设计简介

DF300多层纸复合机组烘干部分设计

摘 要

本次设计是大学四年来最为庞大的设计,是大学知识学以致用的重要体现。

我们的课题是横向来源,目的是节约能源、减少污染。在此设计中我负责机组的烘干部分设计。

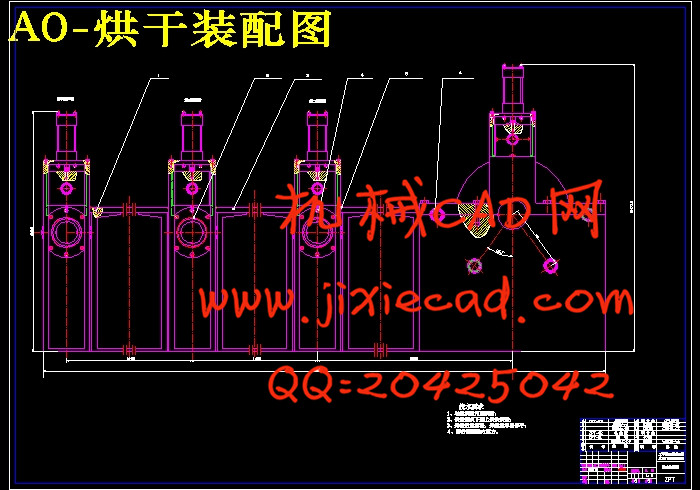

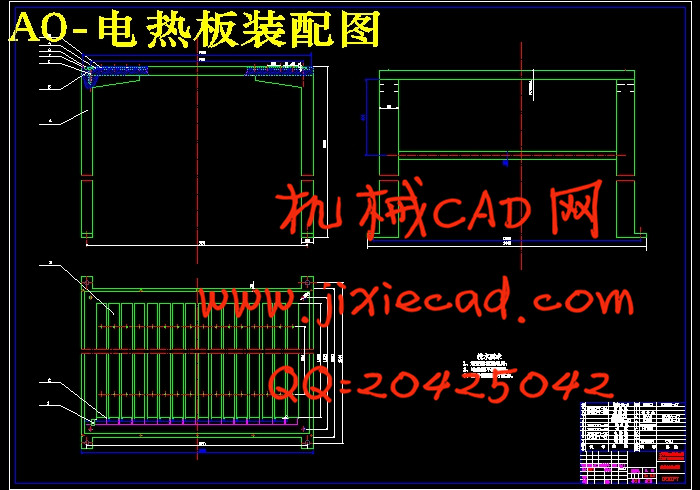

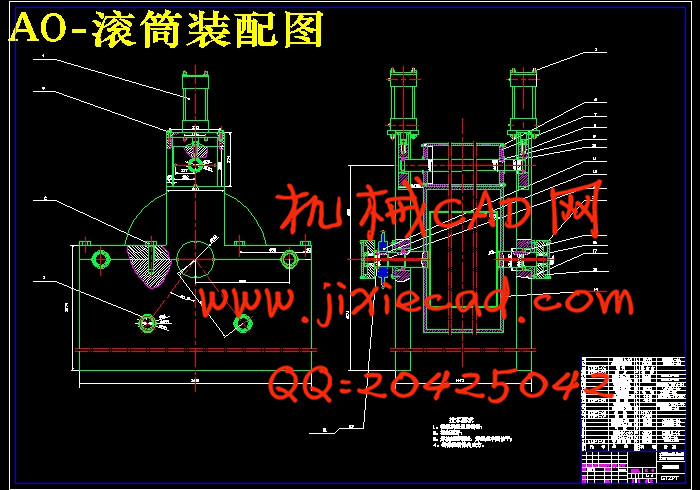

设计中我以烘干设备的设计和传热计算为主要内容,有:选择、设计合适的烘干设备(通过传热方式特点、效率和成本的比较选择),通过比较选择设计了滚筒油加热和电热板加热相结合的方法。滚筒内部通入设定好温度的热油,纸张贴着滚筒绕过大半周从而得到加热。电热板的内部热源是电热膜,通电后电热膜发出辐射能,使加热板达到合适的温度,纸张贴着电热板平行走过而得到加热。

通过传热计算发现设计能满足要求,并且有显著的优点。不仅烘干效果好,而且节能、环保、效率高。

本设计是在国内一些现有设备的基础上改进而成的。在设计过程中借鉴了前人的部分研究成果。

关键词 烘干,滚筒,电热板,传热

Our lesson is a horizontal source, the purpose is to economizes the energy and reduce the pollution. In this design my job is the responsible for machine set dries parts of designs.

In this design I put the design of the Baking dryness equipments and the calculation of the heat transfer as the main contents, there is: choose and design the fine baking dryness equipments (according to comparison of the way of heat transfer) , according to the comparison I choose and design the method of the rotaring cylinder oil heats to heat and together with the glow board to heat. first put the hot oil of the good temperature in enactment into the rotaring cylinder, the paper sticks the rotaring cylinder rounds in great half part to get the heat. The internal hot source in glow board is the hot membrane , after switching on electricity the hot membrane can send out radiation energy, make the glow board get the fit temperature, the paper sticks the glow board parallelism walk through to get the heat.

According to the calculation I find this design can satisfy the request, and have the predominance advantage. Not only having the great effective of baking dryness, but also the economy energy, environmental protection, efficiency is high.

This design is a last improvement in foundation in some current equipments in domestic. I drew the lessons from the part of researches result of the past people in design process.

KEY WORDS Baking dryness,Rotaring cylinder,Glow board ,Heat transfer

目 录

中文摘要………………………………………………………………… Ⅰ

英文摘要…………………………………………………………………Ⅱ

1 绪论………………………………………………………………………1

1.1 毕业设计目的和意义……………………………………………1

1.2 传统机械产品设计的特征 ……………………………………3

1.3 课题的提出 ………………………………………………………4

1.4 选题背景 …………………………………………………………4

1.5 选题目的和研究意义 …………………………………………5

1.6 课题研究的内容 ………………………………………………5

1.7 干燥技术及其发展趋势… ……………………………………6

1.8 干燥过程原理 …………………………………………………6

2方案选择与论证 ………………………………………………………… 7

2.1 传热简介 ………………………………………………………………7

2.1.1 传热的三种基本方式………………………………………… 8

2.1.2 特征…………………………………………………………… 8

2.2 各种干燥设备简介…………………………………… …………… 11

2.2.1 用电热膜做成的加热板………………………………………11

2.2.2 乳白石英红外辐射电加热器…………………………………15

2.2.3 热风循环烘箱…………………………………………………16

2.2.4 热泵……………………………………………………………17

2.2.5 油加热滚筒……………………………………………………17

2.3 选择方案…………………………………………………………17

2.3.1 比较各种方案…………………………………………………17

2.3.2 确定方案…………………………………………………………… 18

2.3.3 纸张的走向………………………………………………………… 18

2.3.4 材料的选择………………………………………………………… 19

3 设计及其计算………………………………………………………………20

3.1 纸张的初步计算…………………………………………………… 20

3.1.1 纸张的走速的计算……………………………………………20

3.1.2 纸中含水量的计算……………………………………………20

3.2 隔热保温技术及保温材料………………………………………21

3.3 滚筒各部分的设计及其参数的确定…………………………… 22

3.4 电热膜加热板的设计及其参数的确定……………………24

4 配套零部件的选择及其计算 ……………………………………27

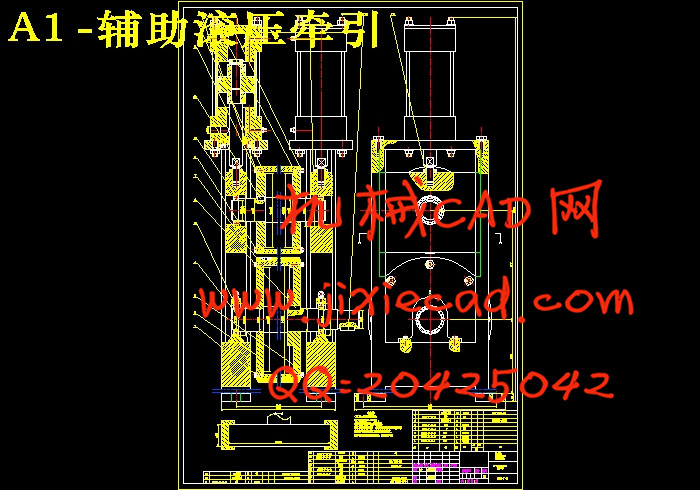

4.1 气缸的设计与选用…………………………………………… 27

4.1.1 气动系统的简介………………………………………………27

4.1.2 气缸的简介……………………………………………………28

4.2 气缸选择及其计算过程………………………………………29

4.2.1 气缸的工作原理………………………………………………29

4.2.2 气缸的选用与计算……………………………………………32

4.3 滚筒轴的设计和校核…………………………………………33

4.4 轴承的设计和校核…………………………………………… 36

4.5 滚动轴承简介及选择…………………………………………37

4.6 自动化控制的应用及选择 …………………………………………40

4.7 传感器的选择 …………………………………………………41

总结 …………………………………………………………………… 42

致谢 …………………………………………………………………… 44

参考文献………………………………………………………………… 45

摘 要

本次设计是大学四年来最为庞大的设计,是大学知识学以致用的重要体现。

我们的课题是横向来源,目的是节约能源、减少污染。在此设计中我负责机组的烘干部分设计。

设计中我以烘干设备的设计和传热计算为主要内容,有:选择、设计合适的烘干设备(通过传热方式特点、效率和成本的比较选择),通过比较选择设计了滚筒油加热和电热板加热相结合的方法。滚筒内部通入设定好温度的热油,纸张贴着滚筒绕过大半周从而得到加热。电热板的内部热源是电热膜,通电后电热膜发出辐射能,使加热板达到合适的温度,纸张贴着电热板平行走过而得到加热。

通过传热计算发现设计能满足要求,并且有显著的优点。不仅烘干效果好,而且节能、环保、效率高。

本设计是在国内一些现有设备的基础上改进而成的。在设计过程中借鉴了前人的部分研究成果。

关键词 烘干,滚筒,电热板,传热

ABSTRACT

This design is the most important and huge design in the four university yeares ,which is an university knowledge learning with a view to its application now.Our lesson is a horizontal source, the purpose is to economizes the energy and reduce the pollution. In this design my job is the responsible for machine set dries parts of designs.

In this design I put the design of the Baking dryness equipments and the calculation of the heat transfer as the main contents, there is: choose and design the fine baking dryness equipments (according to comparison of the way of heat transfer) , according to the comparison I choose and design the method of the rotaring cylinder oil heats to heat and together with the glow board to heat. first put the hot oil of the good temperature in enactment into the rotaring cylinder, the paper sticks the rotaring cylinder rounds in great half part to get the heat. The internal hot source in glow board is the hot membrane , after switching on electricity the hot membrane can send out radiation energy, make the glow board get the fit temperature, the paper sticks the glow board parallelism walk through to get the heat.

According to the calculation I find this design can satisfy the request, and have the predominance advantage. Not only having the great effective of baking dryness, but also the economy energy, environmental protection, efficiency is high.

This design is a last improvement in foundation in some current equipments in domestic. I drew the lessons from the part of researches result of the past people in design process.

KEY WORDS Baking dryness,Rotaring cylinder,Glow board ,Heat transfer

目 录

中文摘要………………………………………………………………… Ⅰ

英文摘要…………………………………………………………………Ⅱ

1 绪论………………………………………………………………………1

1.1 毕业设计目的和意义……………………………………………1

1.2 传统机械产品设计的特征 ……………………………………3

1.3 课题的提出 ………………………………………………………4

1.4 选题背景 …………………………………………………………4

1.5 选题目的和研究意义 …………………………………………5

1.6 课题研究的内容 ………………………………………………5

1.7 干燥技术及其发展趋势… ……………………………………6

1.8 干燥过程原理 …………………………………………………6

2方案选择与论证 ………………………………………………………… 7

2.1 传热简介 ………………………………………………………………7

2.1.1 传热的三种基本方式………………………………………… 8

2.1.2 特征…………………………………………………………… 8

2.2 各种干燥设备简介…………………………………… …………… 11

2.2.1 用电热膜做成的加热板………………………………………11

2.2.2 乳白石英红外辐射电加热器…………………………………15

2.2.3 热风循环烘箱…………………………………………………16

2.2.4 热泵……………………………………………………………17

2.2.5 油加热滚筒……………………………………………………17

2.3 选择方案…………………………………………………………17

2.3.1 比较各种方案…………………………………………………17

2.3.2 确定方案…………………………………………………………… 18

2.3.3 纸张的走向………………………………………………………… 18

2.3.4 材料的选择………………………………………………………… 19

3 设计及其计算………………………………………………………………20

3.1 纸张的初步计算…………………………………………………… 20

3.1.1 纸张的走速的计算……………………………………………20

3.1.2 纸中含水量的计算……………………………………………20

3.2 隔热保温技术及保温材料………………………………………21

3.3 滚筒各部分的设计及其参数的确定…………………………… 22

3.4 电热膜加热板的设计及其参数的确定……………………24

4 配套零部件的选择及其计算 ……………………………………27

4.1 气缸的设计与选用…………………………………………… 27

4.1.1 气动系统的简介………………………………………………27

4.1.2 气缸的简介……………………………………………………28

4.2 气缸选择及其计算过程………………………………………29

4.2.1 气缸的工作原理………………………………………………29

4.2.2 气缸的选用与计算……………………………………………32

4.3 滚筒轴的设计和校核…………………………………………33

4.4 轴承的设计和校核…………………………………………… 36

4.5 滚动轴承简介及选择…………………………………………37

4.6 自动化控制的应用及选择 …………………………………………40

4.7 传感器的选择 …………………………………………………41

总结 …………………………………………………………………… 42

致谢 …………………………………………………………………… 44

参考文献………………………………………………………………… 45