设计简介

摘 要

单绳缠绕式矿井提升机的工作原理:钢丝绳的一端用钢丝绳夹持固定在卷筒幅板上,另一端经卷筒的缠绕后,通过井架天轮悬挂提升容器。这样,利用主轴旋转方式的不同,将钢丝绳缠绕上或放松,以完成提升或下降容器的工作。

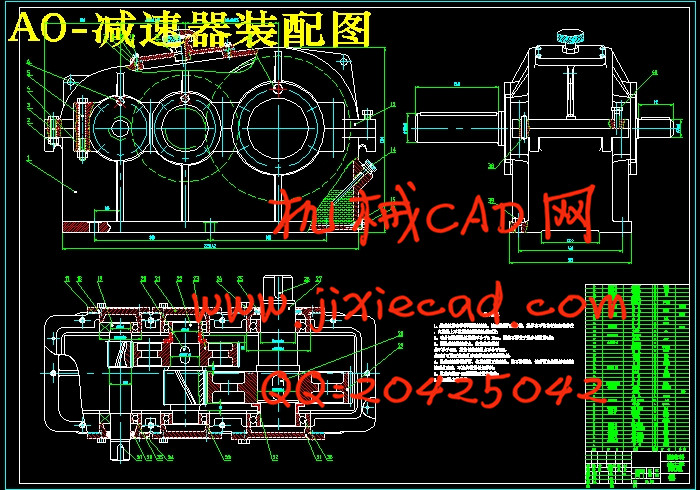

主轴是单绳缠绕式矿井提升机的主要结构,它的作用是:①支撑缠绕提升机钢丝绳的卷筒;②承受各种正常载荷(包括固定载荷和工作载荷);③承受各种积极情况所造成的非常载荷。在非常载荷作用下,主轴部分不应有残余变形。减速器要满足传动比要求,保证提升机正常工作,传动应准确,平稳,可靠。减速器应该在满足强度条件的同时尽可能小型,以减少占用空间。单绳缠绕式矿井提升机的主轴和减速器是其核心部件,要求我们应认真设计,精心制造,这对于确保矿井提升机安全可靠运行,预防和杜绝故障及事故的发生,也具有十分重要的意义。

本设计根据生产实际和预选的数据,以提升机的配套设备为核心,经过科学的计算和分析,设计了矿井提升机的传动系统。

关键词:提升机,主轴,减速器

ABSTRACT

What the principle of the single rope twines mine pit elevator is that: One end of the steel wire rope is fixed to winding by the steel wire rope nip, a nother end after twined hangs and promotes the vessel by derrick wheel. In this way, we make use of the differences of the revolve way to twine or relax the steel wire rope so that to complete the vessel to step up or drop down.

Main axle is the core part of the mine elevator. Its functions are: ① the steel wire rope of twines the type mine pit elevator ; ② endure a kind of normal load( including fixed load and work load ); ③ endure the kinds of unusual load which is result from positive situation. Under the unusual load function, the part of the main axle equipment should not remain remaining distortion. The decelerator should meet the need of reduction rate to make the elevator fuction well. The transmission should be accurate, steady, and reliable. The decelerator should be as small as possible to decrease the space it takes. It required us to be careful designing and manufacturing when. Only in this way can we prevent the occurrence of failures or accidents .Obviously, the processes is very significant.

This design is on the basis of the data which are chosen by advance and actually, take the elevator supplementary equipment as the core, after the analysis and computation in science, has designed and chosen a set of the transmission system of the mine pits elevators.

KEY WORDS: elevator, main axle, decelerator

目录

第一章 前言------------------------------------------------------------ 1

1.1 提升机的发展概况--------------------------------------------------1

1.2 提升机的结构和用途------------------------------------------------2

1.3 提升机的分类和工作原理--------------------------------------------3

第二章 总体方案设计---------------------------------------------------7

2.1 设计数据----------------------------------------------------------7

2.2 罐笼的选择--------------------------------------------------------7

2.3 钢丝绳的选择设计--------------------------------------------------7

2.4 预选电动机--------------------------------------------------------8

第三章 减速器齿轮的设计----------------------------------------------9

3.1 拟定传动方案------------------------------------------------------9

3.2 电机的选择--------------------------------------------------------9

3.3 分配传动比--------------------------------------------------------9

3.4 计算减速器各轴的转速和力矩---------------------------------------10

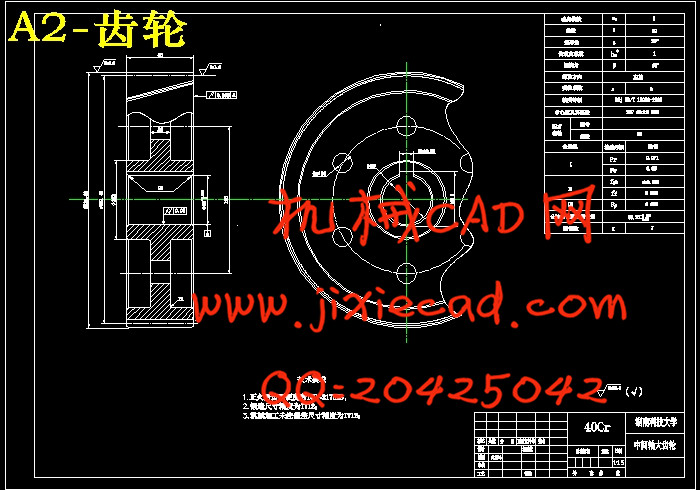

3.5 齿轮设计---------------------------------------------------------11

3.5.1 高速级齿轮设计---------------------------------------------11

3.5.2 低速级齿轮设计---------------------------------------------15

第四章 减速器传动轴的设计-------------------------------------------19

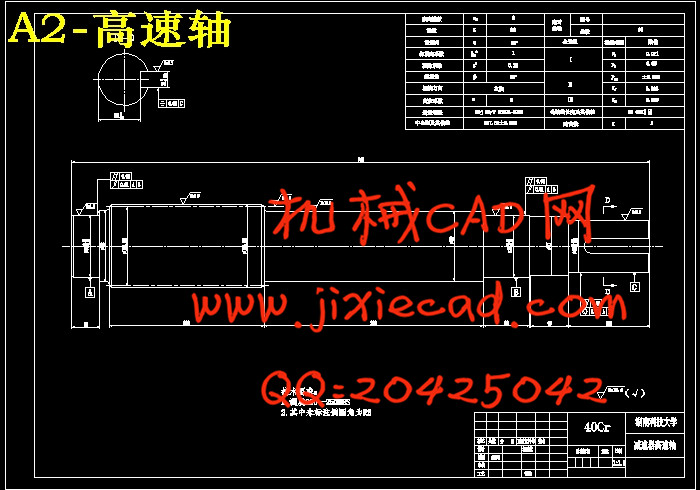

4.1 高速轴的设计-----------------------------------------------------19

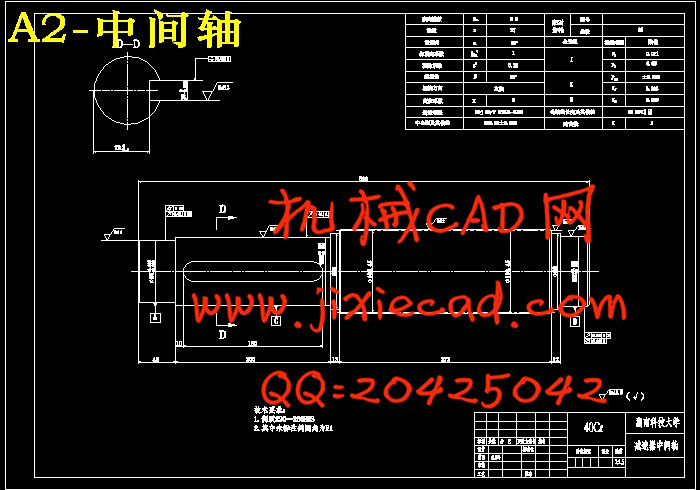

4.2 中间轴的设计-----------------------------------------------------22

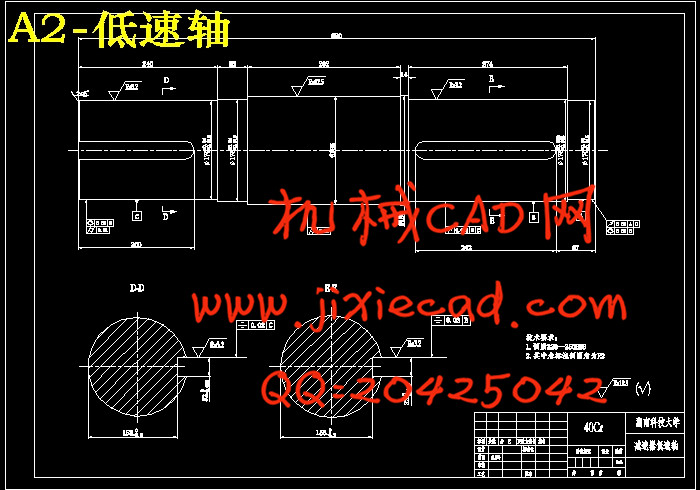

4.3 低速轴的设计-----------------------------------------------------24

第五章 主轴的设计----------------------------------------------------26

5.1 主轴的选择-------------------------------------------------------26

5.2 结构的设计-------------------------------------------------------26

5.3 主轴强度的校核---------------------------------------------------27

5.4 主轴轴承的寿命计算-----------------------------------------------35

5.4.1 左轴承-----------------------------------------------------35

5.4.2 右轴承-----------------------------------------------------36

总结--------------------------------------------------------------------37

参考文献----------------------------------------------------------------38

致谢--------------------------------------------------------------------39

单绳缠绕式矿井提升机的工作原理:钢丝绳的一端用钢丝绳夹持固定在卷筒幅板上,另一端经卷筒的缠绕后,通过井架天轮悬挂提升容器。这样,利用主轴旋转方式的不同,将钢丝绳缠绕上或放松,以完成提升或下降容器的工作。

主轴是单绳缠绕式矿井提升机的主要结构,它的作用是:①支撑缠绕提升机钢丝绳的卷筒;②承受各种正常载荷(包括固定载荷和工作载荷);③承受各种积极情况所造成的非常载荷。在非常载荷作用下,主轴部分不应有残余变形。减速器要满足传动比要求,保证提升机正常工作,传动应准确,平稳,可靠。减速器应该在满足强度条件的同时尽可能小型,以减少占用空间。单绳缠绕式矿井提升机的主轴和减速器是其核心部件,要求我们应认真设计,精心制造,这对于确保矿井提升机安全可靠运行,预防和杜绝故障及事故的发生,也具有十分重要的意义。

本设计根据生产实际和预选的数据,以提升机的配套设备为核心,经过科学的计算和分析,设计了矿井提升机的传动系统。

关键词:提升机,主轴,减速器

ABSTRACT

What the principle of the single rope twines mine pit elevator is that: One end of the steel wire rope is fixed to winding by the steel wire rope nip, a nother end after twined hangs and promotes the vessel by derrick wheel. In this way, we make use of the differences of the revolve way to twine or relax the steel wire rope so that to complete the vessel to step up or drop down.

Main axle is the core part of the mine elevator. Its functions are: ① the steel wire rope of twines the type mine pit elevator ; ② endure a kind of normal load( including fixed load and work load ); ③ endure the kinds of unusual load which is result from positive situation. Under the unusual load function, the part of the main axle equipment should not remain remaining distortion. The decelerator should meet the need of reduction rate to make the elevator fuction well. The transmission should be accurate, steady, and reliable. The decelerator should be as small as possible to decrease the space it takes. It required us to be careful designing and manufacturing when. Only in this way can we prevent the occurrence of failures or accidents .Obviously, the processes is very significant.

This design is on the basis of the data which are chosen by advance and actually, take the elevator supplementary equipment as the core, after the analysis and computation in science, has designed and chosen a set of the transmission system of the mine pits elevators.

KEY WORDS: elevator, main axle, decelerator

目录

第一章 前言------------------------------------------------------------ 1

1.1 提升机的发展概况--------------------------------------------------1

1.2 提升机的结构和用途------------------------------------------------2

1.3 提升机的分类和工作原理--------------------------------------------3

第二章 总体方案设计---------------------------------------------------7

2.1 设计数据----------------------------------------------------------7

2.2 罐笼的选择--------------------------------------------------------7

2.3 钢丝绳的选择设计--------------------------------------------------7

2.4 预选电动机--------------------------------------------------------8

第三章 减速器齿轮的设计----------------------------------------------9

3.1 拟定传动方案------------------------------------------------------9

3.2 电机的选择--------------------------------------------------------9

3.3 分配传动比--------------------------------------------------------9

3.4 计算减速器各轴的转速和力矩---------------------------------------10

3.5 齿轮设计---------------------------------------------------------11

3.5.1 高速级齿轮设计---------------------------------------------11

3.5.2 低速级齿轮设计---------------------------------------------15

第四章 减速器传动轴的设计-------------------------------------------19

4.1 高速轴的设计-----------------------------------------------------19

4.2 中间轴的设计-----------------------------------------------------22

4.3 低速轴的设计-----------------------------------------------------24

第五章 主轴的设计----------------------------------------------------26

5.1 主轴的选择-------------------------------------------------------26

5.2 结构的设计-------------------------------------------------------26

5.3 主轴强度的校核---------------------------------------------------27

5.4 主轴轴承的寿命计算-----------------------------------------------35

5.4.1 左轴承-----------------------------------------------------35

5.4.2 右轴承-----------------------------------------------------36

总结--------------------------------------------------------------------37

参考文献----------------------------------------------------------------38

致谢--------------------------------------------------------------------39