设计简介

摘要

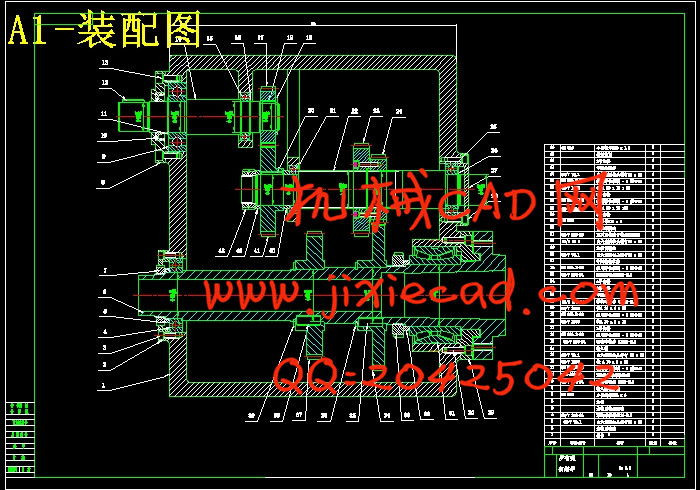

介绍 CA7620 机床主传动系统的设计步骤和设计方法,根据已确定的运动参数以变速箱展开图的总中心距最小为目标,拟订变速系统的变速方案,并引入优化设计的思想,以获得最优方案以及较高的设计效率。

介绍 CA7620 机床主传动系统的设计步骤和设计方法,根据已确定的运动参数以变速箱展开图的总中心距最小为目标,拟订变速系统的变速方案,并引入优化设计的思想,以获得最优方案以及较高的设计效率。

此次设计过程中参考了同类机床主传动箱的设计,机床的主传动箱的布局与 C7620 机床的类似,高效机床,在生产中有着广泛的运用。

关键词: 机床;传动系统;优化设计

Abstract

This thesis introduces the design steps and methods of ma in transimisson system of machine tool and draft the transmission scheme of the system,which the aim of the most minima l center dista nce of expansion graph,accord ing to the motion parameter that has aeady been definited.Adopt the method of CAD and thought of odoptima l design to acqure the super ior project and higher design efficiencies.

The process of designing a similar reference to the ma in transmission boxes of machine design, the key reference C7620 hydraulic machine, CA7620 machine ma in drive me with the la yout of the C7620 machine similar, CA7620 hydraulic multi-tool is hydraulic-d riven semi-automa tic lathes The efficient machine in the production of a wide range of use.

Keywords : machine tool ma in transmission system optima l design

附录........................................................................................................... 44

目 录

1绪论..........................................................................................................1

1.1主传动的设计要求................................................................................................................ 1

1.2主传动的组要设计程序....................................................................................................... 1

2主运动的运动设计........................................................................................2

1.1设计任务................................................................................................................................ 2

2.2拟定转速图............................................................................................................................ 2

2.2.1确定变速组的数目......................................................................................................... 2

2.2.2确定变速的排列方案.................................................................................................... 2

2.2.3确定基本组和扩大组.................................................................................................... 2

3主传动的结构设计........................................................................................3

3.1主传动的布局........................................................................................................................ 3

3.2变速机构............................................................................................................................... 3

3.3齿轮的布置........................................................................................................................... 3

3.3.1滑移齿轮的轴向布置.................................................................................................... 3

3.3.2一个变速组内齿轮轴向位置的排列............................................................................ 4

3.3.3两个变速组内齿轮轴向位置的排列............................................................................ 5

3.3.4缩小径向尺寸................................................................................................................ 5

3.3.5滑移齿轮的结构形式.................................................................................................... 6

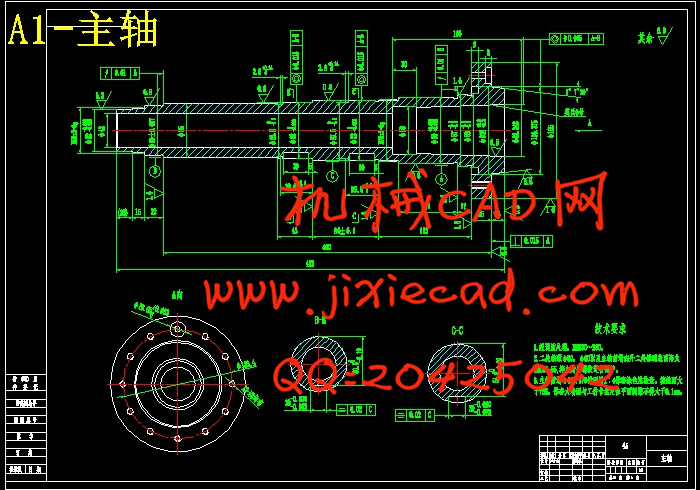

3.4计算转速............................................................................................................................... 7

3.4.1主轴计算转速的确定.................................................................................................... 8

3.4.2采用交换齿轮的变速系统............................................................................................. 9

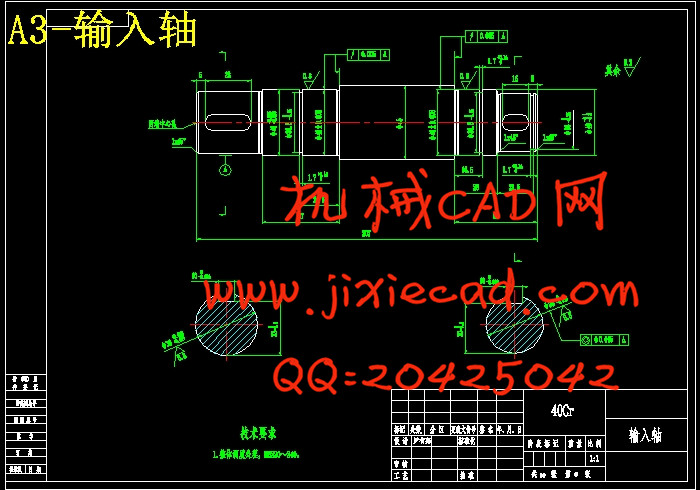

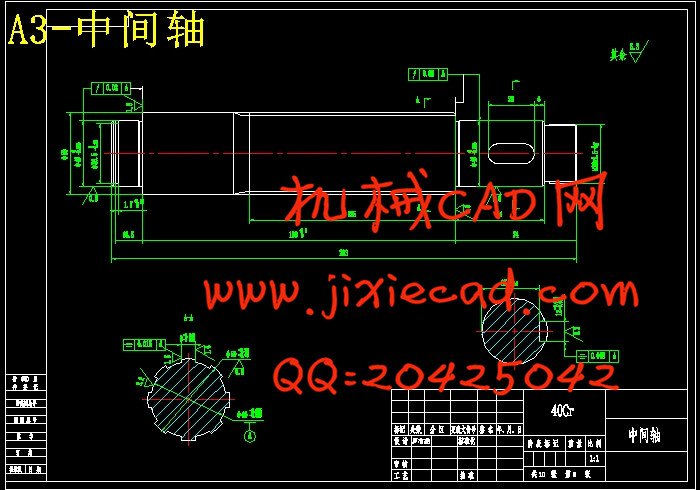

4主传动的零件设计...................................................................................... 10

4.1 主要零件的验算校核...................................................................................................... 13

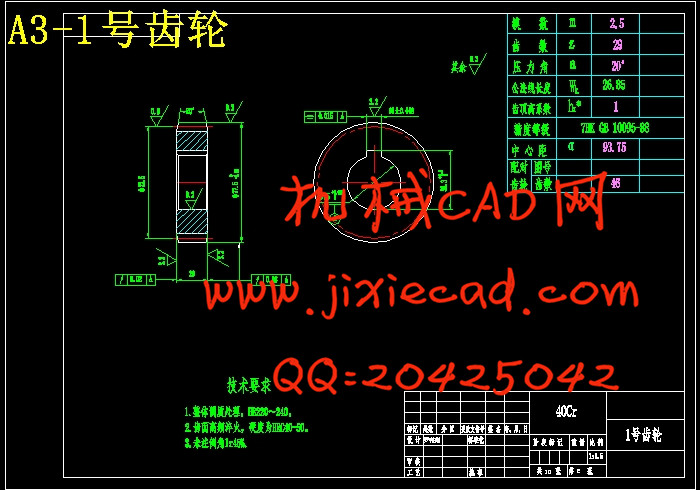

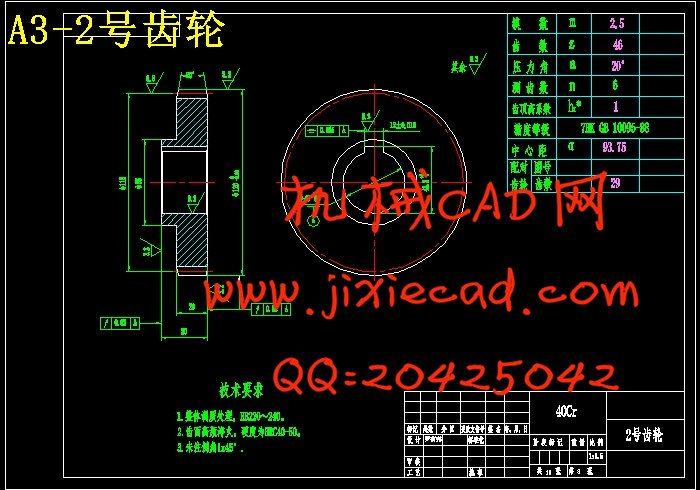

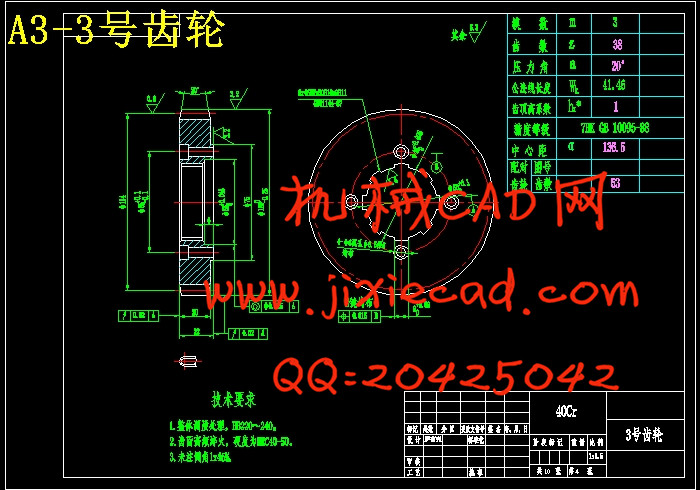

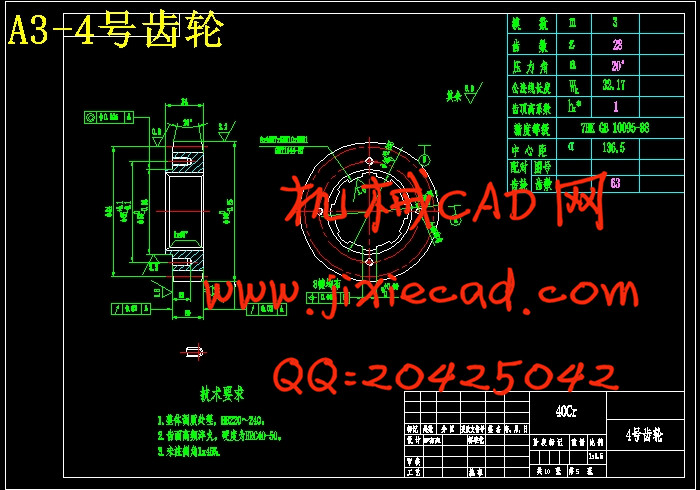

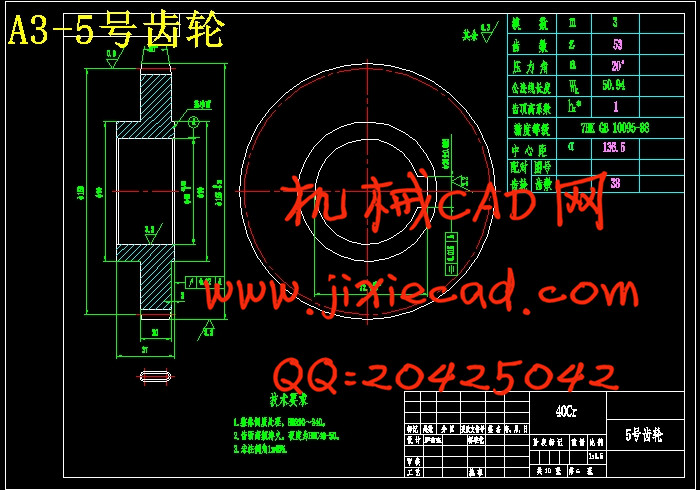

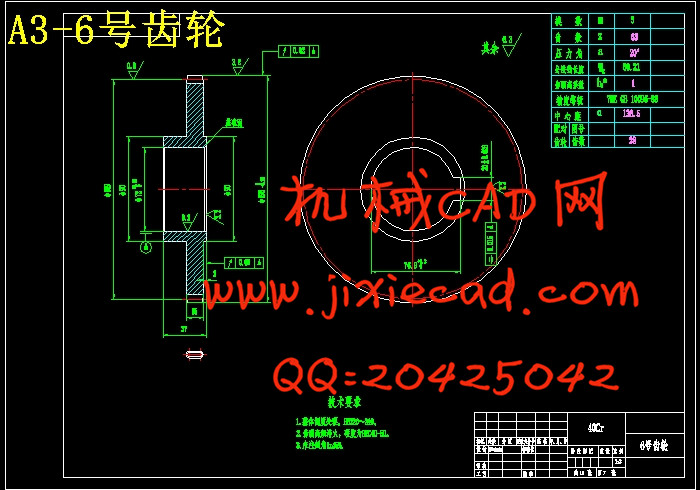

4.1.1直齿圆柱齿轮的基本参数........................................................................................... 13

4.1.2齿轮的校核计算.......................................................................................................... 14

4.1.3计算机辅助设计及零件校合...................................................................................... 18

4.1.4轴的校核...................................................................................................................... 30

5主传动的润滑............................................................................................ 38

5.1润滑系统的要求................................................................................................................. 38

5.2 润滑剂的选择.................................................................................................................... 39

5.3润滑方式的选择................................................................................................................. 39

5.4轴承的润滑及密封方法...................................................................................................... 39

结论........................................................................................................... 41

致谢........................................................................................................... 42

参考文献..................................................................................................... 43

附录........................................................................................................... 44