设计简介

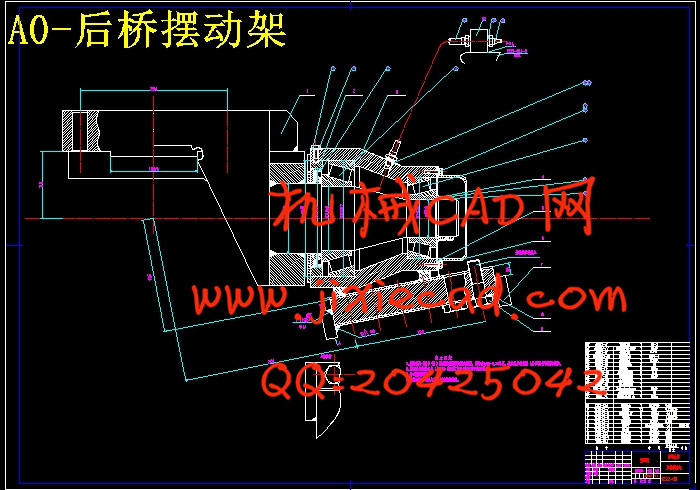

CYE-1电动铲运机后桥摆动架设计

摘要:地下铲运机是专门为地下作业而设计的一种矮车身、中央铰接、前端装载的装、运、卸联合作业设备,具有高效、灵活、机动、多用途和生产费用低等突出优点,在国内外矿山和地下工程中得到了广泛应用。地下铲运机的工作环境非常恶劣,为了使地下铲运机适应不平的采场路面,增加铲运机在装矿或运输工作中的稳定性,其后桥上设计有摆动架,以保证前车的后架在一定角度内作相对摆动。后车架通过摆动架的回转轴与摆动架铰接,后车架与后桥之间有足够的摆动空间。当铲运机通过不平路面时,后桥能够相对后车架摆动,而后架在后桥摆动时仍能保持正常位置。铲运机在平坦的路面上进行铲掘或运输作业时,由于 4 个车轮同时着地,摆动架不工作。铲运机在凹凸不平的地面上进行铲掘或运输作业,当后桥左轮着地,右轮腾空时,左轮受到地面的作用力并作用到摆动架上,加上后车架作用在后桥上的重力,使摆动架产生一个力矩,该力矩使摆动架体绕摆动轴转动,并且带动后桥右轮着地。同理,当后桥右轮着地,左轮腾空时,通过摆动架可保持后桥左、右轮始终着地。因此,当铲运机在不平的路面上行驶时,两侧车轮可以保证同时接触地面,改善车轮的附着条件,充分利用整机的黏着重量,增大牵引力和铲斗的铲掘力。

关键词:地下铲运机;后桥摆动架;后桥

The design of the rear axle swing frame of the CYE-1 electric scrapers

Abstract: The underground scraper is specially designed for underground work.It has a short body,a central hinge , it is a joint operating equipment of front loading ,transporting

and unloading.The highlight advantages of the equipment is efficient ,flexible,versatile

and low production costs and so on.It has been widely used in domestic and foreign mining

and underground engineering,The working environment of the underground scrapers is very bad.In order to adapt to the uneven stope road,increase the stability of the scrapers in mining equipment or transportation work,the subsequent bridge swing is design to ensure that the vehicle in front will be rotate in a certain angle related to swing..There is enough swing space between the rear frame and rear axle.When the scraper passes the uneven road, the rear axle is relatively frame swing, and then mounted on the rear axle swing and still maintain a normal position.when the scraper do the shovel or transport work,as the four

wheels touch the ground,the swing frame does not work.When the scraper shovel or transport on uneven ground ,the rear axle revolver, the right wheel vacated, revolvers by the ground forces and the role to the swing rack, plus rear frame in the post-bridge gravity to produce a torque of the swing frame, the torque to the swing frame body around the swing axis of rotation, and drive the rear axle right wheel to the ground.Similarly, when the right wheel of the rear axle, revolvers vacated ,through the swing frame,it can make the left

and right wheel of the bridge always to the ground.Therefore, when the scraper drives on uneven road, both sides of the wheel can be attached to ensure contact with the ground to improve the wheel, make full use of the adhesive weight of the machine, increases traction

and shovel force.

Key words:The underground scraper;Rear axle swing frame;Rear axle

目 录

1 绪论 ...........................................................................................................................2

1.1 设计研究的目的和意义..................................................................................2

1.2 铲运机应用与发展回顾..................................................................................2

1.3 未来技术发展展望..........................................................................................5

1.4 设计拟解决的关键问题和研究方法..............................................................6

2 铲运机总体分析......................................................................................................8

2.1 铲运机的组成系统及功能 ...........................................................................8

2.2 铲运机的工作方式.........................................................................................9

2.3 铲运机的技术水平.......................................................................................10

2.4 电动铲运机...................................................................................................12

3 CYE型电动铲运机总体参数与原理...............................................................16

3.1 CYE电动铲运机主要技术参数 ..................................................................16

3.2 CYE电动铲运机工作原理............................................................................17

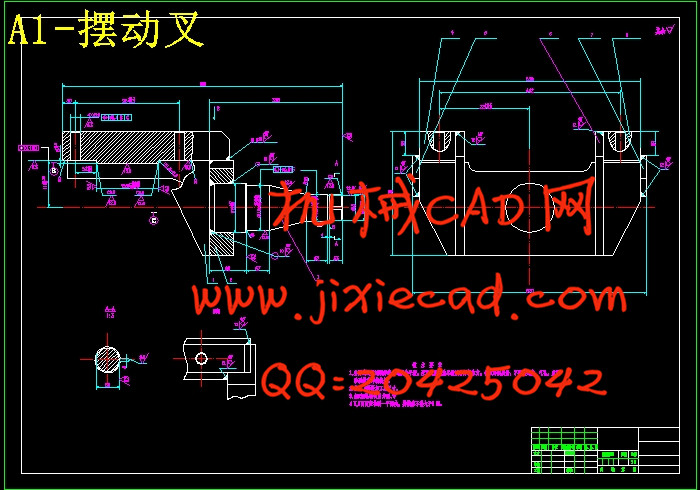

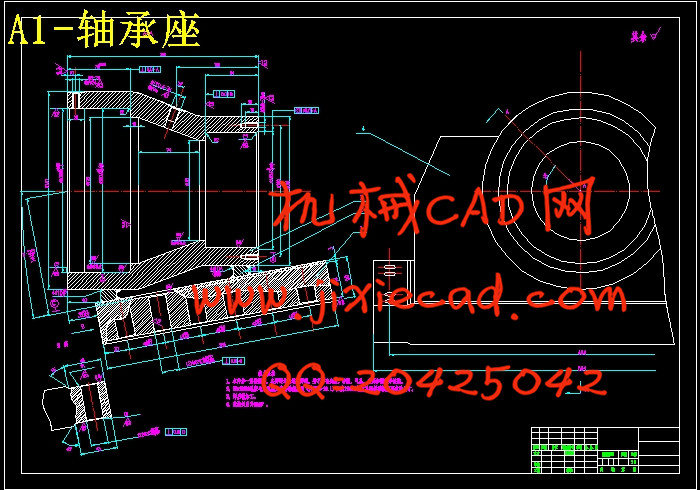

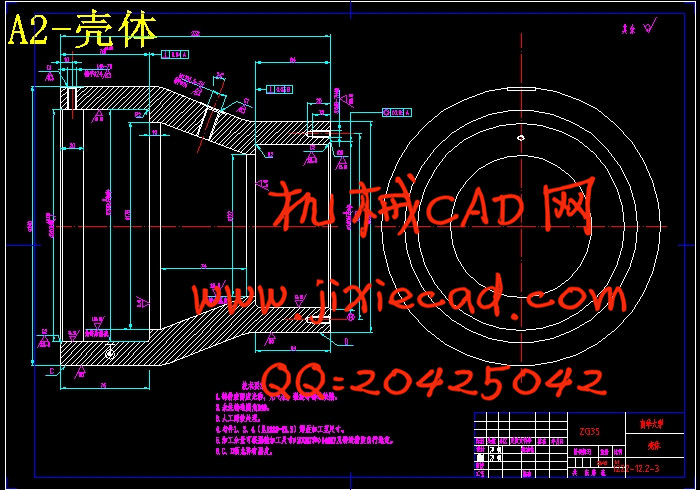

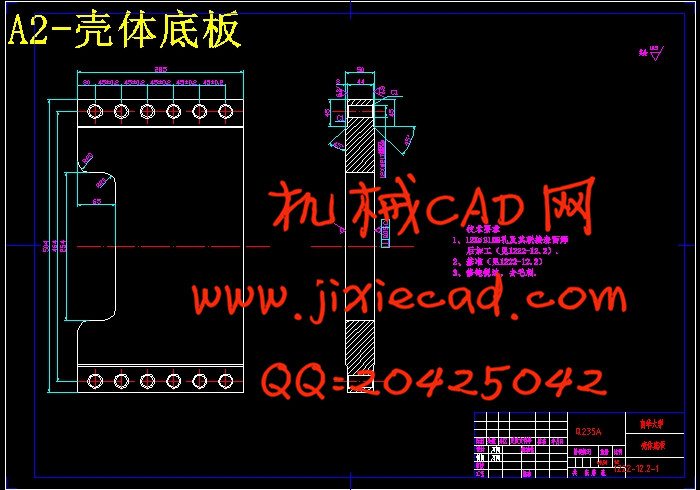

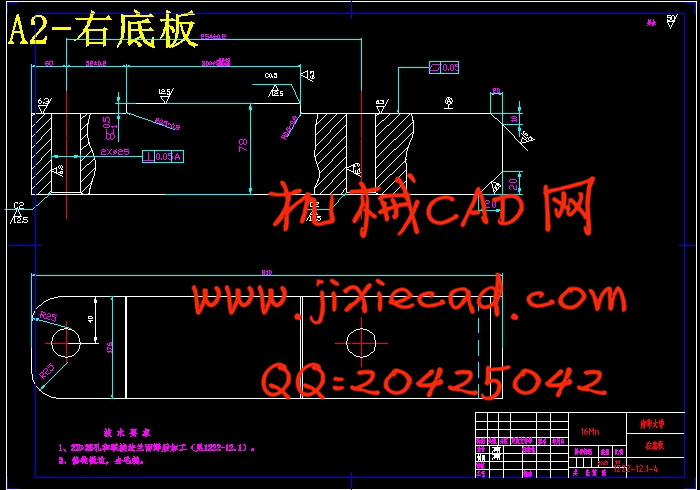

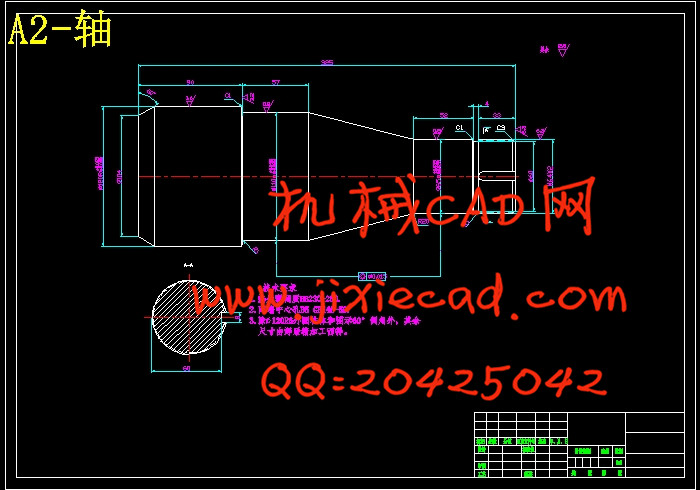

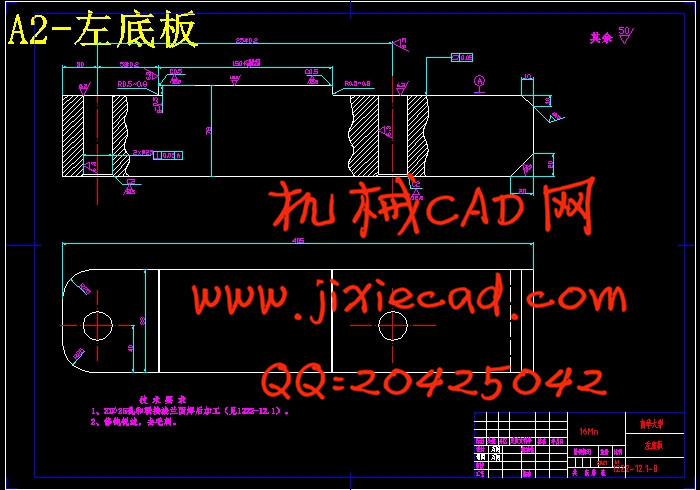

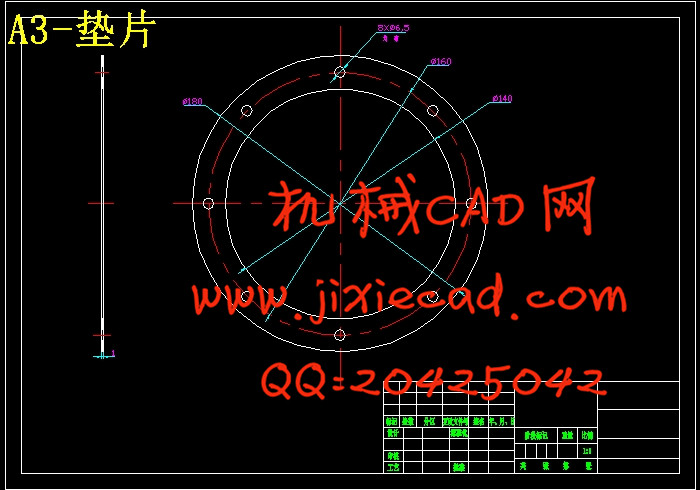

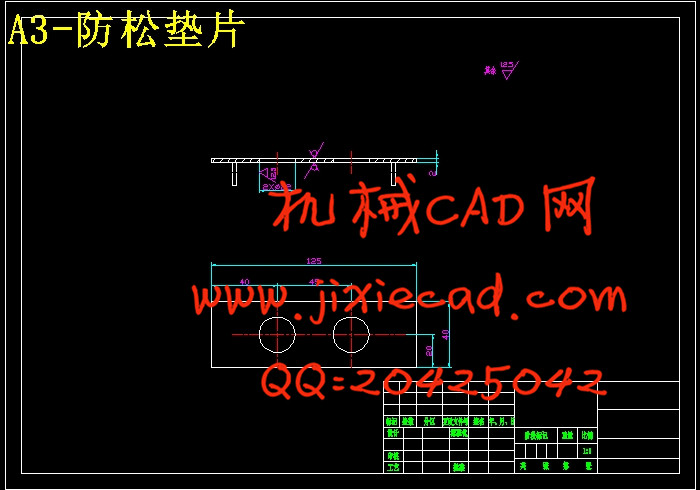

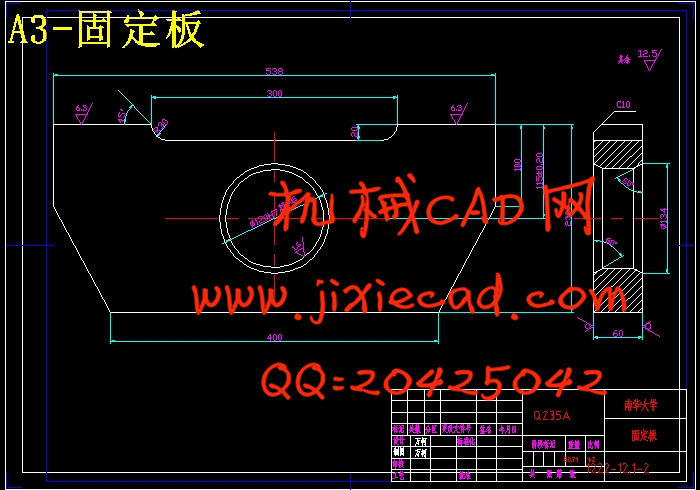

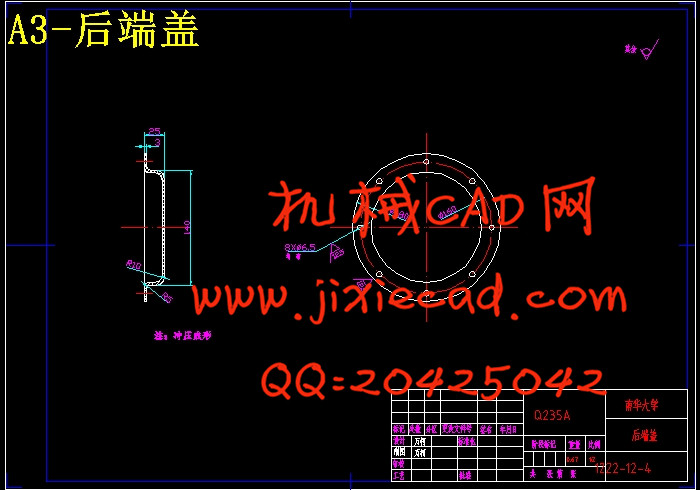

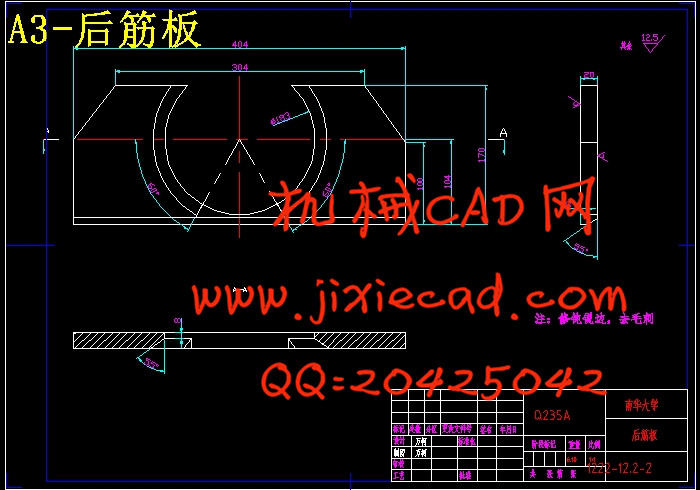

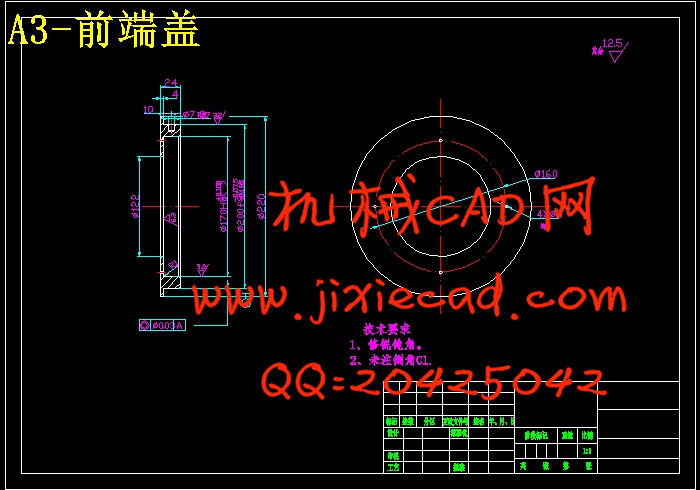

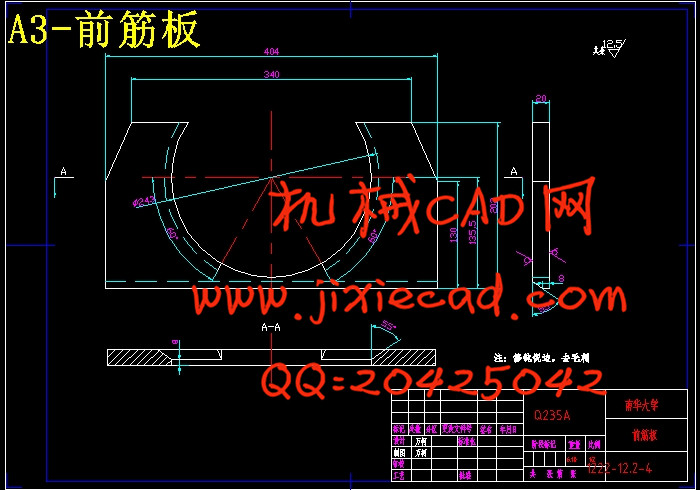

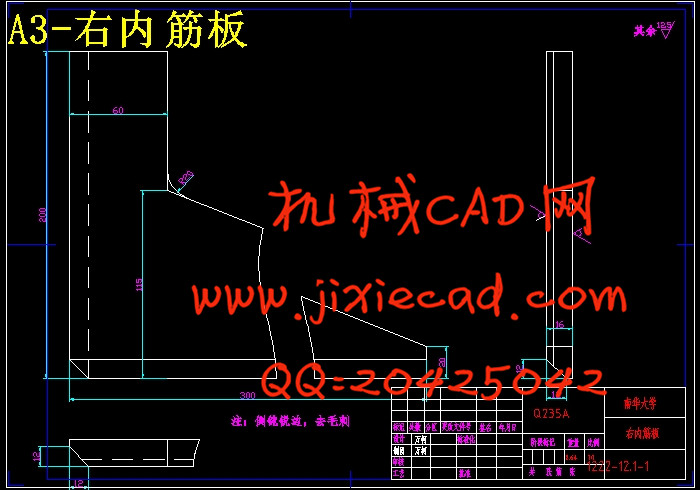

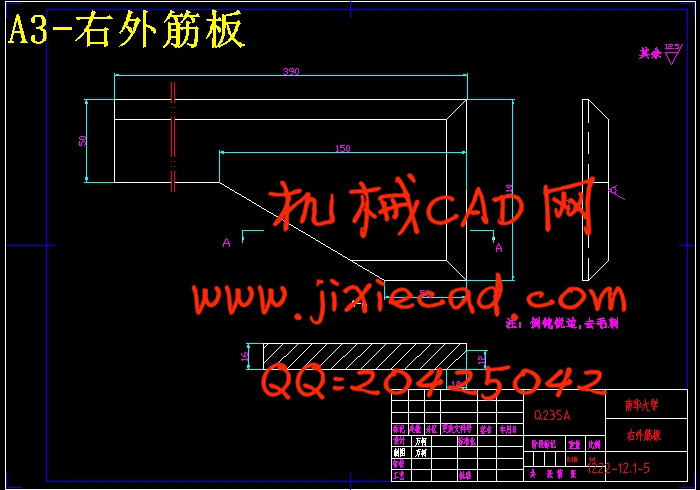

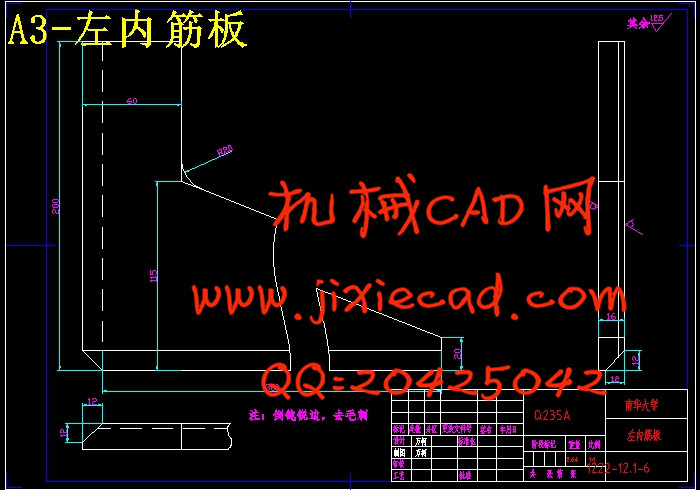

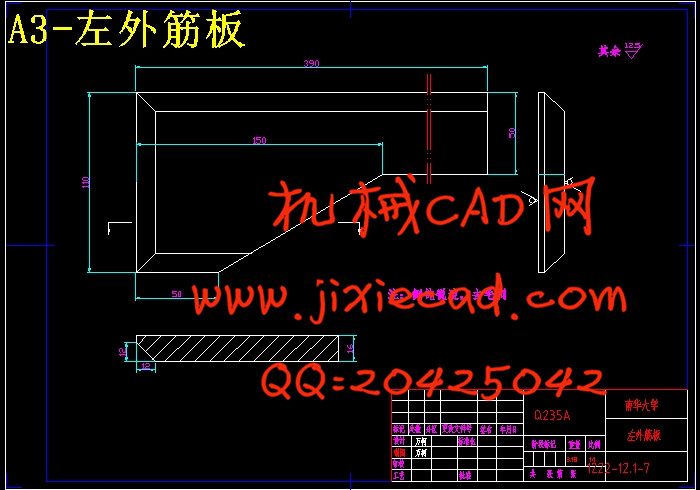

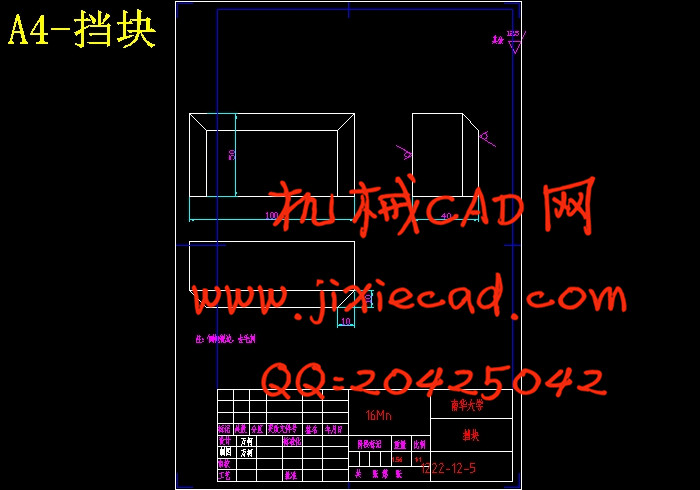

4 铲运机后桥摆动架主要部件的设计及计算................................................20

4.1 设计方案和思路...........................................................................................20

4.2 后桥摆动架的设计和计算...........................................................................20

5 铲运机后桥摆动架主要部件的焊接工艺.....................................................35

5.1 焊接结构的特点...........................................................................................35

5.2 常用的焊接方法...........................................................................................35

5.3 摆动叉的焊接工艺.......................................................................................38

6 后桥摆动架的三维造型......................................................................................42

参考文献......................................................................................................................46

谢辞................................................................................................................................47

摘要:地下铲运机是专门为地下作业而设计的一种矮车身、中央铰接、前端装载的装、运、卸联合作业设备,具有高效、灵活、机动、多用途和生产费用低等突出优点,在国内外矿山和地下工程中得到了广泛应用。地下铲运机的工作环境非常恶劣,为了使地下铲运机适应不平的采场路面,增加铲运机在装矿或运输工作中的稳定性,其后桥上设计有摆动架,以保证前车的后架在一定角度内作相对摆动。后车架通过摆动架的回转轴与摆动架铰接,后车架与后桥之间有足够的摆动空间。当铲运机通过不平路面时,后桥能够相对后车架摆动,而后架在后桥摆动时仍能保持正常位置。铲运机在平坦的路面上进行铲掘或运输作业时,由于 4 个车轮同时着地,摆动架不工作。铲运机在凹凸不平的地面上进行铲掘或运输作业,当后桥左轮着地,右轮腾空时,左轮受到地面的作用力并作用到摆动架上,加上后车架作用在后桥上的重力,使摆动架产生一个力矩,该力矩使摆动架体绕摆动轴转动,并且带动后桥右轮着地。同理,当后桥右轮着地,左轮腾空时,通过摆动架可保持后桥左、右轮始终着地。因此,当铲运机在不平的路面上行驶时,两侧车轮可以保证同时接触地面,改善车轮的附着条件,充分利用整机的黏着重量,增大牵引力和铲斗的铲掘力。

关键词:地下铲运机;后桥摆动架;后桥

The design of the rear axle swing frame of the CYE-1 electric scrapers

Abstract: The underground scraper is specially designed for underground work.It has a short body,a central hinge , it is a joint operating equipment of front loading ,transporting

and unloading.The highlight advantages of the equipment is efficient ,flexible,versatile

and low production costs and so on.It has been widely used in domestic and foreign mining

and underground engineering,The working environment of the underground scrapers is very bad.In order to adapt to the uneven stope road,increase the stability of the scrapers in mining equipment or transportation work,the subsequent bridge swing is design to ensure that the vehicle in front will be rotate in a certain angle related to swing..There is enough swing space between the rear frame and rear axle.When the scraper passes the uneven road, the rear axle is relatively frame swing, and then mounted on the rear axle swing and still maintain a normal position.when the scraper do the shovel or transport work,as the four

wheels touch the ground,the swing frame does not work.When the scraper shovel or transport on uneven ground ,the rear axle revolver, the right wheel vacated, revolvers by the ground forces and the role to the swing rack, plus rear frame in the post-bridge gravity to produce a torque of the swing frame, the torque to the swing frame body around the swing axis of rotation, and drive the rear axle right wheel to the ground.Similarly, when the right wheel of the rear axle, revolvers vacated ,through the swing frame,it can make the left

and right wheel of the bridge always to the ground.Therefore, when the scraper drives on uneven road, both sides of the wheel can be attached to ensure contact with the ground to improve the wheel, make full use of the adhesive weight of the machine, increases traction

and shovel force.

Key words:The underground scraper;Rear axle swing frame;Rear axle

目 录

1 绪论 ...........................................................................................................................2

1.1 设计研究的目的和意义..................................................................................2

1.2 铲运机应用与发展回顾..................................................................................2

1.3 未来技术发展展望..........................................................................................5

1.4 设计拟解决的关键问题和研究方法..............................................................6

2 铲运机总体分析......................................................................................................8

2.1 铲运机的组成系统及功能 ...........................................................................8

2.2 铲运机的工作方式.........................................................................................9

2.3 铲运机的技术水平.......................................................................................10

2.4 电动铲运机...................................................................................................12

3 CYE型电动铲运机总体参数与原理...............................................................16

3.1 CYE电动铲运机主要技术参数 ..................................................................16

3.2 CYE电动铲运机工作原理............................................................................17

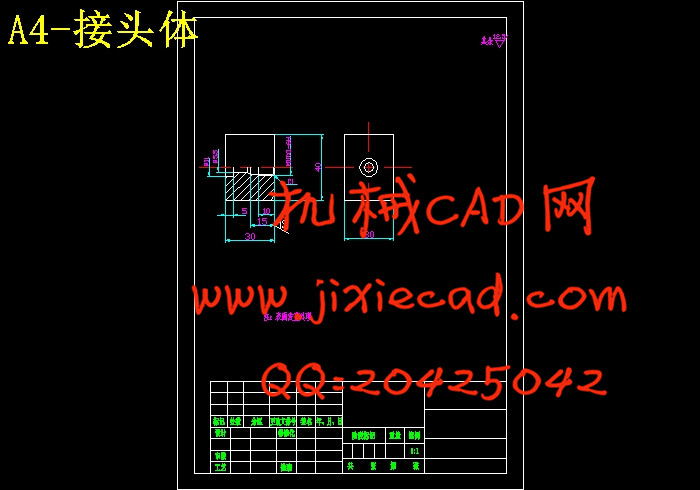

4 铲运机后桥摆动架主要部件的设计及计算................................................20

4.1 设计方案和思路...........................................................................................20

4.2 后桥摆动架的设计和计算...........................................................................20

5 铲运机后桥摆动架主要部件的焊接工艺.....................................................35

5.1 焊接结构的特点...........................................................................................35

5.2 常用的焊接方法...........................................................................................35

5.3 摆动叉的焊接工艺.......................................................................................38

6 后桥摆动架的三维造型......................................................................................42

参考文献......................................................................................................................46

谢辞................................................................................................................................47