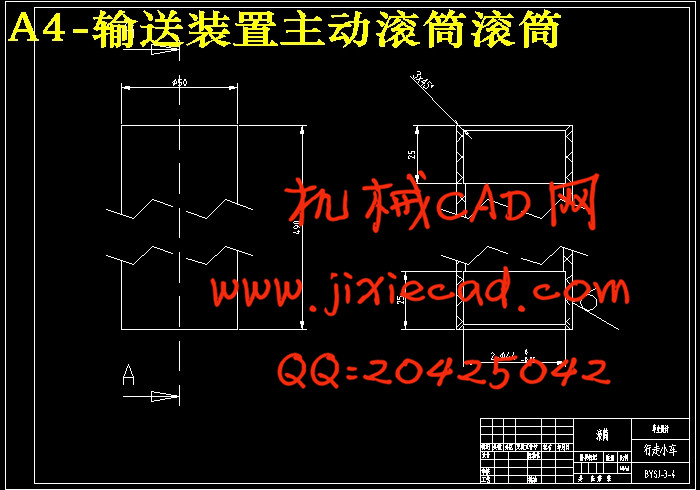

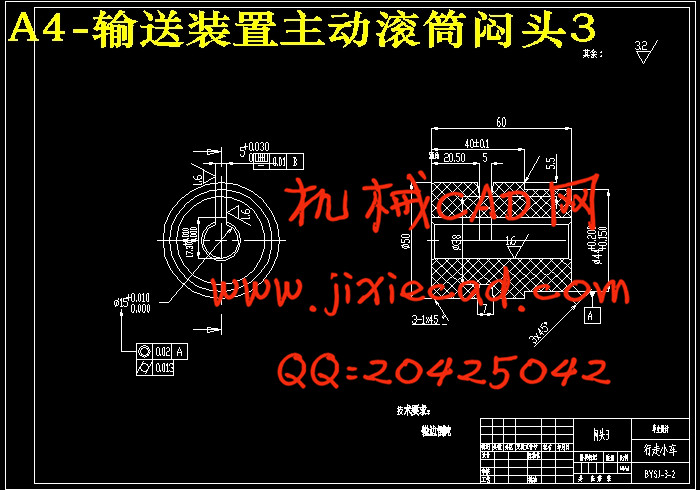

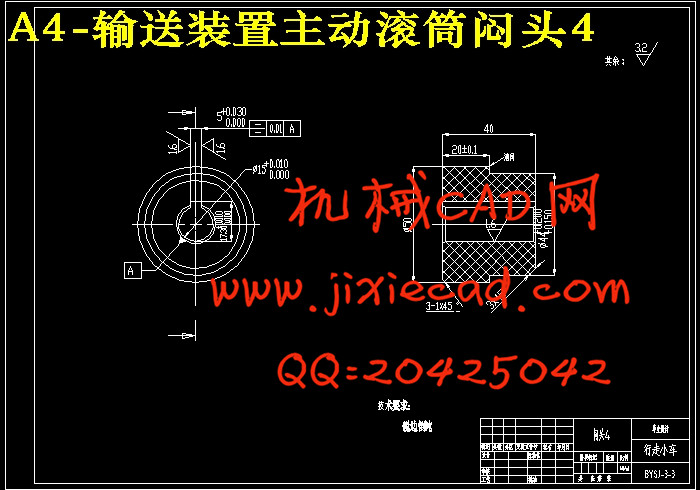

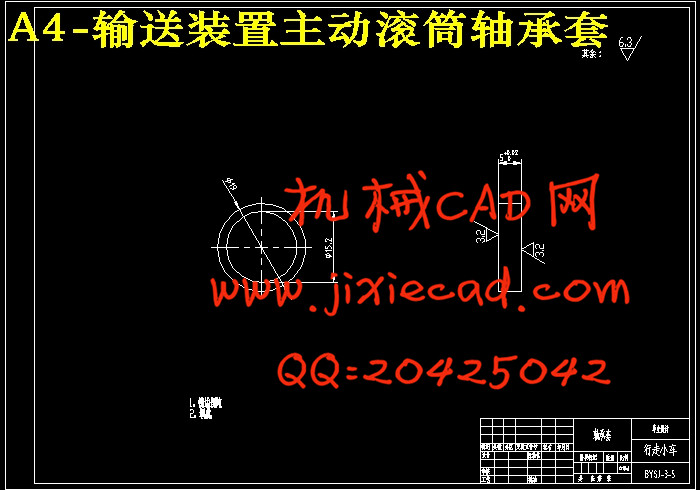

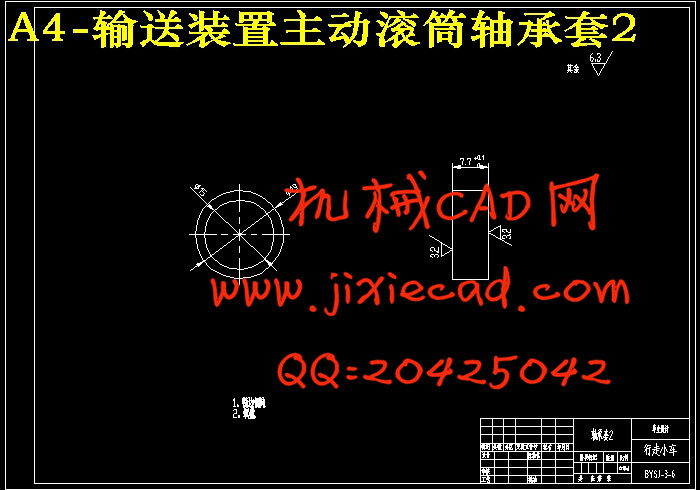

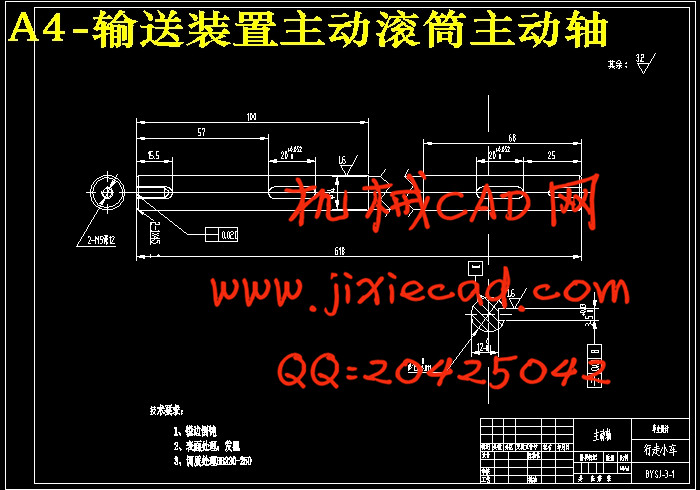

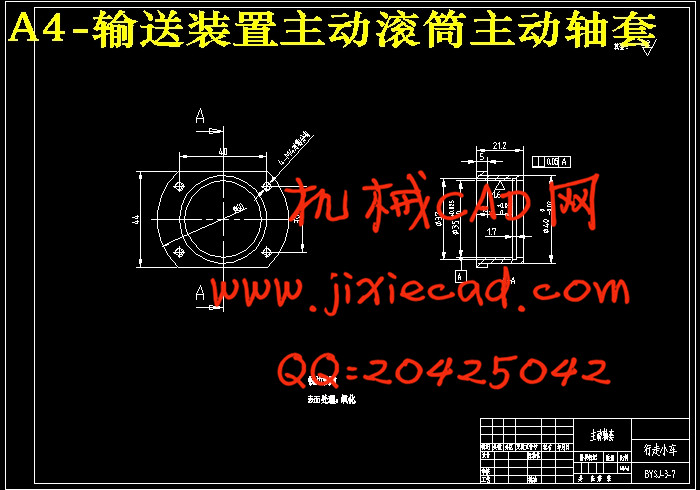

3.1.5带式输送机中的托辊和滚筒·························19

3.1.6托辊的选择·······································20

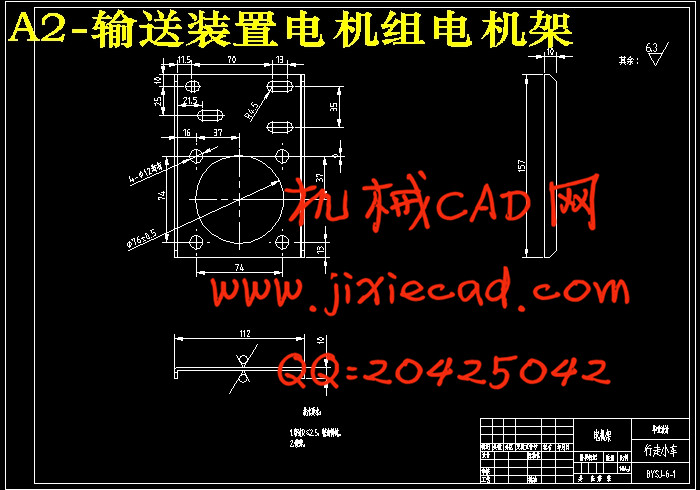

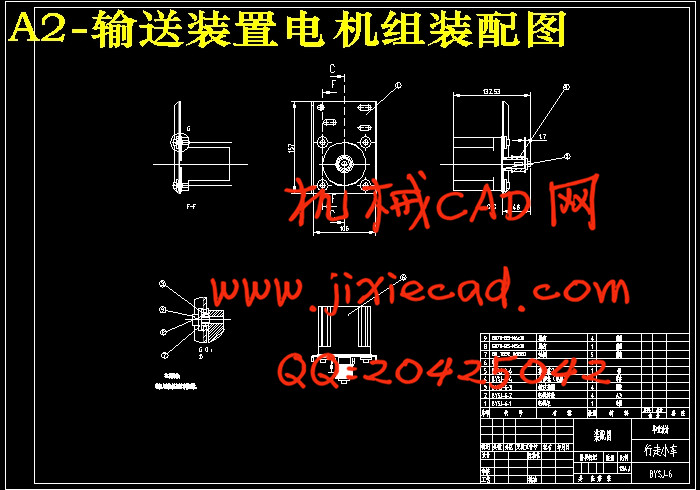

3.2带式输送机中的电机····································21

3.2.1电机综述·········································21

3.2.2电机的分类······································22

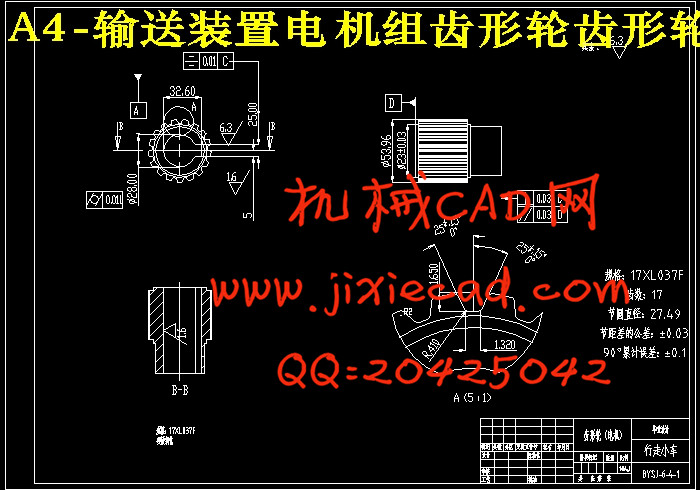

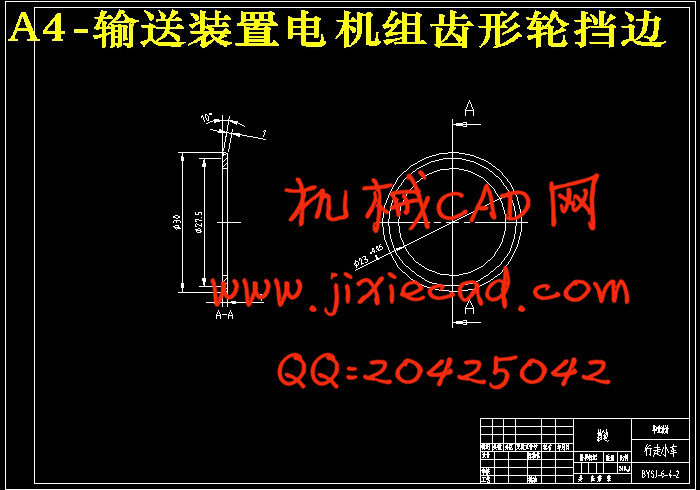

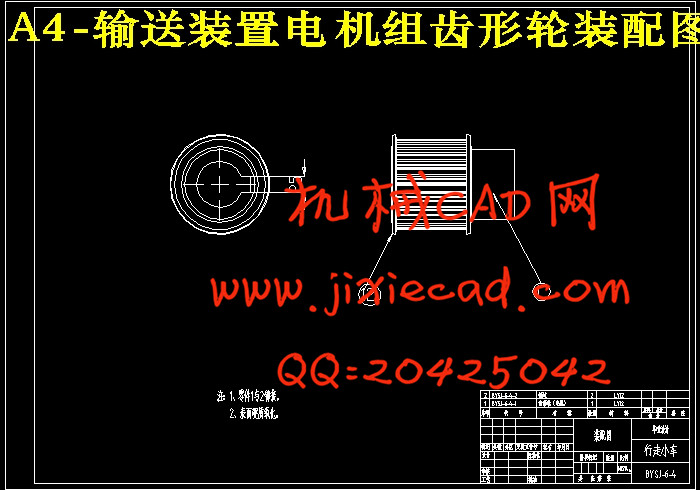

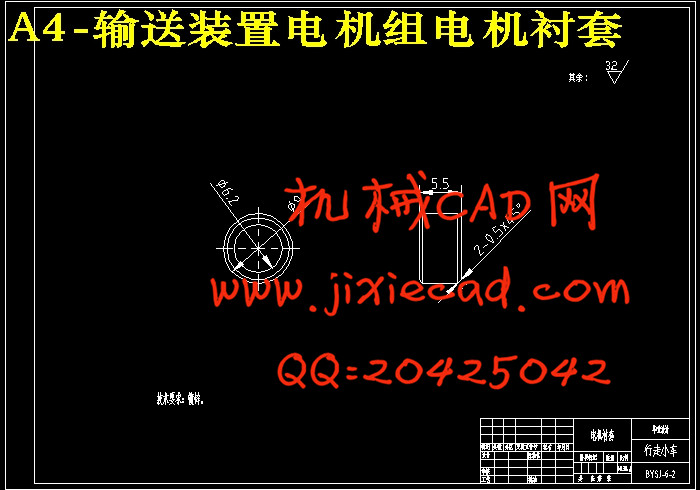

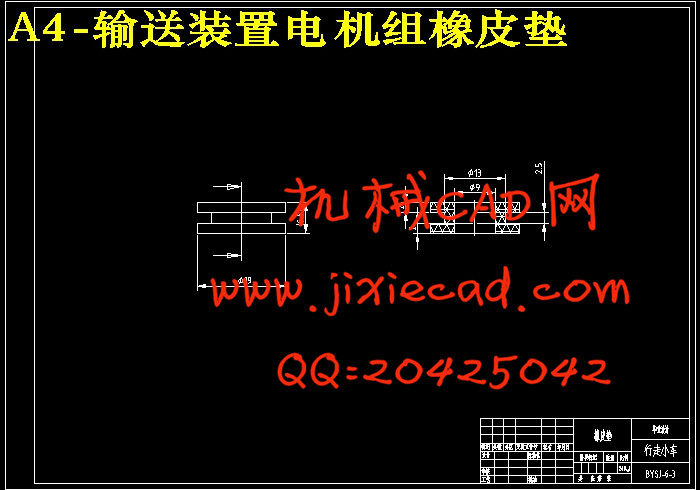

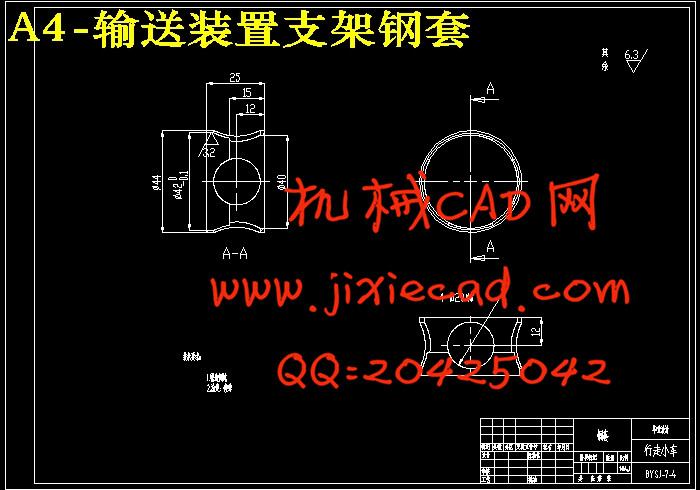

3.2.3设计中输送装置电机的选择························22

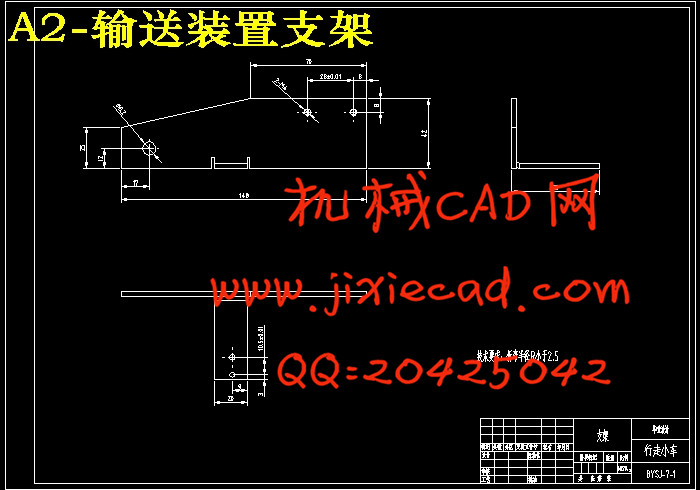

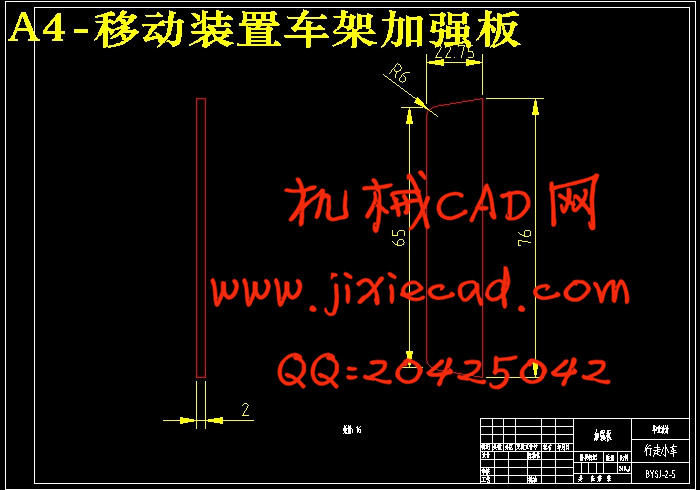

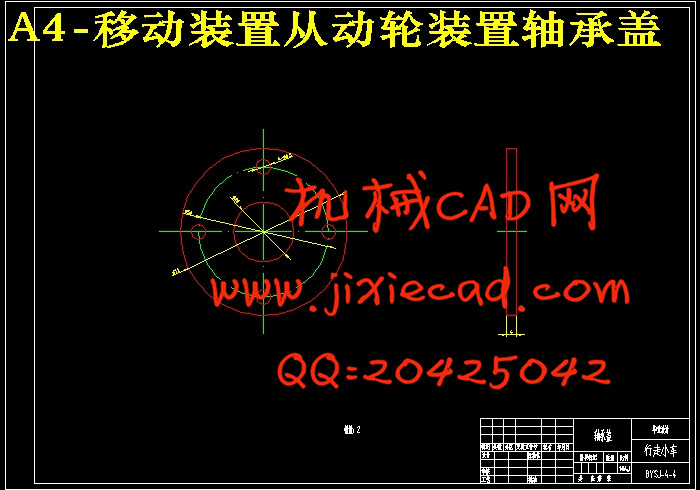

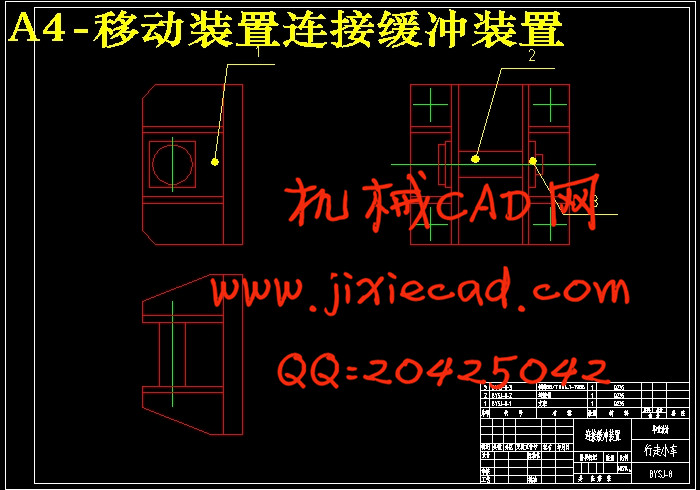

3.3小车的运动部件·······································24

3.3.1电动机···········································24

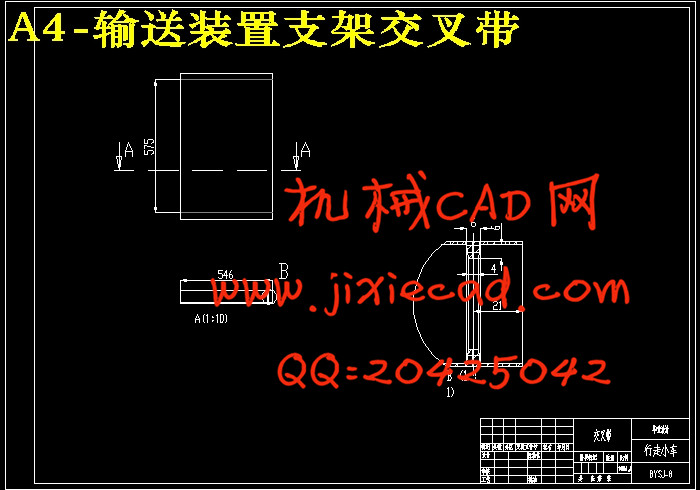

3.3.2行走小车的传动带································24

3.3.3小车运动导轨与轮子······························25

第四章 零件的选型·······································26

4.1带式输送机的电机选型··································26

4.2小车运动部件的电机选型································27

第五章 致谢·············································30

参考文献·················································31

本课题中所研究的物流分拣系统是一种十分先进而高效的设备,它不但提高了物流分拣的效率、速度而且还提高了分拣工作的正确率。设计本课题的目的在于实现物流分拣的自动化,提高工作效率和准确率,节省人工的成本并降低作业成本。

设计中的行走小车,是物流分拣系统中快件传送的一个环节,用于完成快件从上包机至分拣通道之间的传输工作。整个输送过程是由程序控制的,从而达成了节省人工以及作业成本的目标。

关键词:程序 高效 正确率 自动化 节省

目 录

第一章 绪论··············································1

第二章 物流分拣系统·······································1

2.1物流分拣系统综述······································1

2.2国内外分拣系统应用现状及趋势··························4

2.3物流分拣系统的组成····································7

2.4物流分拣系统的特点····································9

2.5物流分拣系统的适用条件································10

2.6物流分拣系统的分类····································11

第三章 方案的确定·······································14

3.1小车上的输送装置(带式输送机)························14

3.1.1带式输送机的分类·································14

3.2.2带式输送机的结构及布置方式·······················15

3.1.3输送带的分类·····································15

3.1.4输送带的选择·····································18

3.1.5带式输送机中的托辊和滚筒·························19

3.1.6托辊的选择·······································20

3.2带式输送机中的电机····································21

3.2.1电机综述·········································21

3.2.2电机的分类······································22

3.2.3设计中输送装置电机的选择························22

3.3小车的运动部件·······································24

3.3.1电动机···········································24

3.3.2行走小车的传动带································24

3.3.3小车运动导轨与轮子······························25

第四章 零件的选型·······································26

4.1带式输送机的电机选型··································26

4.2小车运动部件的电机选型································27

第五章 致谢·············································30

参考文献·················································31