设计简介

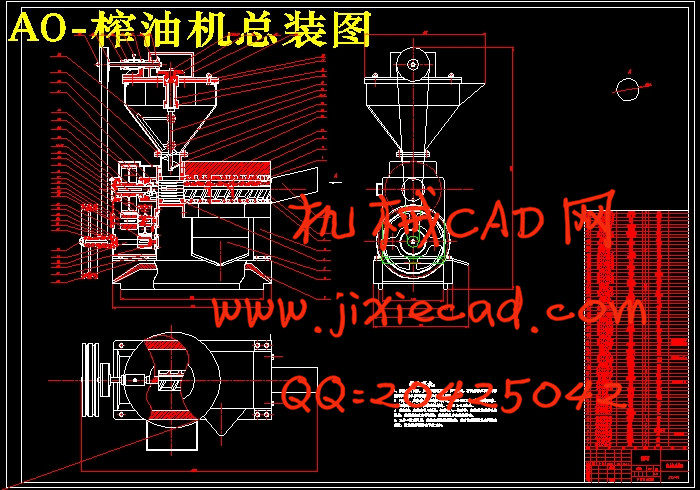

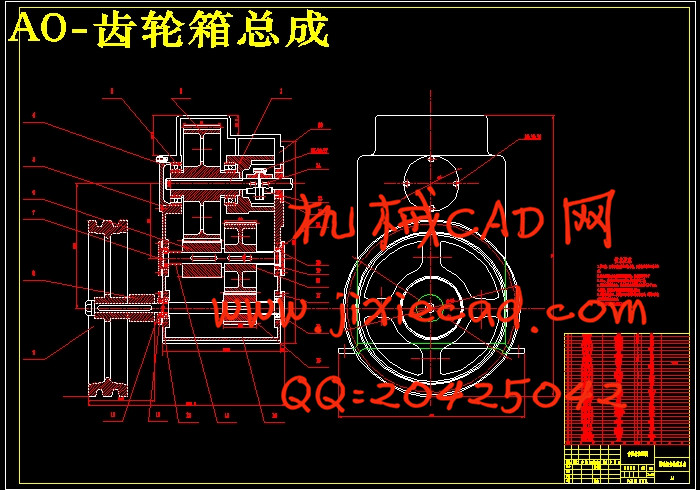

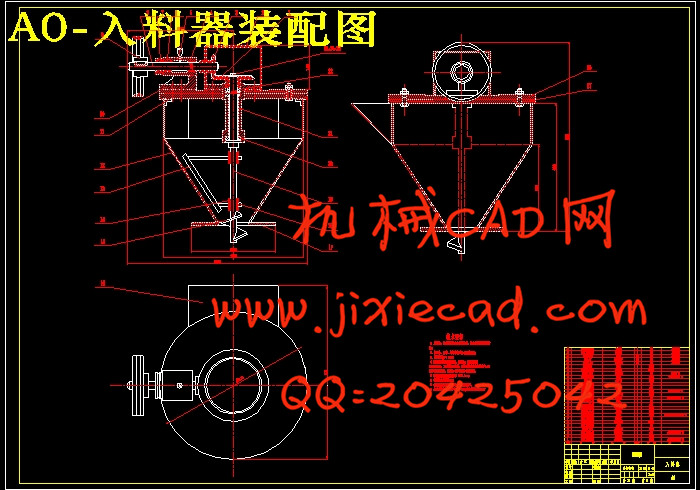

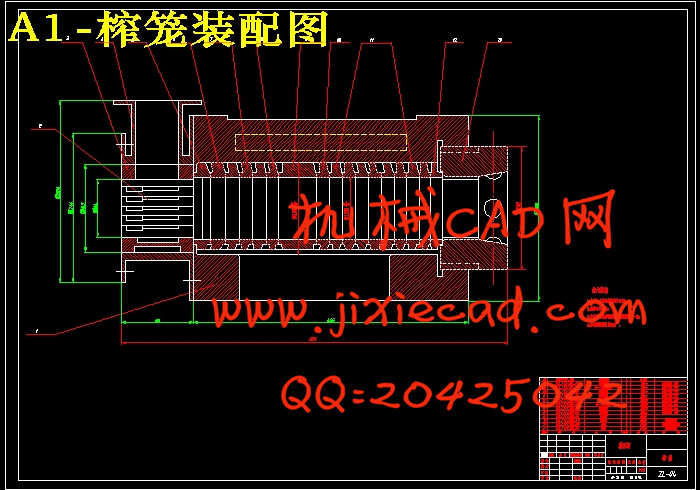

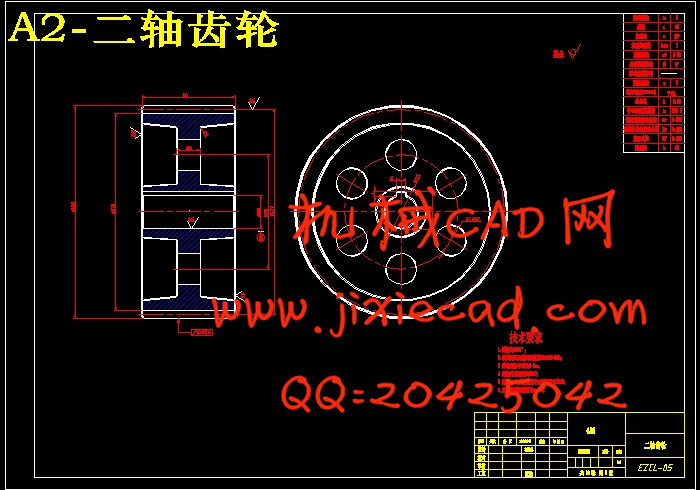

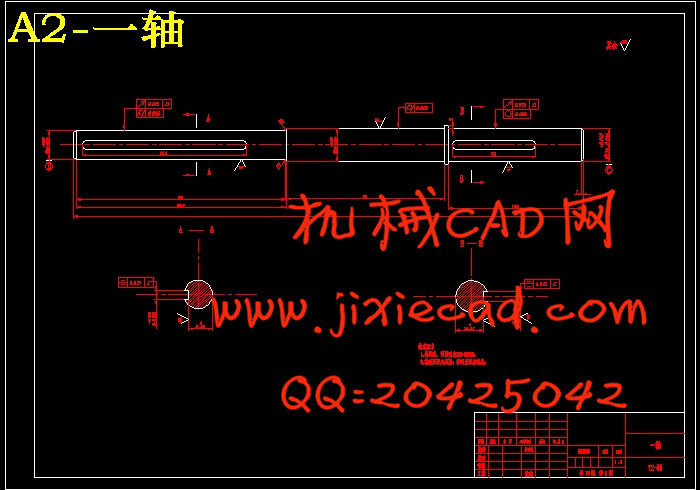

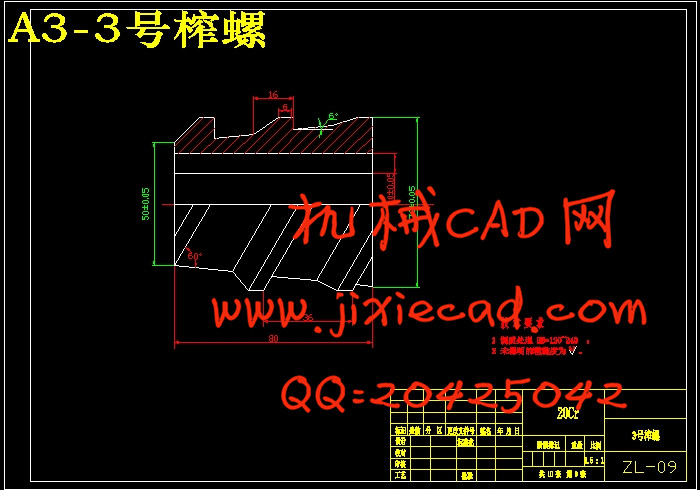

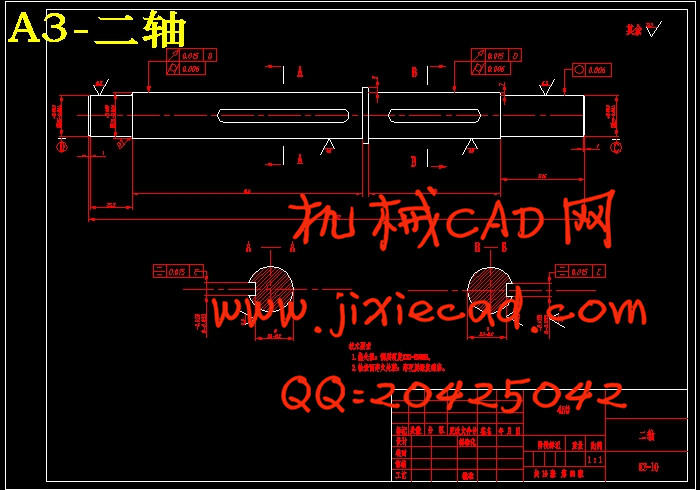

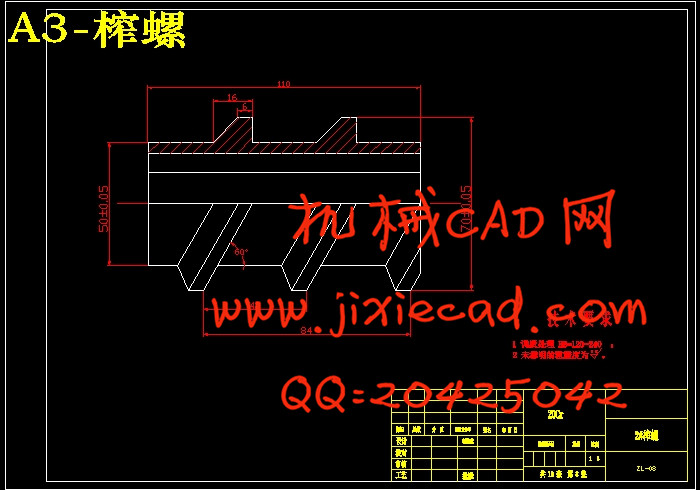

摘 要:本文主要是对螺旋榨油机的总体结构设计。其中包括压榨部分,传动部分,机架部分,出油装置及进料等的结构设计。包括对输入端电动机功率/转速的选择。带及带轮的选择及设计。变速箱中齿轮的设计,轴的设计,轴承、键、联轴器的选择及相关的计算、校核。榨螺榨笼的设计等。其中榨螺和榨笼是榨油机的主要工作部件。榨螺部分主要有榨螺轴和榨螺(共3节).调饼头.锁紧螺母和调节螺栓等组成.榨螺的设计应满足榨螺间的装配要求.榨螺间装配必须严密.用锁紧螺母将其夹紧.防止油饼渗入榨螺孔内,影响榨螺的顺利拆卸.榨笼的榨膛由两部分组成.前段由榨条组成,后段落由榨圈组成.变速箱的设计应注意互相间的配合关系,传动比及扭矩是否满足工作条件等.本机适用于榨取菜籽、花生仁、芝麻、棉籽仁、大豆、椰子、茶籽、葵花籽等植物油脂。(根据用户需要,可更换榨螺,用于榨取米糠等含油的油料。)

关键词:榨油机;轴;花键;联轴器;齿轮箱;榨笼;

Abstract:This paper is the overall structure design of screw press. Including press parts, transmission parts, chassis parts, the structure design of oil device and feed etc.. Including the motor input power / speed selection. The selection and design of belt and pulley. Transmission in gear design, shaft design, bearing, bond, options and related coupling calculation, checking. Screw squeezing cage design etc.. The screw and barrel is the main component of oil press. Screw mainly consists of a screw shaft and screw. Adjustable cake head. The lock nut and an adjusting bolt etc.. Design should meet the requirements of the press screw assembly screw the screw assembly must be strict. Through a locking nut clamping. Prevent the cake into the pressing screw effects of screw, the smooth demolition. Pressing cage pressing chamber consists of two parts. Section by pressing strip, after paragraph by the pressing ring. Attention should be paid to coordination between design of gearbox, whether the transmission ratio and torque to meet the conditions.

This machine is suitable for the extraction of rapeseed, peanut, sesame seed, cottonseed, soybean, coconut, tea seed, sunflower seeds and other plant oils. (according to user needs, can replace the screw, for oily extract rice bran oil.)

Key words:The oil press;Shafts;Splines;Coupling;Gear box;The pressing cage

目 录

摘要 …………………………………………………………………………1

关键词 ……………………………………………………………………………1

1前言 ……………………………………………………………………………2

2螺旋榨油机的设计计算 ………………………………………………………6

2.1 电动机的选取 ………………………………………………………………6

2.2 螺旋榨油机主要参数的确定 ……………………………………………6

2.2.1 榨膛容积比ε……………………………………………………………6

2.2.2进料端榨膛容积比Vj的计算…………………………………………………6

2.2.3功率消耗……………………………………………………………………7

2.2.4榨膛压力……………………………………………………………………7

2.2.5榨膛压缩比曲线……………………………………………………………7

2.3榨螺的设计计算………………………………………………………………7

2.3.1连续型榨螺轴尺寸表………………………………………………………7

2.3.2榨螺齿形……………………………………………………………………8

2.3.3榨螺材料……………………………………………………………………8

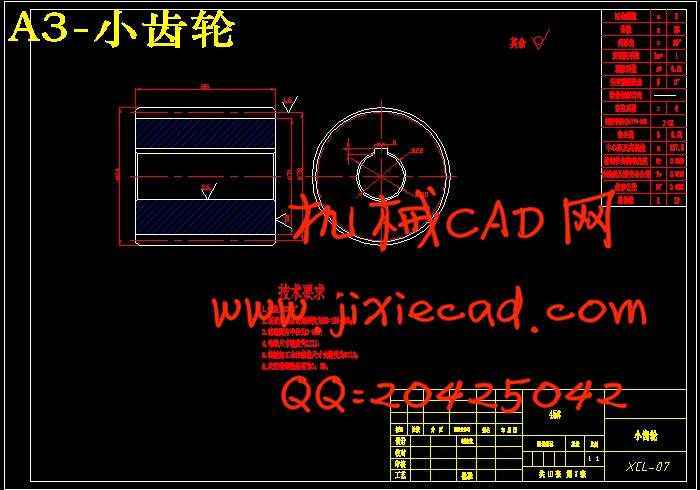

2.4Ⅰ轴和Ⅱ轴啮合齿轮的计算……………………………………………………9

2.4.1齿轮的选用…………………………………………………………………9

2.4.2确定小齿轮的齿形参数……………………………………………………12

2.5轴的计算校核…………………………………………………………………13

2.5.1选材及表面预处理…………………………………………………………13

2.5.2轴的结构设计………………………………………………………………13

2.6皮带轮的设计计算……………………………………………………………15

2.7轴承的设计……………………………………………………………………16

2.7.1轴承寿命……………………………………………………………………16

2.7.2验算轴承寿命………………………………………………………………16

3螺旋榨油机的结构设计…………………………………………………………16

3.1榨螺轴的设计…………………………………………………………………17

3.2榨笼的构造……………………………………………………………………17

3.3齿轮箱的构造及入料器的构造………………………………………………17

3.4带轮的结构设计………………………………………………………………17

3.5调节装置的设计………………………………………………………………18

3.6键的选择与校核………………………………………………………………18

3.6.1Ⅰ轴上的键…………………………………………………………………18

3.6.2Ⅱ轴上的键…………………………………………………………………18

3.6.3芯轴上的键Ⅰ………………………………………………………………18

3.6.4芯轴上的键Ⅱ………………………………………………………………18

3.6.5键的校核……………………………………………………………………19

3.7滚动轴承的选择………………………………………………………………19

3.7.1 Ⅲ轴上的轴承的选择………………………………………………………19

3.7.2 Ⅰ轴和Ⅱ轴的轴承…………………………………………………………20

3.8 榨螺轴与齿轮轴的联接设计…………………………………………………20

4 螺旋榨油机的故障及排除…………………………………………………… ……20

4.1操作过程中出现的故障及排除………………………………………………20

4.1.1熟胚过分干燥时发生的现象………………………………… …… …………20

4.1.2熟坯温度过低、含水量较大时发生的现象……………………………………21

4.1.3一般常见故障及排除………………………………………………… ………21

5结论………………………………………………………………………………22

参考文献……………………………………………………………………………23

致谢…………………………………………………………………………………24

关键词:榨油机;轴;花键;联轴器;齿轮箱;榨笼;

Abstract:This paper is the overall structure design of screw press. Including press parts, transmission parts, chassis parts, the structure design of oil device and feed etc.. Including the motor input power / speed selection. The selection and design of belt and pulley. Transmission in gear design, shaft design, bearing, bond, options and related coupling calculation, checking. Screw squeezing cage design etc.. The screw and barrel is the main component of oil press. Screw mainly consists of a screw shaft and screw. Adjustable cake head. The lock nut and an adjusting bolt etc.. Design should meet the requirements of the press screw assembly screw the screw assembly must be strict. Through a locking nut clamping. Prevent the cake into the pressing screw effects of screw, the smooth demolition. Pressing cage pressing chamber consists of two parts. Section by pressing strip, after paragraph by the pressing ring. Attention should be paid to coordination between design of gearbox, whether the transmission ratio and torque to meet the conditions.

This machine is suitable for the extraction of rapeseed, peanut, sesame seed, cottonseed, soybean, coconut, tea seed, sunflower seeds and other plant oils. (according to user needs, can replace the screw, for oily extract rice bran oil.)

Key words:The oil press;Shafts;Splines;Coupling;Gear box;The pressing cage

目 录

摘要 …………………………………………………………………………1

关键词 ……………………………………………………………………………1

1前言 ……………………………………………………………………………2

2螺旋榨油机的设计计算 ………………………………………………………6

2.1 电动机的选取 ………………………………………………………………6

2.2 螺旋榨油机主要参数的确定 ……………………………………………6

2.2.1 榨膛容积比ε……………………………………………………………6

2.2.2进料端榨膛容积比Vj的计算…………………………………………………6

2.2.3功率消耗……………………………………………………………………7

2.2.4榨膛压力……………………………………………………………………7

2.2.5榨膛压缩比曲线……………………………………………………………7

2.3榨螺的设计计算………………………………………………………………7

2.3.1连续型榨螺轴尺寸表………………………………………………………7

2.3.2榨螺齿形……………………………………………………………………8

2.3.3榨螺材料……………………………………………………………………8

2.4Ⅰ轴和Ⅱ轴啮合齿轮的计算……………………………………………………9

2.4.1齿轮的选用…………………………………………………………………9

2.4.2确定小齿轮的齿形参数……………………………………………………12

2.5轴的计算校核…………………………………………………………………13

2.5.1选材及表面预处理…………………………………………………………13

2.5.2轴的结构设计………………………………………………………………13

2.6皮带轮的设计计算……………………………………………………………15

2.7轴承的设计……………………………………………………………………16

2.7.1轴承寿命……………………………………………………………………16

2.7.2验算轴承寿命………………………………………………………………16

3螺旋榨油机的结构设计…………………………………………………………16

3.1榨螺轴的设计…………………………………………………………………17

3.2榨笼的构造……………………………………………………………………17

3.3齿轮箱的构造及入料器的构造………………………………………………17

3.4带轮的结构设计………………………………………………………………17

3.5调节装置的设计………………………………………………………………18

3.6键的选择与校核………………………………………………………………18

3.6.1Ⅰ轴上的键…………………………………………………………………18

3.6.2Ⅱ轴上的键…………………………………………………………………18

3.6.3芯轴上的键Ⅰ………………………………………………………………18

3.6.4芯轴上的键Ⅱ………………………………………………………………18

3.6.5键的校核……………………………………………………………………19

3.7滚动轴承的选择………………………………………………………………19

3.7.1 Ⅲ轴上的轴承的选择………………………………………………………19

3.7.2 Ⅰ轴和Ⅱ轴的轴承…………………………………………………………20

3.8 榨螺轴与齿轮轴的联接设计…………………………………………………20

4 螺旋榨油机的故障及排除…………………………………………………… ……20

4.1操作过程中出现的故障及排除………………………………………………20

4.1.1熟胚过分干燥时发生的现象………………………………… …… …………20

4.1.2熟坯温度过低、含水量较大时发生的现象……………………………………21

4.1.3一般常见故障及排除………………………………………………… ………21

5结论………………………………………………………………………………22

参考文献……………………………………………………………………………23

致谢…………………………………………………………………………………24