设计简介

摘要

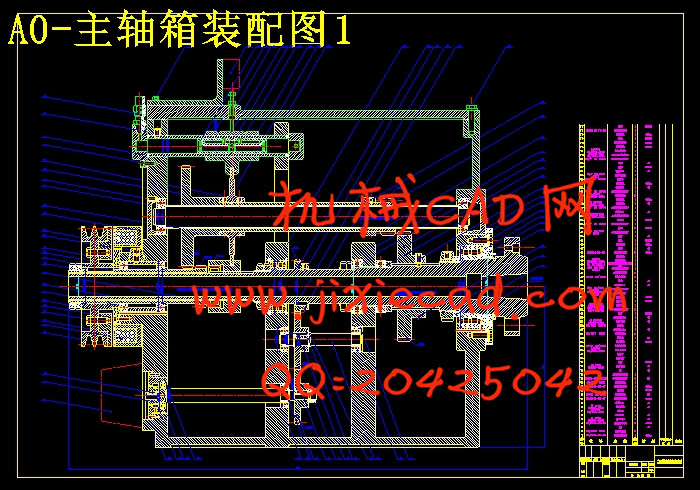

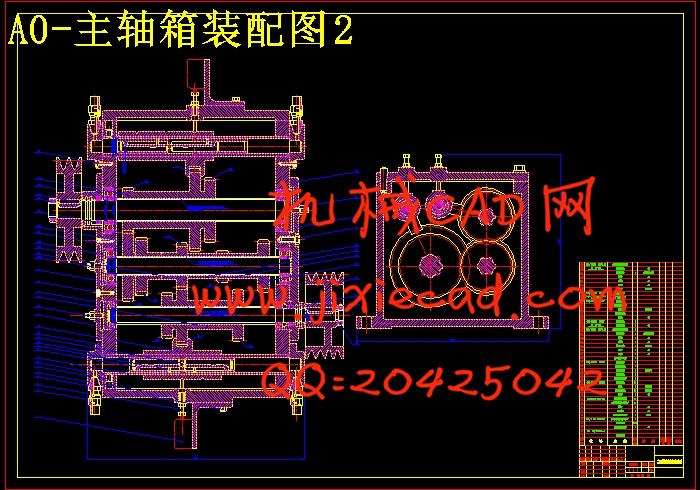

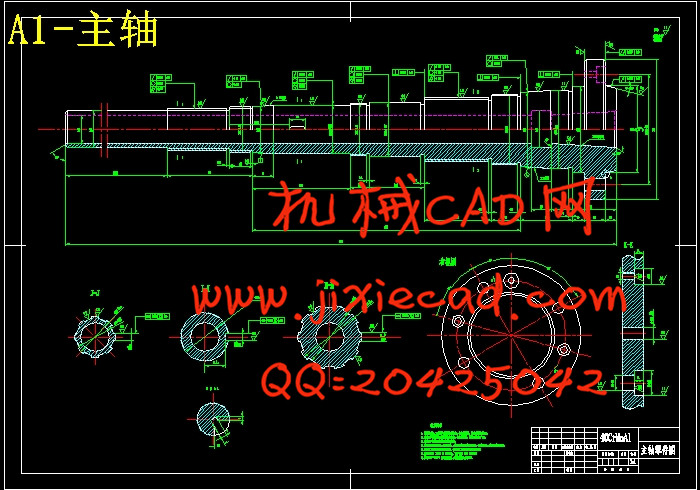

在本次设计中,我采用常规分离式主传动设计,机床主传动采用液压操纵机构,可实现十八级转速。机床主轴箱内的传动齿轮均经淬硬磨齿处理,传动比稳定,运转噪音低。机床主轴为二支撑结构,前支撑采用C级高精度轴承,润滑油润滑,提高了回转精度,使机床主轴具有良好的精度和刚性。

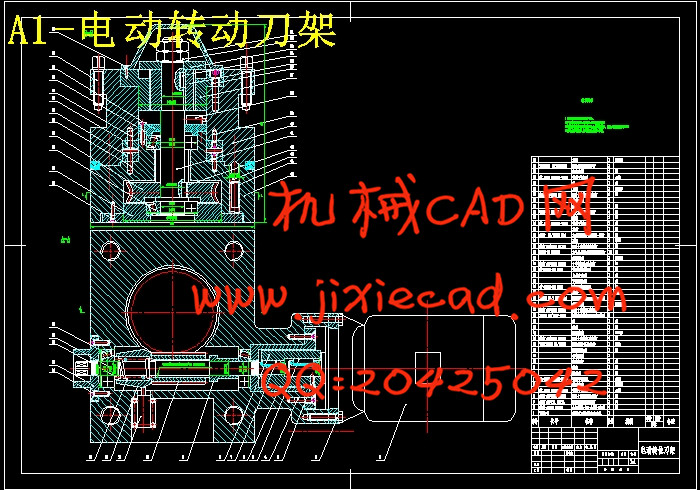

机床采用单片式电磁刹车离合器,解决主轴的刹车及离合问题,离合器安装于主轴箱带轮处,使床头箱内结构大为简化,便于维修。机床两轴进给系统采用步进电机驱动滚珠丝杠的典型传动方式,在滑板与床鞍及床鞍与床身之间的滑动面处贴有TSF导轨板,滑动磨擦系数非常小,有助于提高了机床的快速响应性能及生产效率。机床采用立式四工位刀架,该刀架布刀方便,刚性好。

进给方面,采用开环数控系统,即步进电机数控进给方式。采用步进电机开环数控系统已基本能满足进给精度的要求。主传动由于采用了分离传动发案,可较好的隔离电机及变速箱的震动,解决了热变形对主轴的影响,提高机床的加工精度。再者,数控系统采用单片机技术,可靠性高,成本低,经济性好。在总体性能上可以达到经济精密数控机床之列,达到较好的性价比。

该机床可以加工各种轴类、盘类零件,可以车削各种螺纹、圆弧、圆锥及回转体的内外曲面。作为通用型机床,特别适合汽车工业、摩托车行业、电子工业、航天、军工等行业,对旋转体类零件进行高效、大批量、高精度加工时采用。

机床采用机、电、液一体化结构,整体布局紧凑合理,便于维修和保养,外形符合人机工程学的原理,宜人性好,便于操作。

关键词: CNC CJ6132 分离传动 步进电机

ABSTRACT

In this design, I adopt the normal regulations to separate the type the lord to spread to move the design, Lathes the lord spread to move to adopt the liquid to press to manipulate the organization, and can realize 18 classes turn soon. Lathes principal axis box the spreading of inside move the wheel gear to all was wheted by quench the gear to handle, spread to move the ratio stability, and revolve the noise low. Lathes principal axis is two prop up the construction, and before prop up to adopt the high accuracy bearings of C class, grease, and increase the turn-over accuracy, and make the Lathes the principal axis have the good accuracy with rigid.

Lathes adoption brake for type electromagnetism brake clutch, solution principal axis of single slice and leave to match the problem, clutch to install to take the round in the principal axis box, and make first inside construction is big for the simplification, convenient for maintain. Lathes two stalks enter the system to adopt the step the glide for typical model for entering the electrical engineering drive recirculating-ball screw spreading moving the way, among the skateboard and bed saddle and bed saddle and bed body to stick to have the TSF driver track the plank, glide coefficient of friction very small, is beneficial toed to increase the Lathes of quickly respond to the function and produce the efficiency. Four knifes, the knife's of types of adoption on edge of Lathes cloth knife convenience, rigid good.

Enter to give the aspect, and adopt to open wreath Numerical control the system, namely step enter electrical engineering Numerical control enter to the way. Adoption step request for entering the electrical engineering opening wreath Numerical control the system already basic satisfy into to the accuracy. The lord spreads to move because of adopting the separation to spread to move the hair case, can good insulation electrical engineering and become soon the box's vibration, solve hot transform to influence principal axis, increase the processing of Lathes of accuracy.

Furthermore, Numerical control system adoption the machine technique of single slice, dependable is high, and the cost is low, and the economic is good.

Can attain the row of the bed of economic and precise Numerical control machine on the total function, and attain the ratio of good sex price.

Can cut many kinds of screw thread, round, taper and rotor.

The Lathes can process the every kind of stalk, dish spare parts,

Be used as the bed of in general use type machine, special in keeping with car the industry, motorcycle the profession, electronics the industry, spaceflight, soldier the work the etc. the profession, right revolve the spare parts proceeds efficiently, large quantity measure, the high accuracy process the hour the adoption.

Lathes adoption machine, electricity, liquid incorporate. integrative construction, the whole layout tightly packed reasonable, convenient for maintain with maintain, and the shape match the person machine the engineering the principle, pleasant that learn good, convenient for operation.

Key phrase: Numerical control CJK6132 Apart driver Walking electromotor

目 录

一、总体方案设计 5

(一)、主传动的组成部分 6

(二)、机床主要部件及其运动方式的选定 7

(三)、机床的主要技术参数 8

(四)、各组成部件的特性与所应达到的要求 8

二、机床主传动设计 10

(一)、主要技术参数的确定 11

1.尺寸参数 11

2.运动参数 13

3、主轴转速的确定 15

4、转速范围及公比 的确定 15

的确定 15

5、结构式与结构网的确定 16

6、转速图的拟定 17

7、传动比参数的确定 18

(二)、传动系统图的拟定 19

(三)、电动机的选择 21

(四)、齿轮传动的设计计算 21

(五)、轴的设计计算 25

三、进给系统的设计计算 40

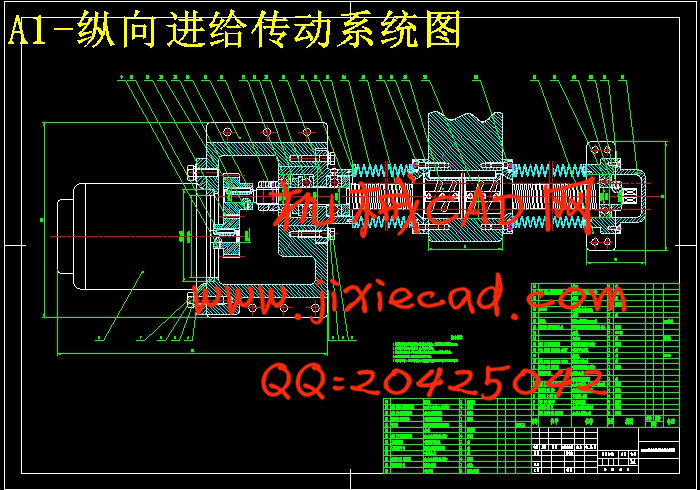

(一)、纵向进给系统的设计计算 40

1、 切削力计算 40

2、滚珠丝杠设计计算 41

(二)、横向进给系统的设计计算 46

1、滚珠丝杠螺母副的选择计算 46

3、步进电机的选择 50

四、 数控系统设计 53

(一)、单片机系统控制设计的基本要求 53

(二)、数字控制系统框图 53

(三)、数控系统的硬件特点: 54

(四)、控制系统图及芯片的选择 54

(五)、存储器及系统扩展设计。 59

1、基本知识 59

2.程序器的扩展 61

3、数据存储器的扩展 61

4、存储器地址空间的分配 62

5、I/O接口的扩展 62

(六)、键盘及键盘接口设计 64

(七)、显示器接口设计 65

(八)、步进电机控制电路 67

(九)、部分控制程序: 73

1. 直线圆弧插补程序设计 73

2直线插补程序 73

3.圆弧插补程序得设计 74

4、LED动态显示程序设计: 78

5、串行扩展口的键盘、显示器接口电路软件设计: 80

6、步进电机控制 83

7、自动转位刀架控制 87

参考文献 96

结束语 97

在本次设计中,我采用常规分离式主传动设计,机床主传动采用液压操纵机构,可实现十八级转速。机床主轴箱内的传动齿轮均经淬硬磨齿处理,传动比稳定,运转噪音低。机床主轴为二支撑结构,前支撑采用C级高精度轴承,润滑油润滑,提高了回转精度,使机床主轴具有良好的精度和刚性。

机床采用单片式电磁刹车离合器,解决主轴的刹车及离合问题,离合器安装于主轴箱带轮处,使床头箱内结构大为简化,便于维修。机床两轴进给系统采用步进电机驱动滚珠丝杠的典型传动方式,在滑板与床鞍及床鞍与床身之间的滑动面处贴有TSF导轨板,滑动磨擦系数非常小,有助于提高了机床的快速响应性能及生产效率。机床采用立式四工位刀架,该刀架布刀方便,刚性好。

进给方面,采用开环数控系统,即步进电机数控进给方式。采用步进电机开环数控系统已基本能满足进给精度的要求。主传动由于采用了分离传动发案,可较好的隔离电机及变速箱的震动,解决了热变形对主轴的影响,提高机床的加工精度。再者,数控系统采用单片机技术,可靠性高,成本低,经济性好。在总体性能上可以达到经济精密数控机床之列,达到较好的性价比。

该机床可以加工各种轴类、盘类零件,可以车削各种螺纹、圆弧、圆锥及回转体的内外曲面。作为通用型机床,特别适合汽车工业、摩托车行业、电子工业、航天、军工等行业,对旋转体类零件进行高效、大批量、高精度加工时采用。

机床采用机、电、液一体化结构,整体布局紧凑合理,便于维修和保养,外形符合人机工程学的原理,宜人性好,便于操作。

关键词: CNC CJ6132 分离传动 步进电机

ABSTRACT

In this design, I adopt the normal regulations to separate the type the lord to spread to move the design, Lathes the lord spread to move to adopt the liquid to press to manipulate the organization, and can realize 18 classes turn soon. Lathes principal axis box the spreading of inside move the wheel gear to all was wheted by quench the gear to handle, spread to move the ratio stability, and revolve the noise low. Lathes principal axis is two prop up the construction, and before prop up to adopt the high accuracy bearings of C class, grease, and increase the turn-over accuracy, and make the Lathes the principal axis have the good accuracy with rigid.

Lathes adoption brake for type electromagnetism brake clutch, solution principal axis of single slice and leave to match the problem, clutch to install to take the round in the principal axis box, and make first inside construction is big for the simplification, convenient for maintain. Lathes two stalks enter the system to adopt the step the glide for typical model for entering the electrical engineering drive recirculating-ball screw spreading moving the way, among the skateboard and bed saddle and bed saddle and bed body to stick to have the TSF driver track the plank, glide coefficient of friction very small, is beneficial toed to increase the Lathes of quickly respond to the function and produce the efficiency. Four knifes, the knife's of types of adoption on edge of Lathes cloth knife convenience, rigid good.

Enter to give the aspect, and adopt to open wreath Numerical control the system, namely step enter electrical engineering Numerical control enter to the way. Adoption step request for entering the electrical engineering opening wreath Numerical control the system already basic satisfy into to the accuracy. The lord spreads to move because of adopting the separation to spread to move the hair case, can good insulation electrical engineering and become soon the box's vibration, solve hot transform to influence principal axis, increase the processing of Lathes of accuracy.

Furthermore, Numerical control system adoption the machine technique of single slice, dependable is high, and the cost is low, and the economic is good.

Can attain the row of the bed of economic and precise Numerical control machine on the total function, and attain the ratio of good sex price.

Can cut many kinds of screw thread, round, taper and rotor.

The Lathes can process the every kind of stalk, dish spare parts,

Be used as the bed of in general use type machine, special in keeping with car the industry, motorcycle the profession, electronics the industry, spaceflight, soldier the work the etc. the profession, right revolve the spare parts proceeds efficiently, large quantity measure, the high accuracy process the hour the adoption.

Lathes adoption machine, electricity, liquid incorporate. integrative construction, the whole layout tightly packed reasonable, convenient for maintain with maintain, and the shape match the person machine the engineering the principle, pleasant that learn good, convenient for operation.

Key phrase: Numerical control CJK6132 Apart driver Walking electromotor

目 录

一、总体方案设计 5

(一)、主传动的组成部分 6

(二)、机床主要部件及其运动方式的选定 7

(三)、机床的主要技术参数 8

(四)、各组成部件的特性与所应达到的要求 8

二、机床主传动设计 10

(一)、主要技术参数的确定 11

1.尺寸参数 11

2.运动参数 13

3、主轴转速的确定 15

4、转速范围及公比

5、结构式与结构网的确定 16

6、转速图的拟定 17

7、传动比参数的确定 18

(二)、传动系统图的拟定 19

(三)、电动机的选择 21

(四)、齿轮传动的设计计算 21

(五)、轴的设计计算 25

三、进给系统的设计计算 40

(一)、纵向进给系统的设计计算 40

1、 切削力计算 40

2、滚珠丝杠设计计算 41

(二)、横向进给系统的设计计算 46

1、滚珠丝杠螺母副的选择计算 46

3、步进电机的选择 50

四、 数控系统设计 53

(一)、单片机系统控制设计的基本要求 53

(二)、数字控制系统框图 53

(三)、数控系统的硬件特点: 54

(四)、控制系统图及芯片的选择 54

(五)、存储器及系统扩展设计。 59

1、基本知识 59

2.程序器的扩展 61

3、数据存储器的扩展 61

4、存储器地址空间的分配 62

5、I/O接口的扩展 62

(六)、键盘及键盘接口设计 64

(七)、显示器接口设计 65

(八)、步进电机控制电路 67

(九)、部分控制程序: 73

1. 直线圆弧插补程序设计 73

2直线插补程序 73

3.圆弧插补程序得设计 74

4、LED动态显示程序设计: 78

5、串行扩展口的键盘、显示器接口电路软件设计: 80

6、步进电机控制 83

7、自动转位刀架控制 87

参考文献 96

结束语 97