设计简介

摘 要

随着社会的进步、科技日新月异,18世纪60年代工业革命时期生产线主要以蒸汽机为动力,到现在已经发展成了全自动化大批量生产。可以说现代工业已经离不开自动化的生产线了,自动化生产线不仅可以大幅度地提高生产效率,而且还可以提高精度、提高合格率、减轻人的工作量等好处。传统的单片机等电器控制技术有很多功能无法实现,在工业如此发达的今天,生产线控制系统逐渐地被PLC控制代替。

针对我国一些小型企业的配料生产线控制系统现状,本文将Siemens S7-200系列的PLC应用于小型的配料生产线,再由组态王制作人机交互的界面,作为监控系统实现实时监控功能。运用与S7-200系列PLC相配的STEP7编程,从而使该配料系统可以按要求完成自动配料,装料全过程。

本文的主要内容包括对生产过程控制系统发展和现状的概述、配料系统工作原理和配料控制系统的总体设计,重点描述了包括硬件设计、软件编程设计在内的S7-200 PLC在配料系统中的详细步骤、组态王监控系统中一些基本设计,以及PLC与组态王之间的通讯。本设计通过合理的选择和编程,提高了配料生产线的生产效率,降低了成本,并且提高了系统安全可靠性。

关键词:配料;PLC;组态王;自动控制

ABSTRACT

With the progress of society and the great changes of science and technology, from the 1760s when the steam engine is acted as the main power of the beginning of the industrial revolution to now, industrial production lines have experienced 300-year developmental history, and has developed into fully automated mass production currently. It can be said that modern industry has been inseparable from the automated production line. Automatic production line not only can greatly improve the production efficiency, but also can improve the precision, boost qualified rate, reduce the workload. Nowadays industry is developed, and production line control system is r gradually replaced the original single chip computer or electrical machinery control with the PLC control. Many of its functions can not be achieved just through traditional control technology .

This paper aims to small business ingredient production line control system in our country, and applys the PLC of Siemens S7-200 series to small batch production line, and treats kingview as a human-computer interaction interface for monitoring function. First, the Siemens PLC S7-200 is used to control automatic proportion system. The proportioning system included the requirements of automatic proportioning, weighing, and loading. Next the Kingview software is used to build the real-time supervisory system. The system can realize the real-time data-logging, as well as various visual.

Paper’s contents mainly include that the industrial control system development and present situation outline. The ingredient system principle of work and the ingredient control system's design, described with emphasis including the hardware design, the programming environment and software design Siemens PLC in ingredient system's application some details, the configuration software configuration king and in the host computer supervisory system some basic designs, as well as communication between PLC and host computer. This paper through the reasonable selection and programming, improve the batching production efficiency, reduce the cost, improve the safety and reliability, and make reasonable adjustment of PLC program parameters according to the different ingredients .

Key words: Proportioning; PLC; Kingview; Automatic control

目 录

摘 要 I

ABSTRACT II

第一章 绪论 1

1.1自动配料控制系统的背景及意义 1

1.2 PLC控制配料生产线的特点 1

1.3课题研究的意义和目的 1

第二章 配料控制系统的原理 3

2.1配料控制系统的概述 3

2.2配料控制系统的工艺流程 3

2.3配料控制系统方案的提出 3

2.4配料控制系统的设计的基本步骤 4

第三章 配料控制系统的硬件电路设计 5

3.1配料控制系统的组成 5

3.1.1检测系统: 5

3.1.2电气控制系统整体设计 5

3.1.3 自动配料系统图 6

3.2系统器件选型 9

3.2.1 PLC的简介及选型 9

3.2.2光电开关的选型 11

3.2.3料位传感器的选型 11

3.2.4称重传感器的选择 11

3.2.5电机的选型 12

3.2.6其他硬件的选择 12

3.2.7主要电气元件目录表 14

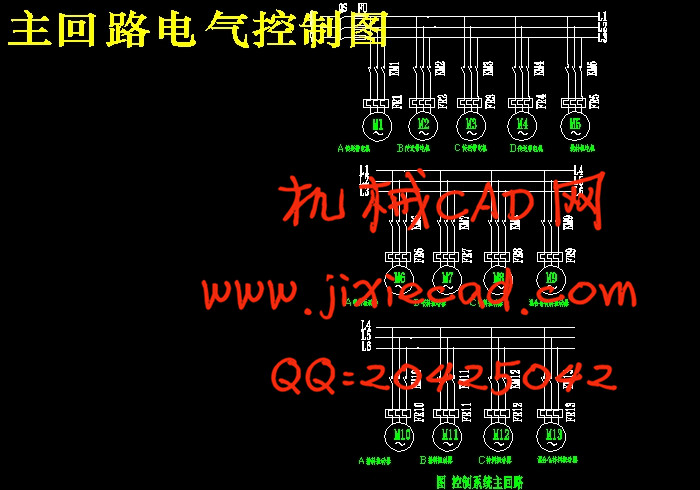

3.3配料控制系统的主回路设计 14

3.4配料控制系统的PLC输入输出回路设计 16

3.5配料控制系统的I/O分配表 18

第四章 配料控制系统的软件设计 20

4.1编程软件STEP7的概述 20

4.2配料控制系统的程序流程图设计 21

4.3配料控制系统的梯形图设计 22

4.3.1 启动/停止程序 22

4.3.2 缺料检测程序 22

4.3.3 补料程序 22

4.3.4 搅拌程序 24

4.3.5 车装料程序 24

4.3.6 车装满料停止程序 25

4.3.7 有重物时停止程序 26

4.3.8 LED数码显示程序 27

4.3.9 车到位及装满显示程序 28

4.3.10 过载报警程序 29

第五章 组态王监控系统设计 30

5.1组态王的简介 30

5.2 PLC远程通讯设置 30

5.3 S7-200与组态王通讯的实现 31

5.3.1组态王串口设置 31

5.3.2组态王PLC设置 32

5.3.3组态变量设置 34

5.3.4在新建画面中建立连接 36

5.3.5切换到view状态 36

结束语 38

参考文献 39

附 件一 梯形图程序 40

附 件二 STL程序 53

随着社会的进步、科技日新月异,18世纪60年代工业革命时期生产线主要以蒸汽机为动力,到现在已经发展成了全自动化大批量生产。可以说现代工业已经离不开自动化的生产线了,自动化生产线不仅可以大幅度地提高生产效率,而且还可以提高精度、提高合格率、减轻人的工作量等好处。传统的单片机等电器控制技术有很多功能无法实现,在工业如此发达的今天,生产线控制系统逐渐地被PLC控制代替。

针对我国一些小型企业的配料生产线控制系统现状,本文将Siemens S7-200系列的PLC应用于小型的配料生产线,再由组态王制作人机交互的界面,作为监控系统实现实时监控功能。运用与S7-200系列PLC相配的STEP7编程,从而使该配料系统可以按要求完成自动配料,装料全过程。

本文的主要内容包括对生产过程控制系统发展和现状的概述、配料系统工作原理和配料控制系统的总体设计,重点描述了包括硬件设计、软件编程设计在内的S7-200 PLC在配料系统中的详细步骤、组态王监控系统中一些基本设计,以及PLC与组态王之间的通讯。本设计通过合理的选择和编程,提高了配料生产线的生产效率,降低了成本,并且提高了系统安全可靠性。

关键词:配料;PLC;组态王;自动控制

ABSTRACT

With the progress of society and the great changes of science and technology, from the 1760s when the steam engine is acted as the main power of the beginning of the industrial revolution to now, industrial production lines have experienced 300-year developmental history, and has developed into fully automated mass production currently. It can be said that modern industry has been inseparable from the automated production line. Automatic production line not only can greatly improve the production efficiency, but also can improve the precision, boost qualified rate, reduce the workload. Nowadays industry is developed, and production line control system is r gradually replaced the original single chip computer or electrical machinery control with the PLC control. Many of its functions can not be achieved just through traditional control technology .

This paper aims to small business ingredient production line control system in our country, and applys the PLC of Siemens S7-200 series to small batch production line, and treats kingview as a human-computer interaction interface for monitoring function. First, the Siemens PLC S7-200 is used to control automatic proportion system. The proportioning system included the requirements of automatic proportioning, weighing, and loading. Next the Kingview software is used to build the real-time supervisory system. The system can realize the real-time data-logging, as well as various visual.

Paper’s contents mainly include that the industrial control system development and present situation outline. The ingredient system principle of work and the ingredient control system's design, described with emphasis including the hardware design, the programming environment and software design Siemens PLC in ingredient system's application some details, the configuration software configuration king and in the host computer supervisory system some basic designs, as well as communication between PLC and host computer. This paper through the reasonable selection and programming, improve the batching production efficiency, reduce the cost, improve the safety and reliability, and make reasonable adjustment of PLC program parameters according to the different ingredients .

Key words: Proportioning; PLC; Kingview; Automatic control

目 录

摘 要 I

ABSTRACT II

第一章 绪论 1

1.1自动配料控制系统的背景及意义 1

1.2 PLC控制配料生产线的特点 1

1.3课题研究的意义和目的 1

第二章 配料控制系统的原理 3

2.1配料控制系统的概述 3

2.2配料控制系统的工艺流程 3

2.3配料控制系统方案的提出 3

2.4配料控制系统的设计的基本步骤 4

第三章 配料控制系统的硬件电路设计 5

3.1配料控制系统的组成 5

3.1.1检测系统: 5

3.1.2电气控制系统整体设计 5

3.1.3 自动配料系统图 6

3.2系统器件选型 9

3.2.1 PLC的简介及选型 9

3.2.2光电开关的选型 11

3.2.3料位传感器的选型 11

3.2.4称重传感器的选择 11

3.2.5电机的选型 12

3.2.6其他硬件的选择 12

3.2.7主要电气元件目录表 14

3.3配料控制系统的主回路设计 14

3.4配料控制系统的PLC输入输出回路设计 16

3.5配料控制系统的I/O分配表 18

第四章 配料控制系统的软件设计 20

4.1编程软件STEP7的概述 20

4.2配料控制系统的程序流程图设计 21

4.3配料控制系统的梯形图设计 22

4.3.1 启动/停止程序 22

4.3.2 缺料检测程序 22

4.3.3 补料程序 22

4.3.4 搅拌程序 24

4.3.5 车装料程序 24

4.3.6 车装满料停止程序 25

4.3.7 有重物时停止程序 26

4.3.8 LED数码显示程序 27

4.3.9 车到位及装满显示程序 28

4.3.10 过载报警程序 29

第五章 组态王监控系统设计 30

5.1组态王的简介 30

5.2 PLC远程通讯设置 30

5.3 S7-200与组态王通讯的实现 31

5.3.1组态王串口设置 31

5.3.2组态王PLC设置 32

5.3.3组态变量设置 34

5.3.4在新建画面中建立连接 36

5.3.5切换到view状态 36

结束语 38

参考文献 39

附 件一 梯形图程序 40

附 件二 STL程序 53