设计简介

摘要

在我国,无论是煤矿还是冶金矿所使用的提升设备都普遍存在着钢丝绳磨损的问题,尤其是斜井提升设备上使用的钢丝绳,最突出的问题就是钢丝绳磨损,直径变细。我国 《煤矿安全规程》 规定,矿用提升钢丝绳断面积减小 5% 时,不能用来提升工作人员;断面积减小 10% 时,不能用来提升矿用物资。而提升钢丝绳的提升能力及使用状态对于提升设备的安全可靠运行至关重要,因此,每天必须对提升钢丝绳进行检测,以确保提升设备的安全可靠运行。目前,厂矿企业仍然沿用传统的人工检测方法,即人工使用游标卡尺进行抽点检测。这种检测方法存在着很大的弊端,它检测精度低,不能进行连续的实时在线检测,漏检的情况也时有发生,这就给提升安全带来严重隐患。同时,这种方法劳动强度大,检测速度慢。另外,在进行人工检测时,提升钢丝绳必须停止提升,这样会降低工作效率和设备利用率。而且人工检测全凭实际工作经验,精度、效率也会随之降低,既不能完成非接触检测,又不能实现在线检测,同时还增加了检测时给工作人员所带来的危险性。针对这种现状,国内外各高校及研究部门对提升钢丝绳直径的连续实时在线检测进行了大量的研究工作。从检测方法看,主要有两类:磁通检测法、激光扫描法,但这两种检测方法都存在着较大的缺点。磁通检测法检测精度低、设备笨重;激光扫描检测法虽然检测精度高,但是设备复杂、成本高。在这种情况下,利用CCD技术本文提出了一种新的提升钢丝直径测量方法 —— CCD 实时在线非接触式线径测量数码管显示 具有测量快速高效 自动化程度高 示直观等特点 并能克服人工检测所具有的缺点.

关键词 钢丝绳磨损;光电技术;非接触式测量;CCD技术

Keywords rope wear photovoltaic technology on-contact measurement CCD technology

目 录

1绪论 …………………………………………………………………………………………… 1在我国,无论是煤矿还是冶金矿所使用的提升设备都普遍存在着钢丝绳磨损的问题,尤其是斜井提升设备上使用的钢丝绳,最突出的问题就是钢丝绳磨损,直径变细。我国 《煤矿安全规程》 规定,矿用提升钢丝绳断面积减小 5% 时,不能用来提升工作人员;断面积减小 10% 时,不能用来提升矿用物资。而提升钢丝绳的提升能力及使用状态对于提升设备的安全可靠运行至关重要,因此,每天必须对提升钢丝绳进行检测,以确保提升设备的安全可靠运行。目前,厂矿企业仍然沿用传统的人工检测方法,即人工使用游标卡尺进行抽点检测。这种检测方法存在着很大的弊端,它检测精度低,不能进行连续的实时在线检测,漏检的情况也时有发生,这就给提升安全带来严重隐患。同时,这种方法劳动强度大,检测速度慢。另外,在进行人工检测时,提升钢丝绳必须停止提升,这样会降低工作效率和设备利用率。而且人工检测全凭实际工作经验,精度、效率也会随之降低,既不能完成非接触检测,又不能实现在线检测,同时还增加了检测时给工作人员所带来的危险性。针对这种现状,国内外各高校及研究部门对提升钢丝绳直径的连续实时在线检测进行了大量的研究工作。从检测方法看,主要有两类:磁通检测法、激光扫描法,但这两种检测方法都存在着较大的缺点。磁通检测法检测精度低、设备笨重;激光扫描检测法虽然检测精度高,但是设备复杂、成本高。在这种情况下,利用CCD技术本文提出了一种新的提升钢丝直径测量方法 —— CCD 实时在线非接触式线径测量数码管显示 具有测量快速高效 自动化程度高 示直观等特点 并能克服人工检测所具有的缺点.

关键词 钢丝绳磨损;光电技术;非接触式测量;CCD技术

Abstract

In our country, whether or metallurgical coal mine upgrade equipment used by the wire rope wear is prevalent problem, particularly the inclined shaft upgrade equipment used wire rope, the most prominent is the issue of wire rope wear, small diameter. China's "coal mine safety regulations", mine hoisting cable basal area decreased 5%, should not be used to enhance staff; basal area decreased 10 percent, can not be used to upgrade mine supplies. Wire Rope for upgrading and enhancing capacity and the use of state equipment to upgrade the safe and reliable operation of utmost importance, therefore, must be to upgrade the rope daily testing to ensure that lifting equipment safe and reliable operation. At present, mining enterprises are still using the traditional methods of detection, the use of a vernier caliper pumping detection. This test is the presence of large defects, it detects low accuracy but not continuous real-time detection, missed the situation occurred from time to time, which to enhance security serious hidden dangers. At the same time, this method labor intensity, slow detection. Meanwhile, in artificial testing, must stop hoisting cable upgrade, which will reduce efficiency and equipment utilization. Detection entirely artificial and practical work experience, accuracy and efficiency will also be reduced, neither complete non-contact detection, and detection can not be achieved online, at the same time also increased the detection of staff to the dangers posed by sexual. In view of this status quo, and colleges and universities at home and abroad and research departments to upgrade the diameter of the wire rope for real-time detection of a large amount of research work. From the detection method, there are mainly two categories: the magnetic flux detection, laser scanning method, but the two detection methods exist more weaknesses. Detection of magnetic flux detection of low accuracy, heavy equipment, laser scanning detection Although the detection of high precision, but the complex equipment, high costs. In such circumstances, the paper using CCD technology, a new upgrade wire diameter measurement method - CCD-line non-contact measurement of diameter measurement with digital display quickly and efficiently show a high degree of automation and intuitive features, such as artificial overcome Detection by the drawbacks.Keywords rope wear photovoltaic technology on-contact measurement CCD technology

目 录

1.1课题的意义和目的………………………………………………………………………… 3

1.2 CCD检测系统的特点和分析……………………………………………………………… 4

1.3 基于CCD技术的钢丝绳检测系统………………………………………………………. 4

2钢丝绳的选用 ………………………………………………………………………………… 6

2.1钢丝绳的计算及合理参数 ……………………………………………………………. 6

2.2钢丝绳的使用 ……………………………………………………………………………. 8

2.3钢丝绳的养护和报废 ……………………………………………………………………. 9

2.4钢丝绳直径的计算………………………………………………………………………. 11

3 CCD工作原理及选用……………………………………………………………………….. 13

3.1电荷的存储………………………………………………………………………………. 13

3.1.1电荷的耦合…………………………………………………………………………… 16

3.2电荷的注入和检测………………………………………………………………………. 17

3.2.1电荷的注入………………………………………………………………………….. 17

3.2.2电荷的检测………………………………………………………………………….. 17

3.2.3 CCD 的特性参数……………………………………………………………………..18

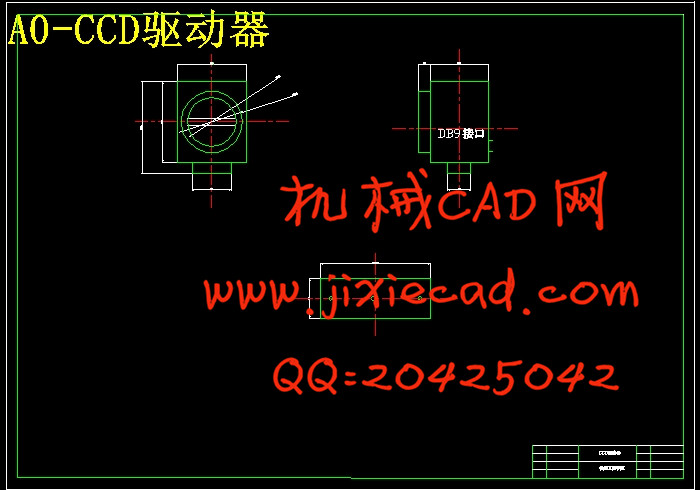

3.3 CCD选型…………………………………………………………………………………..19

3.4 CCD工作原理……………………………………………………………………………..20

4光学系统的设计……………………………………………………………………………… 21

4.1光学成像基本计算公式…………………………………………………………………. 21

4.1.1 理想光学系统的基本参数 ………………………………………………………… 21

4.1.2 理想光学系统成像的物像关系 …………………………………………………… 22

4.1.3 理想光学系统的放大率 …………………………………………………………… 23

4.2光学中光阑的作用………………………………………………………………………. 24

4.2.1 孔径光阑、入射光瞳和出射光瞳…………………………………………………. 24

4.2.2 视场光阑 ………………………………………………………………………….. 25

4.3 照明系统设计 …………………………………………………………………………. 25

4.3.1 照明方法……………………………………………………………………………. 25

4.3.2 聚光镜的作用………………………………………………………………………. 27

4.3.3 照明系统的设计原则………………………………………………………………. 28

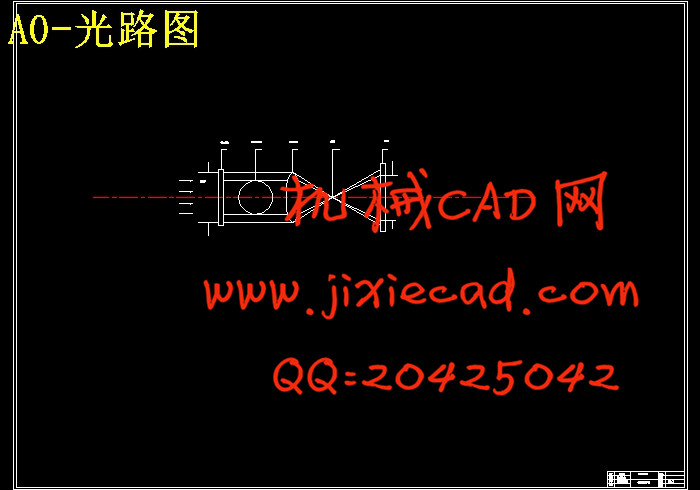

4.4 远心光路的应用………………………………………………………………………… 28

4.5 光学系统的设计 ………………………………………………………………………. 29

4.5.1成像系统的设计…………………………………………………………………….. 29

4.5.2照明系统的设计参数 ………………………………………………………………. 30

5 机械结构的设计 …………………………………………………………………………. 35

5.1 机械设计的原理和要求 ………………………………………………………… …….35

5.2 支架的作用 ……………………………………………………………………………. 36

6 CCD在线的实验 ………………………………………………………………………… .. 37

6.1 实验准备 ……………………………………………………………………………… 37

6.2 实验方案………………………………………………………………………………… 37

6.3实验系统设计……………………………………………………………………………. 38

6.4数据采集 ………………………………………………………………………………. 39

6.4.1系统标定……………………………………………………………………………… 39

6.4.2影响测量的几个因素及改进方法…………………………………………………… 40

结论和展望……………………………………………………………………………………. 41

致谢……………………………………………………………………………………………. 43

参考文献………………………………………………………………………………………. 43