设计简介

摘 要

刀具在机械加工中占据着非常重的位置,一台车床无论它是数控的还是手工操作的,都需要有一把好刀具。而现在企业里大多数还是依靠手工磨削的。这就需要拥有丰富的理论知识和专业经验。如果一个没有经验的学徒工去磨削刀具,那么很可能磨削不出一个称心如意的刀具。结果是降低生产效率并且使加工质量很难控制。因此研制一种具有傻瓜功能的多用途刀具磨床(车削类刀具)显得很有必要。本磨刀机具有三个直线轴和两个旋转轴,可轻易磨出各种角度。磨刀最重要的是要磨好刀尖,工件已加工表面的光洁度几乎完全决定于刀尖的磨削质量,本磨刀机可以把刀尖磨出标准的圆弧形状,且具有很高的光洁度,从而保证了加工工件的光洁度。这点是手工修磨难以做到的。

关键词:机械磨削,圆弧角,多功能磨削机(车削类刀具)

Abstract

Tools occupy an important position in machining, whether it is a numerically controlled lathe or manual, there needs to have a good tool. Now in the majority of enterprises still rely on hand gringding. It needs to have rich theoretical knowledge and professional experience. If an inexperienced apprentice go to grind tools, then it is difficult to meet the requirements. Then caused a bad result that is lower productivity and the machining quality is difficult to control. Therefore the design of a multi-purpose grinding machine (turning tool class) with a fool function seems very necessary. The Tool Grinding Machine has three linear axes and two revolving axes. It is very easy to grind many kinds of angle. The most important thing of grinding tool is grinding tool peak, finished roughness of workpiece depends almost all on the quality of tool peak. The Tool Grinding Machine can grind tool peak to become a standard circular form that has good roughness, thereby, guarantee the fine roughness of workpiece. It is almost impossible to grind tool peak circle if we do not use Tool Grinding Machine.

Key words:mechanical grinding, roughness , circular angle, multi-purpose grinding machine

目录

前 言 5

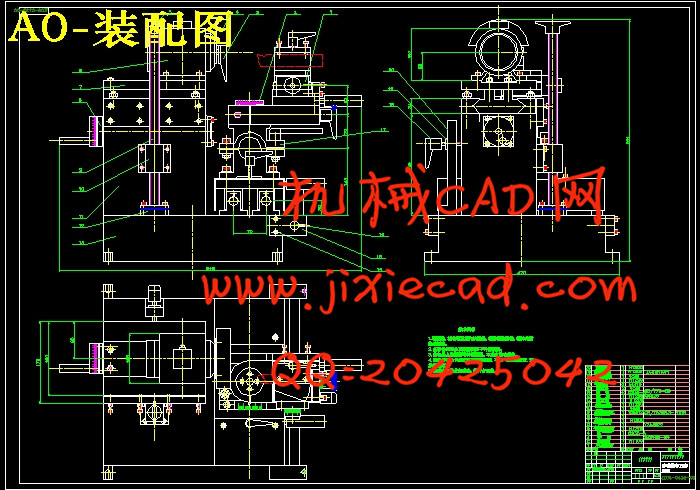

1.方案论述与设计 6

1.1刀具的基本知识 6

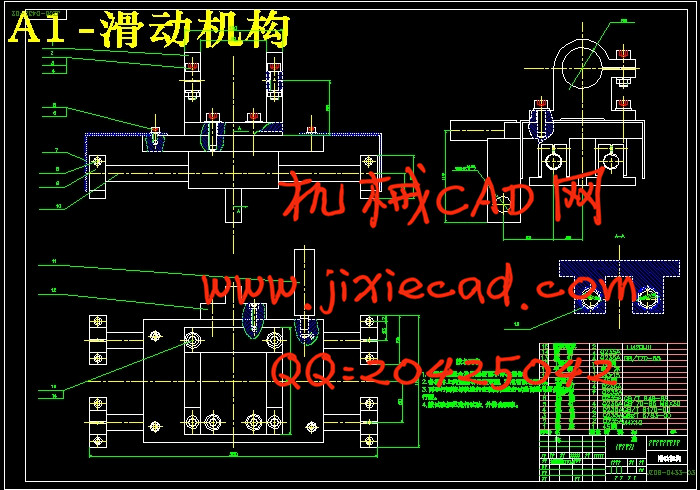

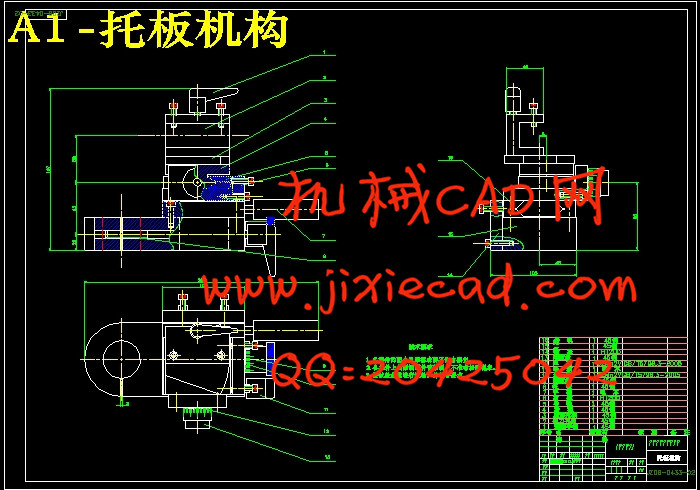

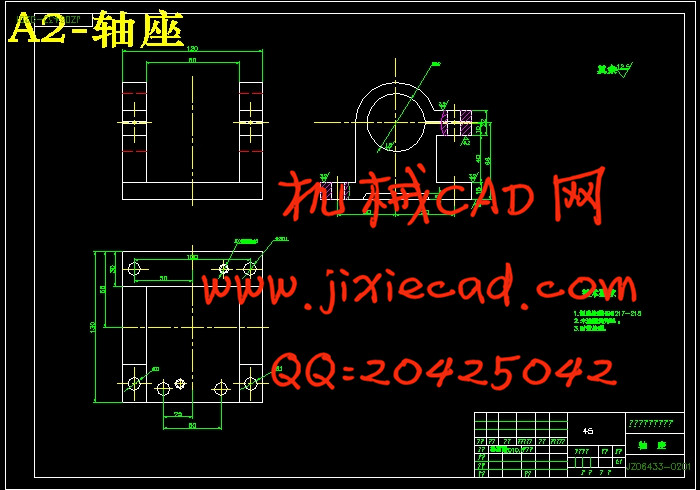

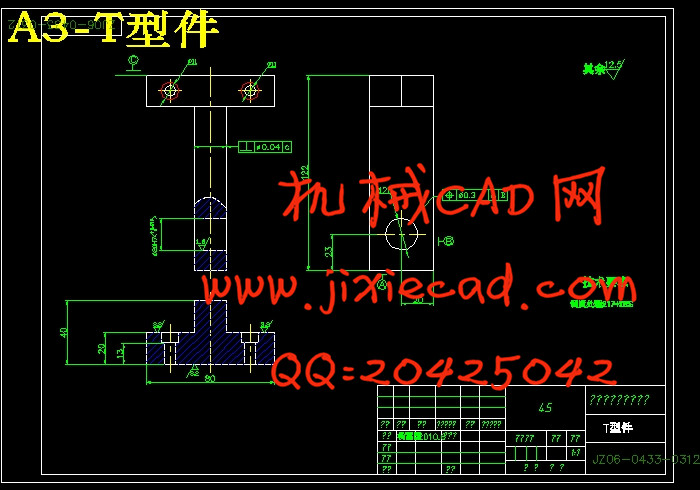

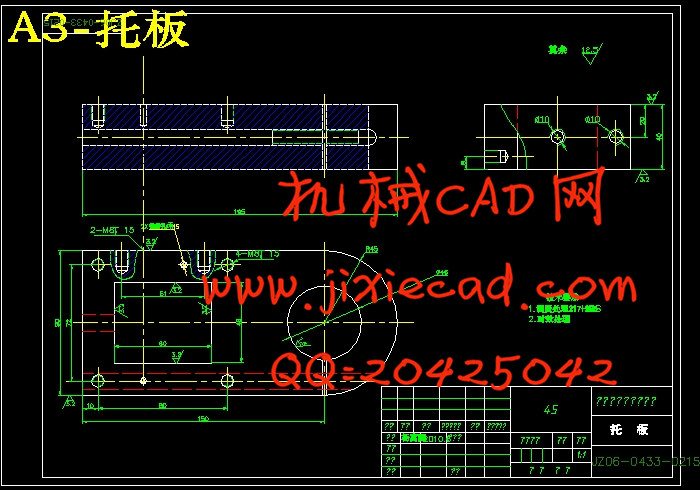

1.2结构的可行性分析 10

2.几何参数的分析和计算 19

2.1砂轮种类的选择 19

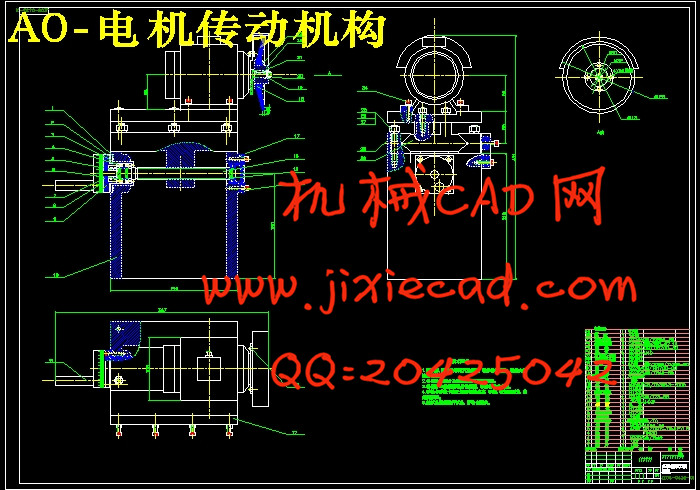

2.2电机的选择计算 19

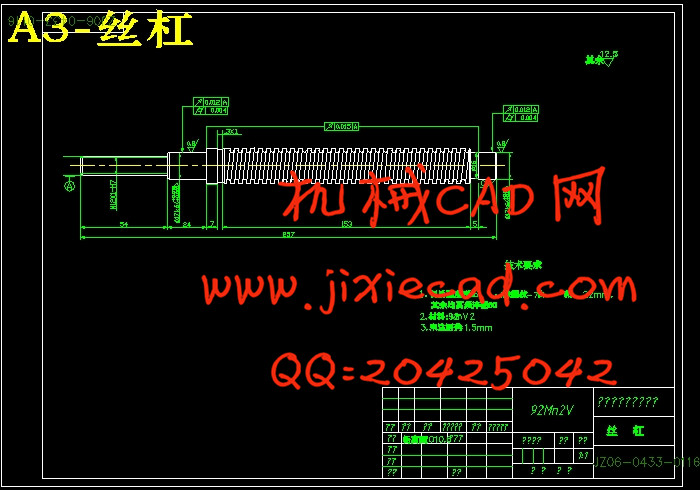

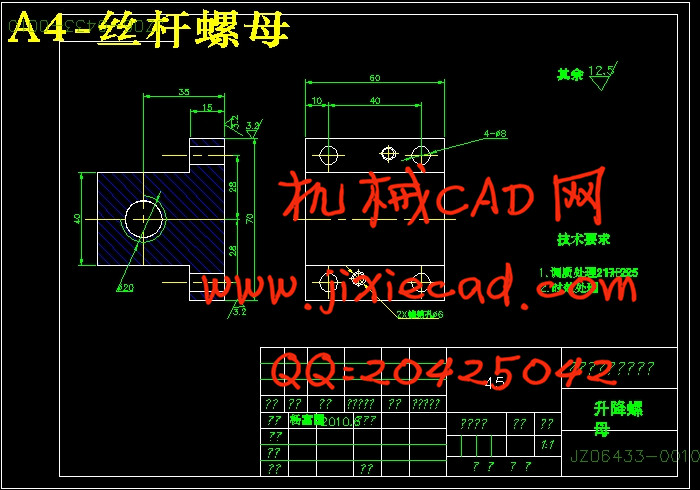

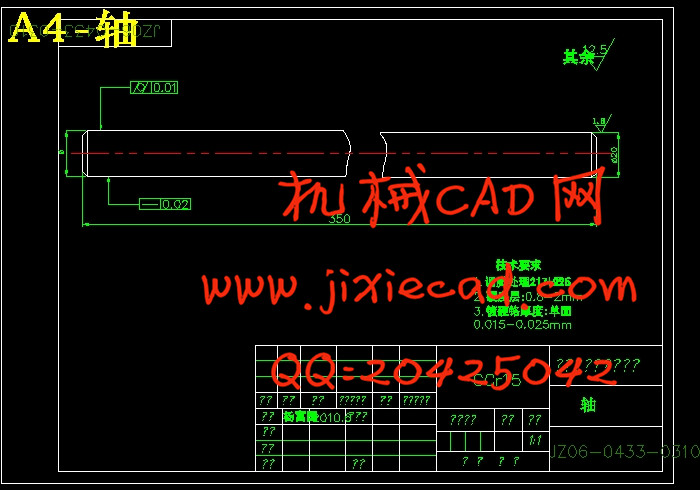

2.3丝杆选择计算 20

3经济性分析 23

4结 论 24

参考文献 26

致谢 27

刀具在机械加工中占据着非常重的位置,一台车床无论它是数控的还是手工操作的,都需要有一把好刀具。而现在企业里大多数还是依靠手工磨削的。这就需要拥有丰富的理论知识和专业经验。如果一个没有经验的学徒工去磨削刀具,那么很可能磨削不出一个称心如意的刀具。结果是降低生产效率并且使加工质量很难控制。因此研制一种具有傻瓜功能的多用途刀具磨床(车削类刀具)显得很有必要。本磨刀机具有三个直线轴和两个旋转轴,可轻易磨出各种角度。磨刀最重要的是要磨好刀尖,工件已加工表面的光洁度几乎完全决定于刀尖的磨削质量,本磨刀机可以把刀尖磨出标准的圆弧形状,且具有很高的光洁度,从而保证了加工工件的光洁度。这点是手工修磨难以做到的。

关键词:机械磨削,圆弧角,多功能磨削机(车削类刀具)

Abstract

Tools occupy an important position in machining, whether it is a numerically controlled lathe or manual, there needs to have a good tool. Now in the majority of enterprises still rely on hand gringding. It needs to have rich theoretical knowledge and professional experience. If an inexperienced apprentice go to grind tools, then it is difficult to meet the requirements. Then caused a bad result that is lower productivity and the machining quality is difficult to control. Therefore the design of a multi-purpose grinding machine (turning tool class) with a fool function seems very necessary. The Tool Grinding Machine has three linear axes and two revolving axes. It is very easy to grind many kinds of angle. The most important thing of grinding tool is grinding tool peak, finished roughness of workpiece depends almost all on the quality of tool peak. The Tool Grinding Machine can grind tool peak to become a standard circular form that has good roughness, thereby, guarantee the fine roughness of workpiece. It is almost impossible to grind tool peak circle if we do not use Tool Grinding Machine.

Key words:mechanical grinding, roughness , circular angle, multi-purpose grinding machine

目录

前 言 5

1.方案论述与设计 6

1.1刀具的基本知识 6

1.2结构的可行性分析 10

2.几何参数的分析和计算 19

2.1砂轮种类的选择 19

2.2电机的选择计算 19

2.3丝杆选择计算 20

3经济性分析 23

4结 论 24

参考文献 26

致谢 27