设计简介

摘 要

轴承是当代机械设备中一种举足轻重的零部件,它们广泛应用于工业、农业、交通运输、国防、航空航天、家用电器、办公机械和高科技等领域,与国计民生息息相关。为了保证轴承质量必须对其进行严格的检测。国内现有的轴承检测装置一般多为国内几大轴承研究所的产品,具有检测精度高、机构简单、操作方便等特点,但是现有的轴承检测装置一般只能进行单个轴承检测,检测效率很低。这必然不能满足轴承厂家对轴承全产品检测的要求。这种方式也必然给轴承的质量留下了安全隐患。因此,为了满足轴承全产品检测的要求,研制一种检测效率高、基本实现自动化的轴承检测装置显得越来越重要。

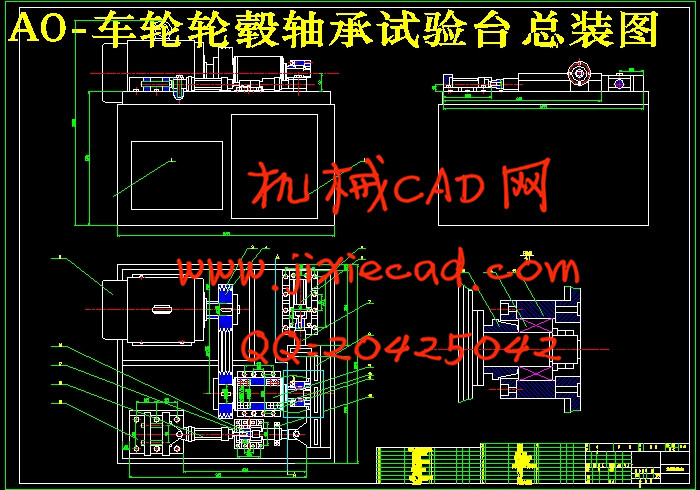

因此,轴承检测装置的外观设计是否先进,将直接影响到轴承产品质量的准确性、可靠性、效率以及工人劳动强度的大小。所以本文的重点是汽车轮毂轴承总成的性能试验台进行了设计。设计工作内容如下:

1)查阅国内外轴承检测设备发展情况,研究了国内外目前使用的轴承检测装置的机构特点,对汽车轮毂轴承试验台进行了总体方案设计;

2)针对论文的要求及总体设计方案思想,设计了该汽车汽车轮毂轴承试验台的驱动系统、加载系统以及测试控制系统;

关键词:汽车轮毂轴承;轴承性能测试;加载驱动系统;测试控制系统

Abstract

The bearings are an important parts of modern machinery and equipment , they are widely used in industry, agriculture, transportation, defense, aerospace, household appliances, office machinery and high-tech fields, closely related to the people's livelihood . In order to ensure the quality of the bearings must be rigorous testing .The existing bearing inspection device for the products of several major domestic Bearing Research Institute , with a high precision mechanism is simple , easy to operate , but the existing bearing inspection device generally only a single bearing detection , detection efficiency is low .This certainly can not meet the bearing manufacturers bearing product testing requirements , the domestic bearing factory detection sampling , this approach also inevitably left a security risk to the quality of the bearing . Therefore, in order to meet the testing requirements of the bearing , the development of a high detection efficiency , bearing inspection device for the basic realization of automation is becoming more and more important .

Therefore, bearing inspection device design is advanced , will directly affect the size of the bearing product quality , accuracy , reliability , efficiency and labor intensity . Therefore, this article focuses on automotive wheel bearing assembly performance test bed has been designed.. Designed to operate as follows :

1) access to domestic and international developments bearing testing equipment to study the characteristics of institutions at home and abroad bearing detection device currently used for automotive wheel bearing test rig were overall program design;

2) requirements and overall design ideas for the paper, the design of the automobile automotive wheel bearing test rig drive system, loading system and test the control system;

Keywords: automotive wheel bearings; bearing performance test;

loading drive system; test control system

目 录

摘要··············································································I

Abstract ·········································································II

第一章 绪论·····································································1

1.1 引言································································1

1.2 汽车轮毂的轴承的发展及研究现状·····························2

1.3汽车轮毂轴承检测技术国内外研究状况························4

1.5本课题的主要研究内容和要求····································5

第二章 汽车轮毂轴承总成性能试验台的总体方案设计·····················6

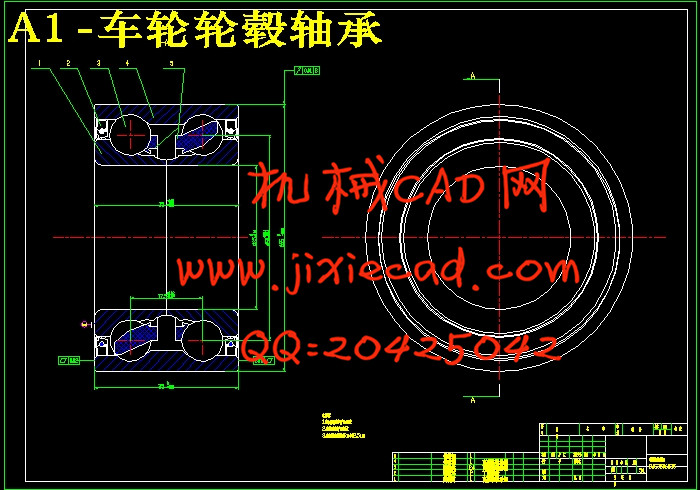

2.1汽车轮毂轴承的概述··············································6

2.1 设计要求···························································6

2.2总体方案设计······················································6

第三章 汽车轮毂轴承总成性能试验台驱动系统的设计·····················9

3.1驱动的选择·························································9

3.2带的传动设计······················································9

第四章 汽车轮毂轴承总成性能试验台加载系统的设计·····················12

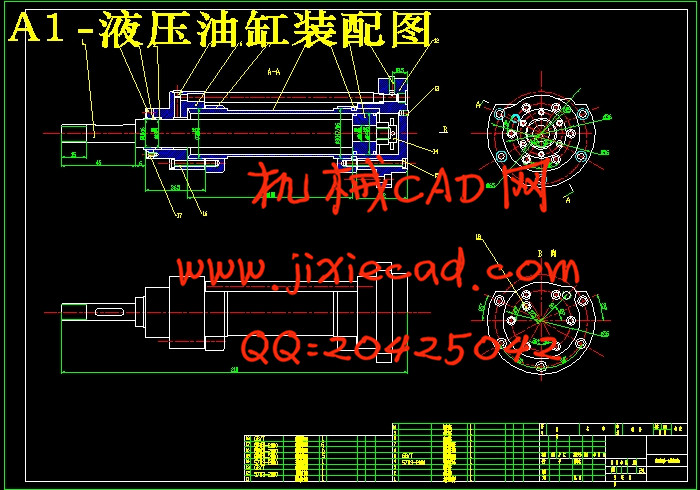

4.1加载的选择························································12

4.2加载系统的设计···················································12

第五章 汽车轮毂轴承总成性能试验台测试控制系统的设计················16

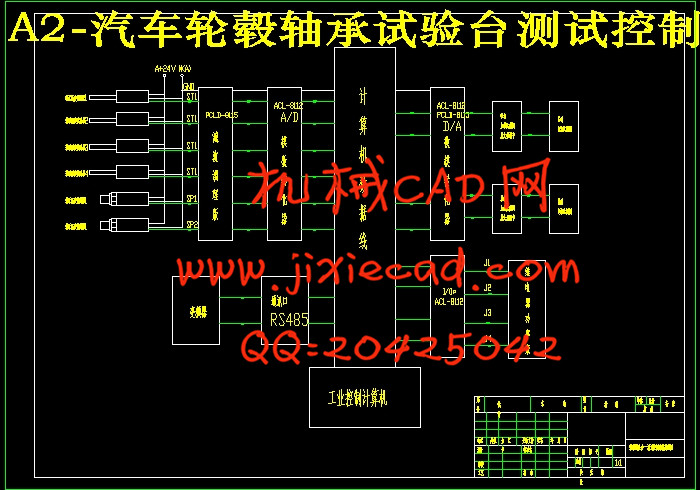

4.1测试控制技术的选择··············································16

4.2测试参数···························································16

4.2测试控制系统的设计··············································17

参考文献·········································································19

结束语············································································20

致谢···············································································21

轴承是当代机械设备中一种举足轻重的零部件,它们广泛应用于工业、农业、交通运输、国防、航空航天、家用电器、办公机械和高科技等领域,与国计民生息息相关。为了保证轴承质量必须对其进行严格的检测。国内现有的轴承检测装置一般多为国内几大轴承研究所的产品,具有检测精度高、机构简单、操作方便等特点,但是现有的轴承检测装置一般只能进行单个轴承检测,检测效率很低。这必然不能满足轴承厂家对轴承全产品检测的要求。这种方式也必然给轴承的质量留下了安全隐患。因此,为了满足轴承全产品检测的要求,研制一种检测效率高、基本实现自动化的轴承检测装置显得越来越重要。

因此,轴承检测装置的外观设计是否先进,将直接影响到轴承产品质量的准确性、可靠性、效率以及工人劳动强度的大小。所以本文的重点是汽车轮毂轴承总成的性能试验台进行了设计。设计工作内容如下:

1)查阅国内外轴承检测设备发展情况,研究了国内外目前使用的轴承检测装置的机构特点,对汽车轮毂轴承试验台进行了总体方案设计;

2)针对论文的要求及总体设计方案思想,设计了该汽车汽车轮毂轴承试验台的驱动系统、加载系统以及测试控制系统;

关键词:汽车轮毂轴承;轴承性能测试;加载驱动系统;测试控制系统

Abstract

The bearings are an important parts of modern machinery and equipment , they are widely used in industry, agriculture, transportation, defense, aerospace, household appliances, office machinery and high-tech fields, closely related to the people's livelihood . In order to ensure the quality of the bearings must be rigorous testing .The existing bearing inspection device for the products of several major domestic Bearing Research Institute , with a high precision mechanism is simple , easy to operate , but the existing bearing inspection device generally only a single bearing detection , detection efficiency is low .This certainly can not meet the bearing manufacturers bearing product testing requirements , the domestic bearing factory detection sampling , this approach also inevitably left a security risk to the quality of the bearing . Therefore, in order to meet the testing requirements of the bearing , the development of a high detection efficiency , bearing inspection device for the basic realization of automation is becoming more and more important .

Therefore, bearing inspection device design is advanced , will directly affect the size of the bearing product quality , accuracy , reliability , efficiency and labor intensity . Therefore, this article focuses on automotive wheel bearing assembly performance test bed has been designed.. Designed to operate as follows :

1) access to domestic and international developments bearing testing equipment to study the characteristics of institutions at home and abroad bearing detection device currently used for automotive wheel bearing test rig were overall program design;

2) requirements and overall design ideas for the paper, the design of the automobile automotive wheel bearing test rig drive system, loading system and test the control system;

Keywords: automotive wheel bearings; bearing performance test;

loading drive system; test control system

目 录

摘要··············································································I

Abstract ·········································································II

第一章 绪论·····································································1

1.1 引言································································1

1.2 汽车轮毂的轴承的发展及研究现状·····························2

1.3汽车轮毂轴承检测技术国内外研究状况························4

1.5本课题的主要研究内容和要求····································5

第二章 汽车轮毂轴承总成性能试验台的总体方案设计·····················6

2.1汽车轮毂轴承的概述··············································6

2.1 设计要求···························································6

2.2总体方案设计······················································6

第三章 汽车轮毂轴承总成性能试验台驱动系统的设计·····················9

3.1驱动的选择·························································9

3.2带的传动设计······················································9

第四章 汽车轮毂轴承总成性能试验台加载系统的设计·····················12

4.1加载的选择························································12

4.2加载系统的设计···················································12

第五章 汽车轮毂轴承总成性能试验台测试控制系统的设计················16

4.1测试控制技术的选择··············································16

4.2测试参数···························································16

4.2测试控制系统的设计··············································17

参考文献·········································································19

结束语············································································20

致谢···············································································21