设计简介

摘要

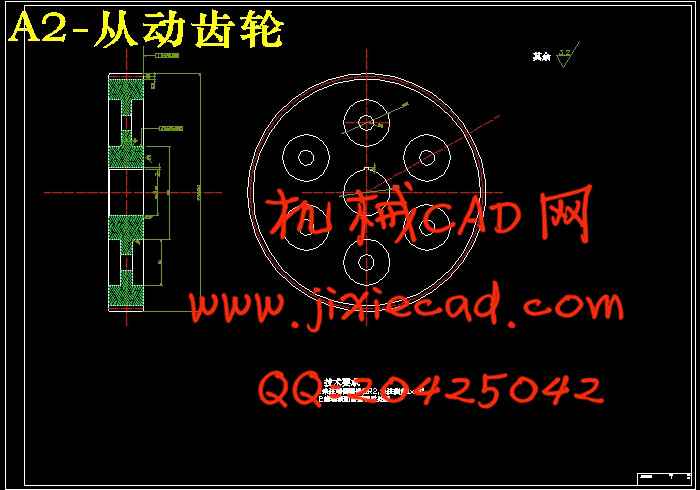

本系统采用一级齿轮减速,带动丝杠传动,通过螺母的直线移动带动工作台运动。根据脉冲当量、步矩角、丝杠导程来确定齿轮的传动比,根据负载转矩的大小来校核丝杠传动的强度。 单片机控制二维工作台是众多控制机械传动方法的一种,它利用单片机发出指令控制步进电机的转角和转速,进而控制X-Y工作台两方向的移动,实现画线,移动物体等功能,常用于试验教学。

单片机控制二维工作台主要由三部分组成:工作台及传动支撑部分,减速装置,控制部分及电机组成。

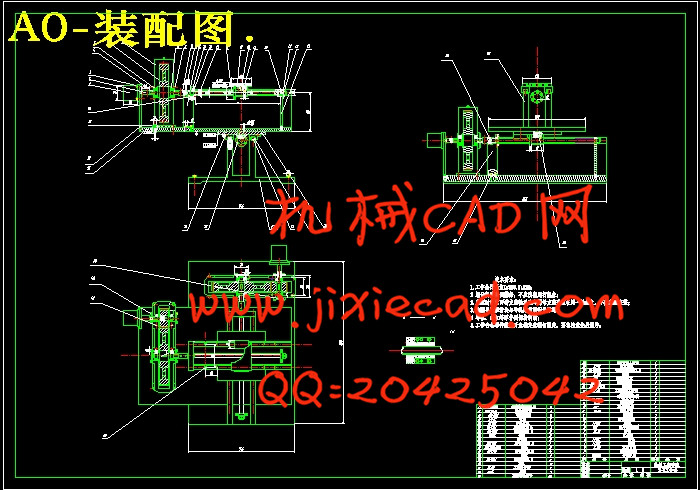

单片机控制的X-Y工作台系统可以设计为开环,半闭环和闭环伺服系统三种。本设计采用开环伺服系统,通过单片机控制步进电动机的驱动,经传动机构动带动工作台的运动。系统没有检测装置。机械结构设计首先根据工作台的最大载荷,选取导轨副,设计工作台,然后进行结构设计,受力分析,转矩计算,画出工作台的装配草图,再选择步进电动机的型号,进而设计选择滚珠丝杠,最后设计出X-Y工作台,画出其装配图。

关键词 工作台;步进电机;脉冲当量;步距角

Abstract

SCM control of the XY table system can be designed for the open-loop, semi-closed-loop system and closed-loop servo three. I design is open-loop servo systems using the stepper motor driven by the stepper motor control microcontroller-driven, driven by the transmission mechanism dynamic table of the campaign. System is not detecting device. Mechanical structural design of the first table under the maximum load, select the rails of the design table, and then the structural design, mechanical analysis, torque, the assembly table to draw the draft, then select the type stepper motor, thereby Design choices ball screw, the final design XY table, draw their assembly.

The system uses a gear to reduce speed transmission driven screw, nut straight through mobile workstation driven campaign. According to pulse equivalent, step moment Kok, screw lead to determine the gear transmission ratio, according to the size of load torque than the strength of the screw drive. SCM control of two-dimensional table of the many methods of control of a mechanical transmission, it issued a directive by SCM stepper motor control and the speed of rotation, thereby control the direction of the two XY table movement, and drawing a line, moving objects , And other functions, commonly used in the trial of teaching.

SCM control of two-dimensional table mainly consists of three parts: transmission and support of the table, deceleration devices, motor control parts and components.

Keywords table stepper motor control microcontroller-driven pulse equivalent step moment kok

目录

1绪论 1本系统采用一级齿轮减速,带动丝杠传动,通过螺母的直线移动带动工作台运动。根据脉冲当量、步矩角、丝杠导程来确定齿轮的传动比,根据负载转矩的大小来校核丝杠传动的强度。 单片机控制二维工作台是众多控制机械传动方法的一种,它利用单片机发出指令控制步进电机的转角和转速,进而控制X-Y工作台两方向的移动,实现画线,移动物体等功能,常用于试验教学。

单片机控制二维工作台主要由三部分组成:工作台及传动支撑部分,减速装置,控制部分及电机组成。

单片机控制的X-Y工作台系统可以设计为开环,半闭环和闭环伺服系统三种。本设计采用开环伺服系统,通过单片机控制步进电动机的驱动,经传动机构动带动工作台的运动。系统没有检测装置。机械结构设计首先根据工作台的最大载荷,选取导轨副,设计工作台,然后进行结构设计,受力分析,转矩计算,画出工作台的装配草图,再选择步进电动机的型号,进而设计选择滚珠丝杠,最后设计出X-Y工作台,画出其装配图。

关键词 工作台;步进电机;脉冲当量;步距角

Abstract

SCM control of the XY table system can be designed for the open-loop, semi-closed-loop system and closed-loop servo three. I design is open-loop servo systems using the stepper motor driven by the stepper motor control microcontroller-driven, driven by the transmission mechanism dynamic table of the campaign. System is not detecting device. Mechanical structural design of the first table under the maximum load, select the rails of the design table, and then the structural design, mechanical analysis, torque, the assembly table to draw the draft, then select the type stepper motor, thereby Design choices ball screw, the final design XY table, draw their assembly.

The system uses a gear to reduce speed transmission driven screw, nut straight through mobile workstation driven campaign. According to pulse equivalent, step moment Kok, screw lead to determine the gear transmission ratio, according to the size of load torque than the strength of the screw drive. SCM control of two-dimensional table of the many methods of control of a mechanical transmission, it issued a directive by SCM stepper motor control and the speed of rotation, thereby control the direction of the two XY table movement, and drawing a line, moving objects , And other functions, commonly used in the trial of teaching.

SCM control of two-dimensional table mainly consists of three parts: transmission and support of the table, deceleration devices, motor control parts and components.

Keywords table stepper motor control microcontroller-driven pulse equivalent step moment kok

目录

1.1课题研究的背景 1

1.2工作台的分类 1

1.3本设计工作台的作用和特点 3

1.4步进电机的发展现状 3

1.5单片机的发展现状 5

2方案原理的设计 6

2.1总体方案的选择和说明 6

2.2总体方案实现的系统组成框图 7

3各零件的设计 8

3.1步进电机的设计 8

3.1.1步进电机的组成及工作原理 8

3.1.2步进电机的选择 9

3.1.3 步进电机的校核 9

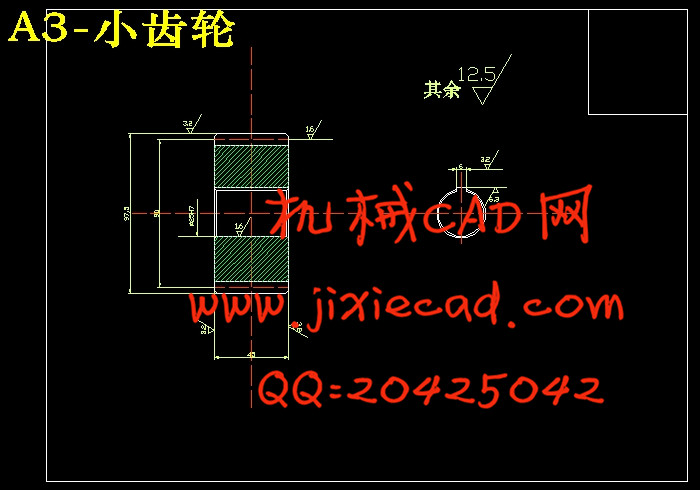

3.2减速器设计 10

3.2.1主动齿轮的选择与计算 10

3.2.2从动齿轮的选择与校核 13

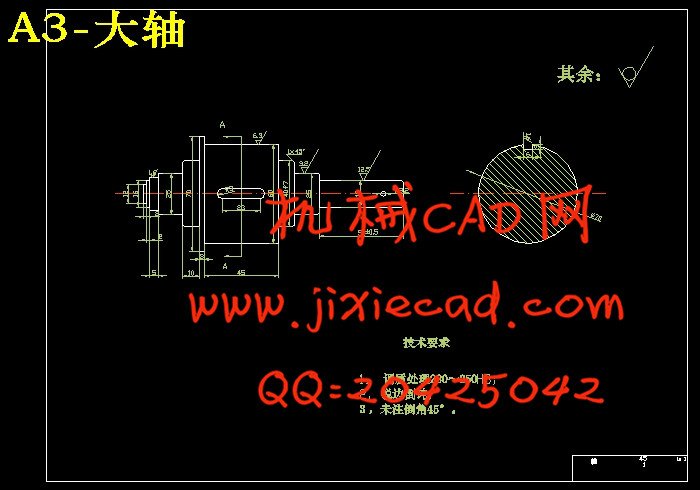

3.2.3轴的设计 13

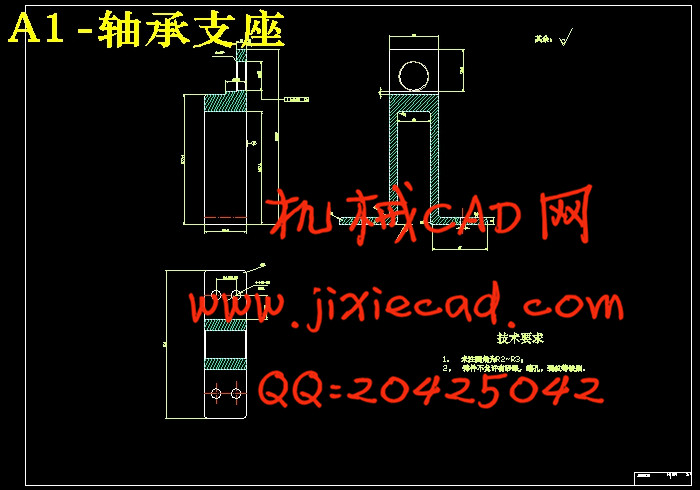

3.3轴承的设计 16

3.3.1小轴两端轴承的选择和计算 17

3.3.2大轴两端轴承的选择和计算 18

3.4联轴器的设计 19

3.4.1步进电机输出轴与小轴之间联轴器的选择与计算 19

3.4.2大轴和滚珠丝杠间联轴器的选择和计算 20

3.5键的设计 21

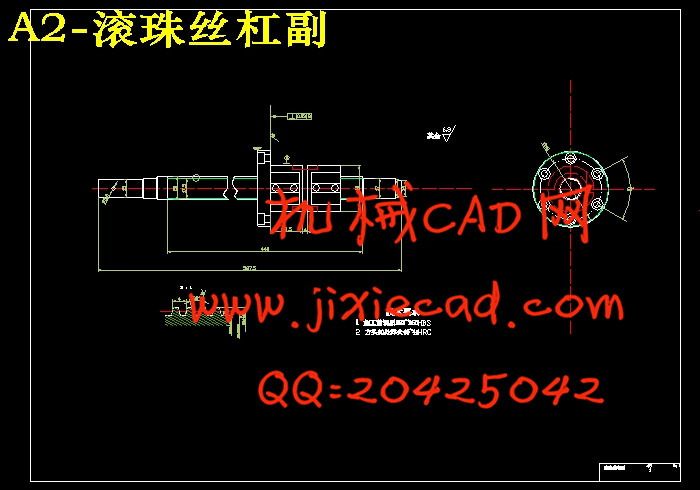

3.6丝杠的设计 22

3.6.1丝杠的特点 22

3.6.2丝杠的选择 23

3.6.3丝杠的校核计算 23

3.7 导轨的设计 25

3.7.1直线滚动导轨的选型 26

3.7.2直线滚动导轨的校核计算 27

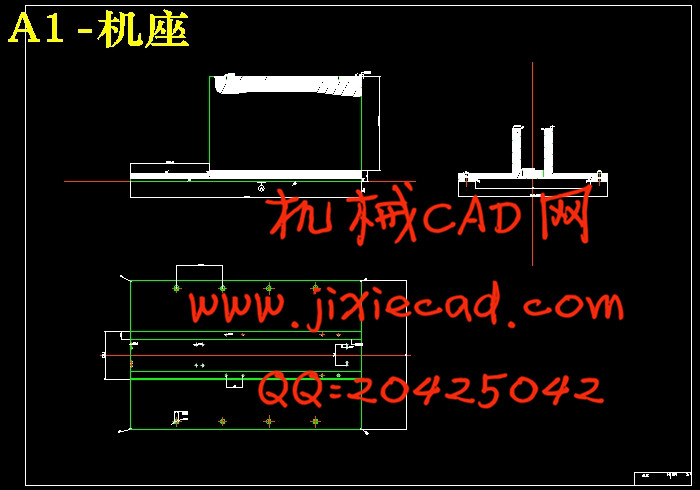

3.8支座的特点及材料组成 29

结论 32

致谢 33

参考文献 34