设计简介

CK600票据连续自动冲孔机设计

摘 要

为了方便使用者,一些票据(如邮票、小型张、纪念张等)周边打有均匀分布的小孔,这些小孔都是在冲孔机上用针模加工出来的。K600型票据自动冲孔机采用PLC控制伺服系统进行票据自动定位、离合器自动控制,加工票据上的小孔。

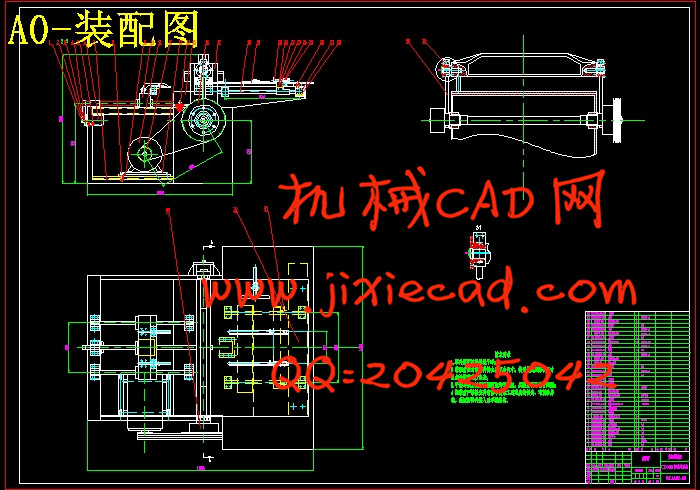

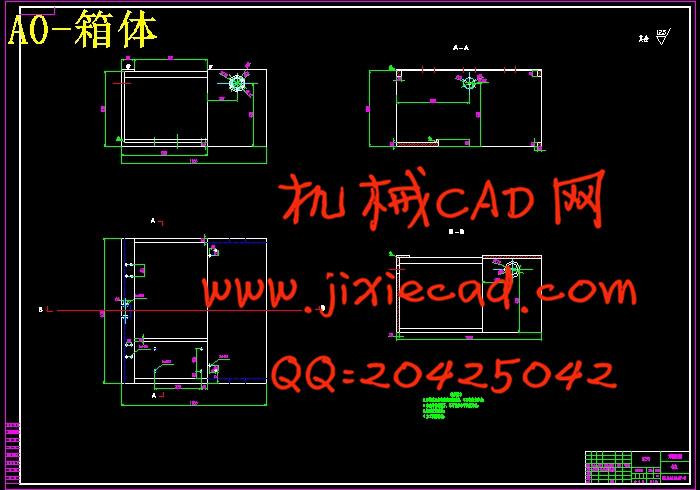

本课题要求设计CK600票据连续自动冲孔机的机械部分,包括机架、送纸定位部分,曲柄滑块冲压部分等。

CK600票据连续自动冲孔机是一种先进的打孔设备,它采用计算机程序控制,由交流伺服电机通过同步带拖动滚珠丝杠螺母副驱动夹紧钳实现进给,它的传动精度较高,同时通过摩擦离合器的开启与闭合来进行上下料的操作。所以要完成本次课程设计必须要对步进电机、离合器、滚珠丝杠螺母副以及同步带、V带等的选择来实现CK600票据连续自动冲孔机的精确定位,以此提高生产效率。

关键词 :自动冲孔机,PLC控制伺服系统步进电机,滚珠丝杠螺母副,离合器

摘 要

为了方便使用者,一些票据(如邮票、小型张、纪念张等)周边打有均匀分布的小孔,这些小孔都是在冲孔机上用针模加工出来的。K600型票据自动冲孔机采用PLC控制伺服系统进行票据自动定位、离合器自动控制,加工票据上的小孔。

本课题要求设计CK600票据连续自动冲孔机的机械部分,包括机架、送纸定位部分,曲柄滑块冲压部分等。

CK600票据连续自动冲孔机是一种先进的打孔设备,它采用计算机程序控制,由交流伺服电机通过同步带拖动滚珠丝杠螺母副驱动夹紧钳实现进给,它的传动精度较高,同时通过摩擦离合器的开启与闭合来进行上下料的操作。所以要完成本次课程设计必须要对步进电机、离合器、滚珠丝杠螺母副以及同步带、V带等的选择来实现CK600票据连续自动冲孔机的精确定位,以此提高生产效率。

关键词 :自动冲孔机,PLC控制伺服系统步进电机,滚珠丝杠螺母副,离合器

The CK600 Bills Continuous Automatic Punching Machine Design

Abstract

For the convenience of users, a number of bills (such as stamps, stamp sheetlet to commemorate the sheets, etc.) surrounding playing uniformly distributed holes, these holes are in the processing out of the mold with the needle punching machine. K800 bills automatically punching machine adopts PLC control servo system notes automatic positioning, clutch control, the hole on the processing of bills.

This project requires the design the CK600 notes continuous automatic punching machine mechanical parts, including the rack, feed positioning part, crank slider stamping part.

The CK600 bills continuous automatic punching machine is an advanced drilling equipment, which uses a computer program control by AC servo motor through timing belt, drag the ball screw pair driven clamping pliers to feed its higher transmission accuracythrough the opening and closing of the friction clutch to the unloading operation. Therefore, the curriculum design to achieve the precise positioning of the the CK600 notes for automatic punching machine must be the choice of stepper motor, clutch, ball screw nut and timing belts, V-belt, etc., in order to improve production efficiency.

Keywords: Automatic punching machine, PLC control servo stepper motor, ball screw nut, clutch

Abstract

For the convenience of users, a number of bills (such as stamps, stamp sheetlet to commemorate the sheets, etc.) surrounding playing uniformly distributed holes, these holes are in the processing out of the mold with the needle punching machine. K800 bills automatically punching machine adopts PLC control servo system notes automatic positioning, clutch control, the hole on the processing of bills.

This project requires the design the CK600 notes continuous automatic punching machine mechanical parts, including the rack, feed positioning part, crank slider stamping part.

The CK600 bills continuous automatic punching machine is an advanced drilling equipment, which uses a computer program control by AC servo motor through timing belt, drag the ball screw pair driven clamping pliers to feed its higher transmission accuracythrough the opening and closing of the friction clutch to the unloading operation. Therefore, the curriculum design to achieve the precise positioning of the the CK600 notes for automatic punching machine must be the choice of stepper motor, clutch, ball screw nut and timing belts, V-belt, etc., in order to improve production efficiency.

Keywords: Automatic punching machine, PLC control servo stepper motor, ball screw nut, clutch

目 录

1 绪论 1

2 设计任务 2

2.1 总要求 2

2.2给定的要求和条件: 2

2.3 文献综述 2

2.3.1 设备的介绍 2

2.3.2 设备的基本组成 2

2.3.3 设备的基本原理 3

3 数据计算 5

3.1传动比的计算 5

3.1.1 电动机的选择 5

3.1.2 传动比的计算 5

3.2离合器的参数计算 5

3.3滚珠丝杠副的选择及参数计算 7

3.3.1滚珠丝杠副传动的特点 7

3.3.2滚珠丝杠副轴向间隙的调整和加预紧力的方法 8

3.3.3滚珠丝杠副的设计计算 9

3.3.4滚珠丝杠副的安装 11

3.3.5滚珠丝杠副的润滑和密封 11

3.4步进电机的选择及参数计算 12

3.4.1步进电机选用的基本原则 13

3.4.2步进电机的选择计算 14

3.4.3步进电动机的使用特性 17

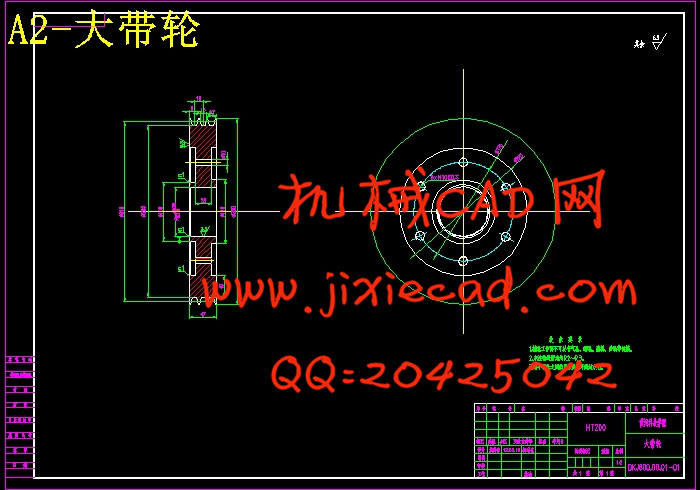

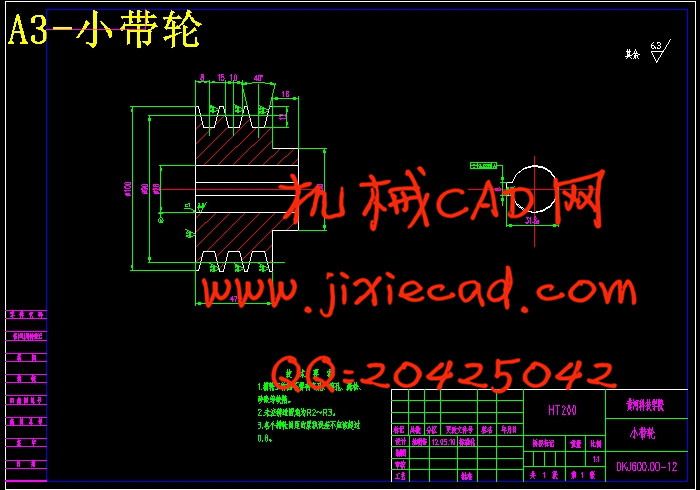

3.5 同步带以及v带传动的设计与计算 18

3.5.1、V带设计 18

3.5.2同步带传动的特点 20

3.5.3同步带的结构、主要参数和尺寸规格 20

3.5.4同步带及带轮的设计计算 21

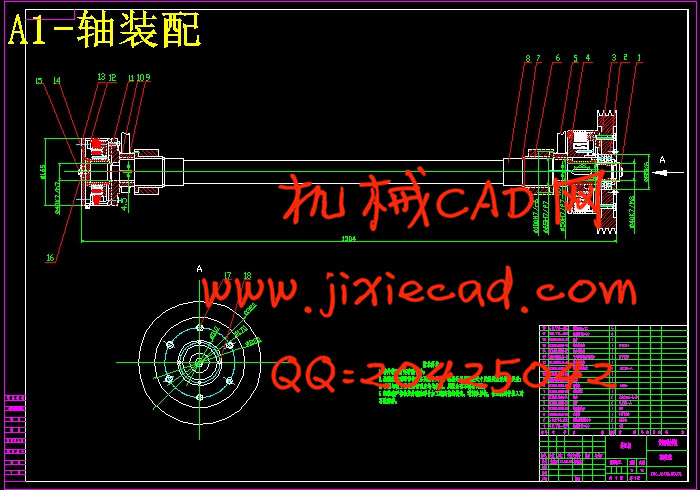

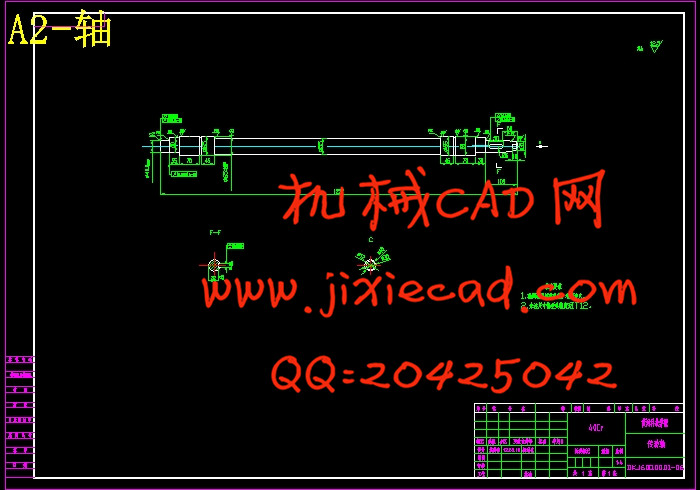

3.6 轴的选择及校核 24

3.6.1轴的概述和材料的选择 24

3.6.2 轴承的选择 28

3.6.3轴承的润滑与密封 29

设计总结 30

致 谢 31

参考文献 32