设计简介

摘要:起重机是一种作循环、间歇运动的机械。一个工作循环包括:取物装置从取物地把物品提起,然后水平移动到指定地点降下物品,接着进行反向运动,使取物装置回到原位。以便进行下一次循环。通常,起重机械由起升机构(是物品能够上下运动)、运动机构(使起重机械移动)、变幅机构和回转机构(使物品作水平移动),加上金属机构,动力装置,操纵控制及必要的辅助装置组合而成。

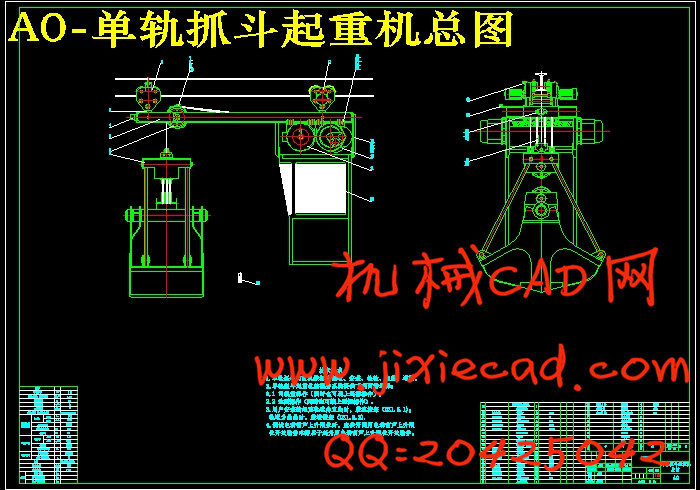

桥式抓斗起重机是桥架在高架轨道上运行,由起重小车带动抓斗抓取物料的一种桥架型起重机。桥架沿铺设在两侧高架上的轨道纵向运行,起重小车沿铺设在桥架上的轨道横向运行,构成矩形的工作范围,就可以充分利用桥架下面的空间吊运物料,不受地面设备的阻碍。桥式抓斗起重机广泛应用于电厂、煤厂等需要散料装卸的场合,由于该设备笨重,运输安装困难,对其产品质量检测一般需要在现场进行。所以要求控制设备接线方便,体积小便于携带。又由于使用现场条件不动,还要求检测设备有随机手动控制功能,以保证运行时的安全。随着对起重运输机械控制要求的不断提高,控制手段也越来越先进。目前国内的桥式起重机控制系统都需要人在现场进行控制,控制方式都比较落后。在中小型起重机中, 大都采用控制器直接控制大、小车运行, 主、副钩提升、下降重物及调速。

关键字:桥式抓斗起重机 运行机构 减速器 控制器 动力装置

Abstract: the derrick is a kind of machine that make circulation ,intermittent sport .A work includes circulary:Take the thing device from take the thing ground to bring up the product,then the level move to specify the location to decline product carry on immediately after anti-to sport,make the thing device to return the home position ,in order to carry on next circulate.Usually , the derrick from rise the organization (make product exercised up and down),circulate the organization (make the derrick move) and become an organization and turn round the organization (make the product make the level ambulation),and the metal organization,the motive equip,the assistance that manipulate the control and necessities equips to combine.

Grab bridge bridge crane is running on the elevated track, the car driven by the lifting of materials crawl grab a bridge-crane. Bridge laying on both sides along the elevated track on the vertical run, lifting trolley along the bridge in laying the track on the horizontal run, a rectangular scope of work, you can make full use of space below the bridge lifting material from Ground equipment hindered. Grab bridge cranes widely used in power plants, Mei Chang, and other needs of bulk material handling of the occasion, because of the heavy equipment, transportation difficulties installation, testing the quality of their products in general need in the field. Therefore, control equipment requirements for wiring, small size and portability. And the use of fixed-site conditions, also called a random testing equipment manual control functions to ensure the safety of operation. With the lifting of the transport requirements of the mechanical control continuously improve, more and more advanced means of control. At present the domestic bridge crane control system requires people at the scene to control, control methods are backward. In small and medium-sized crane, the most direct control over the use of controllers, car running, Lord, vice hook upgrade, dropped weights and speed.

Keyword: Grab bridge crane Operating agencies Reducer Controller Power device

目 录

1 绪论……………………… …………… …………………………………………………..1

2 总体方案确定及基本参数…………………………… …… ……… …………..3

000012.1 总体方案确定………………………………………………………………………..3

2.2 基本参数……………………………………………… ……………… ………..…....3

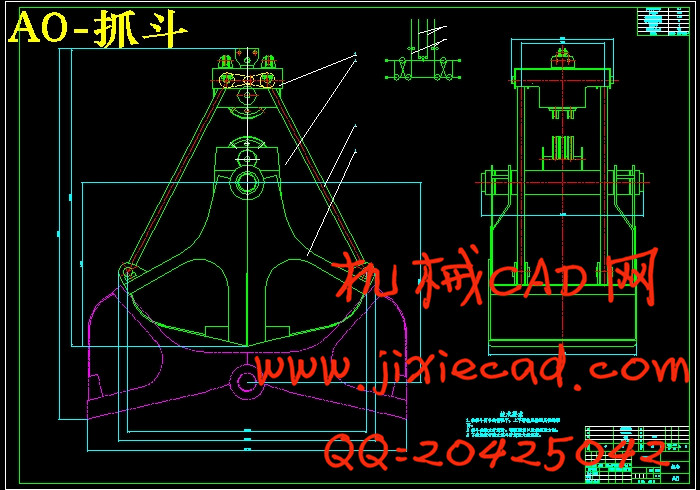

3 抓斗计算…………………………………………………………………………………..3

3.1 抓斗的几何尺寸……………………………………………………...…………3

3.2 滑轮组倍率……………………………………………………………………...5

3.3 钢丝绳计算…………………………………………………………………..….5

3.4 滑轮直径确定…………………………………………………………………...6

3.5 上下横梁轴线倾斜角………………………………………………………..….6

3.6 抓斗强度计算…………………………………………………………………...6

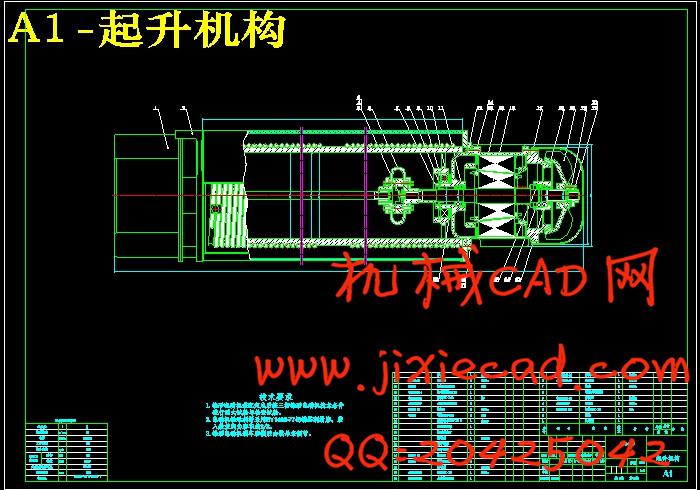

4 起升机构…………………………………………………………………..…….10

4.1 传动比计算………………………………………………………………..…….10

4.2 起升速度………………………………………………………………………...10

4.3 机构效率……………………………………………………………………..….11

4.4 电动机静功率…………………………………………………………………...11

4.5 电动机轴的静转力矩…………………………………………..……………….12

4.6 制动器计算……………………………………………………………..……….12

4.7 起动时间…………………………………………………………...……………13

4.8 制动时间…………………………………………………………………….…..14

4.9 卷筒装置……………………………………………………………………...…15

5 起升机构减速箱………………………………………………… …….. …….21

5.1 轴的计算…………………………………………………………………..…….21

5.2 齿轮校核………………………………………………………….……………..31

6 运行机构…………………………………………………………………………………. 35

6.1 传动比计算…………………………………………………………….……….35

6.2 运行速度…………………………………………………………...…………...35

6.3 机构效率……………………………………………………...………………...36

6.4 运行摩擦阻力……………………………………………………………...…...36

6.5 电动机容量的初选…………………………………………………...………...36

6.6 走轮轮压………………………………………………………………………..37

6.7 验算起动时间………………………………………………………………..…37

6.8 制动器计算………………………………………………………………..…....37

6.9 电动机最大力矩………………………………………………….………….....39

6.10 验算电动机打滑…………………………………………….………………...40

参考文献………………..…………………………………………………...…………………….41

致谢………………..……………………………………….. ……………….……………………...42

桥式抓斗起重机是桥架在高架轨道上运行,由起重小车带动抓斗抓取物料的一种桥架型起重机。桥架沿铺设在两侧高架上的轨道纵向运行,起重小车沿铺设在桥架上的轨道横向运行,构成矩形的工作范围,就可以充分利用桥架下面的空间吊运物料,不受地面设备的阻碍。桥式抓斗起重机广泛应用于电厂、煤厂等需要散料装卸的场合,由于该设备笨重,运输安装困难,对其产品质量检测一般需要在现场进行。所以要求控制设备接线方便,体积小便于携带。又由于使用现场条件不动,还要求检测设备有随机手动控制功能,以保证运行时的安全。随着对起重运输机械控制要求的不断提高,控制手段也越来越先进。目前国内的桥式起重机控制系统都需要人在现场进行控制,控制方式都比较落后。在中小型起重机中, 大都采用控制器直接控制大、小车运行, 主、副钩提升、下降重物及调速。

关键字:桥式抓斗起重机 运行机构 减速器 控制器 动力装置

Abstract: the derrick is a kind of machine that make circulation ,intermittent sport .A work includes circulary:Take the thing device from take the thing ground to bring up the product,then the level move to specify the location to decline product carry on immediately after anti-to sport,make the thing device to return the home position ,in order to carry on next circulate.Usually , the derrick from rise the organization (make product exercised up and down),circulate the organization (make the derrick move) and become an organization and turn round the organization (make the product make the level ambulation),and the metal organization,the motive equip,the assistance that manipulate the control and necessities equips to combine.

Grab bridge bridge crane is running on the elevated track, the car driven by the lifting of materials crawl grab a bridge-crane. Bridge laying on both sides along the elevated track on the vertical run, lifting trolley along the bridge in laying the track on the horizontal run, a rectangular scope of work, you can make full use of space below the bridge lifting material from Ground equipment hindered. Grab bridge cranes widely used in power plants, Mei Chang, and other needs of bulk material handling of the occasion, because of the heavy equipment, transportation difficulties installation, testing the quality of their products in general need in the field. Therefore, control equipment requirements for wiring, small size and portability. And the use of fixed-site conditions, also called a random testing equipment manual control functions to ensure the safety of operation. With the lifting of the transport requirements of the mechanical control continuously improve, more and more advanced means of control. At present the domestic bridge crane control system requires people at the scene to control, control methods are backward. In small and medium-sized crane, the most direct control over the use of controllers, car running, Lord, vice hook upgrade, dropped weights and speed.

Keyword: Grab bridge crane Operating agencies Reducer Controller Power device

目 录

1 绪论……………………… …………… …………………………………………………..1

2 总体方案确定及基本参数…………………………… …… ……… …………..3

000012.1 总体方案确定………………………………………………………………………..3

2.2 基本参数……………………………………………… ……………… ………..…....3

3 抓斗计算…………………………………………………………………………………..3

3.1 抓斗的几何尺寸……………………………………………………...…………3

3.2 滑轮组倍率……………………………………………………………………...5

3.3 钢丝绳计算…………………………………………………………………..….5

3.4 滑轮直径确定…………………………………………………………………...6

3.5 上下横梁轴线倾斜角………………………………………………………..….6

3.6 抓斗强度计算…………………………………………………………………...6

4 起升机构…………………………………………………………………..…….10

4.1 传动比计算………………………………………………………………..…….10

4.2 起升速度………………………………………………………………………...10

4.3 机构效率……………………………………………………………………..….11

4.4 电动机静功率…………………………………………………………………...11

4.5 电动机轴的静转力矩…………………………………………..……………….12

4.6 制动器计算……………………………………………………………..……….12

4.7 起动时间…………………………………………………………...……………13

4.8 制动时间…………………………………………………………………….…..14

4.9 卷筒装置……………………………………………………………………...…15

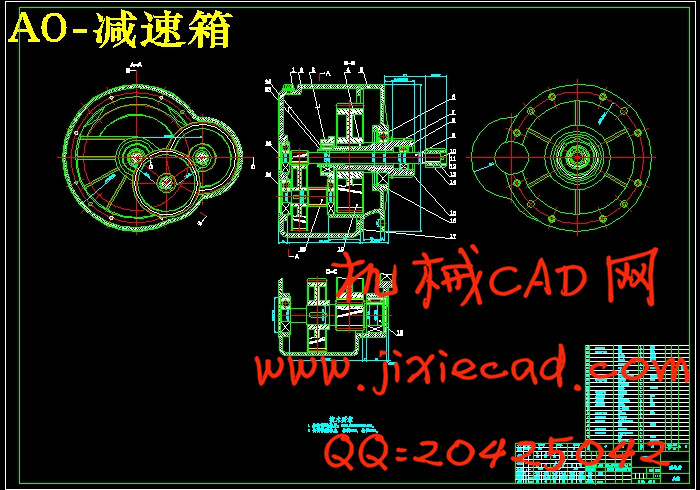

5 起升机构减速箱………………………………………………… …….. …….21

5.1 轴的计算…………………………………………………………………..…….21

5.2 齿轮校核………………………………………………………….……………..31

6 运行机构…………………………………………………………………………………. 35

6.1 传动比计算…………………………………………………………….……….35

6.2 运行速度…………………………………………………………...…………...35

6.3 机构效率……………………………………………………...………………...36

6.4 运行摩擦阻力……………………………………………………………...…...36

6.5 电动机容量的初选…………………………………………………...………...36

6.6 走轮轮压………………………………………………………………………..37

6.7 验算起动时间………………………………………………………………..…37

6.8 制动器计算………………………………………………………………..…....37

6.9 电动机最大力矩………………………………………………….………….....39

6.10 验算电动机打滑…………………………………………….………………...40

参考文献………………..…………………………………………………...…………………….41

致谢………………..……………………………………….. ……………….……………………...42