设计简介

摘 要

金属针布包卷机是重要的梳棉辅机之一,它的性能优劣、质量好坏,会直接影响针布在包覆后的平整度、均匀度和松紧度,与针布的使用寿命和梳理效果也有密切关系。为保证高质量、高效率的包覆金属针布,本设计针对目前国内外包卷机在控制方式和技术性能上存在的不足,采用国际上先进的交流变频调整装置。为满足刺辊金属针布包卷要求,解决刺辊包卷过程中的问题和包卷的后续问题,根据装置的用途、作用及外形、包卷要求,对该装置的加工原理和加工过程中需要注意的问题进行了详细的分析。

针对现有包卷机械存在的缺陷,提出本设计的设计思路。采用被动包覆方式,能包覆各种带槽的刺辊及开清棉机的锯齿打手,速度变频控制无级可调。

关键词

梳棉机,刺辊,金属针布 ,包卷机

Abstract

Cloth for metal rolling machine needle is one of important carding Auxiliary,its performance, quality, good or bad, have a direct impact on clothing in the post-coating flatness, uniformity and tightness, and the life of clothing and combing effects are closely related to it, To ensure high quality, high efficiency of coated metallic wire,the design package for the paper machine at home and abroad in the control and the technical performance deficiencies, adopt international advanced AC variable frequency adjustment device. To meet the taker volume requirements of metal needle cloth, wrapping solution taker in the process of the follow-up questions and convolute the issue, according to device use, function and appearance, including volume requirements, processing principle of the device and processing issues that need attention to a detailed analysis.

Wrapping machinery for the existing shortcomings and put forward the design idea of this design. Coated by passive means, to covering a variety of grooved taker and opening and cleaning machine serrated thugs, staples speed variable frequency control.

Key words

carding Machine,taker,MCC,wrapping Machine

目 录金属针布包卷机是重要的梳棉辅机之一,它的性能优劣、质量好坏,会直接影响针布在包覆后的平整度、均匀度和松紧度,与针布的使用寿命和梳理效果也有密切关系。为保证高质量、高效率的包覆金属针布,本设计针对目前国内外包卷机在控制方式和技术性能上存在的不足,采用国际上先进的交流变频调整装置。为满足刺辊金属针布包卷要求,解决刺辊包卷过程中的问题和包卷的后续问题,根据装置的用途、作用及外形、包卷要求,对该装置的加工原理和加工过程中需要注意的问题进行了详细的分析。

针对现有包卷机械存在的缺陷,提出本设计的设计思路。采用被动包覆方式,能包覆各种带槽的刺辊及开清棉机的锯齿打手,速度变频控制无级可调。

关键词

梳棉机,刺辊,金属针布 ,包卷机

Abstract

Cloth for metal rolling machine needle is one of important carding Auxiliary,its performance, quality, good or bad, have a direct impact on clothing in the post-coating flatness, uniformity and tightness, and the life of clothing and combing effects are closely related to it, To ensure high quality, high efficiency of coated metallic wire,the design package for the paper machine at home and abroad in the control and the technical performance deficiencies, adopt international advanced AC variable frequency adjustment device. To meet the taker volume requirements of metal needle cloth, wrapping solution taker in the process of the follow-up questions and convolute the issue, according to device use, function and appearance, including volume requirements, processing principle of the device and processing issues that need attention to a detailed analysis.

Wrapping machinery for the existing shortcomings and put forward the design idea of this design. Coated by passive means, to covering a variety of grooved taker and opening and cleaning machine serrated thugs, staples speed variable frequency control.

Key words

carding Machine,taker,MCC,wrapping Machine

前 言 5

1.工作原理及其原理分析 6

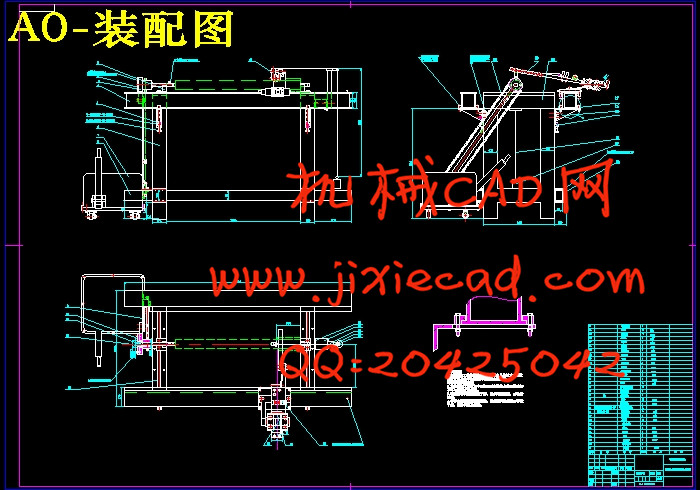

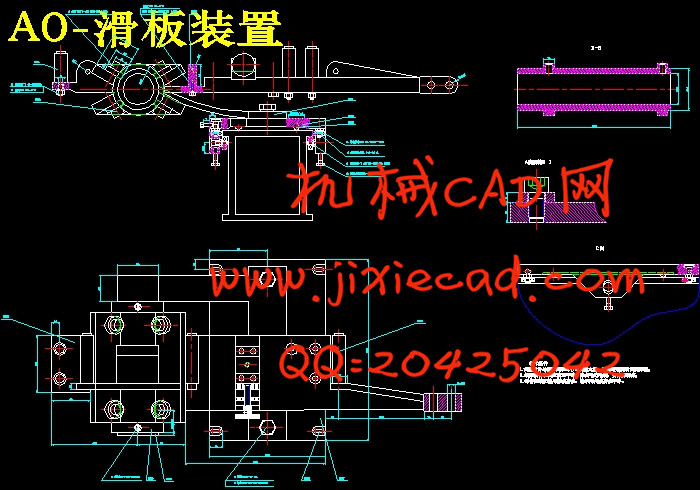

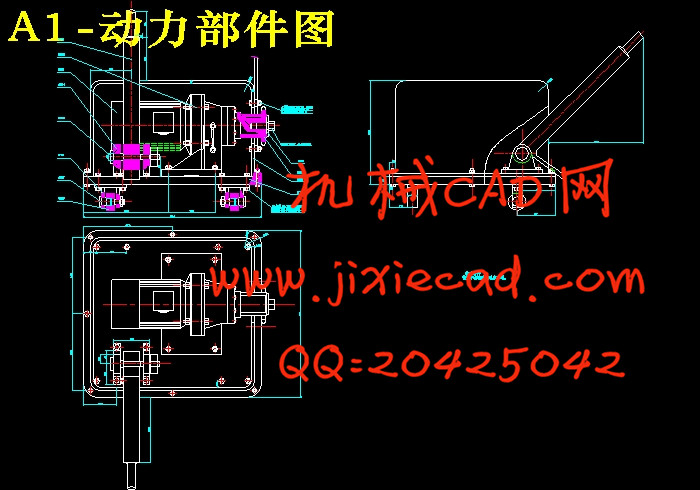

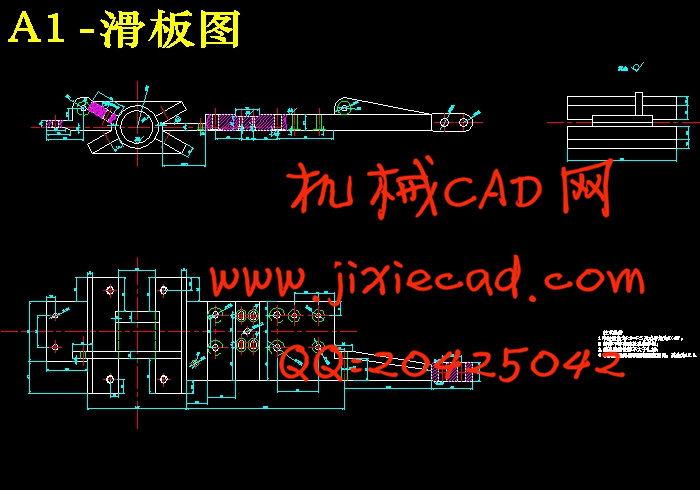

2.主要结构及作用 9

3. 主要技术参数 10

4.工作特点 11

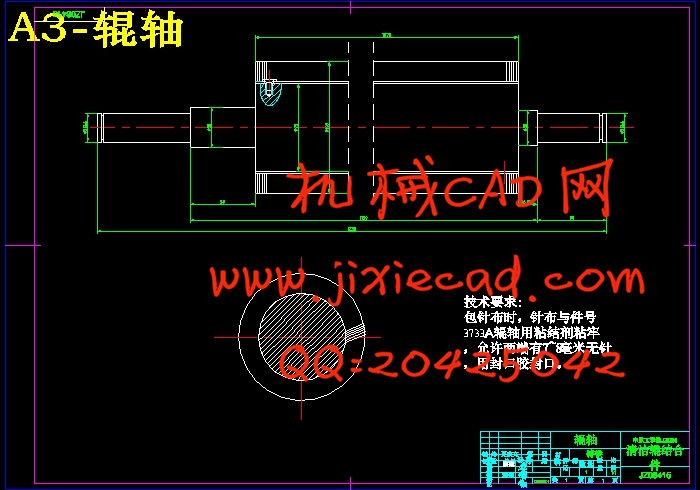

5.刺辊金属针布的分析 12

6.设计方案的确定 14

(1)电机选用计算 14

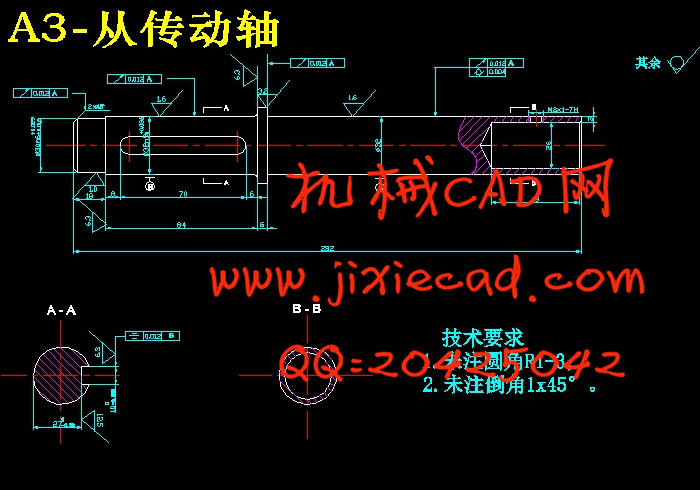

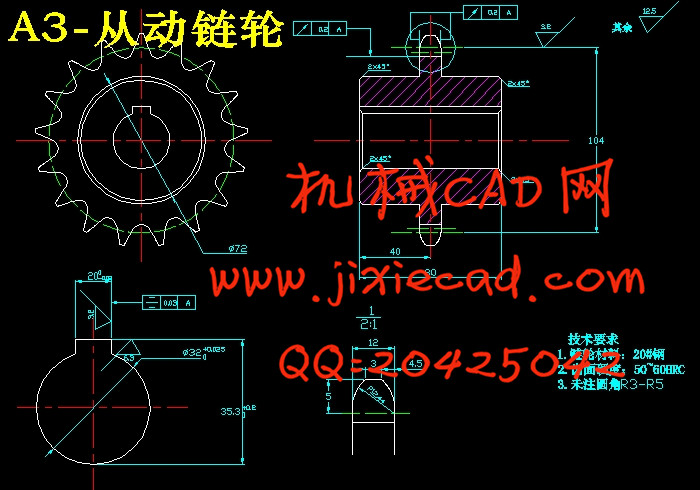

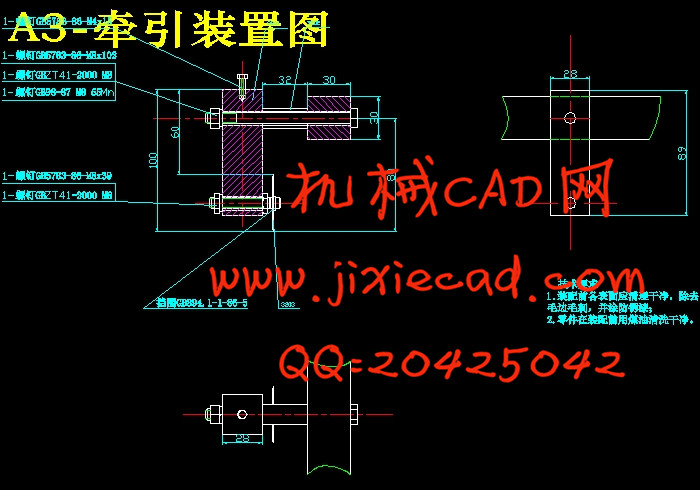

(2) 链传动设计计算 14

(3)键的设计计算 16

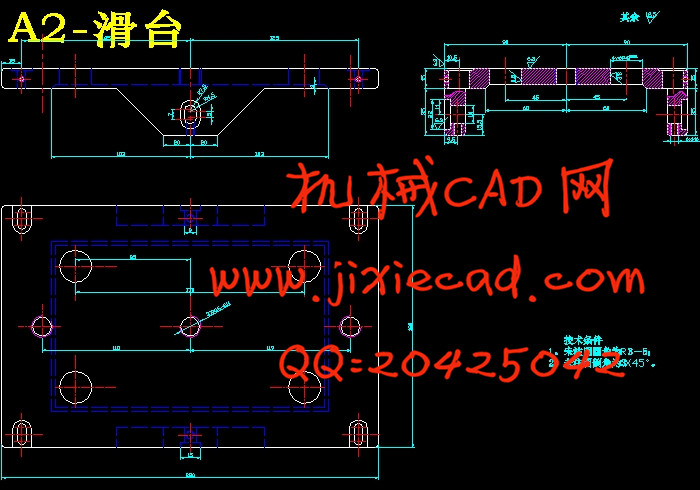

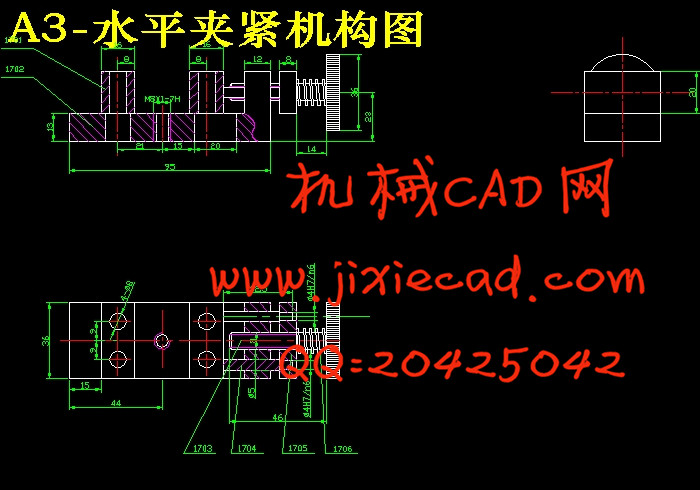

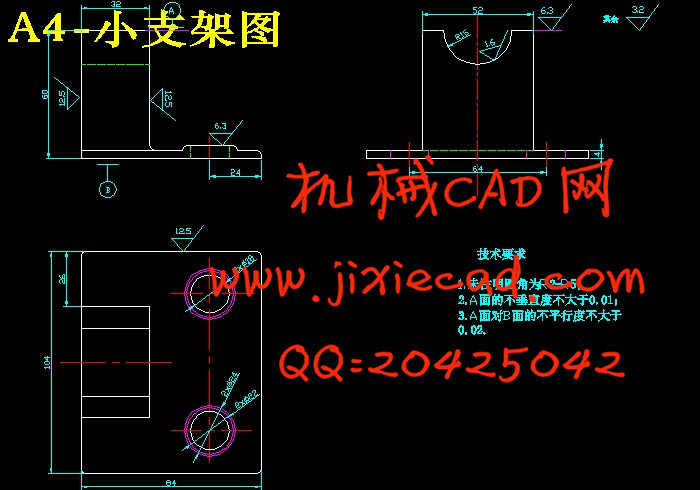

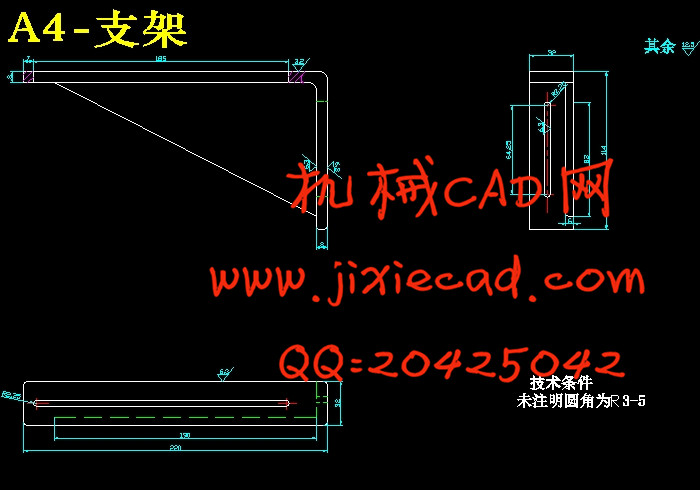

(4)整体结构设计 16

7 .包卷前的准备工作 18

8.包卷中的注意事项 21

(1)包卷 21

(2)修正 22

(3)磨针 22

(4)抄针 23

9.包卷工艺 24

(1).包卷速度 24

(2).包卷张力 24

(3).接触(包围)弧长 24

(4).侧压力 24

(5).包卷中途接头 24

(6).收尾 25

(7).锡焊 25

10.包卷后续工作 27

(1) 修针 27

(2)磨针 27

(3)刷光 27

11.设计方案的优缺点分析 28

12.经济性分析 30

13.结 论 31

14.参考文献 33