设计简介

摘 要

绿豆具有广泛的用途,被誉为粮食中的绿色珍珠,是调节饮食的佳品又是食品工业和酿酒工业的重要原料。自古以来我国城乡人民把绿豆作为防暑和高温作业者的优良饮料。随着我国人民生活水平不断提高,尤其是人民收入的增加,对粮食豆类的需求逐渐走向多样化、多层次化,为粮食豆类加工工业的发展提供了广阔的市场。

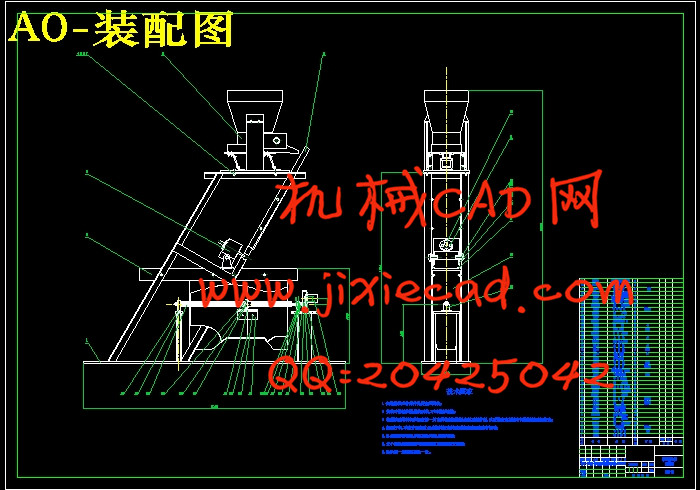

本课题是受黑龙江省粮食厅委托为其下属粮食加工企业设计开发的设备—绿豆精选机。该设备是粮食精加工系列设备的主要设备之一,可提高绿豆质量。通过该课题的研发工作,使学生能够正确运用所学课程的基本理论和有关知识,学会设计方案的拟定、比较、分析及进行必要的计算, 提高学生应用工程技术设计手册、标准以及编写文件的能力。在这样的背景下,本次毕业设计针对粮食豆类加工精选的这个主题,参考各种设备资料,并利用AUTOCAD等现代工具软件,进行了粮食豆类精加工生产线中的绿豆精选机的设计,其技术指标达到7-8吨/小时的生产率和98%的分选精度。相比起传统筛选方法,这种基于风选原理进行作业的粮豆加工机器在机械化、加工精度以及自动化程度等方面都大大提升。从而极大地提高了粮食精加工产品的产量和质量。

关键词:粮食豆类、风选、机械化、自动化

Design of well-chosen machine for mung bean

ABSTRACT

The mung bean, which is called green pearl in foodstuff does have a wide usage. It is not only the nice food for our people to eat but also the important material of food industry and brewing industry. People of our country regard the mung bean as the excellent drink for sunstroke prevention and worker who works under high temperature. But with the development of the living level and especially the income of Today’s people,,the demand to beans-foodstuff of us which provide the beans-foodstuff processing industry a wide market, has been lead to diversification.

Since the food our people take are mostly come from the nature and natural grown. Every year, we loss trillions of money because of lacking essential food process machine that result in the fail of direct processing, storing and fresh keeping for the food resource. And even more resource wasted because of the fail of further processing and general utilizing. So there comes a strong market demand for the processing machine.

And by the background, this paper did the design works of well-chosen machine for mung beans which focuses on the theme of beans-foodstuff well-chosen; and also by the helps of many kinds of equipment reference materials and modern computer software such as AUTOCAD and so on. Its productivity can be up to 7-8 tons per hour, and precision of choosing can be up to 98%. If compared to the traditional choosing ways, this machine based on the principle of winnowing has a great advantage in mechanization, automatization and precision. And then comes follow the much greater quality and quantity of foodstuff production.

Keywords:beans-foodstuff、winnowing、machanization、automatization

目 录

摘要………………………………………………………………………… 1

ABSTRACT…………………………………………………………………… 2

0 引言……………………………………………………………………… 4

1 粮食机电加工机械综述………………………………………………… 5

1.1 国内外粮食机械的现状和发展……………………………………… 5

1.2 绿豆清洗加工简述 ………………………………………………… 9

1.3 可行性分析及研究方法 …………………………………………… 10

1.4 技术路线 …………………………………………………………… 14

2 绿豆精选机设计 ……………………………………………………… 16

2.1 课题的目的与意义………………………………………………… 16

2.2 课题内容 …………………………………………………………… 16

2.3 绿豆精选机初步总体构造 ………………………………………… 16

2.4 方案比较 …………………………………………………………… 19

2.5 粮食加工机械设计参考实物 ……………………………………… 23

3 机械设计计算…………………………………………………………… 29

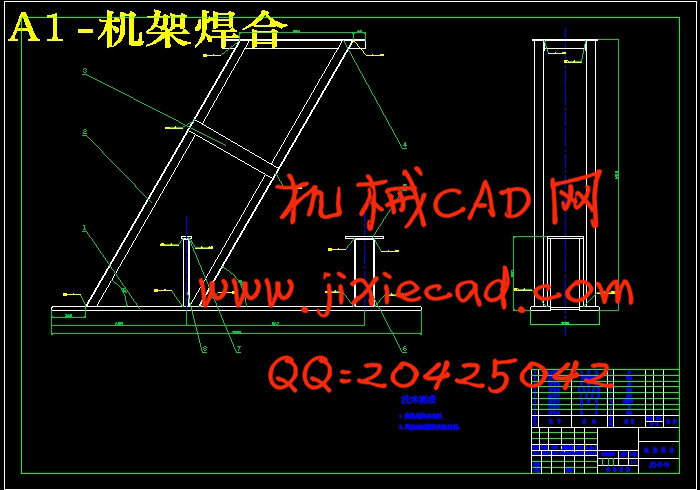

3.1 整机设计及选材……………………………………………………… 29

3.2 部件设计 …………………………………………………………… 32

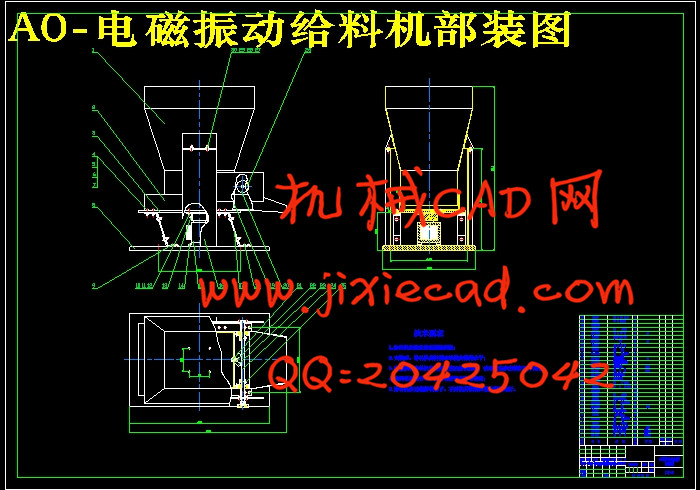

3.2.1 电磁振动给料机设计 …………………………………………… 33

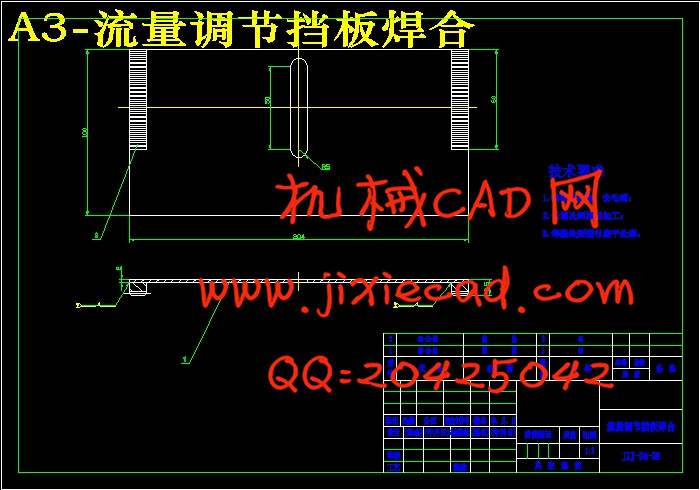

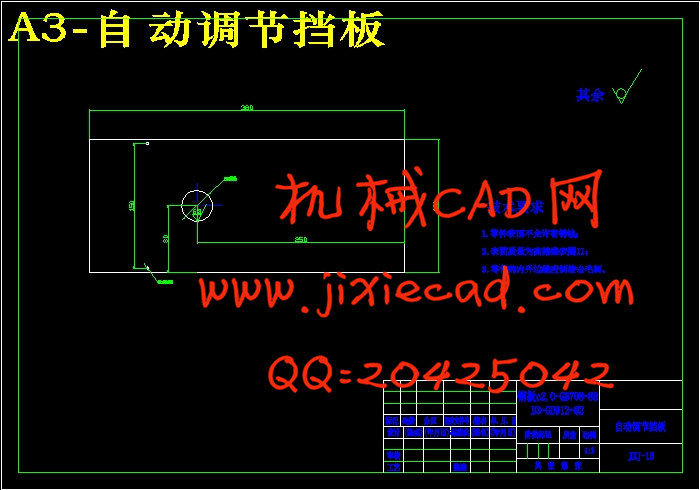

3.2.2 自动调节装置部件设计 ………………………………………… 42

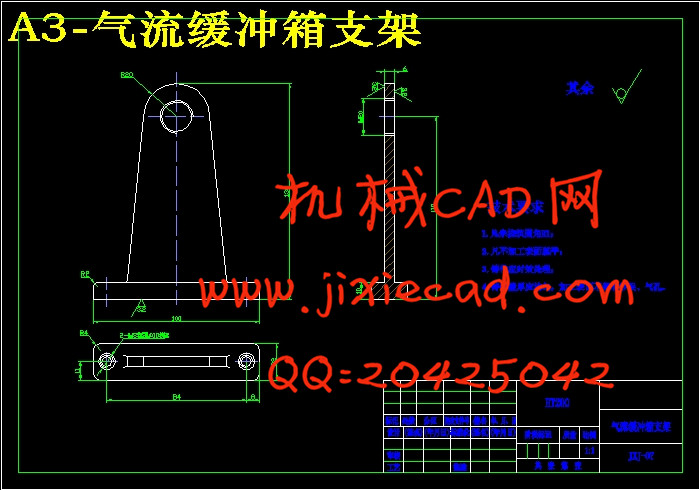

3.2.3 吹风装置的设置 ………………………………………………… 51

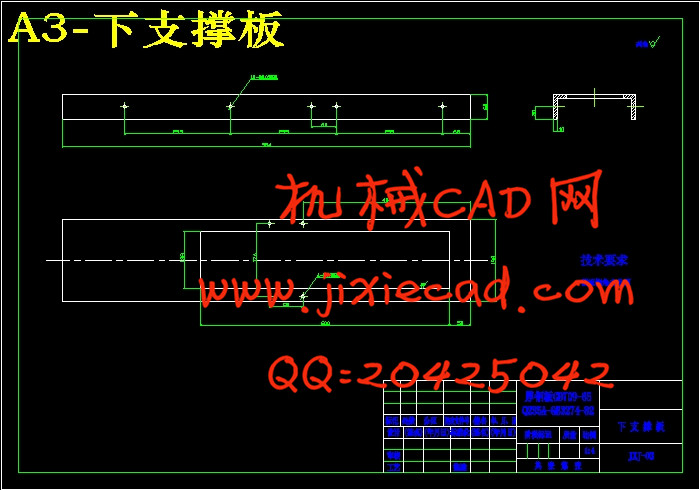

3.2.4 其他部件的设计 ………………………………………………… 53

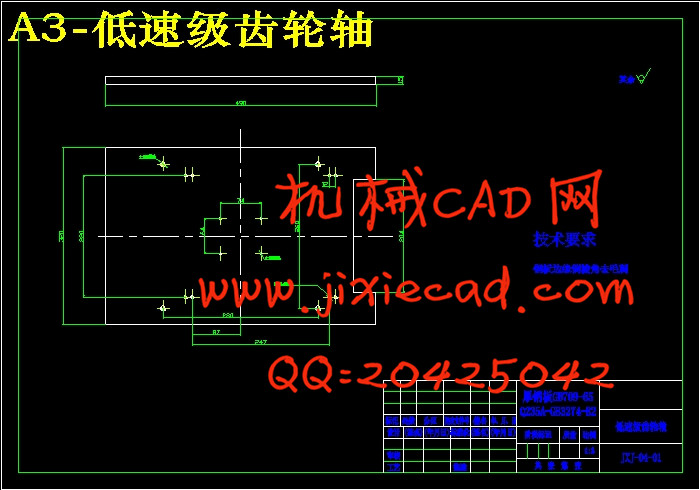

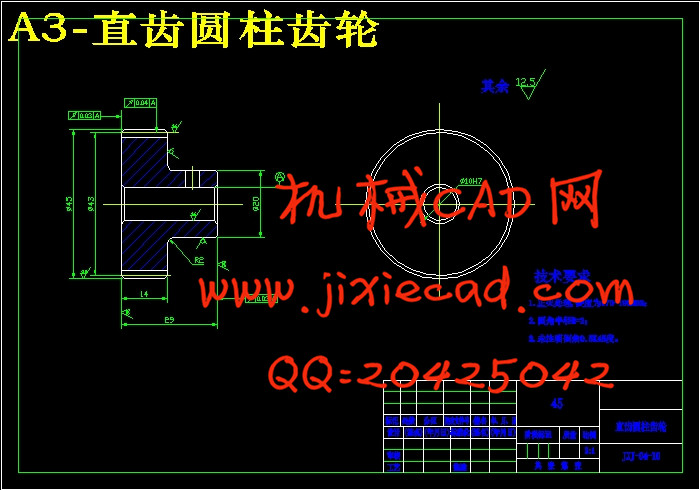

3.3 零件设计 …………………………………………………………… 53

4 设计总结 ……………………………………………………………… 54

5 参考文献 ……………………………………………………………… 56

绿豆具有广泛的用途,被誉为粮食中的绿色珍珠,是调节饮食的佳品又是食品工业和酿酒工业的重要原料。自古以来我国城乡人民把绿豆作为防暑和高温作业者的优良饮料。随着我国人民生活水平不断提高,尤其是人民收入的增加,对粮食豆类的需求逐渐走向多样化、多层次化,为粮食豆类加工工业的发展提供了广阔的市场。

本课题是受黑龙江省粮食厅委托为其下属粮食加工企业设计开发的设备—绿豆精选机。该设备是粮食精加工系列设备的主要设备之一,可提高绿豆质量。通过该课题的研发工作,使学生能够正确运用所学课程的基本理论和有关知识,学会设计方案的拟定、比较、分析及进行必要的计算, 提高学生应用工程技术设计手册、标准以及编写文件的能力。在这样的背景下,本次毕业设计针对粮食豆类加工精选的这个主题,参考各种设备资料,并利用AUTOCAD等现代工具软件,进行了粮食豆类精加工生产线中的绿豆精选机的设计,其技术指标达到7-8吨/小时的生产率和98%的分选精度。相比起传统筛选方法,这种基于风选原理进行作业的粮豆加工机器在机械化、加工精度以及自动化程度等方面都大大提升。从而极大地提高了粮食精加工产品的产量和质量。

关键词:粮食豆类、风选、机械化、自动化

Design of well-chosen machine for mung bean

ABSTRACT

The mung bean, which is called green pearl in foodstuff does have a wide usage. It is not only the nice food for our people to eat but also the important material of food industry and brewing industry. People of our country regard the mung bean as the excellent drink for sunstroke prevention and worker who works under high temperature. But with the development of the living level and especially the income of Today’s people,,the demand to beans-foodstuff of us which provide the beans-foodstuff processing industry a wide market, has been lead to diversification.

Since the food our people take are mostly come from the nature and natural grown. Every year, we loss trillions of money because of lacking essential food process machine that result in the fail of direct processing, storing and fresh keeping for the food resource. And even more resource wasted because of the fail of further processing and general utilizing. So there comes a strong market demand for the processing machine.

And by the background, this paper did the design works of well-chosen machine for mung beans which focuses on the theme of beans-foodstuff well-chosen; and also by the helps of many kinds of equipment reference materials and modern computer software such as AUTOCAD and so on. Its productivity can be up to 7-8 tons per hour, and precision of choosing can be up to 98%. If compared to the traditional choosing ways, this machine based on the principle of winnowing has a great advantage in mechanization, automatization and precision. And then comes follow the much greater quality and quantity of foodstuff production.

Keywords:beans-foodstuff、winnowing、machanization、automatization

目 录

摘要………………………………………………………………………… 1

ABSTRACT…………………………………………………………………… 2

0 引言……………………………………………………………………… 4

1 粮食机电加工机械综述………………………………………………… 5

1.1 国内外粮食机械的现状和发展……………………………………… 5

1.2 绿豆清洗加工简述 ………………………………………………… 9

1.3 可行性分析及研究方法 …………………………………………… 10

1.4 技术路线 …………………………………………………………… 14

2 绿豆精选机设计 ……………………………………………………… 16

2.1 课题的目的与意义………………………………………………… 16

2.2 课题内容 …………………………………………………………… 16

2.3 绿豆精选机初步总体构造 ………………………………………… 16

2.4 方案比较 …………………………………………………………… 19

2.5 粮食加工机械设计参考实物 ……………………………………… 23

3 机械设计计算…………………………………………………………… 29

3.1 整机设计及选材……………………………………………………… 29

3.2 部件设计 …………………………………………………………… 32

3.2.1 电磁振动给料机设计 …………………………………………… 33

3.2.2 自动调节装置部件设计 ………………………………………… 42

3.2.3 吹风装置的设置 ………………………………………………… 51

3.2.4 其他部件的设计 ………………………………………………… 53

3.3 零件设计 …………………………………………………………… 53

4 设计总结 ……………………………………………………………… 54

5 参考文献 ……………………………………………………………… 56