设计简介

CYE-1电动铲运机工作装置设计

摘要:CYE-1电动铲运机的工作装置设计的合理性直接影响整机的性能,对提高效率及其自动化程度具有重要的意义。本次设计分析了国内外铲运机的发展现状及发展趋势,指出了国内相对落后的地方,同时详细介绍了铲运机工作装置的组成及重要性。

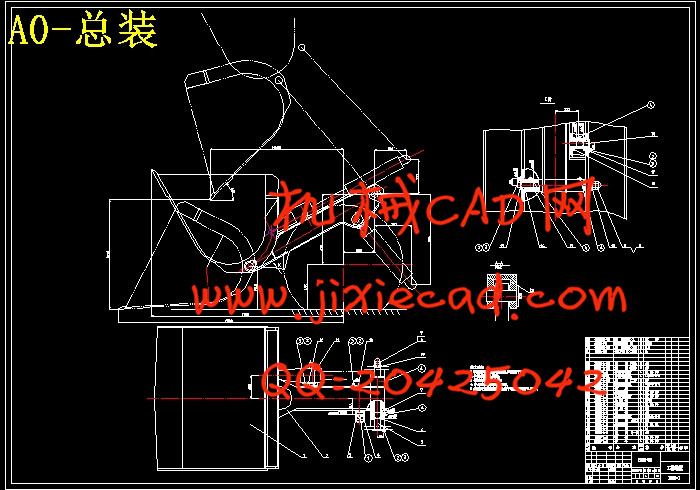

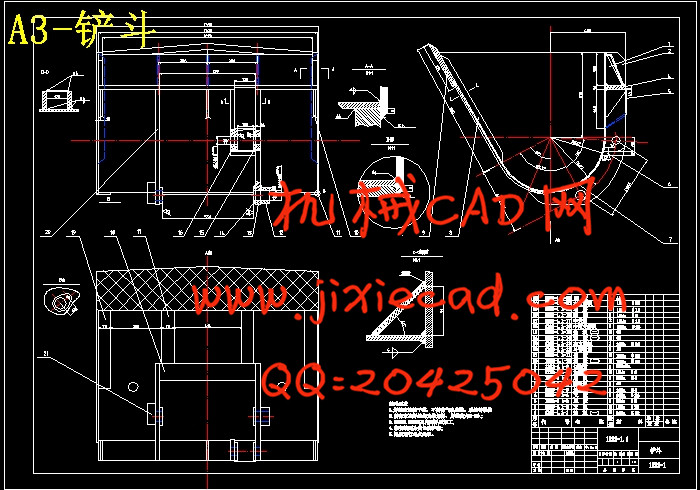

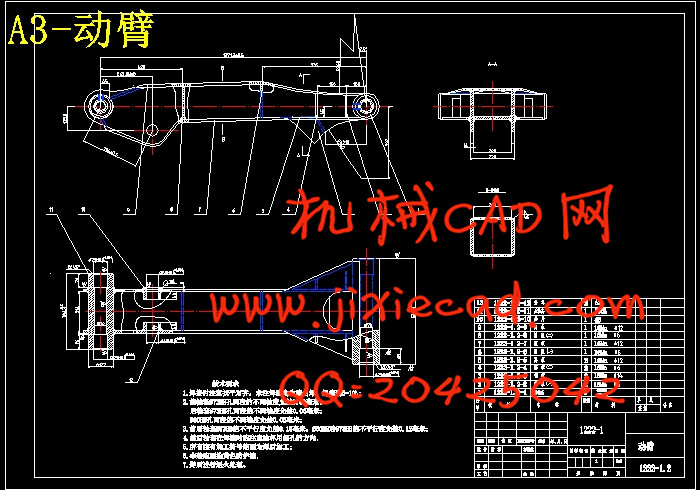

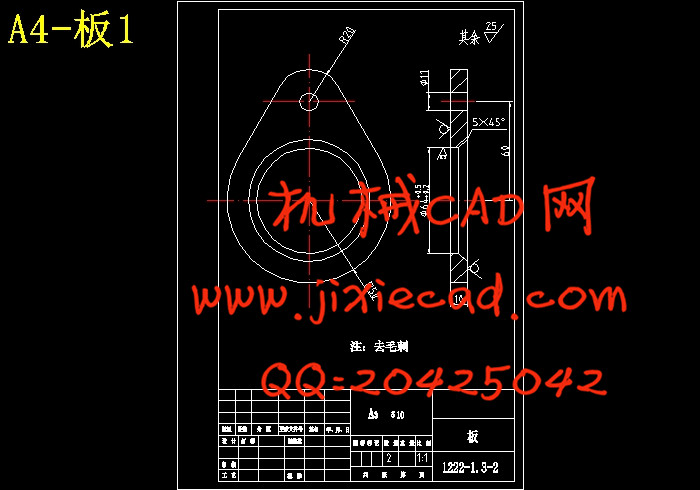

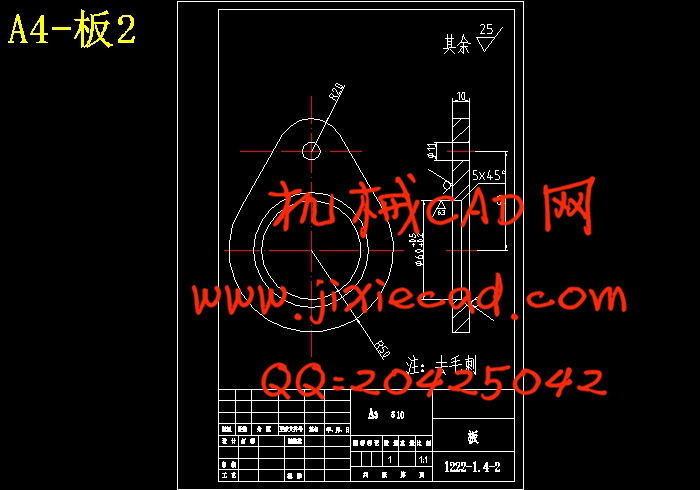

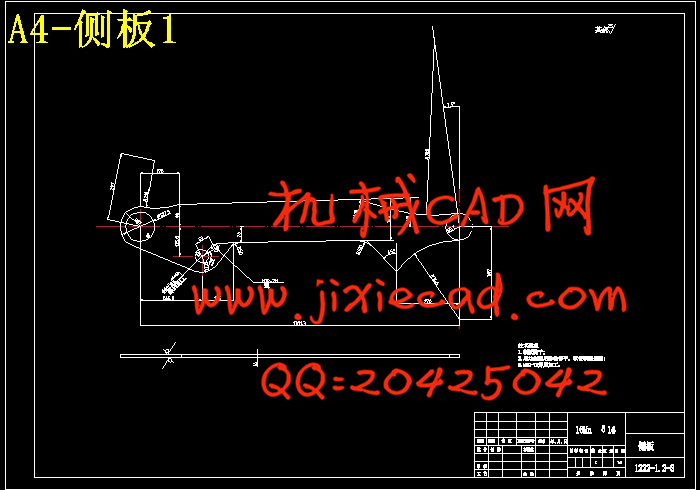

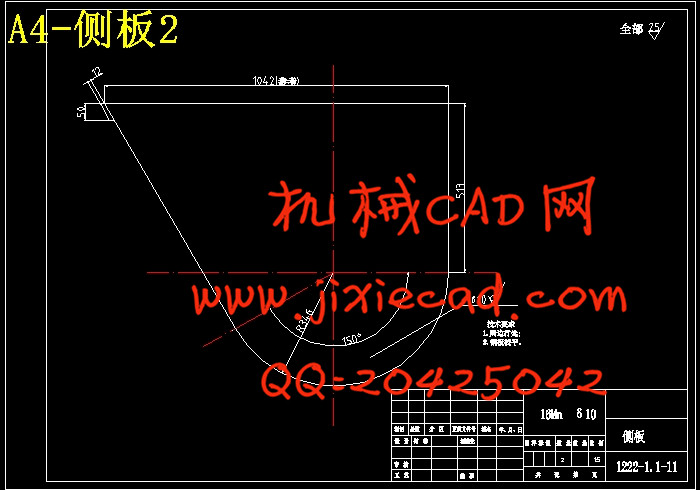

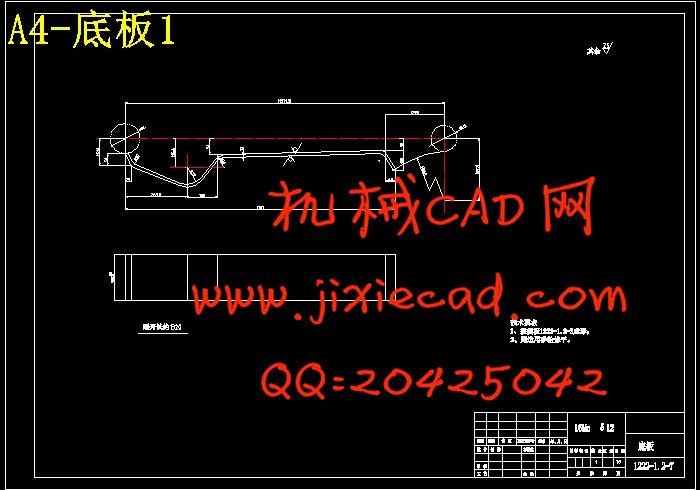

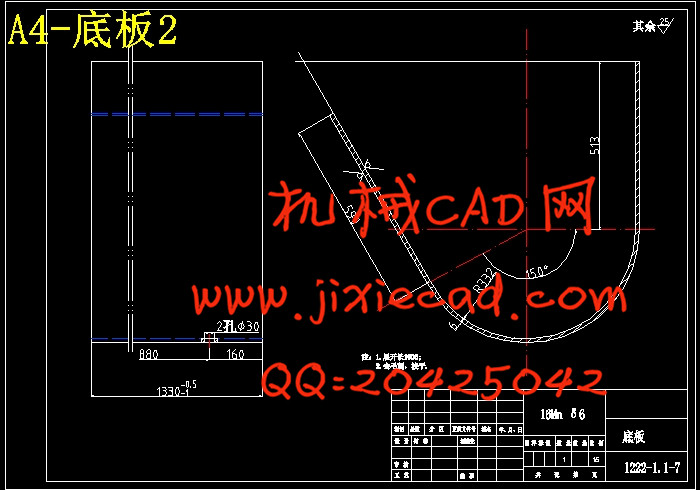

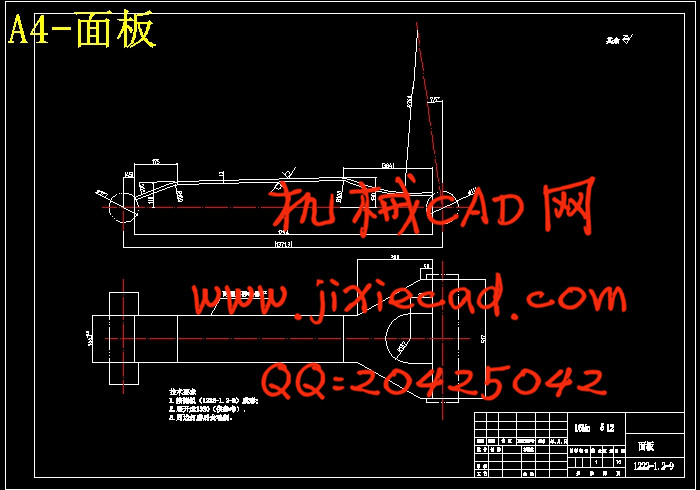

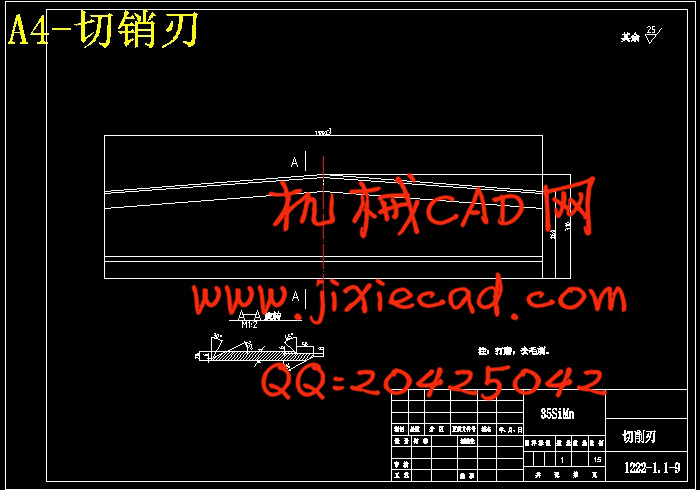

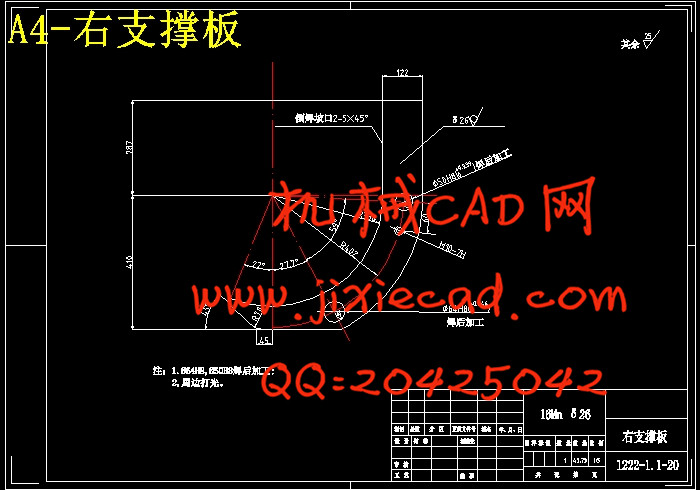

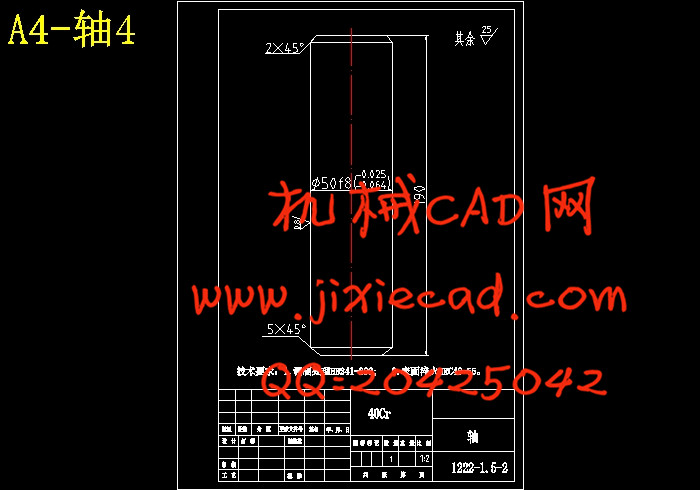

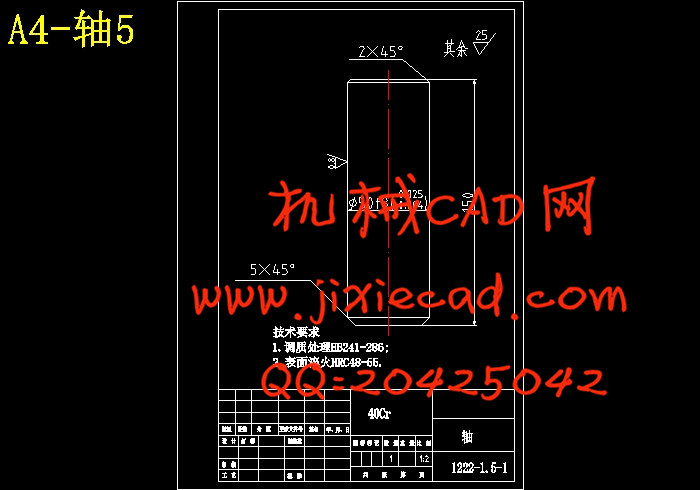

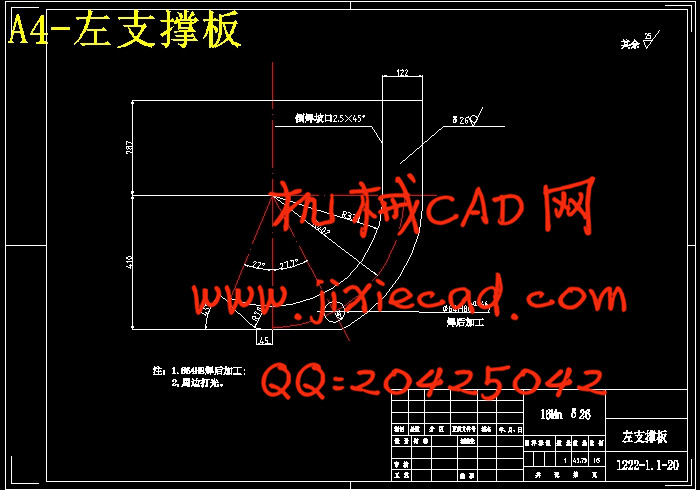

利用cad软件,画出了结工作装置详细二维图纸,清晰地表达了铲运机工作装置的布局、连接。

本次设计是通过计算得出各个结构相应尺寸并查阅国内外资料确定结构类型,将其工作过程分为插入、铲掘、举升、卸载和自动放平五个工况,并通过计算分析了工作装置各个工况中,构件的动作情况及相关的运动参数。最后进行受力分析以及强度校核。

关键词:铲运机;工作装置;运动分析;校核

CYE-1 Load-haul-dump unit Working Device

Abstract:CYE-1 scraper device designed to work directly affects the rationality of machinperformance, efficiency and automation of great significance.Analysis of thedevelopment of domestic and foreign scraper situation and development trend, pointedout the relatively backward areas of domestic, while the scraper detail the compositionand the importance of working equipment.

With CAD software, drawing with two-dimensional drawings, work toachieve a scraper device modeling, a clear understanding of the scraper attachment of the layout, connections.

This design is obtained by calculating the appropriate size of each structure todetermine the structure and access to domestic and international data types, will be inserted into the process of their work shoveL lifiing, unloading and automaticflat five conditions, and detailed analysis of the working conditions of the variousdevices, components and related action, the motion parameters.finally,Will be stress analysis and Strength check.

Keywords: LHD; working device; motion analysis;checking

目录

1 概述…………………………………………………………..................................1

1.1 铲运机的综述………………………………………………………………1

1.2 国、内外地下铲运机的发展和研究状况…………………………………2

1.3 铲运机的工作装置…………………………………………………………4

2 铲运机工作装置分析………………………………………………………….9

2.1 铲斗的基本组成方式………………………………………………………9

2.2 铲斗的分类………………………………………………………………..10

2.3 铲斗的设计………………………………………………………………..11

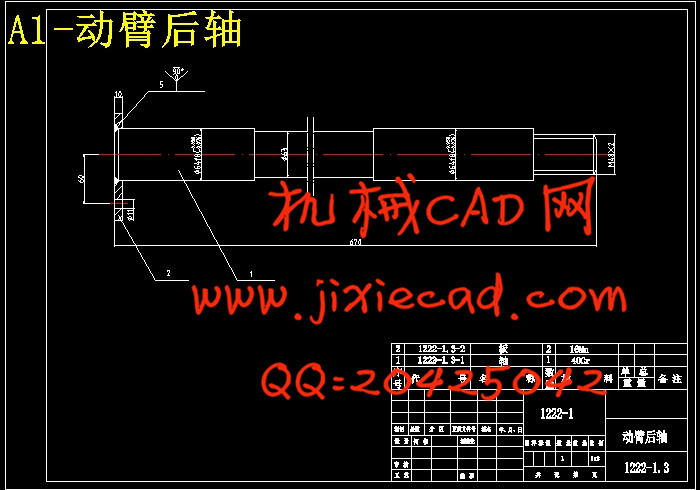

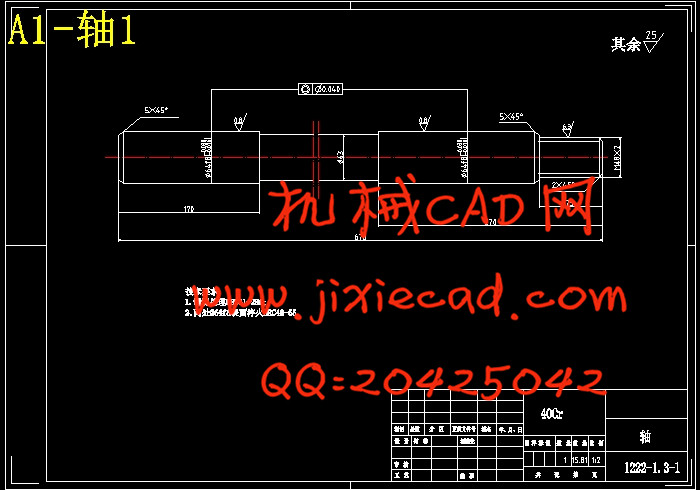

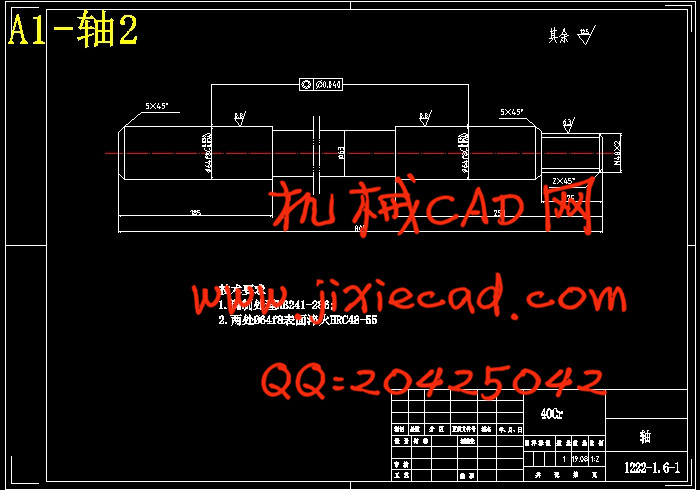

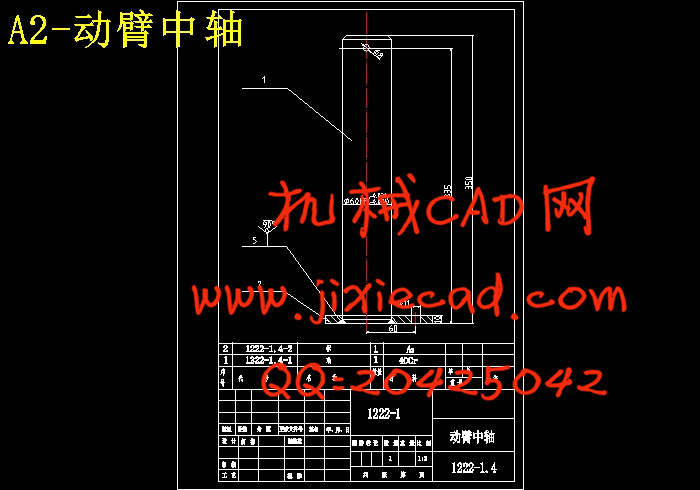

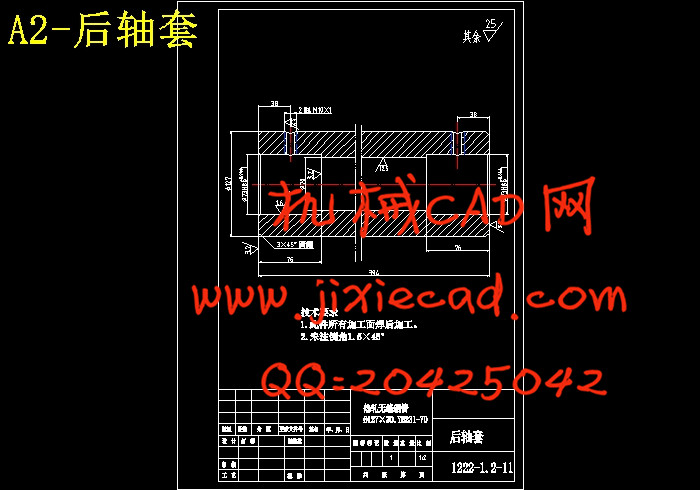

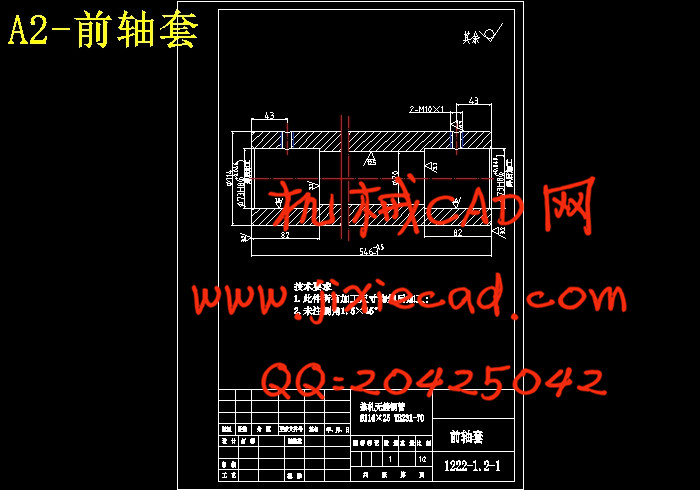

2.4 动臂的设计………………………………………………………………..16

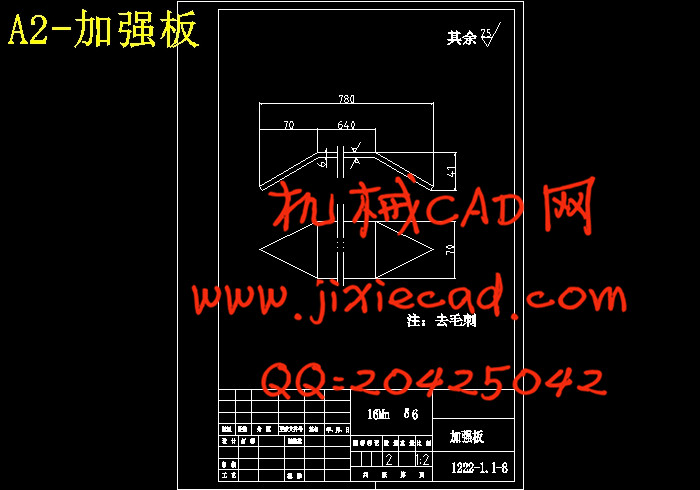

2.5 连杆的设计………………………………………………………………..17

2.6 铲运机工作装置动臂各铰接点位置的确定……………………………..18

2.7 确定摇臂与铲斗的铰接点F………………………………………………19

2.8 动臂举升油缸与动臂和车架铰接点H及M点的确定……………………21

2.9 工作装置连杆机构的运动学与动力学分析……………………………..23

3 力学计算及其强度校核……………………………………………………...29

3.1 外载荷计算………………………………………………………………..29

3.2 工作装置的受力分析……………………………………………………..31

3.3 工作装置的强度校核……………………………………………………..33

4 参考文献………………………………………………………………………...40

5 谢辞………………………………………………………………………………41

摘要:CYE-1电动铲运机的工作装置设计的合理性直接影响整机的性能,对提高效率及其自动化程度具有重要的意义。本次设计分析了国内外铲运机的发展现状及发展趋势,指出了国内相对落后的地方,同时详细介绍了铲运机工作装置的组成及重要性。

利用cad软件,画出了结工作装置详细二维图纸,清晰地表达了铲运机工作装置的布局、连接。

本次设计是通过计算得出各个结构相应尺寸并查阅国内外资料确定结构类型,将其工作过程分为插入、铲掘、举升、卸载和自动放平五个工况,并通过计算分析了工作装置各个工况中,构件的动作情况及相关的运动参数。最后进行受力分析以及强度校核。

关键词:铲运机;工作装置;运动分析;校核

CYE-1 Load-haul-dump unit Working Device

Abstract:CYE-1 scraper device designed to work directly affects the rationality of machinperformance, efficiency and automation of great significance.Analysis of thedevelopment of domestic and foreign scraper situation and development trend, pointedout the relatively backward areas of domestic, while the scraper detail the compositionand the importance of working equipment.

With CAD software, drawing with two-dimensional drawings, work toachieve a scraper device modeling, a clear understanding of the scraper attachment of the layout, connections.

This design is obtained by calculating the appropriate size of each structure todetermine the structure and access to domestic and international data types, will be inserted into the process of their work shoveL lifiing, unloading and automaticflat five conditions, and detailed analysis of the working conditions of the variousdevices, components and related action, the motion parameters.finally,Will be stress analysis and Strength check.

Keywords: LHD; working device; motion analysis;checking

目录

1 概述…………………………………………………………..................................1

1.1 铲运机的综述………………………………………………………………1

1.2 国、内外地下铲运机的发展和研究状况…………………………………2

1.3 铲运机的工作装置…………………………………………………………4

2 铲运机工作装置分析………………………………………………………….9

2.1 铲斗的基本组成方式………………………………………………………9

2.2 铲斗的分类………………………………………………………………..10

2.3 铲斗的设计………………………………………………………………..11

2.4 动臂的设计………………………………………………………………..16

2.5 连杆的设计………………………………………………………………..17

2.6 铲运机工作装置动臂各铰接点位置的确定……………………………..18

2.7 确定摇臂与铲斗的铰接点F………………………………………………19

2.8 动臂举升油缸与动臂和车架铰接点H及M点的确定……………………21

2.9 工作装置连杆机构的运动学与动力学分析……………………………..23

3 力学计算及其强度校核……………………………………………………...29

3.1 外载荷计算………………………………………………………………..29

3.2 工作装置的受力分析……………………………………………………..31

3.3 工作装置的强度校核……………………………………………………..33

4 参考文献………………………………………………………………………...40

5 谢辞………………………………………………………………………………41