设计简介

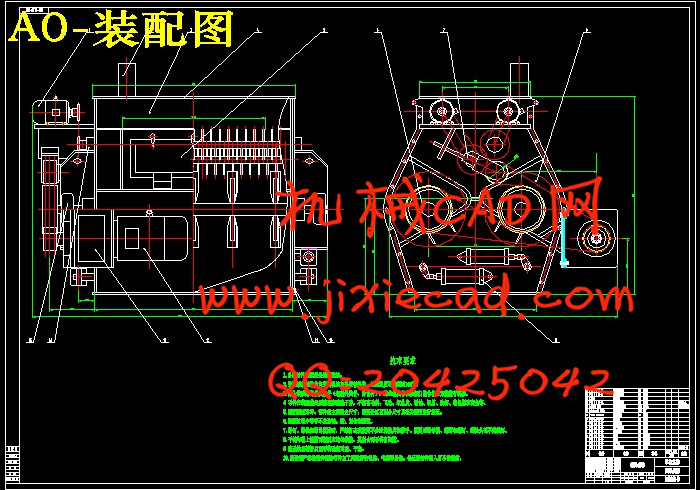

干粉混拌机设计

摘 要

随着科学技术的发展,制造技术的进步,以及社会对产品质量和品种多样化的要求越来越强烈。中、小批量生产的比例明显增加,要求现代干粉混拌机成为一种高效、复合、集成功能和低成本的自动化加工设备。同时,为满足制造业向更高层次发展,为柔性制造单元、柔性制造系统,以及计算机集成制造系统提供基础设备,也要求干粉混拌机向更高水平发展。

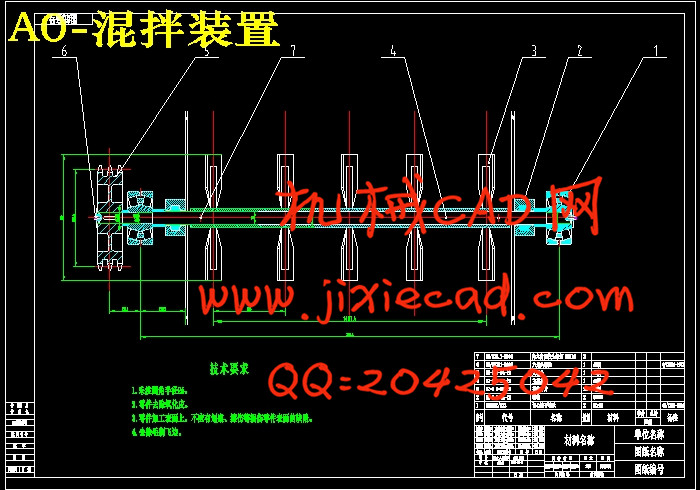

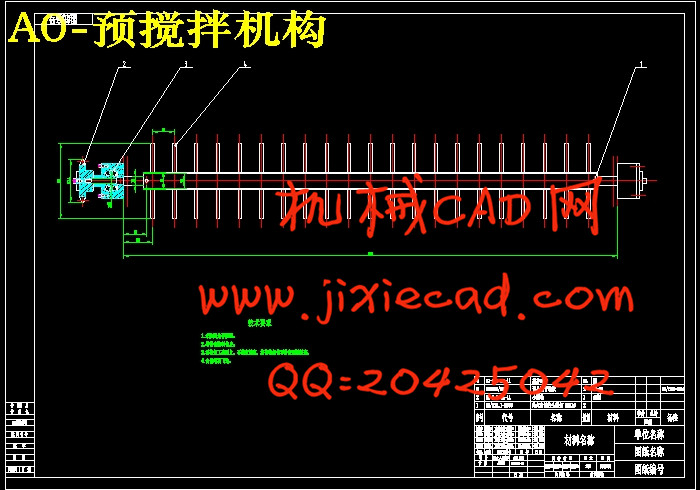

在干粉混拌机行业制造中,混拌机的效率都不是很高,尤其是大批量生产的时候。为了解决这类问题,现在采用的办法是:设计一种双轴的干粉混拌机,这样一来双轴桨叶混合机有强烈、高效的特点,而且混合时间短。卧式筒体内两根搅拌轴等速反向旋转,轴上特殊角度布置的桨叶确保物料径向、环向、轴向三向抛洒运动,形成复合循环,在极短的时间内达到均匀混合。

本设计通过对干粉混拌工艺分析,确定了无重力双轴干粉混拌机设计方案。根据设计参数,选择了电动机,对主要结构进行了详细地设计,并对位置调节机构、联接机构等也进行了简单地设计。

关键字:双轴桨叶、干粉混拌机机、电动机

Dry powder mixing machine design

Abstract

With the development of science and technology, the improvement of manufacturing technology, as well as social on product quality and variety of the increasingly strong demand. In small batch production, the proportion increased significantly, the demands of modern dry powder mixing machine becomes a kind of high efficient, complex, integrated function and low cost automatic processing equipment. At the same time, in order to satisfy the manufacturing industry to a higher level of development, as the flexible manufacturing unit, flexible manufacturing system, computer integrated manufacturing system provides the basic equipment, also called dry powder mixing machine to develop to higher level.

In the dry powder mixing machine manufacturing industry, mixing machine efficiency is not very high, especially when large batch production. In order to solve this problem, now used approach is: design a gravity biaxial powder mixing machine, thus the gravity-free twin-shaft paddle mixer with strong, high efficiency, and short mixing time. In horizontal tube the two stirring shafts isokinetic reverse rotation, axis angle arrangement to ensure that materials special blade radial, circumferential, axial three to throwing motion, to form a composite circulation, in a very short time to achieve uniform mixing.

Through the design of the dry powder mixing process analysis, identified the gravity-free twin-shaft powder mixing machine design scheme. According to the design parameters, selection of the motor, the main structure was designed in detail, and the position adjusting mechanism, coupling mechanism are simply design.

Keywords: twin-shaft paddle, dry powder mixing machine, motor

目录

1绪 论 2

1.1 课题的背景及目的 2

1.2 国内干粉砂浆技术发展的状况 4

1.3 干粉混拌机的分类及特点 6

1.4 干粉混拌机的适用范围 7

2 总体方案设计 8

2.1 工艺方案的分析与设计 8

2.2 传动方案分析与设计 9

2.3 电动机的选择 10

2.4 减速器的选择 10

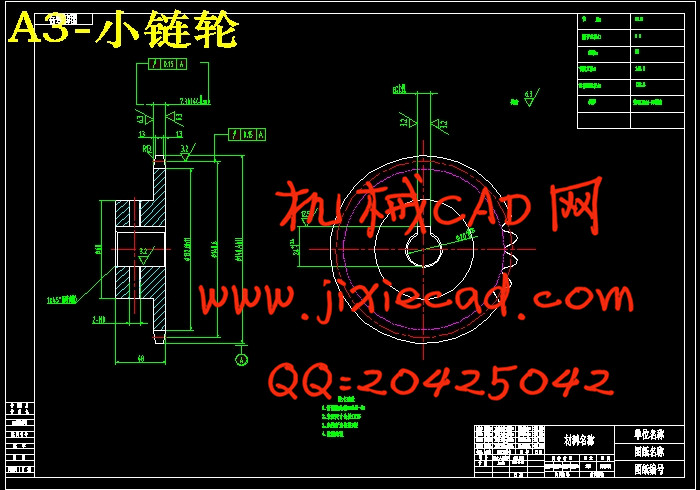

2.5 链轮的计算及链条的选择 10

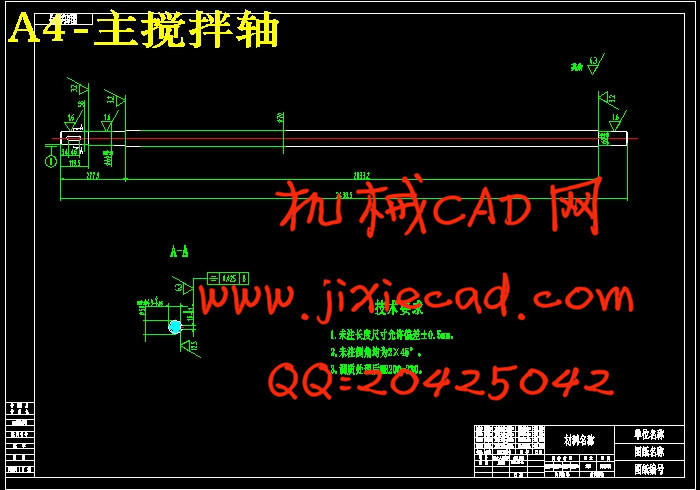

2.6 轴的设计与计算 14

结 论 17

致 谢 18

参考文献 19

摘 要

随着科学技术的发展,制造技术的进步,以及社会对产品质量和品种多样化的要求越来越强烈。中、小批量生产的比例明显增加,要求现代干粉混拌机成为一种高效、复合、集成功能和低成本的自动化加工设备。同时,为满足制造业向更高层次发展,为柔性制造单元、柔性制造系统,以及计算机集成制造系统提供基础设备,也要求干粉混拌机向更高水平发展。

在干粉混拌机行业制造中,混拌机的效率都不是很高,尤其是大批量生产的时候。为了解决这类问题,现在采用的办法是:设计一种双轴的干粉混拌机,这样一来双轴桨叶混合机有强烈、高效的特点,而且混合时间短。卧式筒体内两根搅拌轴等速反向旋转,轴上特殊角度布置的桨叶确保物料径向、环向、轴向三向抛洒运动,形成复合循环,在极短的时间内达到均匀混合。

本设计通过对干粉混拌工艺分析,确定了无重力双轴干粉混拌机设计方案。根据设计参数,选择了电动机,对主要结构进行了详细地设计,并对位置调节机构、联接机构等也进行了简单地设计。

关键字:双轴桨叶、干粉混拌机机、电动机

Dry powder mixing machine design

Abstract

With the development of science and technology, the improvement of manufacturing technology, as well as social on product quality and variety of the increasingly strong demand. In small batch production, the proportion increased significantly, the demands of modern dry powder mixing machine becomes a kind of high efficient, complex, integrated function and low cost automatic processing equipment. At the same time, in order to satisfy the manufacturing industry to a higher level of development, as the flexible manufacturing unit, flexible manufacturing system, computer integrated manufacturing system provides the basic equipment, also called dry powder mixing machine to develop to higher level.

In the dry powder mixing machine manufacturing industry, mixing machine efficiency is not very high, especially when large batch production. In order to solve this problem, now used approach is: design a gravity biaxial powder mixing machine, thus the gravity-free twin-shaft paddle mixer with strong, high efficiency, and short mixing time. In horizontal tube the two stirring shafts isokinetic reverse rotation, axis angle arrangement to ensure that materials special blade radial, circumferential, axial three to throwing motion, to form a composite circulation, in a very short time to achieve uniform mixing.

Through the design of the dry powder mixing process analysis, identified the gravity-free twin-shaft powder mixing machine design scheme. According to the design parameters, selection of the motor, the main structure was designed in detail, and the position adjusting mechanism, coupling mechanism are simply design.

Keywords: twin-shaft paddle, dry powder mixing machine, motor

目录

1绪 论 2

1.1 课题的背景及目的 2

1.2 国内干粉砂浆技术发展的状况 4

1.3 干粉混拌机的分类及特点 6

1.4 干粉混拌机的适用范围 7

2 总体方案设计 8

2.1 工艺方案的分析与设计 8

2.2 传动方案分析与设计 9

2.3 电动机的选择 10

2.4 减速器的选择 10

2.5 链轮的计算及链条的选择 10

2.6 轴的设计与计算 14

结 论 17

致 谢 18

参考文献 19