设计简介

高静水压磨削装备

摘要:

虽然目前磨床技术已有了飞速发展。国内外的磨削技术也有了相对的成熟度。但是它们在磨削过程中,都会共同的造成材料的损伤。所以如何降低材料的损伤成为一个值得研究的热点问题,国内外的很多学者也都对此做出了大量的研究工作。本文就磨削陶瓷器件过程中,如何降低陶瓷器件的损伤,提高加工效率,实现陶瓷器件的高效低损伤加工和降低陶瓷器件的加工成本进行研究。

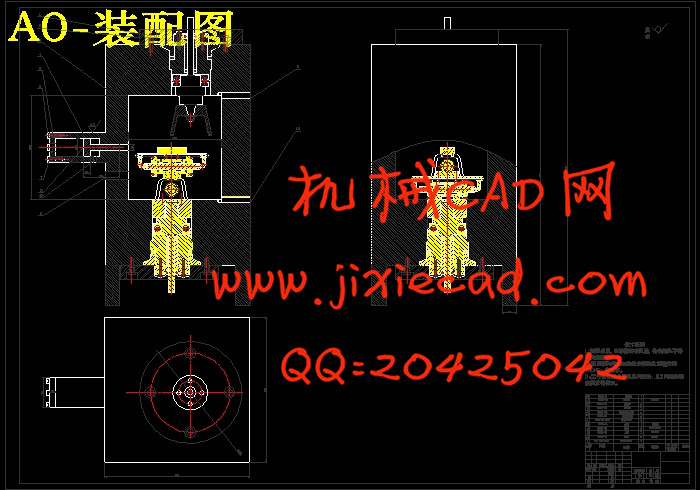

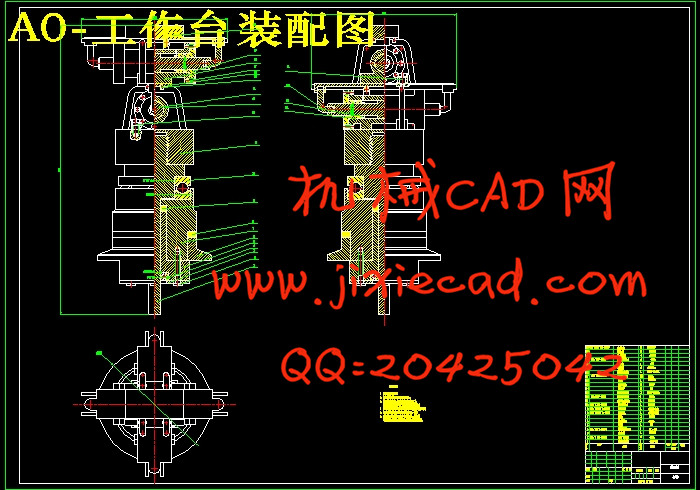

本文采用设计出一个高静水压磨削装备,即为保证高静水压磨削装备能承受400MPa以上的高静水压力,装备主体结构采用合金钢整体铸造的框架结构,并采用有限元进行强度分析。磨削装备型腔空间的长、宽、高均控制在30cm以内,工作台的移动范围:X向≤10cm;Y≤10cm;Z≤5cm,磨削装备上各机械部件的联接均采用8.8级以上的高强度连接螺栓(屈服强度﹥640MPa)。

采用30-100MPa的高压泵与放大倍数为10的增压缸相结合实现100-400MPa的高静水压力,通过对高压泵电机进行变频调速实现静水压力的调节,磨削装备的高静水压力可以通过液压回路上的高压油表测量值乘以增压缸放大倍数计算而得,也可以通过磨削装备内壁的应变片进行静水压力的测量。采用高压组合密封环实现磨削装备的磨头主轴与三向移动工作台的密封,磨头主轴只旋转不移动,工作台的X、Y轴移动采用液压缸驱动,Z轴采用滚珠丝杆驱动并实现Z轴的半闭环控制。

本设计的进行能大大提高磨削加工的加工效率,实现陶瓷器件的高效低损伤加工,从而降低磨削加工的加工成本。

关键词:磨床,高效低损伤,高静水压,陶瓷器件,加工效率

GAOJING WATER PRESSURE GRINDING EQUIPMENT

ABSTRACT:

Although at present the grinding technology have rapid development. The grinding technology at home and abroad have relative maturity. But they are in the grinding process, will cause the damage of the common material. So how to reduce the material damage to become a worth a hotspot,many scholars at home and abroad have made a great deal of research. This paper grinding of ceramic components in the process, how to reduce the damage to the ceramic components, the improvement of the machining efficiency and realize the ceramic components of high efficiency low damage processing and reduce the processing cost ceramic components.

In this article, the design a Gao Jing water pressure grinding equipment, that is, to ensure that Gao Jing water pressure grinding equipment can withstand the 400 MPa above the GaoJingShui pressure, equipment structure and the main body of the whole casting alloy steel frame structure, and by using the finite element strength analysis. Grinding equipment cavity space the length, width and height are controlled in less than 30 cm, the stage of the mobile range: X to more than 10 cm; Y than 10 cm; Z than 5 cm, grinding equipment on the mechanical parts of the link above all use 8.8 magnitude of high strength bolt connection (yield strength ﹥ 640 MPa).

The 30-100 MPa high-pressure pumps and magnification of 10 of intensification cylinder combination realize 100-400 MPa pressure of GaoJingShui, through to the high-pressure pump motor frequency control realization of hydrostatic pressure regulation, grinding equipment GaoJingShui pressure can through hydraulic oil measurement of high pressure on the way back to signal is multiplied by boosting cylinder magnification and calculation, but can be by grinding equipment for the inner surface of the strain gauge hydrostatic pressure on the measurement. The high pressure combination sealing ring realize the grinding equipment grinding head spindle and three to moving workbench sealing, grinding head spindle rotation only does not move and the stage of the X, Y mobile using hydraulic cylinder driving, the Z axis a ball screw driver and realize the Z axis half closed loop control.

This design can greatly enhance the grinding machining efficiency, realize ceramic device of high efficiency low damage processing, so as to reduce the cost of the grinding process.

Keywords: Grinding machine, high efficiency low damage, Gao Jing water pressure, ceramic components, processing efficiency.

目录

第一章 绪论 1

1.1 课题的提出背景 1

1.2 课题的意义及主要研究内容 2

第二章 工作台的整体布置 4

2.1 工作台的简易设计 4

2.2 工作台导轨的选择 4

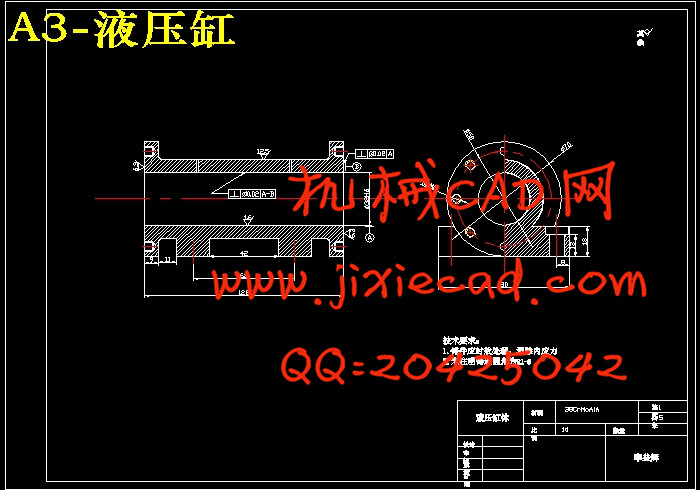

第三章 液压缸的设计 7

3.1 缸筒设计 7

3.2 缸筒壁厚的计算 10

3.3 缸筒壁厚的验算 10

3.4 缸筒的加工要求 12

3.5 最小导程 12

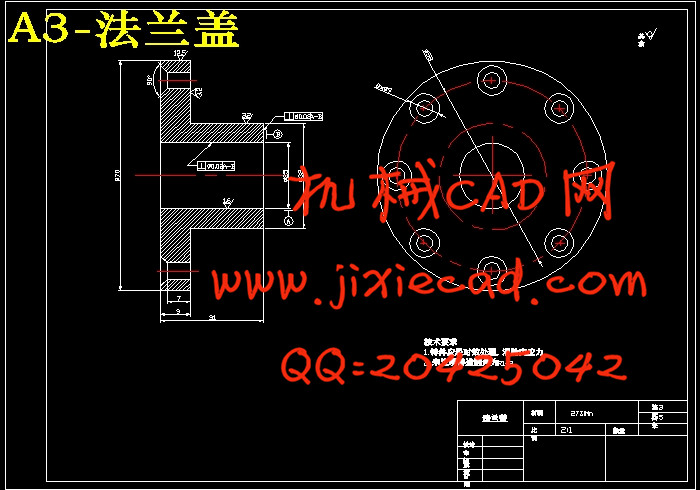

3.6 法兰设计 13

3.7 活塞设计 16

3.8 活塞杆的设计 17

3.9 活塞杆的导向、密封和防尘 20

3.10 缓冲装置 20

3.11 排气装置 20

3.12 油口 21

第四章 主轴的设计 22

4.1 轴的设计 22

4.2 轴承的设计 24

第五章 滚珠丝杆的设计 26

第六章 伺服电机的选择 27

第七章 设计总结 28

第八章 参考文献 29

摘要:

虽然目前磨床技术已有了飞速发展。国内外的磨削技术也有了相对的成熟度。但是它们在磨削过程中,都会共同的造成材料的损伤。所以如何降低材料的损伤成为一个值得研究的热点问题,国内外的很多学者也都对此做出了大量的研究工作。本文就磨削陶瓷器件过程中,如何降低陶瓷器件的损伤,提高加工效率,实现陶瓷器件的高效低损伤加工和降低陶瓷器件的加工成本进行研究。

本文采用设计出一个高静水压磨削装备,即为保证高静水压磨削装备能承受400MPa以上的高静水压力,装备主体结构采用合金钢整体铸造的框架结构,并采用有限元进行强度分析。磨削装备型腔空间的长、宽、高均控制在30cm以内,工作台的移动范围:X向≤10cm;Y≤10cm;Z≤5cm,磨削装备上各机械部件的联接均采用8.8级以上的高强度连接螺栓(屈服强度﹥640MPa)。

采用30-100MPa的高压泵与放大倍数为10的增压缸相结合实现100-400MPa的高静水压力,通过对高压泵电机进行变频调速实现静水压力的调节,磨削装备的高静水压力可以通过液压回路上的高压油表测量值乘以增压缸放大倍数计算而得,也可以通过磨削装备内壁的应变片进行静水压力的测量。采用高压组合密封环实现磨削装备的磨头主轴与三向移动工作台的密封,磨头主轴只旋转不移动,工作台的X、Y轴移动采用液压缸驱动,Z轴采用滚珠丝杆驱动并实现Z轴的半闭环控制。

本设计的进行能大大提高磨削加工的加工效率,实现陶瓷器件的高效低损伤加工,从而降低磨削加工的加工成本。

关键词:磨床,高效低损伤,高静水压,陶瓷器件,加工效率

GAOJING WATER PRESSURE GRINDING EQUIPMENT

ABSTRACT:

Although at present the grinding technology have rapid development. The grinding technology at home and abroad have relative maturity. But they are in the grinding process, will cause the damage of the common material. So how to reduce the material damage to become a worth a hotspot,many scholars at home and abroad have made a great deal of research. This paper grinding of ceramic components in the process, how to reduce the damage to the ceramic components, the improvement of the machining efficiency and realize the ceramic components of high efficiency low damage processing and reduce the processing cost ceramic components.

In this article, the design a Gao Jing water pressure grinding equipment, that is, to ensure that Gao Jing water pressure grinding equipment can withstand the 400 MPa above the GaoJingShui pressure, equipment structure and the main body of the whole casting alloy steel frame structure, and by using the finite element strength analysis. Grinding equipment cavity space the length, width and height are controlled in less than 30 cm, the stage of the mobile range: X to more than 10 cm; Y than 10 cm; Z than 5 cm, grinding equipment on the mechanical parts of the link above all use 8.8 magnitude of high strength bolt connection (yield strength ﹥ 640 MPa).

The 30-100 MPa high-pressure pumps and magnification of 10 of intensification cylinder combination realize 100-400 MPa pressure of GaoJingShui, through to the high-pressure pump motor frequency control realization of hydrostatic pressure regulation, grinding equipment GaoJingShui pressure can through hydraulic oil measurement of high pressure on the way back to signal is multiplied by boosting cylinder magnification and calculation, but can be by grinding equipment for the inner surface of the strain gauge hydrostatic pressure on the measurement. The high pressure combination sealing ring realize the grinding equipment grinding head spindle and three to moving workbench sealing, grinding head spindle rotation only does not move and the stage of the X, Y mobile using hydraulic cylinder driving, the Z axis a ball screw driver and realize the Z axis half closed loop control.

This design can greatly enhance the grinding machining efficiency, realize ceramic device of high efficiency low damage processing, so as to reduce the cost of the grinding process.

Keywords: Grinding machine, high efficiency low damage, Gao Jing water pressure, ceramic components, processing efficiency.

目录

第一章 绪论 1

1.1 课题的提出背景 1

1.2 课题的意义及主要研究内容 2

第二章 工作台的整体布置 4

2.1 工作台的简易设计 4

2.2 工作台导轨的选择 4

第三章 液压缸的设计 7

3.1 缸筒设计 7

3.2 缸筒壁厚的计算 10

3.3 缸筒壁厚的验算 10

3.4 缸筒的加工要求 12

3.5 最小导程 12

3.6 法兰设计 13

3.7 活塞设计 16

3.8 活塞杆的设计 17

3.9 活塞杆的导向、密封和防尘 20

3.10 缓冲装置 20

3.11 排气装置 20

3.12 油口 21

第四章 主轴的设计 22

4.1 轴的设计 22

4.2 轴承的设计 24

第五章 滚珠丝杆的设计 26

第六章 伺服电机的选择 27

第七章 设计总结 28

第八章 参考文献 29