设计简介

摘要

从汽车诞生时起,车辆制动器在车辆的安全方面就起着决定性作用。目前,汽车所用制动器几乎都是摩擦式的,可分为鼓式和盘式两大类。盘式制动器的主要优点是在高速刹车时能迅速制动,散热效果优于鼓式刹车,制动效能的恒定性好。鼓式制动器的主要优点是刹车蹄片磨损较少,成本较低,便于维修、由于鼓式制动器的绝对制动力远远高于盘式制动器,所以普遍用于后轮驱动的卡车上,故本次轻型载货汽车采用前盘后鼓式制动器。

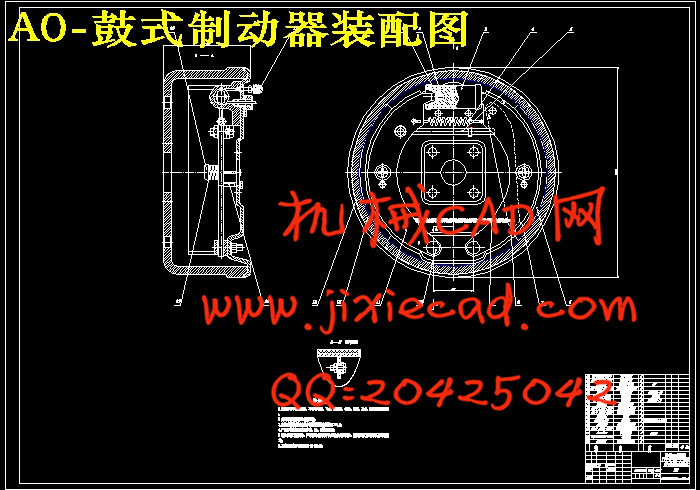

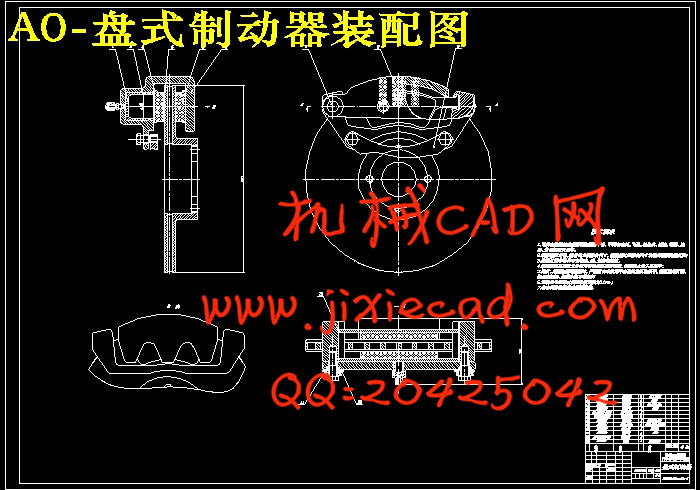

本设计前轴采用浮动钳盘式制动器,后轴采用制动器为领从蹄式鼓式制动器。设计的主要内容包括:制动器的研究现状及意义、制动器方案的选择与分析、盘式制动器结构的设计、鼓式制动器结构的设计。

关键词:轻型载货汽车,盘式制动器,鼓式制动器,制动蹄,设计

ABSTRACT

The brake has played a significant role in vehicular security since the car was born. In current, most of the brake is frictional, which concludes disc brake and drum brake. The chief advantages of disc brake are that it can apply the brake quickly in high-speed trig, that it has a better cooling function than drum trig, and that the application of the brake can have a long affection. While the chief advantages of drum brake are that trig hoof can have less abrasion and cost, and that it can be easily mended .As the drum brake has a higher drag force than disc brake, it use in rear wheel drive truck widely, due to these factions, We use before the disc brakes followed by the drum brake in this light shipment car.

The front axle of this design use before the floating disc brakes, and the rear axle use brought from the hoof type drum brake.The first chapter of the design instruction chiefly introduces the current state and the purport of brake, the second chapter tells the choice and the analysis of the brake project mostly, the following chapter describes the calculation and check of the disc brake structural design, and the last chapter introduces the calculation and check of the drum brake structural design.

Keywords: Light bills car,Disc brake ,drum brakes, Brake shoes, design.

目 录

摘要 I从汽车诞生时起,车辆制动器在车辆的安全方面就起着决定性作用。目前,汽车所用制动器几乎都是摩擦式的,可分为鼓式和盘式两大类。盘式制动器的主要优点是在高速刹车时能迅速制动,散热效果优于鼓式刹车,制动效能的恒定性好。鼓式制动器的主要优点是刹车蹄片磨损较少,成本较低,便于维修、由于鼓式制动器的绝对制动力远远高于盘式制动器,所以普遍用于后轮驱动的卡车上,故本次轻型载货汽车采用前盘后鼓式制动器。

本设计前轴采用浮动钳盘式制动器,后轴采用制动器为领从蹄式鼓式制动器。设计的主要内容包括:制动器的研究现状及意义、制动器方案的选择与分析、盘式制动器结构的设计、鼓式制动器结构的设计。

关键词:轻型载货汽车,盘式制动器,鼓式制动器,制动蹄,设计

ABSTRACT

The brake has played a significant role in vehicular security since the car was born. In current, most of the brake is frictional, which concludes disc brake and drum brake. The chief advantages of disc brake are that it can apply the brake quickly in high-speed trig, that it has a better cooling function than drum trig, and that the application of the brake can have a long affection. While the chief advantages of drum brake are that trig hoof can have less abrasion and cost, and that it can be easily mended .As the drum brake has a higher drag force than disc brake, it use in rear wheel drive truck widely, due to these factions, We use before the disc brakes followed by the drum brake in this light shipment car.

The front axle of this design use before the floating disc brakes, and the rear axle use brought from the hoof type drum brake.The first chapter of the design instruction chiefly introduces the current state and the purport of brake, the second chapter tells the choice and the analysis of the brake project mostly, the following chapter describes the calculation and check of the disc brake structural design, and the last chapter introduces the calculation and check of the drum brake structural design.

Keywords: Light bills car,Disc brake ,drum brakes, Brake shoes, design.

目 录

ABSTRACT II

第1章 绪论 1

1.1 制动器的目的意义 1

1.2 制动器的研究现状 1

1.3 制动器的研究内容及方法 3

1.4 本章小结 4

第2章 制动器方案论证分析与选择 5

2.1 制动器结构方案的确定 5

2.1.1鼓式制动器结构方案的确定 5

2.1.2盘式制动器结构方案的确定 8

2.2制动器主要参数及其选择 9

2.2.1制动器设计相关主要技术参数 9

2.2.2同步附着系数 10

2.2.3前后轴制动力矩分配系数b 10

2.2.4制动器最大制动力矩 11

2.3 本章小结 11

第3章 盘式制动器结构设计 12

3.1 盘式制动器的主要参数确定 12

3.1.1 制动盘直径D 12

3.1.2 制动盘厚度h 12

3.1.3 摩擦衬片内半径R1与外半径R2 12

3.1.4 摩擦衬片工作面积A 12

3.2 盘式制动器的主要零部件设计 12

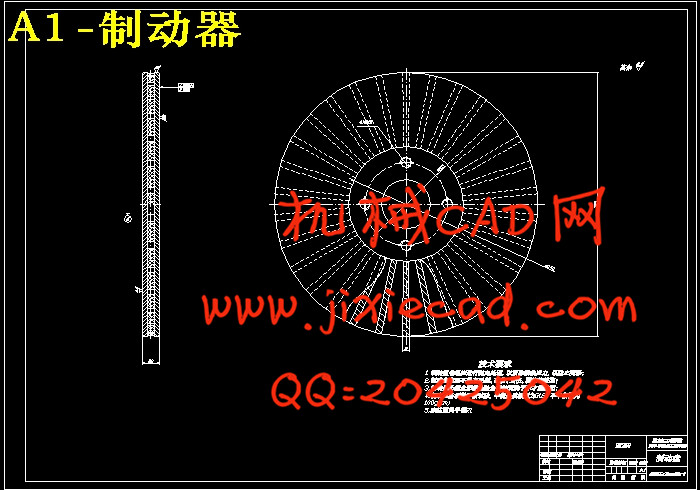

3.2.1 制动盘 12

3.2.2 制动钳 13

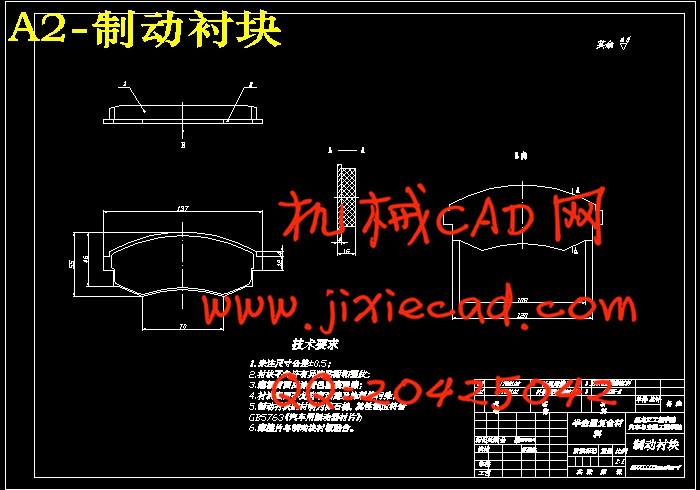

3.2.3 制动块 13

3.2.4 摩擦材料 14

3.2.5 制动轮缸 14

3.2.6制动器间隙的调整方法 15

3.3 盘式制动器强度校核 15

3.3.1摩擦衬片的磨损特性的计算 15

3.3.2 盘式制动器最大制动力矩的计算 16

3.3.3 盘式制动器最大制动力矩的计算 18

3.4 本章小结 20

第4章 鼓式制动器结构设计 21

4.1 鼓式制动器的主要参数确定 21

4.1.1 鼓式制动器的结构参数与摩擦系数 21

4.2 鼓式制动器的主要零部件设计 22

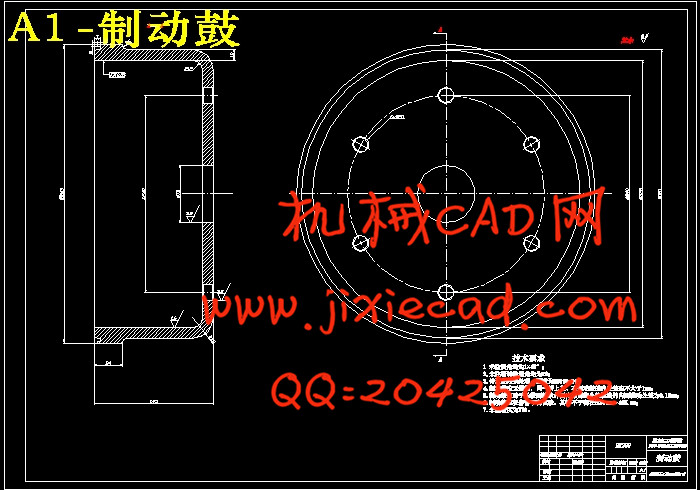

4.2.1 制动鼓 22

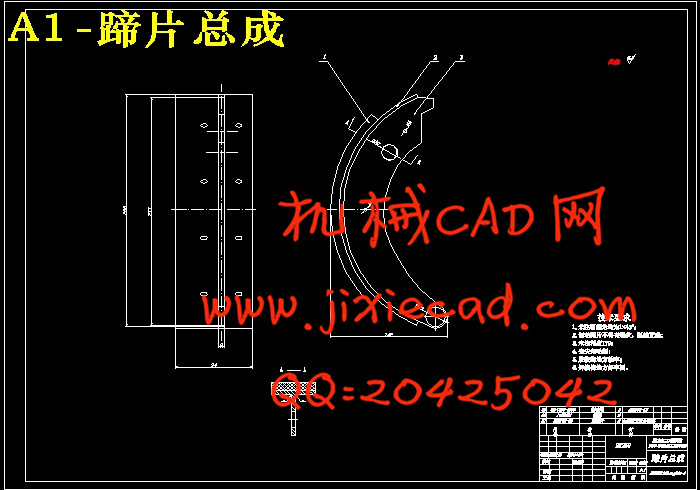

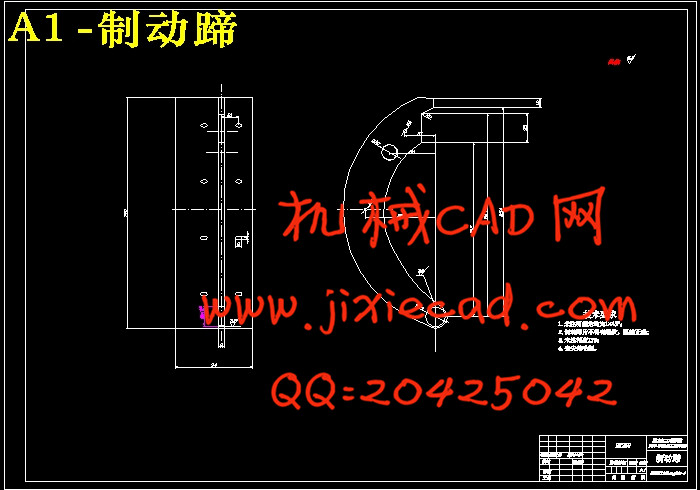

4.2.2 制动蹄 22

4.2.3 制动底板 22

4.2.4 制动蹄的支承 23

4.2.5 制动蹄片上的制动力矩与张开力 23

4.2.6 制动器因数与制动蹄因数的分析计算 27

4.2.7 驻车制动计算 30

4.2.8 制动轮缸的选择 31

4.3 鼓式制动器强度校核 32

4.3.1紧固摩擦片铆钉的剪切应力验算 32

4.3.2制动蹄支承销剪切应力计算 32

4.3.3 回位弹簧强度校核 33

4.4 本章小结 34

结 论 35

参考文献 36

致 谢 37