设计简介

摘 要

在迅猛发展的当今社会,随着经济发展模式的循环化,市场竞争白炽化,产品高速率的更新换代,使得人们对高技术含量和高质量设计制造的产品也有越来越多的期待,所以企业只有低成本高效率地研发新产品,才能在激烈的市场竞争中立于不败之地。目前各行各业的生产中广泛应用的传动装置——减速器的设计逐渐暴露出很多弊端,如设计花费的时间太多,耗资较大,重复性的操作较多等。这些都限制了减速器的结构和性能的发展,不能满足企业生产的新需求。本文主要就是针对出现的以上问题,通过对常用的圆柱齿轮减速器的结构进行全面的阐释,利用现代化的手段如特征建模、参数化技术等,来进行减速器的三维参数化设计研究。作为各种 CAD 软件核心技术的参数化技术,已经广泛地应用于当今社会各行各业产品的设计中,获得的社会效益也是显而易见的。

在该论文中,主要的研究内容包括以下几个方面:

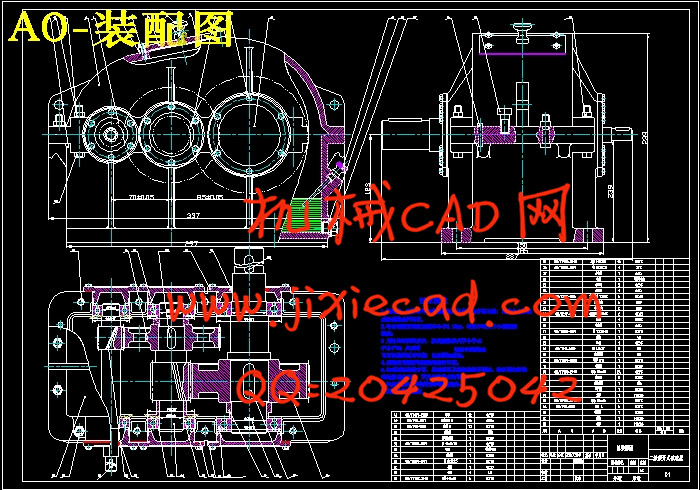

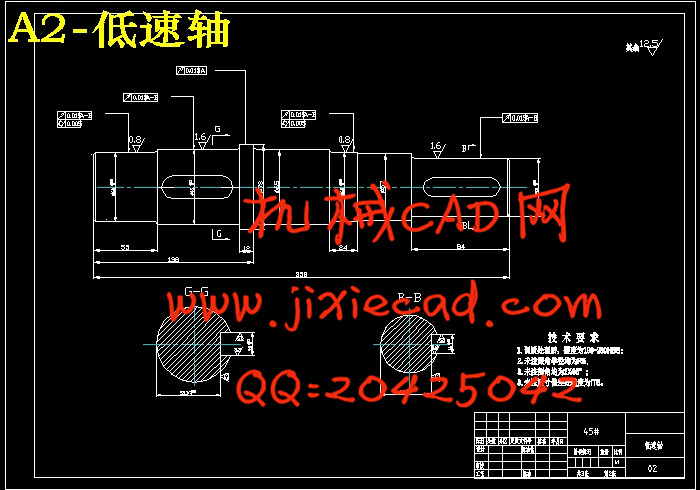

1、对减速器的结构特点及其各组成零部件的功能要求进行了详细分析,得出了减速器及其各零件的主要参数、一般参数以及参数之间的相互联系。

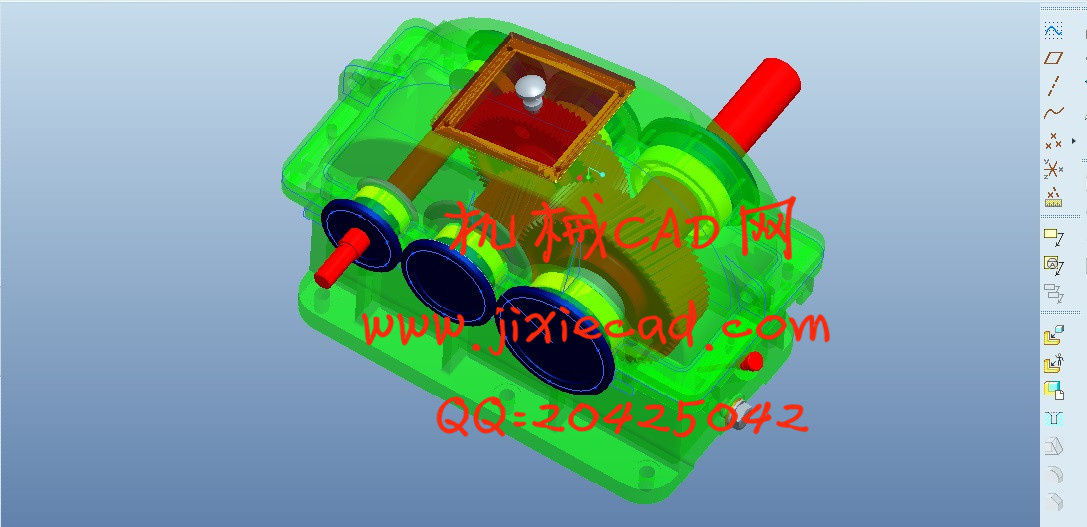

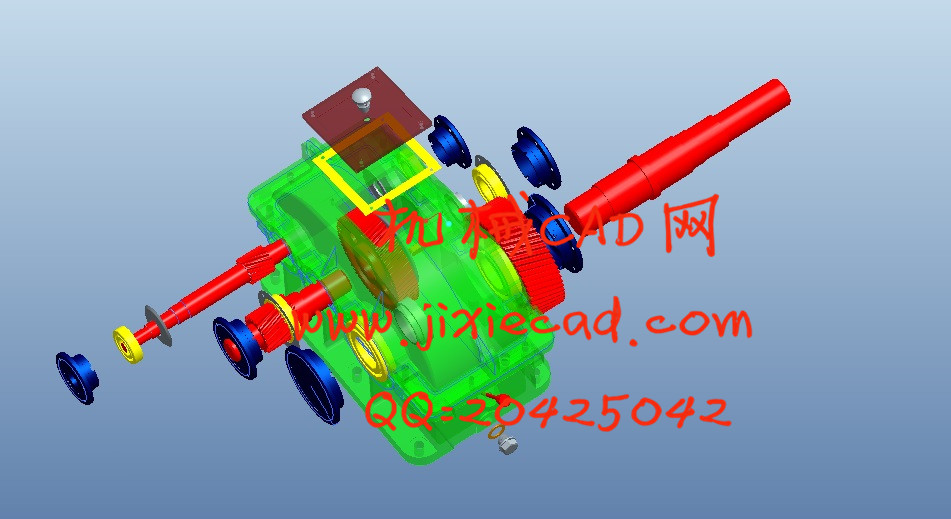

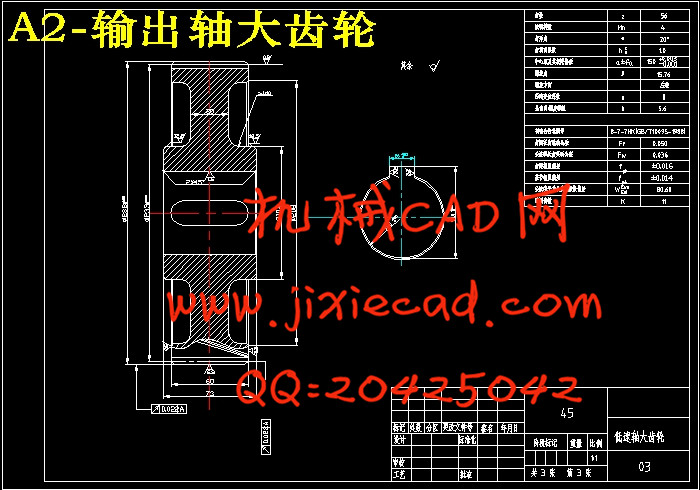

2、通过 Pro/E 软件建立了斜齿圆柱轮、直齿圆柱齿轮、齿轮轴、轴承、套筒、上箱体、下箱体等特征的参数化实体模型,设计者只需提供有关的参数,Pro/E 就能自动建立新的实体模型。

关键词:圆柱齿轮,减速器,Pro/E,特征建模

ABSTRACT

In the development of the current society, with the development of economic mode of circulation, the market competition of the incandescent, product the high rate of renewal and to make the people with high technology content and high quality design and manufacture products also have more and more looking forward to, so the enterprise only low cost high efficiency of research and development of new products, to the fierce market competition. At present people from all walks of life widely applied in production of transmission device--the design of the speed reducer gradually revealed some shortcomings, such as design cost so much of their time, cost is larger, repeatability of operation more, etc. These limits the speed reducer structure and performance of development, can not meet the new demands of enterprise production. This paper is mainly for the above problems appear, through to the common cylindrical gear reducer structure of comprehensive explanation, use of modern means such as characteristic modeling, parametric technology, etc, to reducer 3D parametric design research. As different kinds of CAD software core technology of parametric technology, has been widely used in today's society all walks of life in the design of the product, get social benefits is obvious. In this paper, the main research contents include the following aspects:

(1)According to the general requirements of speed reducer design, structural features and reducer each composition parts of the function requirement on detailed analysis, it is concluded that the reducer and the main parameters of the parts, and the general parameters and the relationship between the parameters.

(2) through the Pro/Engineer software established a helical wheel, spur gears, the gear axis, bearing, box, the case on the lower case, characteristics of the solid model parameter, designers need to offer the related parameters, Pro/Engineer can be set up new entity model.

Keywords: cylindrical gears,reducer, Pro/Engineer,feature modeling.

目 录

摘 要 2

ABSTRACT 3

第一章 绪论 6

1.1选题背景及意义 6

1.2减速器的研究现状 6

第二章 传动装置的总体设计 8

2.1分析和确定传动方案 8

2.2电动机的选择 9

2.3 确定传动装置总传动比和分配传动比 10

2.4计算传动装置的运动和动力参数 10

1. 各轴的转速 10

2.各轴的输入功率 10

3.各轴的输入转矩 11

第三章 减速器的齿轮设计 12

3.1高速级齿轮的设计 12

3.1.1齿轮材料及齿数初步确定 12

3.1.2按齿面强度设计 12

3.1.2按齿根强度设计 14

3.1.3几何尺寸计算 16

3.2低速级齿轮的设计 16

3.2.1齿轮材料及齿数初步确定 16

3.2.2 按齿面强度设计 17

3.2.3 按齿根弯曲强度设计 19

3.2.4 几何尺寸计算 20

3.3 滚动轴承和传动轴的设计 21

3.3.1.输出轴的设计 21

3.2.输入轴的设计 23

3.3 轴的强度校核 25

3.4 键联接设计 27

3.5箱体结构的设计 28

第四章 Pro/E 软件介绍和减速器参数设计方法 31

4.1 Pro/E 软件介绍 31

4.1.1 Pro/E 建模功能简介 31

4.2减速器参数设计方法 32

4.2.1 参数化设计技术及总体思路 32

4.2.2 Pro/E 中参数化建模的方法 33

总 结 34

参考文献 35

致 谢 36

在迅猛发展的当今社会,随着经济发展模式的循环化,市场竞争白炽化,产品高速率的更新换代,使得人们对高技术含量和高质量设计制造的产品也有越来越多的期待,所以企业只有低成本高效率地研发新产品,才能在激烈的市场竞争中立于不败之地。目前各行各业的生产中广泛应用的传动装置——减速器的设计逐渐暴露出很多弊端,如设计花费的时间太多,耗资较大,重复性的操作较多等。这些都限制了减速器的结构和性能的发展,不能满足企业生产的新需求。本文主要就是针对出现的以上问题,通过对常用的圆柱齿轮减速器的结构进行全面的阐释,利用现代化的手段如特征建模、参数化技术等,来进行减速器的三维参数化设计研究。作为各种 CAD 软件核心技术的参数化技术,已经广泛地应用于当今社会各行各业产品的设计中,获得的社会效益也是显而易见的。

在该论文中,主要的研究内容包括以下几个方面:

1、对减速器的结构特点及其各组成零部件的功能要求进行了详细分析,得出了减速器及其各零件的主要参数、一般参数以及参数之间的相互联系。

2、通过 Pro/E 软件建立了斜齿圆柱轮、直齿圆柱齿轮、齿轮轴、轴承、套筒、上箱体、下箱体等特征的参数化实体模型,设计者只需提供有关的参数,Pro/E 就能自动建立新的实体模型。

关键词:圆柱齿轮,减速器,Pro/E,特征建模

ABSTRACT

In the development of the current society, with the development of economic mode of circulation, the market competition of the incandescent, product the high rate of renewal and to make the people with high technology content and high quality design and manufacture products also have more and more looking forward to, so the enterprise only low cost high efficiency of research and development of new products, to the fierce market competition. At present people from all walks of life widely applied in production of transmission device--the design of the speed reducer gradually revealed some shortcomings, such as design cost so much of their time, cost is larger, repeatability of operation more, etc. These limits the speed reducer structure and performance of development, can not meet the new demands of enterprise production. This paper is mainly for the above problems appear, through to the common cylindrical gear reducer structure of comprehensive explanation, use of modern means such as characteristic modeling, parametric technology, etc, to reducer 3D parametric design research. As different kinds of CAD software core technology of parametric technology, has been widely used in today's society all walks of life in the design of the product, get social benefits is obvious. In this paper, the main research contents include the following aspects:

(1)According to the general requirements of speed reducer design, structural features and reducer each composition parts of the function requirement on detailed analysis, it is concluded that the reducer and the main parameters of the parts, and the general parameters and the relationship between the parameters.

(2) through the Pro/Engineer software established a helical wheel, spur gears, the gear axis, bearing, box, the case on the lower case, characteristics of the solid model parameter, designers need to offer the related parameters, Pro/Engineer can be set up new entity model.

Keywords: cylindrical gears,reducer, Pro/Engineer,feature modeling.

目 录

摘 要 2

ABSTRACT 3

第一章 绪论 6

1.1选题背景及意义 6

1.2减速器的研究现状 6

第二章 传动装置的总体设计 8

2.1分析和确定传动方案 8

2.2电动机的选择 9

2.3 确定传动装置总传动比和分配传动比 10

2.4计算传动装置的运动和动力参数 10

1. 各轴的转速 10

2.各轴的输入功率 10

3.各轴的输入转矩 11

第三章 减速器的齿轮设计 12

3.1高速级齿轮的设计 12

3.1.1齿轮材料及齿数初步确定 12

3.1.2按齿面强度设计 12

3.1.2按齿根强度设计 14

3.1.3几何尺寸计算 16

3.2低速级齿轮的设计 16

3.2.1齿轮材料及齿数初步确定 16

3.2.2 按齿面强度设计 17

3.2.3 按齿根弯曲强度设计 19

3.2.4 几何尺寸计算 20

3.3 滚动轴承和传动轴的设计 21

3.3.1.输出轴的设计 21

3.2.输入轴的设计 23

3.3 轴的强度校核 25

3.4 键联接设计 27

3.5箱体结构的设计 28

第四章 Pro/E 软件介绍和减速器参数设计方法 31

4.1 Pro/E 软件介绍 31

4.1.1 Pro/E 建模功能简介 31

4.2减速器参数设计方法 32

4.2.1 参数化设计技术及总体思路 32

4.2.2 Pro/E 中参数化建模的方法 33

总 结 34

参考文献 35

致 谢 36