设计简介

摘要

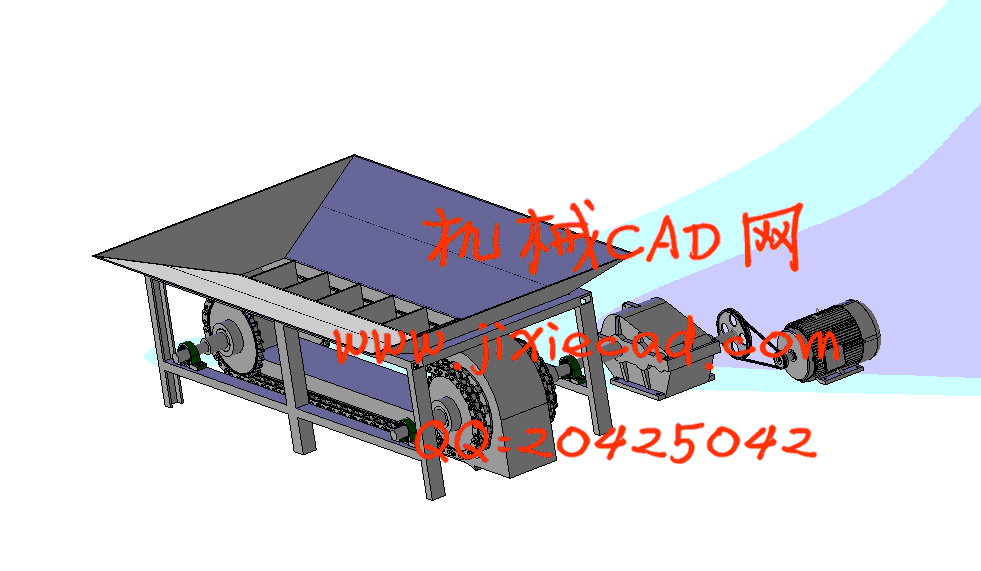

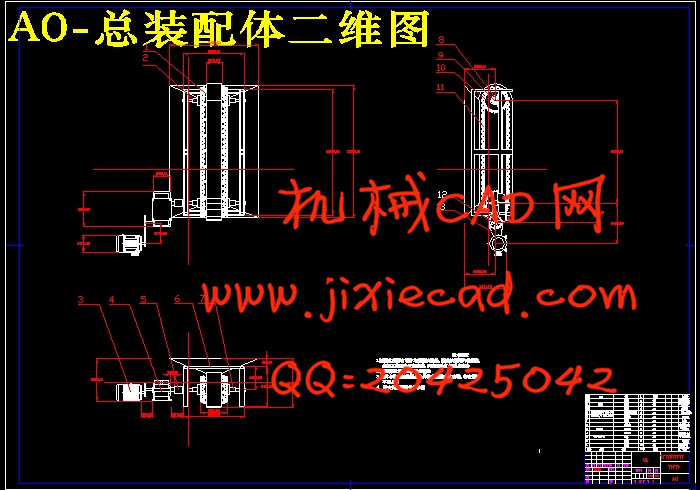

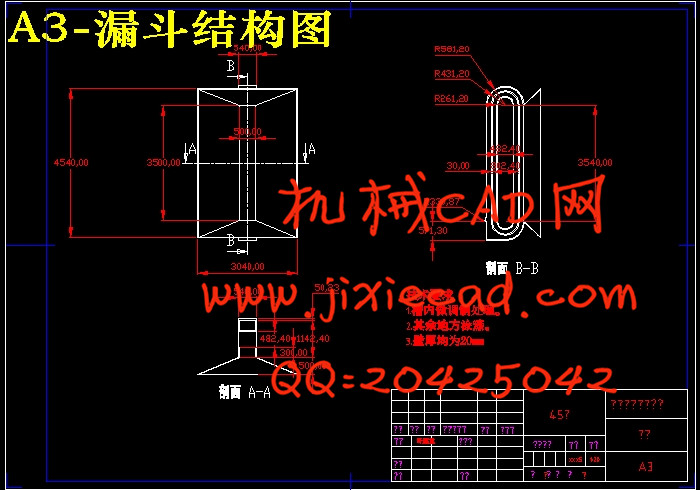

本文设计了钢坯火焰清理机排屑系统,该排屑系统适用于大中型钢坯火焰清理的排屑,该排屑系统由两大部分组成,即动力系统部分和排屑系统部分,该设备采用了简单高效的刮板式排屑方式,本设备相比其余排屑机构最大的优点是能在比较恶劣的生产环境中工作,能够排屑各种状态,何种形状和温度的杂志,包括高温的铁屑,液体等等,性能稳定,制作成本效低。该设备先通过漏斗状的容器把废屑收集起来然后通过由动力带动的运动的刮板把收集到的废屑排放到指定地点,此过程完全由设备自动完成,无需任何人力。

该设备的投产大大提高了排屑的能力和生产的自动化程度,更重要的是能够提高企业的生产效率和管理水平。

关键词:数控装置 排屑系统 数控机床

目录

摘要································································1

ABSTRACT·························································2

1 绪论

1.1 本课题研究的目的与意义········································4

1.2 本课题国内外发展情况··········································4

1.3 本排屑系统的特点··············································4

2 系统总体方案的确定················································6

2.1 设计思想·······················································6

2.2 初选电机减速器系统方案·········································6

2.3 输送外传动系统的确定···········································7

2.4 系统总体方案的确定·············································7

3 电动机的选择······················································9

3.1 电动机的类型选择···············································9

3.2 电动机功率的选择···············································9

3.3 确定电动机型号·················································9

4 V带设计计算······················································11

4.1 传动比的分配··················································11

4.2 各轴的转速、功率和转矩·········································11

4.3 带传动方案的确定··············································11

4.4 带传动设计计算················································12

4.5 带轮的结构设计················································13

5 减速器设计·······················································13

6 链传动设计的计算·················································14

6.1 链传动方案确定················································14

6.2 链传动设计计算················································14

6.3 链轮的结构设计················································15

6.3.1 主、从动轮设计··············································15

7 排屑装置的保养与维护·············································18

7.1 排屑装置的保养················································18

7.2 排屑装置的维护················································19

结论·······························································19

参考文献···························································10

致谢·······························································21

本文设计了钢坯火焰清理机排屑系统,该排屑系统适用于大中型钢坯火焰清理的排屑,该排屑系统由两大部分组成,即动力系统部分和排屑系统部分,该设备采用了简单高效的刮板式排屑方式,本设备相比其余排屑机构最大的优点是能在比较恶劣的生产环境中工作,能够排屑各种状态,何种形状和温度的杂志,包括高温的铁屑,液体等等,性能稳定,制作成本效低。该设备先通过漏斗状的容器把废屑收集起来然后通过由动力带动的运动的刮板把收集到的废屑排放到指定地点,此过程完全由设备自动完成,无需任何人力。

该设备的投产大大提高了排屑的能力和生产的自动化程度,更重要的是能够提高企业的生产效率和管理水平。

关键词:数控装置 排屑系统 数控机床

目录

摘要································································1

ABSTRACT·························································2

1 绪论

1.1 本课题研究的目的与意义········································4

1.2 本课题国内外发展情况··········································4

1.3 本排屑系统的特点··············································4

2 系统总体方案的确定················································6

2.1 设计思想·······················································6

2.2 初选电机减速器系统方案·········································6

2.3 输送外传动系统的确定···········································7

2.4 系统总体方案的确定·············································7

3 电动机的选择······················································9

3.1 电动机的类型选择···············································9

3.2 电动机功率的选择···············································9

3.3 确定电动机型号·················································9

4 V带设计计算······················································11

4.1 传动比的分配··················································11

4.2 各轴的转速、功率和转矩·········································11

4.3 带传动方案的确定··············································11

4.4 带传动设计计算················································12

4.5 带轮的结构设计················································13

5 减速器设计·······················································13

6 链传动设计的计算·················································14

6.1 链传动方案确定················································14

6.2 链传动设计计算················································14

6.3 链轮的结构设计················································15

6.3.1 主、从动轮设计··············································15

7 排屑装置的保养与维护·············································18

7.1 排屑装置的保养················································18

7.2 排屑装置的维护················································19

结论·······························································19

参考文献···························································10

致谢·······························································21