设计简介

摘 要

矿用磨机由于其可靠性高、适应性强、处理能力大等特点,是相关行业中应用最广泛的磨矿设备,有着不可替代的作用。

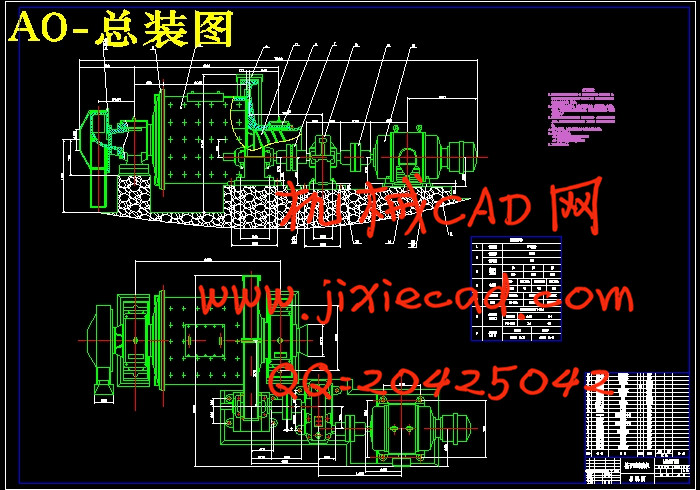

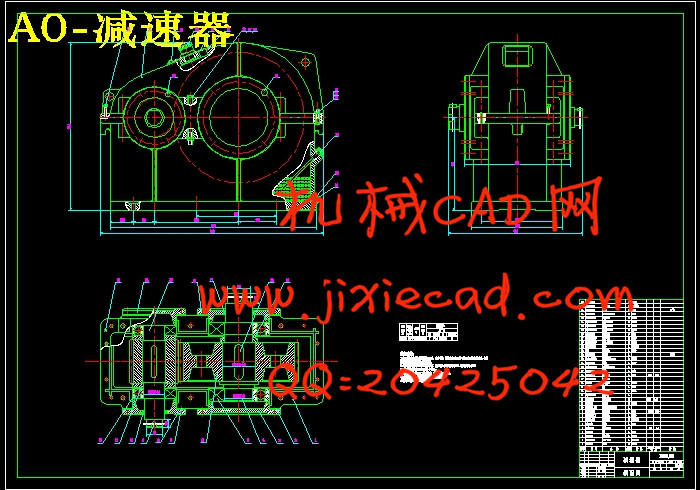

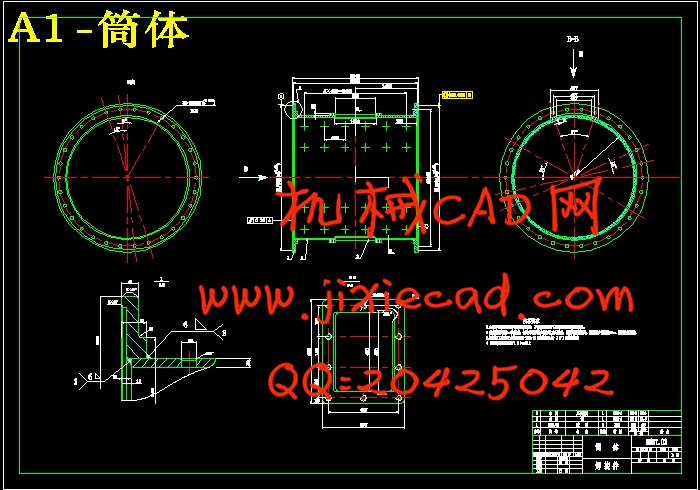

本论文主要是针对矿用磨机在生产使用过程中出现的筒体开裂、强度不足等问题,对球磨机的筒体、传动部件及其主要部件进行设计计算。结合现有的理论,经验公式进行重新设计。对回转部的主要零部件:筒体进行了较为详细的计算。并根据它在不同载荷下的应力和变形,运用简支梁结构进行了筒体强度的分析与计算。然后对传动装置进行了设计与计算,包括电机的选择以及减速器传动方式的选择。并对本次采用的减速器箱体及其附件进行了介绍。

总之,本设计为对矿用磨机的更深入的研究提供了一定的基础,同时也为开展该方面的工作提供了有效的分析途径和方法。为我以后的工作和学习打下了坚实的基础。

关键词: 球磨机 传动部 筒体 减速器

Abstract

Mine mill because of its high reliability, adaptability, processing capacity, related industries, the most widely used in grinding equipment, has an irreplaceable role

This thesis in the production process for the mine mill cylinder cracking, lack of strength issues such as ball mill cylinder, transmission components, and its main components, the design calculations. Combination of existing theoretical, empirical formula to be redesigned. Turning part of the main components: cylinder in a more detailed calculation. And in accordance with the stresses and deformations under different loads, the use of a simply supported beam structure analysis and calculation of the cylinder strength.Gear design and calculation, including the choice of motor selection and reducer drive way. And the reducer used the box and its annex were introduced.

In short, the design for a more in-depth study of the mine mill a certain foundation, but also to carry out the work of the aspects of effective ways and means. Laid a solid foundation for my future work and learning.

Key words: ball mill ransmission part barrel body annex the reducer

目 录

前言 1矿用磨机由于其可靠性高、适应性强、处理能力大等特点,是相关行业中应用最广泛的磨矿设备,有着不可替代的作用。

本论文主要是针对矿用磨机在生产使用过程中出现的筒体开裂、强度不足等问题,对球磨机的筒体、传动部件及其主要部件进行设计计算。结合现有的理论,经验公式进行重新设计。对回转部的主要零部件:筒体进行了较为详细的计算。并根据它在不同载荷下的应力和变形,运用简支梁结构进行了筒体强度的分析与计算。然后对传动装置进行了设计与计算,包括电机的选择以及减速器传动方式的选择。并对本次采用的减速器箱体及其附件进行了介绍。

总之,本设计为对矿用磨机的更深入的研究提供了一定的基础,同时也为开展该方面的工作提供了有效的分析途径和方法。为我以后的工作和学习打下了坚实的基础。

关键词: 球磨机 传动部 筒体 减速器

Abstract

Mine mill because of its high reliability, adaptability, processing capacity, related industries, the most widely used in grinding equipment, has an irreplaceable role

This thesis in the production process for the mine mill cylinder cracking, lack of strength issues such as ball mill cylinder, transmission components, and its main components, the design calculations. Combination of existing theoretical, empirical formula to be redesigned. Turning part of the main components: cylinder in a more detailed calculation. And in accordance with the stresses and deformations under different loads, the use of a simply supported beam structure analysis and calculation of the cylinder strength.Gear design and calculation, including the choice of motor selection and reducer drive way. And the reducer used the box and its annex were introduced.

In short, the design for a more in-depth study of the mine mill a certain foundation, but also to carry out the work of the aspects of effective ways and means. Laid a solid foundation for my future work and learning.

Key words: ball mill ransmission part barrel body annex the reducer

目 录

1 绪 论 2

1.1论文题目的选择 2

1.2 矿用磨机的发展及现状 3

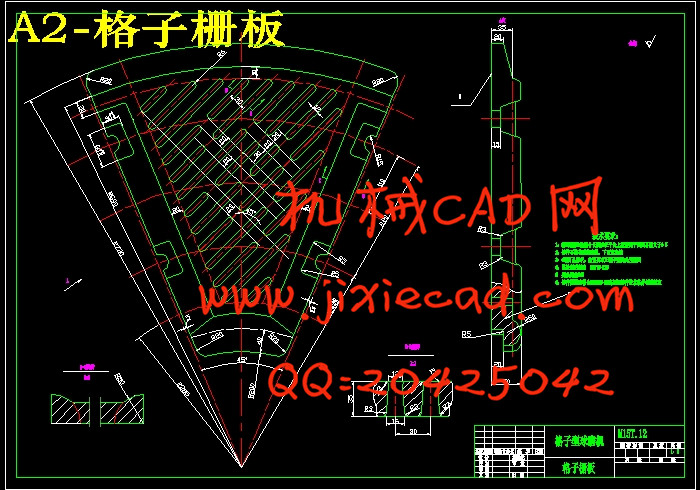

2 干式格子型球磨机介绍 5

3 筒体设计与参数计算 8

3.1 筒体直径和长度的设计 8

3.1.1 长径比的选择 8

3.1.2 用磨矿机的生产率来反算筒体直径和长度 8

3.1.3 各参数的选择和计算 12

3.2 筒体厚度设计 13

3.2.1 装球量计算 13

3.2.2 介质直径、质量配比计算 14

3.2.3 厚度的确定 15

3.2.4 筒体厚度的验算校核 16

3.3 球磨机筒体设计关键数据归纳 23

4 球磨机传动设计 25

4.1 减速器的总体设计 25

4.1.1 拟定传动方案 25

4.1.2 电机选型 25

4.1.3 传动装置的总传动比及其分配 27

4.1.4 计算传动装置的运动和动力参数 27

4.2 齿轮设计 29

4.2.1 减速器内斜齿轮设计 29

4.2.2低速级齿轮传动的设计计算 36

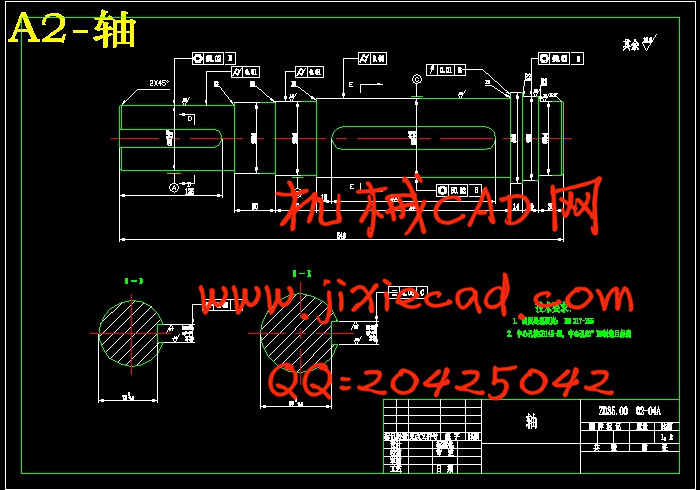

4.3轴的设计 41

4.3.1减速器高速轴1的设计 41

4.3.2减速器轴2的设计 47

4.3.3安装与滚筒大齿轮相齿合的轴3的设计 53

5 减速器箱体的尺寸选择 59

6 减速器附件的设置 60

7 总结 61

致谢 62

参考文献 63