设计简介

简要:介绍了直缝钢管去除内、外毛刺的原理和方法,分析了国内外去毛刺装置的发展进程及发展状况,综合考虑了加工原理、加工方案和结构设计,制定合理可行的设计方案,重点设计了内毛刺清除装置。与传统直缝钢管去除内毛刺装置相比,本方案具有工作效率高和操作简单可靠等优点,可以进行在线调节,内、外毛刺同步切削,效果良好。在结构设计时,采用斜面传动和螺纹传动,使得整个装置具有创造性,结构简单。

关键词 : 直缝钢管 去毛刺装置 内毛刺 刀具 结构设计

Abstract

The principle and method of removing inner and outer burr on-line for straight steel tube are introduced briefly. Development of burr-cleaning in domestic and internationl is analyzed. Process principle, method and construction are considered synthetically, the suitable and reliable project is drafted. The inner burr –remove equiment is designed in detail.Compared with the traditional design, this equipment is possessed of high work efficiency and traits of simple and credible operation and so on. It can be used to cut the inner and outer burr syncchronously, and the effect is good. In the detailed structure design, the Incline and Screw transmission are used ,which make the whole equipment creative and simple.

Keywords :Straight steel tube Burr-removing System Inner burr Cutter Design of structure

目录

第一章 绪 论 1

1.1课题背景 1

1.2国内外发展进程 1

1.3课题任务及主要的研究内容 8

1.3.1课题的主要内容 8

1.3.2 实现方法及途径 8

第二章 方案设计 9

2.1毛刺的形成及后果 9

2.1.1 清楚内毛刺的常用方法 9

2.2 内毛刺清除装置的装备水平 10

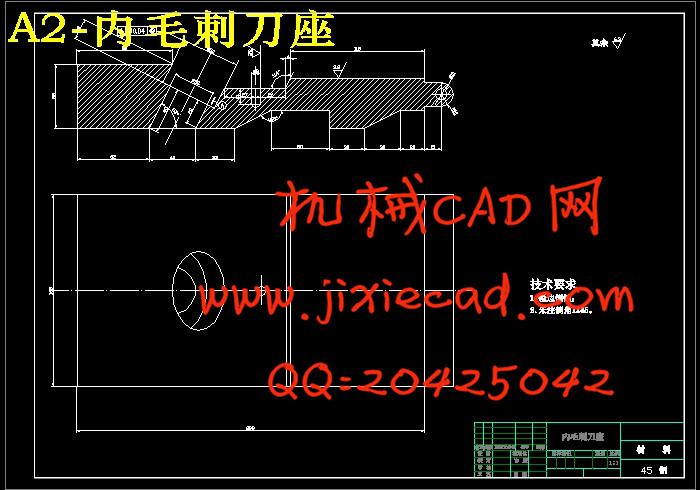

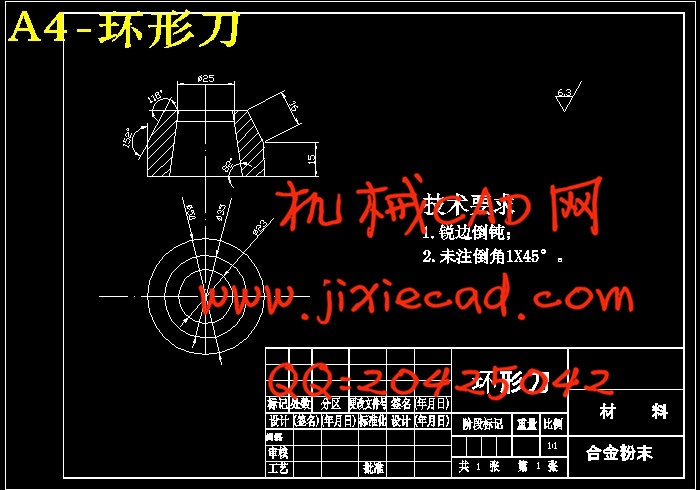

2.2.1刀头的结构和性能............................................................................10

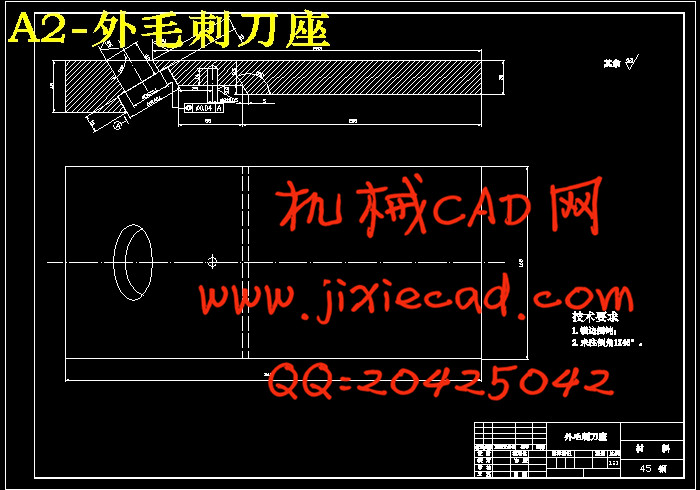

2.2.2刀座架................................................................................................12

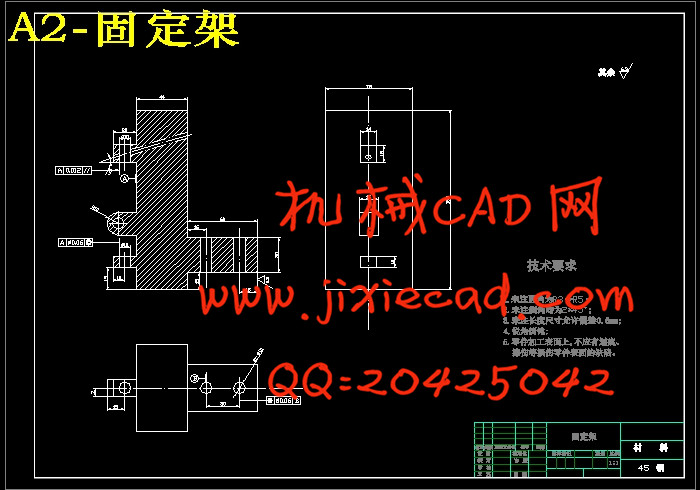

2.2.3固定架................................................................................................13

2.3常见问题及处理方法...............................................................................13

2.3.1毛刺残留高度超标............................................................................13

2.3.2毛刺刮得过深....................................................................................13

2.3.3毛刺被偏............................................................................................13

第三章 结构设计 15

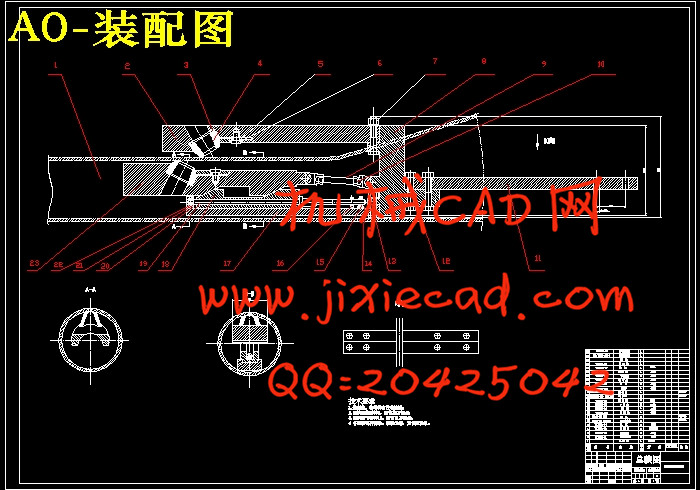

3.1 方案主题结构设计 15

3.1.1 前人方案结构设计 15

3.1.2 确定方案结构示意图 18

3.1.3两种方案的比较 19

3.2 刀具系统的受力与变形分析 20

3.2.1切削力的估算与切削功率 20

3.2.2上臂悬梁截面的力学性能................................................................21

3.2.3刀具系统的变形................................................................................23

3.2.4上臂悬梁的中心拉伸及变形............................................................25

3.3各部分零件结构设计..............................................................................26

3.3.1毛刺结构设计....................................................................................26

3.3.2胀缩滑块的结构设计........................................................................27

3.3.3.套筒的设计和压力块的设计.............................................................30

第四章螺旋传动设计....................................................................................31

4.1选择螺旋传动的种类 31

4.2 螺纹副的螺纹种类、特点及应用 32

4.3 螺旋传动设计 34

4.3.1 螺旋传动的运动形式 34

4.3.2 螺母、螺杆材料的选择 35

4.3.3 耐久性计算 35

4.3.4计算螺杆强度 36

4.3.5 螺纹牙强度计算 36

4.3.6 螺杆强度计算 37

4.3.7计算效率 38

结束语 39

致 谢 40

参考文献 41

关键词 : 直缝钢管 去毛刺装置 内毛刺 刀具 结构设计

Abstract

The principle and method of removing inner and outer burr on-line for straight steel tube are introduced briefly. Development of burr-cleaning in domestic and internationl is analyzed. Process principle, method and construction are considered synthetically, the suitable and reliable project is drafted. The inner burr –remove equiment is designed in detail.Compared with the traditional design, this equipment is possessed of high work efficiency and traits of simple and credible operation and so on. It can be used to cut the inner and outer burr syncchronously, and the effect is good. In the detailed structure design, the Incline and Screw transmission are used ,which make the whole equipment creative and simple.

Keywords :Straight steel tube Burr-removing System Inner burr Cutter Design of structure

目录

第一章 绪 论 1

1.1课题背景 1

1.2国内外发展进程 1

1.3课题任务及主要的研究内容 8

1.3.1课题的主要内容 8

1.3.2 实现方法及途径 8

第二章 方案设计 9

2.1毛刺的形成及后果 9

2.1.1 清楚内毛刺的常用方法 9

2.2 内毛刺清除装置的装备水平 10

2.2.1刀头的结构和性能............................................................................10

2.2.2刀座架................................................................................................12

2.2.3固定架................................................................................................13

2.3常见问题及处理方法...............................................................................13

2.3.1毛刺残留高度超标............................................................................13

2.3.2毛刺刮得过深....................................................................................13

2.3.3毛刺被偏............................................................................................13

第三章 结构设计 15

3.1 方案主题结构设计 15

3.1.1 前人方案结构设计 15

3.1.2 确定方案结构示意图 18

3.1.3两种方案的比较 19

3.2 刀具系统的受力与变形分析 20

3.2.1切削力的估算与切削功率 20

3.2.2上臂悬梁截面的力学性能................................................................21

3.2.3刀具系统的变形................................................................................23

3.2.4上臂悬梁的中心拉伸及变形............................................................25

3.3各部分零件结构设计..............................................................................26

3.3.1毛刺结构设计....................................................................................26

3.3.2胀缩滑块的结构设计........................................................................27

3.3.3.套筒的设计和压力块的设计.............................................................30

第四章螺旋传动设计....................................................................................31

4.1选择螺旋传动的种类 31

4.2 螺纹副的螺纹种类、特点及应用 32

4.3 螺旋传动设计 34

4.3.1 螺旋传动的运动形式 34

4.3.2 螺母、螺杆材料的选择 35

4.3.3 耐久性计算 35

4.3.4计算螺杆强度 36

4.3.5 螺纹牙强度计算 36

4.3.6 螺杆强度计算 37

4.3.7计算效率 38

结束语 39

致 谢 40

参考文献 41