设计简介

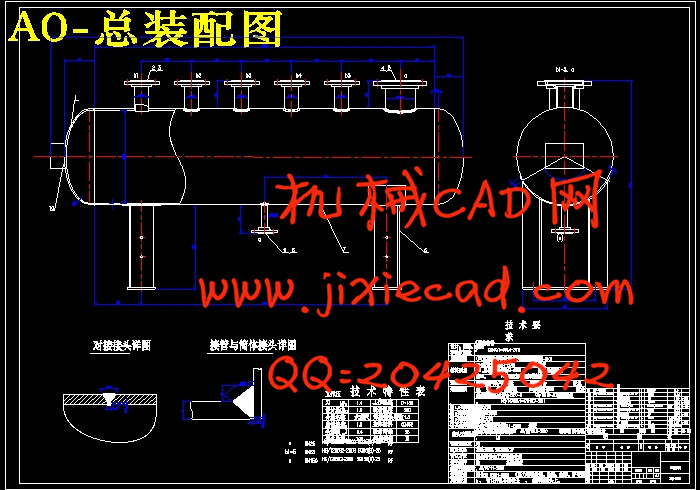

摘 要:本设计分为焊接结构基础知识、焊接生产过程和焊接产品检验等三个部分,共九章设计内容。第一、二主要介绍汽缸的相关知识,第三、四主要介绍汽缸使用的材料及制作,第五、六、七主要介绍焊接生产前、中、后三过程知识,焊接材料、焊接工艺性审查,这部分内容是本产品设计课题重点,汽缸是锅炉的主要配套设备,用于把锅炉运行时所产生的蒸汽分配到各路管道中去,汽缸系承压设备,属压力容器,其承压能力,容量应与配套锅炉相对应。

关键词:分汽缸;压力容器;承压;焊接;装配;

Abstract: The design is divided into three parts, basic knowledge of welding structure, welding process and welding inspection. It contains nine chapters. The first and second chapter mainly introduce the knowledge of cylinders, the third and fourth chapter are about materials used in cylinders and cylinder production. The fifth, sixth and seventh chapter mainly introduce the whole process of welding production, welding materials, and welding technical inspection. The content of this part is the most important. Cylinder is the main auxiliary equipment of a boiler. It is used to allocate the boiler steam produced during the boiler running to each pipe. Cylinder is a pressure bearing equipment, and its pressure bearing capacity should be corresponding with the auxiliary boiler.

Key words: Cylinder ;Pressure vessel ;Pressure welding; assembly;

目 录

摘 要………………………………………………………………………………1

关键词…………………………………………………………………………………1

1前言…………………………………………………………………………………2

1.1选题研究意义……………………………………………………………………2

1.2国内外研究现状…………………………………………………………………2

1.3分汽缸的设计要求………………………………………………………………2

2分汽缸的基本知识…………………………………………………………………3

2.1分汽缸的分类……………………………………………………………………3

2.2分汽缸的应用和相关压力容器焊接结构………………………………………4

2.2.1压力容器的分类及应用………………………………………………………4

2.3制作技术参数……………………………………………………………………6

2.3.1气缸组成零部件及材料………………………………………………………6

3生产准备……………………………………………………………………………7

3.1制造材料介绍……………………………………………………………………7

3.1.1 Q345R……………………………………………………………………………7

3.1.2 16Mn……………………………………………………………………………7

3.1.3 Q235……………………………………………………………………………8

3.1.4 20号钢…………………………………………………………………………8

3.1.5 20G无缝钢管…………………………………………………………………9

4备料…………………………………………………………………………………10

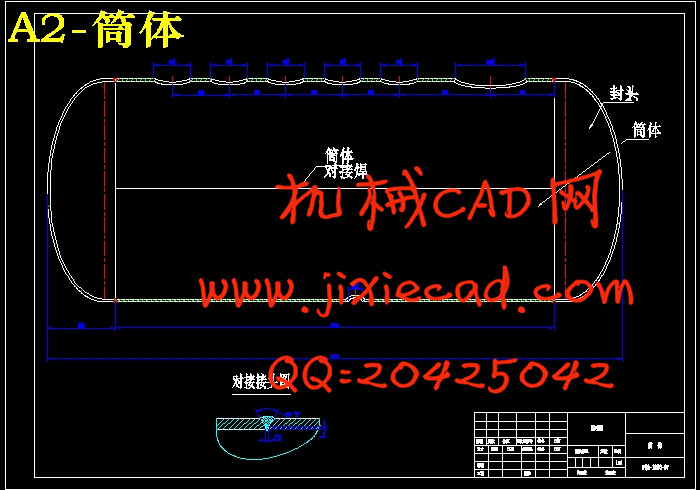

4.1筒体………………………………………………………………………………10

4.1.1制作步骤………………………………………………………………………11

4.1.1制作步骤………………………………………………………………………11

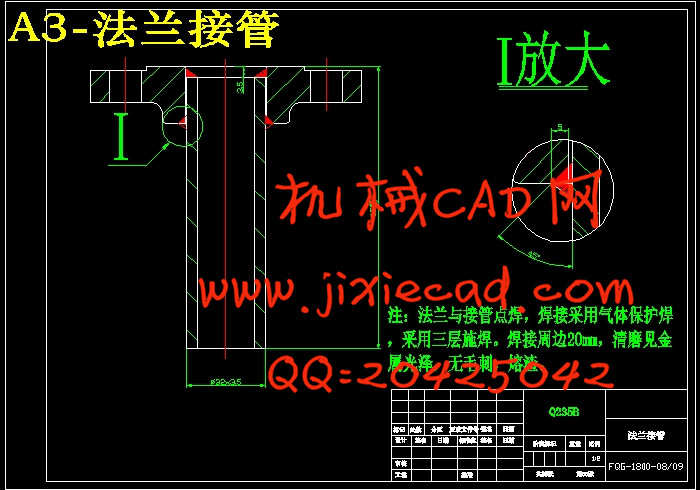

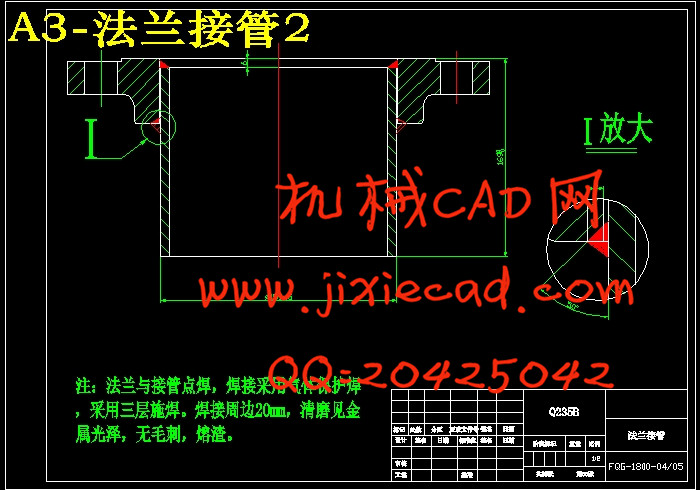

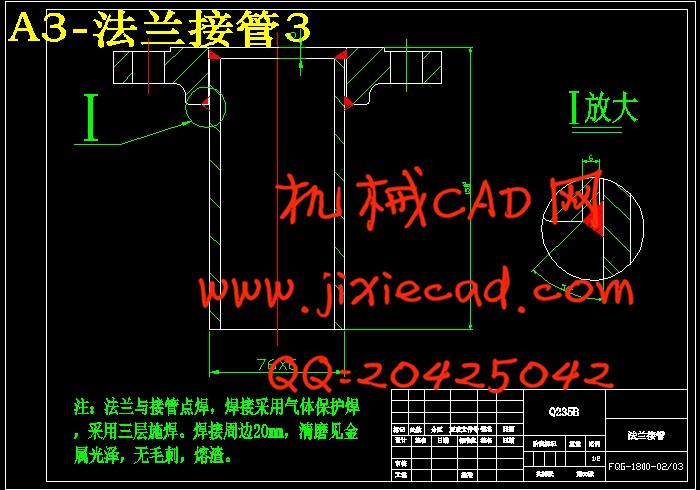

4.2法兰………………………………………………………………………………12

4.2.1法兰结构形式…………………………………………………………………12

4.2.2法兰密封形式…………………………………………………………………12

4.3封头………………………………………………………………………………12

4.3.1计算步骤………………………………………………………………………13

4.4接管………………………………………………………………………………14

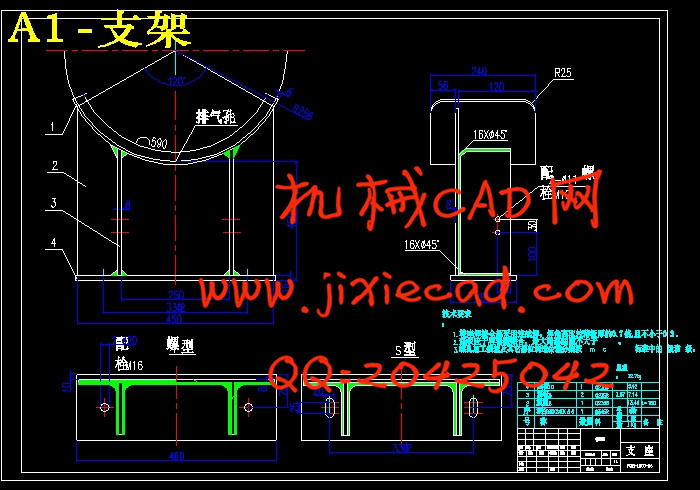

4.5支座及铭牌座……………………………………………………………………14

4.5.1支座制作步骤…………………………………………………………………14

4.5.2铭牌座制作步骤………………………………………………………………15

5装配焊接……………………………………………………………………………15

5.1焊接环境…………………………………………………………………………15

5.2焊前预热…………………………………………………………………………16

5.3法兰与接管组装…………………………………………………………………16

5.4封头与筒体组装…………………………………………………………………16

5.4.1开孔……………………………………………………………………………17

5.4.2装配……………………………………………………………………………17

5.5接管与筒体组装…………………………………………………………………17

5.5.1Ф76/159接管焊接方式………………………………………………………18

5.5.2Ф32接管焊接方式……………………………………………………………18

6成型组装……………………………………………………………………………18

7焊后处理……………………………………………………………………………19

7.1外观质量检测……………………………………………………………………19

7.2无损探伤…………………………………………………………………………19

7.2.1无损探伤方法及检验…………………………………………………………21

7.3检验结果…………………………………………………………………………24

8总结…………………………………………………………………………………24

参考文献……………………………………………………………………………25

致 谢…………………………………………………………………………25

关键词:分汽缸;压力容器;承压;焊接;装配;

Abstract: The design is divided into three parts, basic knowledge of welding structure, welding process and welding inspection. It contains nine chapters. The first and second chapter mainly introduce the knowledge of cylinders, the third and fourth chapter are about materials used in cylinders and cylinder production. The fifth, sixth and seventh chapter mainly introduce the whole process of welding production, welding materials, and welding technical inspection. The content of this part is the most important. Cylinder is the main auxiliary equipment of a boiler. It is used to allocate the boiler steam produced during the boiler running to each pipe. Cylinder is a pressure bearing equipment, and its pressure bearing capacity should be corresponding with the auxiliary boiler.

Key words: Cylinder ;Pressure vessel ;Pressure welding; assembly;

目 录

摘 要………………………………………………………………………………1

关键词…………………………………………………………………………………1

1前言…………………………………………………………………………………2

1.1选题研究意义……………………………………………………………………2

1.2国内外研究现状…………………………………………………………………2

1.3分汽缸的设计要求………………………………………………………………2

2分汽缸的基本知识…………………………………………………………………3

2.1分汽缸的分类……………………………………………………………………3

2.2分汽缸的应用和相关压力容器焊接结构………………………………………4

2.2.1压力容器的分类及应用………………………………………………………4

2.3制作技术参数……………………………………………………………………6

2.3.1气缸组成零部件及材料………………………………………………………6

3生产准备……………………………………………………………………………7

3.1制造材料介绍……………………………………………………………………7

3.1.1 Q345R……………………………………………………………………………7

3.1.2 16Mn……………………………………………………………………………7

3.1.3 Q235……………………………………………………………………………8

3.1.4 20号钢…………………………………………………………………………8

3.1.5 20G无缝钢管…………………………………………………………………9

4备料…………………………………………………………………………………10

4.1筒体………………………………………………………………………………10

4.1.1制作步骤………………………………………………………………………11

4.1.1制作步骤………………………………………………………………………11

4.2法兰………………………………………………………………………………12

4.2.1法兰结构形式…………………………………………………………………12

4.2.2法兰密封形式…………………………………………………………………12

4.3封头………………………………………………………………………………12

4.3.1计算步骤………………………………………………………………………13

4.4接管………………………………………………………………………………14

4.5支座及铭牌座……………………………………………………………………14

4.5.1支座制作步骤…………………………………………………………………14

4.5.2铭牌座制作步骤………………………………………………………………15

5装配焊接……………………………………………………………………………15

5.1焊接环境…………………………………………………………………………15

5.2焊前预热…………………………………………………………………………16

5.3法兰与接管组装…………………………………………………………………16

5.4封头与筒体组装…………………………………………………………………16

5.4.1开孔……………………………………………………………………………17

5.4.2装配……………………………………………………………………………17

5.5接管与筒体组装…………………………………………………………………17

5.5.1Ф76/159接管焊接方式………………………………………………………18

5.5.2Ф32接管焊接方式……………………………………………………………18

6成型组装……………………………………………………………………………18

7焊后处理……………………………………………………………………………19

7.1外观质量检测……………………………………………………………………19

7.2无损探伤…………………………………………………………………………19

7.2.1无损探伤方法及检验…………………………………………………………21

7.3检验结果…………………………………………………………………………24

8总结…………………………………………………………………………………24

参考文献……………………………………………………………………………25

致 谢…………………………………………………………………………25